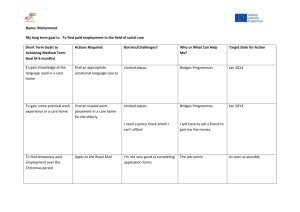

Document 11066736

advertisement

M,UT.

UBRARIE8 - DEWEY

J

tJewey

HD28

1^

MIT LIBRARIES

The International Center for Research, on the

Management of Technology

3 9080 00932 7732

Metrics for Managing Researcli and

Development

Marc H. Meyer*

Peter Tertzakian

James M. Utterback

WP # 124-95

April 1995

Sloan

WP # 3817

*Northeastern University

©

1995 Massachusetts Institute of Technology

Sloan School of Management

Massachusetts Institute of Technology

38 Memorial Drive, E56-390

Cambridge,

02139

MA

Abstract

The paper proposes methods

product development.

to

measure the performance of research and development

in

new

We base the work in the context of evolving product families in the

technology-based firm with the goal of more clearly understanding the dynamics and consequences

of platform renewal and product generation for long term success.

We test the proposed methods with data gathered from a large measurement systems manufacturer.

We find that the methods and the resulting measures provide management with a technique to

identify both the technological

and market leverage achieved from the

firm's present

and past

product platforms. This provides a foundation for transforming single product, single period

planning processes into a multi product, multi period form that embraces the product family and the

renewal of product architecture. The research also shows the need to integrate data from

engineering, manufacturing, and sales organizations to produce information for managing the

growth of the

firm's product families.

;MSSACnus£;'rrs institute

OF TECHNOLOGY

JUN 2

8 1995

LIBRARIES

When

should a firm renew the underlying technologies and designs of

will these efforts cost

and how long may they be expected

commercial benefits can the firm expect

its

to gain

essential characteristics of products

planning and management of

improvement

in the

way

in

What

from product redesign?

approaches and strategies for product development?

sustained success in product development that

to take?

we seek

How much

types of engineering and

How can

a firm improve

We

to address in this article.

creation. Systematic

which a firm creates new products

commercially successful product development. In

products?

These are fundamental questions for

and propose measurement methods

new product

its

is

turn, learning

will define the

to guide the firm in

its

and continuous learning and

the basis for

more rapid and

cannot be achieved without clear

and purposeful measurement.

1

.

Measurement

for Research

and Development

What measures

of performance can help firms better manage the development of

What might be

the purpose and goal of these measures ?

desired outcomes of effective

new product development.

of generating a continuous stream of

competitive position and die.

It

new

has been

shown

that the

1991

;

commonly

lie in

products ?

examining the

Productive, innovative firms are capable

products. If firms do not

the individual products, can be efficiently constructed

product architectures,

The answer may

new

make new

elements of

this

products, they lose

stream of products,

ie.

on successive generations of underlying

referred to as product platforms. (Sanderson and Uzumeri,

Wheelwright and Clark, 1992; Meyer and Utterback, 1993). Modular platforms (Uhrich

and Tung, 1991) with clear interfaces between embodied modules (Smith and Reinertsen, 1992)

can allow a firm

to rapidly

and

efficiently derive follow-on products

platforms. Clear understanding of customers' needs that

is

based on

its

product

then incorporated into platform and

follow-on product designs can generate high levels of sales to engineering resource productivity.

(Hauser and Clausing, 1988). As a product family evolves, platform architectures must be

continuously renewed and

new component technology

firm's offerings freshly competitive

The

integrated into these designs to keep the

(Meyer and Utterback, 1993;

lansiti, 1993).

purpo.se of measures of the effectiveness of research and development should be to

demonstrate firm performance

in this critical

way towards improvement. How do

dimension of new product development, pointing

firms measure

R&D performance observed in Moser's (1985)

R&D performance now

indu.stry

?

the

The measures of

survey were short-term in nature and

focused on single products or projects. These measures either qualitatively assessed goal

attainment or computed the variance between project plans and actual outcomes along the

dimensions of cost and time. Mo.ser found

that the

most commonly used

R&D metric

was

/'(/1,'C

/

"slip."

ie.

the

gap between expected and actual project time and budget. Slip

management's schedule predictions. Some firms

rate

measures the quality of

that use a stage-gate product generation process

(Cooper 1990) compute slippage between the development phases for respective products,

determining which phases encounter the greatest estimation

found

that

difficulty.

Gupta and Wilemon 1990)

(

poor or unclear product definition was the primary cause of delayed projects. The

measurement systems manufacturer whose data

successive phase slip for

market definition

to be

its

projects.

will

Management

be used

later in this

has found the

initial

paper currently tracks

stage of technical and

most problematic.

Accurate project estimation should not necessarily be construed as a predictor of successful

technical and commercial outcomes in product development. Mansfield's (1972) study of a

successful pharmaceutical

company showed

the firm experienced overruns

on

80%

of

its

new

products efforts, with an average slip of 1.78 over planned costs, and 1.61. on planned schedules.

(Mansfield, et

al.

1971) Yet, the firm prospered from these "late" products.

aluminum company's

efforts to create industrial products outside

its

A study of an

traditional smelting business

revealed that "tight schedules" for novel products led to poor financial outcomes (Utterback et

1992) Slip rate

is

also

products). This has

commonly used

little

to

to

examine

do with what occurs

the experiences of individual projects (or

in the

aggregate across the stream of

products generated by the typical product-making company.

the

al.

development of base architectures may take a long time

From

to

new

a product family perspective,

complete, but once finished,

may

serve as the foundation for rapid development of derivative products.

Numerous measures of R&D

in total

based on our

effectiveness have been proposed in the literature (some seventy-five

literature search

of the topic). Appendix

typology based on the purpose of measurement (Cordero

The purposes of various measurement may be seen

the sequential stages of the product

life

1

I

places these measurements in a

990) and the method of measurement.

as seeking to understanding performance in

cycle: measuring the effectiveness of product planning

before actual development, controlling projects during development, measuring the technical

outcomes of

the

completed development, measuring the commercial outcomes associated with

completed products, and

full life

cycle.

