Document 11039477

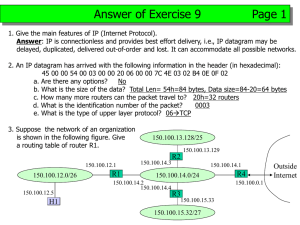

advertisement

M.I.T.

LIBRARIES

-

DEWEY

Dewey

HD28

.M414

Bottleneck Resource Allocation in Manufacturing

Anantaram Balakrishnan

Richard L. Francis

Stephen J. Grotzinger

#3729-94-MSA

October 1994

uiASSACHUSETTS UMSTiiure

OF TECHNOLOGY

DEC 01

1994

LIBRARIES

Abstract

Many

resource-allocation problems in manufacturing and service operations require

selecting integer-valued levels for various activities that

limited resources.

System productivity,

(bottleneck) activity.

We

first

to

consume "nondecreasing amounts" of

be maximized,

is

limited by the least productive

review a basic bisection method that can solve

this discrete,

monotonic resource-allocation problem even with nonlinear objective and constraints.

We

then

generalize the basic algorithm to solve an enhanced version of the problem containing

additional coupling constraints on the allocation decisions.

assembly-release planning (ARP)

commonality. The

ARP

in a

multiproduct assemble-to-foreccist environment with part

problem requires finding feasible amounts of each product to release

for assembly in each period using the available parts.

minimum

periods.

and part

This generalization applies to

The

objective

is

difference between the actual and desired service levels over

We

also consider extensions of the

substitutability,

and show how

to

ARP

to

all

maximize the

products and time

model incorporating precedence constraints

modify the bisection method to solve these problems.

1

.

Introduction

Many

resource-allocation problems in manufacturing and service operations require

choosing integer-valued levels for various activities that compete for limited,

resources

in

minimum

order to maximize the

return or productivity over

ail

common

the activities.

Applications of bottleneck (max-min or min-max) resource-allocation models include line

balancing, raw material allocation, maintenance planning, and storage allocation.

These problems have the following general formulation. Let

activity levels X:.

Sj

Each

activity

consumes varying amounts of

and gj(X) denote, respectively, the

resource

consumed by

the system's productivity f(X)

f(X) = min

{fj(Xj): j

=

1, ...,

i

For

(Cj).

=

1, ...,

and the amount of

We

must select

m,

let

this

denotes the "productivity" of activity

If fi(Xj)

activity levels that

j,

i.e.,

maximize system

productivity while satisfying resource constraints, and lower and upper bounds,

=

i

limited by the least productive or "bottleneck" activity,

is

n}.

be an n-vector of integer

resources.

of resource

total availability

the activity levels in X.

m

X

B =

(Bj) and

C

This discrete, bottleneck resource-allocation problem has the following nonlinear,

integer

programming formulation:

f"'"

maximize f(X) =

[P]

j=l,

f-(x:)

...,

n

J

(1)

J

subject to

gi(X)

<

Sj

B

X

<

<

Xj

We

assume

not decrease,

foralli=

for

i

=

1,

...,

m,

m.

(2)

C.and

(3a)

for all

integer

that as the activity levels increase the

i.e.,

1,...,

j

=

1,

...,

(3b)

n.

amount of each resource consumed does

the resource-usage function gj(X) satisfies the following

monotonicity (nondecreasing) property: given any two integral vectors X' and X" satisfying the

upper and lower bounds (3a), gi(X') < gi(X")

applications satisfy this assumption.

model economies of scale

setup time, and so on).

in the

The

if

X'

< X". Most

practical resource-allocation

Nondecreasing functions are quite general; they can

resource constraints, including fixed charges

(e.g.,

productivity functions f:(Xj) need not be monotonic.

fixed cost,

We

only

require fj(Xj) to be real-valued and defined for all integer activity levels in the closed interval

[Bj, Cj].

We

assume

that the

problem

is

feasible,

-

1

i.e.,

X

= B

satisfies constraints (2).

Past research on bottleneck resource allocation (see, for instance, Luss [1992] and Ibaraki

and Katoh (1988) for reviews of

the

this literature)

has addressed continuous-variable versions of

problem and/or models with special structure

(e.g.,

a single resource or linear functions).

