GAO BEST PRACTICES Increased Focus on Requirements and

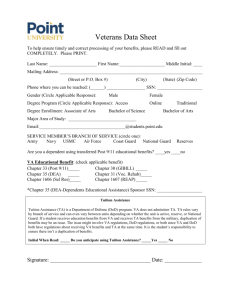

advertisement