As shown

lastly,

in

understanding overall performance across the span of a product's

Appendix

the literature to

measure performance

assessments of

new products

in

1

in

,

the techniques of

measurement

that

in

these various stages included: (I) comparative

terms of success, (2) scoring models on product features relative

to competitors' products, (3) benefits contribution

methods based on the sales-related outcomes of

products. (4) various forms of performance to schedule analy.ses (the most

today being

we found proposed

total project slip or slip at different

commonly used form

key phases of a project), and (5) analyses of

l',i

w-

individual and organization technical accomplishment, including the counting and comparison of

patents awarded to

The impact of

are

that

members of a group

these various measures

is

for measuring

commercial outcomes on a quantitative

found

that

35%

that

basis.

A recent survey of 248 R&D executives by the Industrial

"measuring and improving

R&D productivity and effectiveness"

problem" for respondents (Industrial Research

(1994)

in his

Another survey of 700 manufacturing firms also

of the sample failed to systematically assess the performance of

and Panicelli, 1982).

showed

suspect, however. Schainblatt (1982) found that "there

R&D productivity that are not flawed." Of the firms

59% did not measure the R&D function and only 20% compared R&D costs to

no currently used systems

he studied,

or publications emerging from them.

Institute, 1993), a finding

R&D (Rockwell

Research

was

Institute

the "biggest

confirmed by Roberts

survey of corporate executives.

We believe that the limited utility of existing measures of R&D performance is that by their design

and implementation, these measures do not help management understand the longer term dynamics

of evolving product

lines, the

renewal of their underlying architectures, and the leverage that these

architectures provide in derivative products. Addressing this need

it

is

the key point of comparison between

literature.

It

market introduction and

to

the purpose of this paper, and

what we propose and the existing

should also be clearly noted that our primary focus

development as opposed

is

is

the

R&D performance

R&D phase of product

performance measurement for the manufacturing (Kaplan 1990),

distribution.

A truly

comprehensive picture would incorporate

these

all

dimensions.

We will

propose measures of

R&D performance compatible with the management model of

evolving product families. Data from a more than twenty year period within a large measurement

systems manufacturer

will then

be used to

product family and then measures of

test

and explain these measures.

R&D effectiveness suited for

it.

We

will first define the

These metrics

are then

applied to a sample of industrial measurement systems and interpreted within the management,

marketing, and technological factors influencing the evolution of these product families.

We then

conclude the paper with a discussion of the benefits, costs, and qualifications of the proposed

methods and suggest areas

make

a contribution to

for

complementary research. The overriding goal of the paper

management

practice in the understanding of the effectiveness of

product development that encompasses groups of individual products related by

is

lo

R&D for

common

architecture.

P</vc

.<

Meta- Metrics for the Product Family

3.

3.

1

Defining the Product Family

The

effectiveness of the firm's

new product

generation activity

lies in:

(1) its ability to create a

continuous stream of successful new products over an extended period of time; and

(2) the

attractiveness of these products to the firm's chosen markets.

Streams of new products generated by firms may be thought of as evolving product families.

A product family

is

defined as a set of products that share

related set of market applications. This

common

technology and address a

commonality may be validated

for a

group of products by

applying the technology and market newness criteria proposed by Meyer and Roberts (1986).

Successive products within a product family can be assessed by virtue of newness of embodied

An evolving

core technology and market applications.

technologies into product designs and target

change

will be

bounded.

"related" to older ones:

New

new

product family will introduce

new customer

new

requirements. However, the scope of

technologies and market applications of a product family will be

technologies will be combined with and enhance existing core

technologies and the resulting products will target existing and related market applications.

commonality of technologies and markets leads

distribution,

and service, where the firm

tailors

to efficiency

and effectiveness

in

The

manufacturing,

each general resource or capability to the needs of

specific market niches.

The

is

technological foundation of the product family

we

define as the product platform.

A

platform

the physical implementation of a technical design that serves as the base architecture for a

of derivative products. The efficiency of the platform

derivatives

is

logically

The concept of

in

.series

serving as a foundation for such

one key aspect of product family management.

platforms, product derivatives, and renewal

is

not new. Wheelwright and Clark

(1992) differentiated between platforms, their derivative products, and platform "extensions

renewals for vacuum cleaners; Meyer and Utterback (1993) did the same

electronic imaging systems and peripherals, as did Sanderson and

of portable cassette players, and Lehnerd

(

in their study

Uzumeri (1993)

strategy.

its

or

of

in the

evolution

1987) for power tools. These examples reflect more

recent industrial experience and practice. Chrysler's newly achieved success with

automobiles, and more recently,

"

Neon automobiles, was based on

Timely platform renewal has been

its

LH

.series

of

a clear platform development

essential to Intel's continuing success with

family of microprocessors. As soon as a particular microproces.sor platform

is

its

X8086

completed, and

I'lii^c

4

derivative products start to be generated from

the current platform with

new

it,

resources are immediately allocated to obsoleting

designs. Planning looks out into the future for several or

more

platform generations.

These cases can be generalized

Figure

new

1.

It

into an evolutionary

model

shown

for the product family as

in

represents a single product family that undergoes successive platform extensions, a

platform development, and the respective follow-on product developments of these platform

versions.

To

achieve sustained success, a firm must seek to continuously renew

architectures. This approach generates a set of engineering activities focused

that coexist with specific follow-on product

in

platform design

product family.

modules and

is

1

on platform renewal

here

and success of a

centrally important to sustaining the quality

A platform design consists of a basic

the interfaces

base product

developments based on existing product platforms.

Insert Figure

Excellence

its

architecture,

comprised of subsystems or

between these modules. Smith and Reinertsen (1992) made the analogy

of the subsystems being bricks, and the interfaces the mortar that binds them together. In an

assembled product such as a camera, subsystems include the shutter mechcinism, the lenses, the

various operator controls and focus mechanisms, the flash, the power source, and the camera

The

housing.

internal

fittings

subsystem

and electronics by which these subsystems are integrated serve as the

interfaces.

The mechanisms

for controlling shutter speed

and the aperture, for

rewinding and changing film, or for using a flash are the "user interfaces". The

one puts into the camera can also be viewed as having subsystems

which the film

is

roll

that include the spool

wrapped, the cover over the film, and the end caps. Even the film

comprised of various layers

(the subsystems)

of film that

combined through chemistry

in

itself

around

may be

a continuous

production process. The width of the spool, the length of the film leader, and the spacing of the

edge perforations on the film are external interfaces

that allow

many

types of films to be used

in

different cameras.

The notion of subsystems and

shown

o

in

interfaces leads to a typology of product family evolution that

Figure 2 and which mirrors the approach of Wheelwright and Clark (1992)

The

initial

is

:

plarfonn of a product family consists of the subsystems and subsystem

interfaces of the basic product design.