For the discrete allocation problem with one linear resource constraint

(i.e.,

a knapsack

Porteus and Yormark

constraint), Jacobsen (1971) proposed a marginal allocation approach.

Brown

[1972] developed an improved bisection search algorithm to solve this special case, and

[1979] described efficient solution procedures for knapsack-sharing problems with piecewise

linear

and nonlinear productivity functions.

For problems with multiple resources. Tang [1988] developed an

linear

model

in

which the resource-usage functions gj(X) are

all

variable coefficients), and the productivity fj(x:) of each activity

function.

The method

finds an optimal integer solution

problems without integer

restrictions.

0(m

n^) algorithm for a

linear (with nonnegative

is

a

strictly increasing linear

by solving a sequence of relaxed

Tang described various manufacturing

applications of

this

model, including a storage space-allocation problem (also called the reel-allocation model,

see

Ahmadi, Grotzinger and Johnson [1988]). All of these applications

monotonicity (nondecreasing) assumption.

bisection search

and easy

to

method

Recently, Francis and Horak [1993] described a

to solve the storage space-allocation

implement, and although

its

problem.

computational complexity

method was quicker than Tang's algorithm

satisfy the

in

computational

is

The method

is

robust

data-dependent, the

tests.

This paper, motivated by some resource-allocation decisions

in electronics

manufacturing

and assembly, explores extensions of the bisection approach to address these decision

problems.

One of

these applications

is

a cleanroom sampling problem described and

formulated by Grotzinger and Cooper [1992] as a bottleneck resource-allocation model with a

nonlinear objective function and a monotonic resource constraint.

activity levels are the

sample sizes for n samples

samples are required for an inspection plan

varies by location, and increases with the

at

In this application, the

n specified locations of a cleanroom. These

to certify the

cleanroom.

The

cost of sampling

number of samples. The cleanroom has a

fixed

budget for sampling. To meet the federal standard for certification as a particular class

cleanroom, the sample average contaminant concentration

prespecified class limit.

at

each location must be

less than a

Since the variance of the sample average at any location varies

inversely with the size of the sample at that location, a larger sample size will increase the

probability that the sample average at that location will be less than the class limit.

However,

the limited sampling budget introduces tradeoffs in allocating samples to various locations as

we

attempt to increase the overall likelihood that the cleanroom will be certified,

2-

i.e.,

the

likelihood that the sample average will be below the class limit at aU locations.

effective inspection plan, Grotzinger and

maximum

minimize the

sizes that

Cooper proposed a bottleneck model

variance of the sample averages over

to a linear financial resource (budget) constraint.

the continuous relaxation of this problem

proposed heuristic adjustments

In Section 2

we review

(i.e.,

To develop

to select

They developed a method

to optimally solve

permitting fractional sample sizes), and

to the fractional solution to obtain

an integer solution.

the basic bisection algorithm to solve discrete,

monotonic

model even with

nonlinear (but nondecreasing) sampling cost functions that reflect economies of scale.

3,

we

O'Connor [1993]

serviceability constraints introduced by Grotzinger and

resource-allocation

discuss

how

consider more general

Section 4,

we

ARP

motivate

first

approach to solve

this

model. In Sections 4 and 5

we

parts substitutability.

from the interaction of

production planning decisions across products and time periods.

We

particular part,

part

we can

from a specified

still

set

to solve this

when

assembly-release decisions

In

models with general precedence constraints governing the

allocation of resources; these precedence constraints might stem

modify the bisection approach

We

the allocation decisions.

models with precedence constraints and

ARP

for an assemble-to-

This problem can be formulated as a monotonic

model with additional coupling constraints on

to adapt the bisection

In

(ARP) problem with

describe a multiperiod assembly-release planning

forecast environment with part commonality.

sample

the locations subject

all

(nonlinear) resource-allocation problems such as the cleanroom sampling

Section

an

new

class of problems.

part substitutions are permitted,

produce products that normally use

of substitutes.

incorporate substitutability of parts.

We

then describe

In Section 5,

i.e., if

this part

we

how

we

to

consider

run out of a

by using an alternate

further extend the bisection algorithm to

To our knowledge,

multiperiod

precedence constraints and substitutable parts are unstudied.

