Framework for the Determination of Yield Limits In Pharmaceutical Operations ARCHIVES

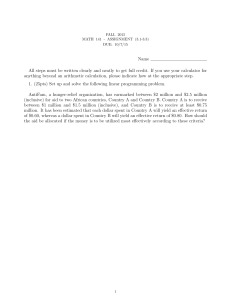

advertisement