These subsystems are incrementally reengineered or

refined to generate specific product offerings.

Pdi-c

5

A platform extension occurs when (a) particular

o

subsystems within the existing platform

design are substantially changed and enhanced, and/or (b)

new subsystems

are added to the

design without disturbing the primary subsystems and interfaces in the existing design.

For example, a computer manufacturer

faster processor offered

by a chip

may

supplier.

replace a particular processor subsystem with a

Both the

initial

platform and

its

extensions

may

be referred to as successive platform versions.

A platform renewal occurs

o

when

the product design

new subsystems and new subsystem

specific

interfaces.

The

platform,

dimensions of value and cost competition

rearchitected to incorporate major

The new

subsystems from older product platforms.

as well as subsystem interfaces.

is

if

architecture

may

will also incorporate

It

carry forward

new subsystems

architected well, should provide

new

to the firm.

Insert Figure 2 here

Specific derivative products can be based any these versions of platform architectures.

refer to derivatives as {he follow-on products of a platform.

events

may

We

will

Appendix 2 shows how these key

be formed as an identifying records for subsequent data gathering.

3.2 Defining Metrics for the Product Family

We propose the following measurements of R&D performance

follow-on products within a product family:

(a)

focused on platforms and their

platform efficiency, being the degree to which a

platform allows economical generation of derivative products; and (b) platform effectiveness,

being the degree to which the products ba.sed on a product platform produce revenue for the firm

relative to the cost of

developing those products.

R&D productivity is the degree to which an organization can translate relevant technological

made by

discoveries,

firm.

itself

or others, into functioning products that reap financial benefits for the

As argued above, platform

efficiency indicates the degree to

which a product platform serves

as an economical base for generating follow-on products. Platform effectiveness

the

commercial productivity of a

used

to create products with the

Freeland. 1975; Foster et

of firms into

al.,

series of related products,

new

a measure of

comparing the engineering resources

commercial outcomes derived from those products (Baker and

1985;

R&D are represented by

with the development of

is

Brown and Svenson.

1988; and Cordero. 1990).

the engineering budget

products.

We

The

inputs

amounts and project times associated

believe that product sales

is

a better measure of

P(ii;c

6

commercial outcomes than

profits

due

to the lack of consistency with

which firms compute and

maintain profits for specific products (Patterson, 1983). Profits from product sales are not

consistently gathered at the product level by firms, and the definition of "profit"

business units. In comparison, sales figures are absolute.

may

vary

We have also found them to be

among

more

accessible than profit figures in our field research.

These measures, when combined with

management understand

visual interpretation of product family

the timing of platform renewal

and the frequency of follow-on product

generation from existing platforms. Further, these measures can be applied

product family

maps, can also help

at three levels

of the

(1) individual products within a platform version of product family, (2) at an

:

aggregated level for the product family as a whole for successive platform versions, and (3)

comparatively across different platform versions for different product families.

measures as meta-metrics because

refer to these

their

purpose

is

to help

We have come to

understand the dynamics of

innovation across sets of products rather than individual ones.

3.2.

1

Variables and Indices

This section presents the symbolic notation for the mathematical description of the metametrics. These notations are the building blocks for creating the measures of

performance

to

R&D

be presented thereafter.

Variables:

S =

Sales attributable to a platform or derivative product within a product family.

C=

Costs attributable to a platform or derivative product within a product family.

D-

The

deflator factor relative to a base year.

Used

to correct for inflationary effects for very

long product cycles.

Indices:

Np =

Number of platforms

in

a product family excluding the

initial

platform version or

architecture.

Ny =

Number

of platform extensions, or generations created off the base platform

architecture, excluding the initial platform version.

Nf =

Number

initial

Nj[) =

The

of follow-on products in a platform, or platform extension, excluding the

platform version.

total

number of follow-on products

in a

family excluding the

initial

piatfonn

version.

T[) =

The

last

time period number prior to entering the commercial cycle.

T^ =

The

last

time period for which sales were recorded

in the

commercial cycle.

I'diiv

7

p-

platform index;

v=

platform version index; v = base,

p =

base,

/=

follow-on product index;

/=

time period index;

For example, the sales

would be given

(1)

in

period

r,

=

t

1,

/=

2, 3,

base,

1, 2, 3,

...,

2, 3,

1,

1,

2, 3,

...,

Ny

...,

Nf

Tj) or T^;

of the second follow-on product, for the

initial

platform version

by:

ijl.'xur.;.!

3.2.2 Aggregating the Sales and Costs of a Product

From

Np

....,

Over Time

these basic variables, sales and engineering costs attributable to products can be aggregated

as part of performance measurement. Ideally, sales and costs are recorded at regular time intervals.

t,

throughout the entire product cycle.

If so, the

corresponding aggregated sales and costs are

given by:

T,

(2)

5..-.,

=5^(5.,./),

and,

Ti>

G..,=X(<^"")'

(3)

where

sales

accumulate from introduction to the end of product

from research

initiation to the

Over long product

deflator

is

cycles,

computed

life,

and research costs accumulate

time of commercial entry of a product.

it is

desirable to correct for inflationary effects in the

for each time period relative to the desired base year.

The

economy.

A

deflators are

applied to the formulas above to yield the adjusted aggregate sales and costs. Adjusted metrics are

denoted with a superscript 'primed' symbol

n

(4)

.

S'r..,^'^{S,..,).D.

1=1

(5)

C',..r=X(C,

•')£>'

These formulas represent the aggregated

the specific platform version within the

sales

and costs for individual /o//on'-o/j products within

same product

family.

To accumulate

costs at the platform

version level, the summations are extended. For example, the accumulated inflation adjusted sales

for an entire platform, p. including

all its

platform extensions, would be given by:

Pa^c S

N.

(6)

5'.

=

Ni

£

£s'.....

Similarly, the accumulated inflation adjusted costs for an entire platform

the cost variable, C.

With these

definitions,

it

is

now

would be computed using

possible to define the proposed meta-

metrics.

3.2.3

Platform Efficiency

At the follow-on product

level,

R&D leverage shall be defined as the costs incurred in

average

developing a follow-on product, divided by the costs incurred

platform upon which the products are derived.