ARP

problems with

Our concluding

discussion in

Section 6 includes a broad interpretation of the various extensions to the monotonic resourceallocation

2.

problem

[P] that this

paper has addressed.

Bisection Method for Discrete, Bottlenecit Resource Allocation

The

bisection

method

for discrete, bottleneck resource allocation, although originally

proposed for problems with linear productivity functions and resource constraints, also applies

to the nonlinear,

we must

monotonic version

[P]

of the problem.

However, before applying

the method,

replace any productivity functions that are not nondecreasing with equivalent

nondecreasing functions.

In this section,

we

first

the bisection algorithm.

-3-

describe the transformation, and then present

Suppose a given productivity function fX^\)

it

We

nonmonotonic or decreasing.

is

transform

into an "equivalent" nondecreasing function fj(Xj) by setting

= max

fj(Xj)

(fj(y):

x}

=

for all x

Bj.

Bj+I

Cj.

(4)

problems with linear knapsack

for bottleneck

also valid for problems with nonlinear, nondecreasing resource-usage functions.

constraints,

is

To confirm

its

and

validity, first note that fj()

smallest value of

Using

Bj+1

Bj,

Brown [1991]

This transformation, proposed by

versa.

=

y

Xj that

maximizes

fj(x:) is

we can show

this property,

f-()

have the same

maximum

values, and the

also the smallest value maximizing

that, if the

fjCx:),

and vice

resource-usage functions gj(X) are

nondecreasing, then the optimal objective function value of the transformed problem [P], with

fj() instead of fj(), equals the optimal value of the original problem.

optimal solution

X*

to the transformed

(Since the objective has the

problem

max-min form and

also optimal for the original problem.

is

the resource-usage functions are

nondecreasing, problem [P] has an optimal solution

equal to

solution.

Our

other alternate optimal solutions.)

all

For convenience, we

assume

will

productivity functions are nondecreasing

Moreover, the smallest

in all

X*

that is

bisection

component-wise

method

less than or

finds this smallest optimal

of our subsequent discussions that the

the transformation (4) has been applied, if

(i.e.,

necessary).

We

refer to any vector

X

satisfying constraints (2) and (3) as a feasible solution.

an optimal feasible solution (OFS) X*,

f(X*).

i.e.,

a feasible solution that maximizes f(X).

We

seek

Let z*

=

Since the productivity functions are nondecreasing, f(B) < f(X) < z* < f(C) for any

feasible solution X.

Given any value z e

yj(z)

Thus, yj(z)

is

=

rain {xj: z

<

[f(B), f(C)], define yj(z)

fj(Xj). Xj

=

Bj,

Bj+1

the smallest value of the j'" activity level

of this activity equals or exceeds

z.

When

Cj}

by

for all j

=

I. .... n.

(5)

needed to ensure that the productivity

X:

the inverse of the function fj() exists (for instance,

if

fj() is linear), then

yj(z)

where ful

is

=

rfj"'(z)1 for all fj(Bj)

the smallest integer

bisection search over the

maximum

Horak [1993] showed

less than u.

domain of

Given any positive number

within e of the

no

e,

value,

that,

we

<

z

<

Otherwise,

fj(Cj),

we can compute

yj(z) using

fj().

call

i.e., if

a feasible solution

z* - e

< f(X) <

z*.

X an e-OFS

if its

objective value

For the linear model, Francis and

given a value z e [f(B), f(C)], the following three conditions are

-4-

is

equivalent:

z*.

(i)

Y(z) =

This result

Y(z) satisfies constraints

(y:(z)) is a feasible solution; (ii)

Both the

the basis for their bisection algorithm.

is

(2);

and

(iii)

<

z

and the algorithm

result

extend directly to discrete resource-allocation problems with nonlinear, nondecreasing

resource-usage and productivity functions.

The underlying idea of

at the

X

the algorithm

midpoint of the current search

with f(X) >

needed

We

z.

check

is

to iteratively select a trial objective function value z

and check

interval,

feasibility

by

first

the

if

problem has a feasible solution

determining the smallest possible value yj(z) of

to ensure that the overall objective function value f(X) equals or

verify if the solution Y(z)

=

(yj(z)) satisfies the resource constraints (2).

a feasible solution to the problem, and so the

z* (actually, f(Y(z))

initialize the

>

z

is

value z

= (LB + UB)/2, determine

termination, the vector

If

it

We

z.

then

does, then Y(z)

is

a lower bound on the optimal value

is

We

z*. We

a better valid lower bound); otherwise, z overestimates z*.

depending on whether or not Y(z)

One

trial

algorithm with lower and upper bounds,

iteratively select z

exceeds

Xj

Y(LB)

is

LB =

f(B) and

Y(z), and update

satisfies (2).

LB

UB

=

f(C),

to f(Y(z)) or

Iterations repeat until

UB

on

UB

- LB <

to z

e.

At

an e-OFS.

potential disadvantage of this approach

is

that

its

effort

is

data-dependent.

The

algorithm requires up to log2((f(C) - f(B))/e) iterations, each requiring n evaluations of the

yj(z) values.

We

not so big as to

literature

approach

3.

view

make

this

bisection impractical.

assume special

is

disadvantage as principally theoretical

data

The polynomial-order algorithms proposed

structure (e.g., linear resource constraints),

is

in the

whereas the bisection

quite general.

The Assembly-Release Planning Problem

In this section,

we review

a production planning problem in an assemble-to-forecast

environment with part commonality.

this

in nature; typically, the

Grotzinger and O'Connor [1993] described and modeled

problem as a continuous, bottleneck resource-allocation problem. In

consider the integer version of this model.

The problem

is

this paper,

we

formulated using variables for

cumulative production quantities instead of monthly (or weekly) production quantities.

resource constraints,

when expressed

the nondecreasing property.

in

first

The

terms of these cumulative production variables, satisfy

The model contains

additional coupling constraints to ensure that

the solution corresponds to a feasible production plan.

We

algorithm to incorporate these constraints.

4 and 5 we consider enhancements of

In Sections

extend the basic bisection

the assembly-release planning

model

to

account for precedence constraints and parts

substitutability.

Assemble-to-forecast (ATF) or make-to-stock refers to systems that produce goods based

on demand forecasts rather than actual orders

(see, for instance.

Baker [1993]) because

the

procurement and production (fabrication or assembly) Lad times are longer than the customer

lead time

the time

(i.e.,

between placing an order and shipping the product to the customer).

Electronics assembly facilities producing personal computers provide one example of an

environment.

several

In this context, the

months

ATF

procurement and assembly lead times could range from

few weeks whereas

(to procure certain specialized integrated circuits) to a

customer lead times might be only a few days. The personal computer assembly example also

illustrates

another feature, part commonality, found in

same

refers to using the

several personal

component)

part (or

many ATF environments. Commonality

for several different products.

computer models might require

For instance,

same microprocessor. Increasing

the

part

commonality provides many benefits including decreasing ordering and inventory

administration expenses, and reducing safety stocks of parts due to risk pooling (see, for

instance, Bagchi and Gutierrez [1992], Baker,

Magazine and Nuttle [1986], Collier [1982],

Gerchak and Henig [1989], Gerchak, Magazine, and Gamble [1988], and Grotzinger

et al.

[1993]).

In

ATF

regarding

facilities that

how many

products, and

produce multiple products with part commonality, decisions

parts to procure in each period,

how many

"kits"

(component

sets for

how

to allocate these parts to different

each product) to release for assembly

in

each period must be based on estimates of probable future demands for each product, service

level requirements,

and inventory considerations. To address these decisions, Grotzinger and

O'Connor [1993] developed a general nonlinear optimization model, and formulated a

program for a

subproblem" incorporating the parts allocation and assembly-

"feasibility

release decisions.

We

focus on the integer version of this feasibility problem, which

as the assembly-release planning

Consider a

parts).

parts,

facility that

(ARP) problem.

is

L

periods for

all

products.

and the same assembly lead time

are easy to incorporate.