Costs for Follow-on Product

R&D

Costs for Platform Version

Mathematically, the notation for efficiency shall be

developing the version of the

generally defined as:

R&D

=

(7) Platform Efficiency

It is

in

E The

.

indices defined above shall apply

accordingly. At the individual follow-on product level, the mathematical formulation for E, the

efficiency of developing an individual follow-on product relative to

E„...

(8)

=

that this

fraction of what

r"

\^

(9)

i.

is

given by:

Ihue

measure seeks

was allocated to

The average platform

base platform,

^'^''

p.

The question

its

to

answer

is:

"How much did

the product cost to develop as a

the base platform architecture?"

efficiency

is

defined

as:

E,.^—^,

R&D costs associated with

developing all the follow-on products of a platform version divided by the R&D costs of

The average platform

efficiencies

developing the platform

itself.

is

therefore the average of the

By grouping

versions, the question being addressed

is:

follow-on products within their base platform

"How much

did

it

cost on average to develop follow -on

products relative to what was spent on developing the base plarfonn versions within the product

family?"

Piii-c

y

One can

also

compare

product families

the corporation

.

the platform efficiency of different platform versions across different

The question being asked

compare with one another in

development of several or more

the respective engineering

groups within

which provide

their abilities to build robust platforms

the basis for efficient product development?"

the

"How do

is:

This might be useful for managers responsible for

An

distinct product lines.

aggregate

R&D cost leverage value

can be computed for an entire product family by summing across follow-on products, platform

versions, and

(10)

between successive new platform

E =

N/

Nv

Nf

f=hitie

\=hiue

f =\

'X

-";:

S

p = Itase

What

is

architectures:

lev.

V = huie

We

a reasonable platform efficiency value?

strongly suspect that the answer

is

industry

specific for particular types of products within assembled, nonassembled, information system

pure information product categories.

Our

application of this metric to the product families of the

firm studied (described in the next major section of the paper)

platforms yielded values for

E as

low as

produce streams of follow-on products

and

.

at

10,

meaning

10%

showed

that strong product

that efficient platforms allow the firm to

per product of the cost of developing their

respective base platform architectures.

If

resources are being effectively used, and learning

E should therefore

efficiency should improve (that

of a product family.

been added

in the

E values of

or close to

new product and

corrected. Conversely, the closer

follow-on product generation.

If

a product platform, the platform

posit that platform

may

indicate that

little

problems

or no

the firm

much

spends as

poorly designed.

its

in earlier

to

consistent with the S-curve

generation performance

is

indicate

done

weakness

phenomenon where,

in

in

as

it

does on

conjunction with assessments of

in the

An

later in the paper.

increase in

after a certain point,

management

E over

underlying product architecture. This

little

additional product

achieved from incremental investment. (Foster 1986)

platform efficiency can also signify a change

proved for

suppliers could produce very low values of

Platfonn efficiency can be used as an indicator of platform demise.

is

products had been

make follow-on products

product change and effectiveness. This combined analysis are provided

may

functionality has

should also be noted that technological

It

component

Interpretation of the metric should therefore be

successive follow-on products

new

to 1.0, the less efficient the base platform design

breakthroughs achieved by the firm or

E.

we

decrease) with each successive platform version

that perhaps only that

E is

is

it

taking place,

is

or key resources,

A

decline in

human

or

l\i^c 10

otherwise. For example, the advantage gained by reusing a proven pool of resources can be lost

through organizational change or by shifting the charter for developing a particular product family

Key managers

to another facility in a different geographical location.

been

lost.

All these factors must be considered as

Market factors may greatly influence

the

the efficiency with

form of new products for market applications

case of a firm venturing into a

new

management

or engineers

interprets the

also have

E metric.

which existing platforms can be applied

that the firm has not

in

addressed before. Take the

business area by trying to create products that leverage existing

The requirements of the new market may be so

technical competencies.

may

different that the firm

encounters great difficulty satisfying the customers' needs, even with access to robust product

platforms from

its

core business. The efficiency metric

may

in this

new product

success of management's strategic decision to create a

Platform efficiency

may

case provide insight into the

family.

also be considered from the standpoint of development time cycles.

One

can posit that a product platform, while taking relatively longer to create than follow-on products,

is

robust

if

it

the start and

allows the firm to experience rapid generation of those follow-on products. Using

end of

R&D for product platforms and follow-on products, an elapsed time cycle

measure of platform efficiency can be expressed

rCwUTime

(11) £"'""""' r...ha.e

=

'p.

I p.v.

and replicated

i:

as:

f

ha'it

to the aggregated levels of all products within a platform version,

and across

platforms versions within distinct product families.

It

stands to reason that

on product

efforts,

if

indeed platform development efforts take longer to complete than follow-

R&D aimed at platform renewal should be pursued concurrent within product

developments on existing platforms. This

will insure a continuous stream of products that

embody

competitive technology.

3.2.4

Platform Effectiveness

Computing

R&D returns as accumulated profits divided by development costs on a product by

product basis was proposed by Foster, et al.(1985) to assess the productivity for products over the

full

R&D and commercial

reliability

and

life

accessibility.

comparing the product

cycle.

As

stated above,

we used

product sales instead for reasons of

We propose that the effectiveness of a platform

sales to product

development

may be

assessed by

costs, either at the individual product level, or

P(if;e II

for groups of products within distinct platform versions. This

measuie of effectiveness

may be

considered one of understanding the commercial leverage provided by technologies applied by the

firm in

in the

its

products. Platform effectiveness

is

synonymous with platform leverage,

referred to as

L

equations below.

The platform leverage measure,

What have been

L, seeks to address the following questions:

the returns realized

on the firm's

products to the costs of developing them

R&D investments comparing sales from

?

How has a particular product family trended over time through

versions?

Have

its

successive platform

returns on investments improved or declined?

Are certain development groups more

effective in creating leverage from their

respective platform development efforts than other groups within the firm?

Platform effectiveness

L...

(12)

at the

follow-on product level

is

given by:

^

=

and, aggregated at the platform version level by:

Lr.=^

(13)

which

the

is

the

sum

of the sales of products within a platform version divided by the

sum

of

R&D costs for creating those products.

Platform leverage

and then used

(14)

to

may

be further aggregated across

compare

L,.

the platform effectiveness

all

platform versions within a product family,

between

= ^^^^7?

I S

C'„.

.

The L metric provides information on product performance,

the entire product

distinct product families as follows:

life

cycle inclusive of

individually and in aggregate, across

R&D and commercial activities.