We

The

is (p-t-l)

time periods for

(t

=

refer to

m

all parts,

part types (or

and the assembly

For simplicity, the same procurement lead time for

for all products,

is

parts ordered during the past

beginning of the current period

we

next describe this problem.

assembles to forecast n (finished) products using

Suppose the procurement lead time

lead time

linear

assumed. Item-dependent lead times

p+1 periods

0) and subsequently for periods,

-6-

all

t

will arrive at the

=

1, ..., p.

We

are

concerned with how to allocate these parts (including those currently on-hand)

products, and

1

how many

assume

Figure

events: procurement decisions, part arrivals, release of

and assembly completion.

parts for assembly,

We

assembly during each of the next p periods.

kits to release for

shows a timeline depicting various

to various

that the probability distribution of

the next (L+p) periods

for every product during each of

These distributions are revised each period based upon current

given.

is

demand

market conditions and trends, and so the assembly-release plans must be updated each period.

Since the assembly lead time

assembly

at

time

for

t,

L

is

=

t

time units, the number of kits for each product released for

p,

must be chosen

product in period (L+t). The planner's objective

every period L,

L+p

...,

We

time

t

is

that the unsatisfied

demand

is

than the

is less

plus the total output

(i.e.,

t

target service level

is

equals or exceeds

the desired

product and time period.

We

determine

if

t

is

demand during

t

>

as

its

model maximizes

if

the

minimum

its initial

inventory at

to period

The

t.

t.

The

value for this probability; this target might vary with

between the actual and

target service levels

Grotzinger and O'Connor [1993] developed a linear program to

not to determine the

minimum

we

that period,

cumulative demand up to and including time

the target service level can be achieved for all products

available parts, and

for each product in

the probability that the cumulative availability of

refer to the difference

as the service-level difference.

for that

If the available

completed assemblies) from period

actual service level for a product at time

that product at time

demand

backlogged.

define the cumulative availability of a product at time

=

demand

to satisfy the

with a given probability or target service level.

inventory of a finished product in any period

assume

to service the probable

minimum

and time periods using the

possible deviation from target.

service-level difference over

integer version of this model, the Assembly-Release Planning

all

The

products and periods.

The

(ARP) problem, has the following

formal definition.

Given

the current parts inventory, the quantities

next p periods, the

bill

next (L+p) periods, the

the

minimum

on order and

of materials for each product, and the

ARP

to be received during the

demand

distributions for the

probl-^m seeks integer assembly-release quantities to maximize

service-level difference over all products

and time periods

subject to parts

availability.

If the

optimal objective function value

is

nonnegative, then the currently available parts

plus the anticipated receipts (based on prior procurement decisions) are adequate to provide

the desired service levels for

products

all

periods

in

L through

specifies a set of assembly-release quantities that meets the targets.

value

Otherwise

case, the assembly-release quantities specified by the

ARP

solution

(if

future parts procurement quantities based on the

ARP

In this

solution ensure that the actual service

how

Grotzinger and O'Connor [1993] discuss

level is as close to target as possible.

the optimal

more products.

negative), the target service level cannot be attained for one or

is

ARP

(L+p); the

to decide

solution.

Problem formulation:

For

=

j

number of

m,

and

n,

1

=

t

0,

units of product

....

p,

we

define nonnegative, integer variables

denote the number of units of part

let Hjj

through

time

which

is

equal to product

j's

decide to release

+

Let D:

...

i.e.,

-Kljt)

through

periods

j^^j

for all

j

For

t

Sj^ is the

t

=

=

0,

...,

p, the total

in

The minimum

that

=

define

n,

1

•

fjtCqio"'"

and

qjQ

+

t

...

=

•''^it)

0,

+

service-level difference f(Q)

each

f:,(),

Q' implies f(Q)

fjj(q:Q+

The

p, let S^^

the initial on-

...

+qj()

ARP

is

= min{fj,(qjQ+

...,

qjj

period (L-

in

assemblies just

f(Q').

is

(i.e.,

amount of product

periods

L through

^

j

(L+t))

j

j

that

is

in

from

*^^ service level difference for product

j

p,

> Dj

l^,}

— Target

service level for product

j

period (L+t).

is:

...+qjt): j

and hence f(Q),

<

j

be the cumulative demand (a random variable) for product

= Prob{ Aj l_, +

f(Q)

Q<

1, ...,

the cumulative availability of product

in

Note

sum of

0, including

(and will complete

t

amount gives

to this

We

to period (L+t).

time (L+t),

fjj(qjO+

in

Adding A: j^j

q:j.

period (L+t).

at

i.e..

t

quantity released for assembly during the past (L-1) periods

to period -I inclusive).

period

t,

current inventory (at time

from period (-L+1)

...

time

at

For

=

denote the (known) cumulative availability of (finished) product

j_^_|

total

qjQ+

i

j.