As

the costs of follow-on

Fiii^c

12

product developments decline relative to that of their underlying platforms, the values for platform

effectiveness for the product stream should increase.

There are many factors that can lead

the platform architecture itself

the denominator,

above,

ie.

may have

market

that are competitive in the

to declining

platform leverage within a product family.

outlived

in features

and

its utility

as a basis for creating specific products

This would lead to declining sales. As for

cost.

R&D costs may be rising due to problems in platform efficiency as defined

the economical generation of follow-on products. If this

posit an inverse relationship

platform efficiency.

is

the case, then one could

between the two respective measures of platform effectiveness and

A decline in platform efficiency may well

The causes

platform architecture.

for that decline

indicate the need to create a

may be many. For example, changes

organization

may impede

the ability of the technical staff to perform well.

technologies

may emerge

that competitors use in their products

understand and integrate into

its

own

Or new

new

in the

external

and which the firm

fails to

products.

Applying and Interpreting Meta-Metrics

4.

4.

First,

1

The Sample

The data used

company's

to test the metrics

sales in 1993

were gathered from a measurement systems manufacturer. The

exceeded $1

measurement technologies

billion.

The

firm's core capability has

to industrial applications.

Management

been the application of

considers these products as

"front-end" devices that gather data in real-time and assess them, identifying problems and sending

these data to "back-end" information systems.

Studying the historical record of these product families required many discussions with

engineering and marketing managers working

family.

The

first

goal

was

in the

business unit responsible for each product

to construct product family

prior section to distinguish

between

(a) the initial

to existing platforms, (c) the creation of

wholly

new

new

maps, using the typology described

in the

platform development efforts, (b) extensions

platforms or product architectures to replace

those in existence, and (d) the specific products associated with each platform generation.

Drawings of product architectures

at the

subsystem and interface

platform enhancements and the development of

firm's internal product

new

naming conventions proved

level

were used to help identify

platforms within each product family. The

particularly u.seful for initial grouping of

l\n;c

/.<

product streams within successive platform generations.' The product family maps were presented

to the

engineenng teams working on the respective product

consensus on

their validity.

In total, the data set

used

lines for

in this

feedback and to create

paper contains information for five

product families, which collectively, provided a rich database of platforms, platform extensions,

and follow-on products

to test

our methods.

Figure 3 shows the product family

and control stations

that gather

map

for

Family

line,

information display

and manipulate data from front-end data collection devices

purposes of event handling and data trending. The

denoted by a thick

A comprised of centralized

representing the start of

life

cycles of Family A's

for the

two platforms

are

R&D for each architecture until the end of active

marketing of products based on the platforms. These two platforms contained two very different

product architectures, as described by engineers

at the

subsystem and interface

The

level.

first

platform was based on analog signal processing, and the second, on digital signal processing.

Products based on the two platforms also "looked" very different to the outside observer. The

first

platform had two versions; the second platform, only one. The specific follow-on products based

on each platform version

date of the earliest

lines

line is

into a particular product.

number

The

starting

R&D project associated with each product is represented as the thinnest of the

on the map. This

projects

are described in the text enclosed in the right-angled lines.

in the

an aggregate representation of numerous individual projects folded

For several hundred products

in the total

R&D

sample, individual

thousands. Allocation of these individual projects to specific platform and

follow-on product development was performed by engineers

who had worked on

the development

efforts.

Insert Figure 3 here

While

R&D managers within the firm identified product families and their components, we applied

the technology and market applications

newness method of Meyer and Roberts (1986)

the relatedness of the product families.

Appendix 3 shows

the application of the

A. The reader can note that relatedness of the products within

in

method

to

Family

terms of embodied

that family in

core technologies and market applications. The assessments of newness

to validate

technology generally

correlate with the engineering costs associated with each successive product

shown

for

Family A.

The determination of platform and follow-on product spending within each product family was

based on the following assumption: the costs associated with individual projects who.se

'

Tomatsky and Klein (1982) have argued

that

knowledgeable observers

ot a particular industry will

results

make

consistent

interpretation of those individual products that belong to specific product families.

Pa^c 14

were embodied

deemed

first

to

in the first

product spinning off from a particular version of a given platform were

be platform development efforts for that version. In other words, the spending for the

product of a platform version and the spending for that platform version were treated as one

the same.

Note

R&D efforts longer term in nature.

had

that often the firm

Such

pursued concurrently with work on a current platform version but not completed

new

rolled into a subsequent platform version or an entirely

concurrent platform development that

we deem

efforts

in

would be

until later

and

platform. This illustrates the idea of

essential to product renewal

and sustain success

within the product family.

Maps

similar to Figure 3 were created for

all

the product families incorporated in the study. For

each product within a family we sought to construct from corporate record the following data:

the start of

R&D (for the projects associated with the product), (b) the end of R&D, (c) the start of

marketing, (d) the end of active marketing of a product,

manufacturing engineering costs,

dollar equivalents. All financial

the

(a)

Consumer

(g) the

(e) the

development

costs,

(0 the

product introduction costs, and (h) the sales

amounts were recomputed

to their value in

in

1993 dollars.

U.S.

We used

Price Index to inflate dollars from prior years to their 1993 dollar equivalents.

These yearly adjustment

factors are provided in

Appendix

5.

Because

historical data for

engineering costs and sales revenue were not maintained on a yearly basis for individual products,

we

first

aggregated these amounts to a product and then applied the CPI index to these

the index value for the last year of the

would want

to maintain these data

R&D cycle and commercial cycle respectively.

on a yearly basis so

that the

totals,

using

Ideally,

one

CPI index might be applied more

precisely to the numbers.

The combination of the product family maps and

for

their associated data

comprised the complete basis

computing the measures of platform efficiency and effectiveness (leverage), and

timing factors

in

development. While these data might seem reasonable for any firm to maintain,

On

they proved difficult to gather.

cost allocations for individual

the shelves of

for observing

one hand, the company maintained very detailed information on

R&D projects, either in paper form as project data sheets sitting on

R&D managers, or for more recent years,

man-months of direct

in

computer

labor, an internal "cost" for that labor,

files.

These data provided

and materials charges.

We were

unable to gather manufacturing engineering costs and market introduction costs on a consistent

basis,

and therefore excluded these from the development cost

sample. For several product families

in the

multiplied these amounts by a cost per

man

for the product families in the

sample, only man-year allocations were available.

year amounts for the given years

in

development

were supplied by management.