=

i

plus the total anticipated receipts of this part during periods

completed) plus the

we

For every part

t.

t.

Let Aj

I),

at

i

period

in

used per unit of product

i

denote the (known) cumulative supply of part

hand inventory of part

assembly

to be released for

j

representing the

q:.

=

n,

1

and

t

=

p}.

a nondecreasing function of the release quantities,

(6)

i.e.,

Also, for a given vector Q, every service-level difference function

nonnegative

if

and only

if

f(Q) > 0.

problem, is formulated as follows:

8

-

[ARP]

maximize f(Q)

subject to:

n

Z

ajj

j=l

+

(q:Q

+

...

<

q-,)

i

=

1, ...,

m, and

all j

=

1

n,

for all

Sj,

q^ >

and integer

for

Constraints (7) ensure that the total amount of each part

through

t

does not exceed

its

cumulative supply

maximize

release quantities qj^ to

all

t

=

the

We

Sjj.

minimum

used

i

and

in all

t

=

(7)

p,

^

•*

0,

....

(8)

p.

products during periods

wish to find nonnegative, integer

service-level difference over

all

products and

periods.

Although formulation [ARP] has

solution

method (described

in the

^]0

+

1j

1

+

•••

S,

assuming

Q' = (qL) and

i.e., if

^jt

next section) also applies to problems with nonlinear

G(Q) <

resource constraints of the form

nondecreasing (TND),

linear parts-availability constraints (7), our bisection

- IjO

"^ ^Ij

+

i

+

•••

Q" =

TND,

but this property

is

are

TND

any two feasible solutions

=

fo"" all j

Note

not necessary.

productivity function with an equivalent

analogous to equation

(qj'j)

'Ijt

then G(Q') must be less than or equal to G(Q").

(6) is also

that the vector function G(-) is tier-

I

n,

and

t

that satisfy

=

p.

by

that the objective function f() defined

We

can replace any given

non-TND

function, obtained by applying a transformation

(4).

Formulation [ARP] uses the service level differences as the productivity functions.

However, the enhanced bisection method

that

we

describe in the next section applies to the

broader class of problems in which each productivity function

defined function (not necessarily

ARP

a special case, consider the

each product

j,

we

TND)

of the cumulative availability of product

The

additional

maximum

bisection

TND

Q

ARP

denote the

= max[f(Q):

Q

set

penalty over

method can solve

at

time

t.

As

for

this

all

products and time periods

is

problem, and can also

resource constraints, such as labor and budget constraints with

economies of scale and/or fixed charges.

Let

j

assign a penalty n- per unit shortfall of cumulative availability relative to

the objective function.

Solving the

any real-valued and well-

problem with known, deterministic demands. Suppose,

cumulative demand; minimizing the

accommodate

f:j() is

In Section 4,

we

consider further model extensions.

problem:

of

g Q}. Set

all

Q

is

Q satisfying constraints (7) and (8), and let z*

is a feasible ARP solution) and finite.

(since Q =

feasible solutions

non-empty

-9

and so z*

exists.

therefore,

we

LB =

The

f(0) is a valid

if

we

(qjo

is

J

and

+

...

< S^

qj,)

monotonic,

for all

i,

and

j,

Q

e Q,

t.

= min{LSjj/ajJ:

=

i

such that

>

aj:

0},

(9)

1,

...,

U=

Let

t.

n and

=

t

(Uj,).

0,

...,

(J)

Since each function

p}

is

is

+

+

...

<

q-^

\i^

nondecreasing,

a valid upper bound on z*.

for all products

UB

=

f(U)

Furthermore, q^ <

yx-^

j

= min

for all

t.