Pafie 15

We

that

Project data had to be aggregated during interviews where individual projects were assigned to the

products by

maintained

R&D managers who had been associated with the projects.

in the

accounting department in various forms, and for the majority of product families,

were already allocated

a product

was

to individual products

actively marketed.

It is

and merely had

to

be totaled for those years

in the

practice in the firm (particularly for the development of wholly

management between

In the next three sections of the paper

which

firm to provide

information. This reflects the fact that while concurrent engineering

versions), concurrent

in

of further importance to note that the integration of

engineering data with sales data had not been systematically performed

management

Sales data were

we

new

platforms or

functional areas has proven

will

now

more

is

a regular

new

platform

difficult to achieve.

apply and interpret these metrics

at three levels

of analysis: within a single generation of a product family, comparatively between generations of a

product family, and comparatively between different product families.

4.2 Metrics Applied at the Follow-on Product Level

Two

the

product families. Family

A and Family

B, demonstrate the application and interpretation of

measures of platform efficiency and effectiveness

Family

A

,

described above,

is

at the specific

follow-on product

comprised of central information systems products.

successive platform architectures, with the

first

It

level.

had two

platform having two basic versions (the second

being a major enhancement of the technology embodied

were based on these platforms. The data gathered

in the first).

for these products

A total of twelve products

and the computed measures of

platform efficiency are provided in Appendix 4 (which contains the computed metrics for

product families used

in the paper).

The

first

all

products released from a product platform are

considered the denominator of the efficiency equation. All data were normalized to their 1993

dollar equivalents.

Insert Figure

Figure 4 shows both platform efficiency metric and

4 here

its

running average for the products within

each respective platform version. The running average of platform efficiency smoothes wide

fluctuations that

trend.

may

be observed for individual products, helping to show more clearly the overall

Product CIS lA-Fl (Central Information System, Platform

on Product

for 18 cents

was developed on approximately

1)

on the platform

management

initiated a

new component

dollar.

While

this

15 cents

1,

Platform Version A, Follow-

on the platform

dollar,

and CIS

1

A-F2.

follow-on product was being developed,

concurrent effort to substantially improve the underlying architecture with

technologies and software development tools.

It

understood that

its

cunent

hii;c 16

architecture could not support the efficient development of the stream of products planned over the

next five years.

While the

first

The

results

of this decision, and the

came

follow-on product of CIS IB

subsequent products were developed rapidly

IB platform

Management

dollar.

at

initiated yet

in

new platform

a cost of 16 cents on the platform dollar,

very incremental cost of under 5 cents on the CIS

another platform enhancement effort even while

products were being created from the CIS IB architecture. In

and the

availability of

Upon

architecture.

the

new hardware and

the related platform

this case, the

needs of customers

software components mandated an entirely

new

completion, derivative products were created for approximately 10 cents on

its

CIS 2A platform

extension, were dramatic.

dollar.

Across our sample, platform efficiency values of 10 cents or below on

development dollar represent very good values

terms of leveraging platform

in

architectures in specific follow-on products. This level of efficiency can only be maintained over

time with a policy of continuous platform renewal. Otherwise, as an architecture ages,

it

presents

increasingly greater obstacles to engineers to achieve customer requirements.

We turn to another product family

metrics

may used

to indicate the

measurement "boxes"

to illustrate the platform effectiveness

need for platform renewal.

Family

B

is

measure, and

shown

in

Figure

commercial cycle

5.

that gather industrial process information in real-time, identifying

The period from

for products derived

the start of

from

it

both

comprised of

events and sending data to information systems such as those of Family A. The

is

how

map

emergency

for Family

B

R&D of the product platform to the end of the

exceeds ten years. The base architecture contained a

microprocessor, communications, and display electronics, a data acquisition and filtering

subsystem, and a data management subsystem. This product platform took 3.5 years to develop,

and from

it,

developed

five follow-on products

in

approximately

30%

were created. The

first

three follow-on products were

of the elapsed time allocated to platform development, and the

two, spiking up to almost half that time. In

total, the

platform start of

last

R&D to end of commercial

cycle spanned more than a ten year period. Figure 5 also contains the engineering cost and sales

figures for Family B's products.

that they reflect

end of

Time

wise, these data existed only in aggregate form,

meaning

R&D and commercial cycle totals respectively.

Insert Figure 5 here

Using the equations defined above, values

for

for platform efficiency

Family B. These data and the computed metrics

are plotted in Figure 6.

To

facilitate

measures, the efficiency scale

efficiency,

is

is

for

and effectiveness were computed

Family B are provided

in

Appendix 4 and

comparison between the efficiency and effectiveness

plotted in reverse value order

plotted at the top of the axis and

(ie.

a value of

weaker values of efficiency

.05,

at the

showing strong

bottom).

him- 17

The platform

efficiency measure

shows high

levels of efficiency for the first three follow-on

products based on the platform, where each was developed for on average

platform dollar. Then, for the fourth follow-on product, the metric spikes

The

cents on the platform dollar.

fifth

1 1

cents on the original

down

to a value of

42

product experienced a similar lack of platform efficiency,

costing about 36 cents on the platform dollar.

Insert Figure

The platform

commercial leverage of products

indicates the

to

product development costs.

basis (rather than

efficiency).

B

effectiveness measures for Family

By

definition,

6 here

cire

also highly revealing. Platform effectiveness

(or sets of products) as a ratio of total product sales

we compute

comparing any given product

to

its

this

measure on a product by product

base platform as in assessing platform

For Family B, commercial leverage grew strongly from the

Initial) to that

of the third follow-on product

(MS 1-3).

In particular,

commercial success, returning $259 for every dollar spent on

follow-on products

(MS 1-4 and MS

its

initial

MS 1-3

product

was an outstanding

development. The fourth and

-5) experienced a decline in sales relative to

I

(MS 1-

fifth

development

costs.

Taken

together, these measures of platform efficiency

management

words of one

and effectiveness were interpreted by

to indicate that underlying product platform for

R&D manager,

follow-on product in

its

Family

B needed

renewal. In the

the product platform began "running out of gas" after the third

ability to a) facilitate rapid

and cost effective development of derivative

products, and b) deliver the features required by customers at a price point that

would lead

continued strong sales. This deduction would not have been obvious by looking

budgets or product sales, nor by simply looking

rule out several factors that

at the

might have otherwise caused changes

time the market was relatively stable. There were no significant

market growth was

fairly

associated with Family

B

constant

at

about

5%

map

product family

per year.

The

in costs

annual

at

(Figure

and

new market

5).

sales.

to

R&D

We can

During

also

this

entrants and the rate of

.sales force, pricing,

and practices

also remained fairly stable.

Organizational issues strongly affected the evolution of Family B. Earlier generations of this

particular

measurement device prior

laboratory. Senior

Family B had been developed

management moved

in

the charter for developing the

an American

new product

R&D

architecture

R&D laboratory, a group that had demon.strated

in creating low-cost, modular products in related product areas. The R&D charter

represented by Family

competence

to

B

to a

European

/'r/c'c

IS

for

Family

B was

(MS 1-4)

groups.

with

its

then shifted back to the American group starting with the fourth follow-on product

as part of a larger initiative to rationalize

R&D foci among the firm's various R&D

The American group defined follow-on products and jointly implemented

European

partner.

these definitions

As expected, some degree of organizational turbulence ensued and

The

helped lead to higher costs and longer development times.

charter wars experienced within

embark on a platform renewal

the product family contributed to the firm's failure to

effort in a

timely manner and has placed a stellar product line under substantial market risk in the future.

Today, management has embarked on a crash

effort

would have been

better started earlier during the

of efficiency and effectiveness during product

declining efficiency of

development plan

is

effort to create a

MS 1-4.

new product

architecture. This

peak of the platform's success

in

its

terms

MS 1-3 shown in Figure 6 and certainly after the

Seeking to avoid

this

problem, the group's

new platform

being extended to include initiation of the "next generation" several years

hence. Additionally, senior

R&D to place American and European

management has reorganized

laboratories within a single business unit to ameliorate the destructive charter wars of the past.

4.3

Meta Metrics Applied

The measures of platform

at the

Platform Version Level

efficiency and commercial effectiveness

aggregate level for the product family,

product family.

To

illustrate this,

we

ie.

in

turn to

may

also be

computed

at

an

aggregate for successive platform versions within a

Family C, comprised of highly complex imaging

products used for measurement applications. Current products

in the

30,000 different components (making platform version tracking

necessary for this type of analysis). The family's

map

is

at

shown

in

family contain more than

subsystem and interface

Figure

7.

It

level

spans more than

15 years.

Family

C has

had two underlying product architectures, IM

1

and IM2. IMl had three successive

platform versions, IMl A, IMIB, and IMIC. The two platform extensions of IMl introduced

imaging modalities

that

new

provided users with substantially improved diagnostic capabilities. The

second product platform,

IM2

(replacing

IMl) featured an

entirely

new

architecture that

was

a

combination of more powerful image gathering and processing subsystems and new software

subsystems for the user interface and data management.

"horsepower"

IM2D.

to users.

IM2B was

new imaging

IM2

itself

IM2D

effectively offered twice the

had four platform versions, noted as IM2A, IM2B, IM2C, and

an extension of the platform to a

modality.

It

both incorporated a

new market

application.

new modality and applied

IM2C

it

to a

incorporated a

new market

application.

Pane /y

Insert Figure 7 here

These various platform

efforts

perspective, however, the firm

six

were each three to five years

was introducing new products every

months. The ability to generate

platform renewal, which

itself

this

measure plotted

the pursuit of

on a platform version basis

in reverse

recently, every

stream of products was based on a strategy of concurrent

was based on

even longer term research into new

for

C

Family

These measures plotted

platform efficiency and effectiveness.

the customer's

and more

year,

measurement techniques and associated technologies. Appendix 4 contains

sales data aggregated

From

in the malcing.

the engineering

and

and the resulting metrics for

in

Figure 8, with the efficiency

value order.

Insert Figure 8 here

The metrics help

reveal

two very

different types experiences for the

family. Family C's product family

initial

platform,

in a concurrent

of that platform's two successive versions,

were generated

platform version dollar. The quality of the product

efficiency in introducing

new

products,

came

to a propitious

product platform (IMIC). Just as the firm was putting

first

product

IMIB and

manner. Strong levels of platform efficiency resulted. For

three versions of the first platform, follow-on products

their respective

in this

(Figure 7) shows the careful, patient development of the

IMIA. The development

IM IC, was approached

all

map

two platforms

line,

at less

and the accumulating cost

peak during the

its

than 10 cents on

third version of the

best foot forward in terms of

engineering, two major competitors, themselves large, diversified businesses, exited this market

due

to highly publicized scandals that elicited

government intervention. The firm exploited the

opportunity. Family C's products during this time yielded over 80 dollars in sales for each dollar

of engineering cost to develop them (as seen under

The second platform of Family

experienced a different

Management decided

fate.

to

C

IMIC)

in

Figure

(noted in Figures 7 and 8 as

The team sought

to

8.

IM2A, IM2B, IM2C, and IM2D)

double the imaging power of the system.

produce the image processing subsystem boards with a newly installed

process technology (surface mount manufacturing). Given the major change in both product

design and manufacturing process, the platform renewal was started too

earlier,

that

one of the company's lead engineers had

was

directly competitive.

management seemed

new

to

He had

left to start his

initiated a platform

be resting on the laurels of the

startup's efforts, a crash effort initiated to create a

own

late.

Further, several years

firm and created a product line

renewal "on the outside." Meanwhile,

first

new

platform.

When

it

received word of the

platform. Then, the

new competitor

Pai;c

20

announced

IM2A

its

new products

were brought

to

to industry acclaim.

Management had

to respond: products

based on

market quickly thereafter even though the new technology had not yet

sufficiently ripened.

The

initial

this

time offered

product under

little

IM2A experienced problems

new

in the field.

functionality to customers (being

The team was consumed with

new

generated from

the metric for

introduced a

IM

IM2B were

IM2B

platform, a

The

new measurement

introduced

The

a

produce follow-on products during

more acceptable

efficiency, however, that

of Family C's

The

first

(IM2D) extended

was

stabilized

by

cost of 30 cents on the

targeted.

dollar.

Then,

that

in

IM2C,

the product line to a

this point,

IM2D

computed

the

team

IM2C

Figure

in

new measurement

and the derivative products were

platform dollar.

It

was a

level of

to declining leverage in

IM2C, and

fifteen year period, overall

efficiency for these

further decline in

in the creations

two platforms could be

within the platform led

15%

this

per year.

IMl and IM2, our measures of

compared.

In this case,

development of IM2 was nearly twice as costly as IMl (which, as shown

part to the late start

LM2B

should be noted that during

excess of

in

of platforms

clearly

application targeted by

It

IM2

platform architectures. Sales

new products

IM2D.

market growth remained strong

equal costs had been incurred

for the successive versions

new market

reversed the downslide. However, the difficulty of creating

however, the

in

Figure

8,

was due

in

and hasty development of IM2). But even without correction the explosion of

costs for derivative products from

IM2

is

obvious.

An advantage

of product family maps

is

that

both raw data and efficiency measures between successive generations within a

product family can be clearly seen and compared.

Our

the

The products

time (referring to

move smoothly between

of the product line plummeted during IM2A. The

in

IM2B,

platform.

effectiveness measure of commercial leverage

such differences

In

8).

three times poorer than that experienced throughout the products

still

platform shows the results of this failure to

If

Figure

efficiency metric deteriorated to almost 2.5 dollars relative

The platform technology had

at

(in

technique. Significant technical obstacles in the underlying

fourth version of the platform

application.

was

application

30 cents on the platform

architecture had to be surmounted.

8).

new market

IM2A

very successful commercially. However, the efficiency decreased with

rising to over

to the platform dollar to

output peripherals, for example).

fixing problems in the underlying architecture. This yielded the

extremely high platform efficiency measure for products under

next version of the second

The follow-on products during

interpretation of these metrics

and the events

that

caused them was reinforced when

Pcijic

21

management provided

staffing information. Staffing data

had worked on underlying platform projects versus those

over time. Note the sharp

activity

thie

number of engineers who

for follow-on products

on a year by year

9 shows these allocations as percentages, together with the increase

basis. Figure

replace the

comprised

shift in this allocation

when management sensed

in total staffing

the urgent

need

to

product platform, IMl, with IM2. The percentage allocation to platform-related

first

swung from 10% of the engineering

staff to

70%

in

Once IM2

a single year!

stabilized,

resources were shifted largely to follow-on product development.

9 here

Insert Figure

Management

learned from this experience.

development

effort

(which

we may

call

The team

IMS)

initiated

to replace

EM2

an entirely

new platform

with better imaging and user interface

We visited the company during the week when IM3 had passed all the internal quality

control tests. To our delight, the R&D manager was convening a meeting of his best engineers.

capabilities.

Their purpose: to begin the design of the next product platform (IM4). The

allocations

between platform work and

that for follow-on products has

shift in

become

engineering

less dramatic,

indicating a policy of continuous platform renewal.

4.4 Comparisons between Product Families

The platform metrics can

performance for a

we

set of

management

also be used by senior

product families and

facilitate learning

two

will use the platform efficiency experiences of

Family

D and E

.

to comparatively assess

from

that endeavor.

R&D

To show

different product families, referred to as

Both product families are comprised of measurement devices, each targeted a

different but related market application. Family

versions of that platform and

1

1

D had a single product platform, with three

follow-on products. Family

with several or more platform versions, and also

1

1

E had two

follow-on products.

product platforms, each

We gathered data,

maps, and computed platform efficiencies as described above (see Appendix 4 for specific

The two product

groups.

10.

The

families were developed during equivalent time periods by

different

is

shown

two versions of the Family D's platform were highly productive

in

terms of

in

economical generation of follow-on products. The

this regard.

two

terms of platform efficiency

The performance of these two groups

first

this,

Discussions with managers involved

suspicion that the platform had reached

capabilities required by customers.

its

A new

in

limit in

third platform version,

development

at that

data).

R&D

in

Figure

however, suffered

in

time confirmed our

terms of efficiently delivering the

architecture for Family

made

new

D (as opposed to the

platform

Pai^c 22

Dl C

extension labeled

the renewal of

in

Family

in

Figure 10) would have best been started

D was initiated in the late

in the early 1980's.

new

1980's, resulting in a

Instead,

platform (labeled

D2 A

Figure 10) from which products were released starting in 1990. While the efficiency of this

platform for creating derivative products (.27) was better than that of

(.42),

that value

was

below the strong platforms

still

in

its

immediate predecessor

terms of technical leverage within the

company.

Insert Figure 10 here

In contrast, the platform efficiency values for Family

The values

for the successive platforms versions are

range, including the today's present platform (E2

B

E

indicate consistently strong performance.

all in

in

the 10 cents

Figure

10).

on the platform dollar

Note further the overlap

between the development of the second platform (E2 A) and the creation of follow-on products

from

its

precursor (El C). Family

we deem

organization must

memory

facilitates internal

remember

rhythm

in

platform enhancement and renewal that

benchmarking of R&D

past experience. In the context of

activities.

In order to leam, an

new product development,

skills,

Measurement of these

and customer perceptions and participation

factors

and analysis of

their results in areas

in the creation

identified product families with high levels of platform efficiency

effectiveness relative to other product families,

of

such as platform

efficiency and effectiveness provides information for experimentation and learning.

management has

this

includes the evolution of product families and their architectures, the

composition of teams and

products.

indicates a

highly desirable.

This comparative analysis

corporate

E

Once

and

management may then explore underlying

approaches and techniques for product planning, design, and integration.

5.

Discussion

In our field work,

\V/it';i

we encountered

a

number of frequently asked

should we renew our platforms?

to take?

What

complete?

types of engineering

How can we

How much

questions:

will platform efforts cost,

and commercial

benefits

and how long can we

can we expect to gain from these

expect them

efforts

once

improve our approaches and strategies for product development?

Page

2.*

The work presented

new product

to

in this

paper does not exphcitly

tell

management

when

precisely

to create a

platform. However, our concepts and metrics provide managers with a rich context

determine when product platforms should be obsoleted with new platform designs and what to

expect from these

new

new

designs once

products are developed from them. In short, the work

R&D dimension of product

comprises a framework for learning, specifically targeting the

development. (Maidique and Zirger, 1985) The axiom "hind-sight

is

20-20"

is

well remembered.

Without descriptions of factors influencing events, such as those provided for the product families

in this paper,

The

R&D performance may be prone to misinterpretation.

observed measures of

cost-effectiveness of implementing these measures within a

start is to

ask management

if it

company

will vary.

The place

to