To

how

better understand

Xjt

=

+

qjo

-

+

=

forallj

qjt

1, ....

denote the cumulative release quantity of product

[ARP] with

variables in formulation

r(X) =

approach to the

to adapt the original bisection

reformulate the problem by transforming the variables.

we

is

obtain an upper bound, note that for every

the largest integer less than or equal to h, then, qjQ

and time periods

{fjj(Ujj): j

+

Since the function f()

z*.

define

Ujj

where LhJ

To

lower bound on z*.

search interval for the optimal value;

initial

develop upper and lower bounds on

first

ajj

Thus,

method requires an

bisection

j

in

ARP

model,

we

Let

andt =

n,

0, 1,

through

periods

(10)

p,

...,

t.

Replacing the q-

the x-variables, and defining

min{fjj(Xj,):

j

=

t

=

0,

i

=

1

for all

j

=

1

...,n,

and

t

=

1, ...,p,

for all

j

=

1

...,n,

and

t

=

0,1,

for all

j

=

I

...,

n,

1

and

...,

p}

get the following equivalent model:

[ARP']

subject

maximize f'(X)

to:

n

Z

<

ajj Xjj

for

Sjj

all

m, and

=

t

(11)

p,

j=l

-

'^jt

Xjj

<

x-j

>

The coupling constraints

assembly

at

time

t

''j,t-l

Ujj

and integer

must equal or exceed

its

cumulative release quantity

in

formulation [ARP].

not require the resource constraints (11) to be linear;

G"(X) < S

andt =

and

as long as the function

satisfy constraints (12), (13)

G"(X)

it

is

and (14) (requiring G"()

-

10-

(13)

(14)

0,1,... ,p.

(12), specifying that the cumulative quantity of product

nonnegativity constraints on the variables q^

constraints

n,

...,p,

(12)

j

released for

time (t-1), reflect the

at

Our

solution

method does

can also handle nonlinear resource

nondecreasing for

to

all

be nondecreasing

vectors

is

X

that

equivalent to our

previous

TND

condition on the resource-usage function G(Q)).

Luss and Smith [1988] have

considered a multiperiod model similar to [ARP'] but with continuous variables, linear resource

constraints, and hnear productivity functions fjt(Xj,) that represent the relative deviation of

cumulative production from cumulative demand.

Observation

1:

X

Every feasible solution

the

Q

[ARP'] has a corresponding feasible solution

to

same objective value) and vice

[ARP] (with

to

versa.

Proof:

Q

Given a feasible solution

we

value by setting q^

i.e.,

<

X'

X

= \^ -

x- j_j

for

all

t

=

=

(q-j) to

p,

1

model

Note

[P].

if

[ARP] with

that the function hjj(X)

the

=

satisfies the constraints

of

same objective function

all j

=

1,

....

n.

the basic monotonic

X: j_|

Let us

now

explain intuitively

how

to

G"(X) <

-

S, but

not monotonic in

Xj^ is

resource-allocation variable

which ensures

x-

However, these values might not

we modify

need

to treat

them

modify the bisection method described

Recall that, for a given

objective function value, the value yj(z) defined using equation (5)

is

trial

value z of the

the smallest value of the

that the objective value equals or

exceeds

satisfy the coupling constraints (12) in formulation

the definition of the y-values as follows.

For

in

all j

=

1,2,

....

n,

z.

[ARP].

and

t

=

0,

p, let

1

Wjj(z)

We

is

does not necessarily imply that hjj(X') < hjj(X). Therefore, we cannot include

Section 2 to handle these additional constraints.

Therefore,

X

and q:Q = Xjq for

constraints (12) in the set of general resource constraints

separately.

obtained using equation (10)

model [ARP'] from

constraints (12) differentiate

resource-allocation

X,

Q

obtain a feasible solution

The coupling

X

[ARP], the solution

and has the same objective value. Conversely,

feasible in [ARP']

[ARP'], then

to

= min

{xjj:

z

<

fjt(Xjj), Xjj

then successively compute yu(z), for

Note

yjo(z)

=

yjj(z)

= max{yjj_,(z).

that

Let

each

il'

t

=

0. I,

....

=

1,

p, as:

...,

^i^^}.

(16a)

Wjq(z), and

yi((z) is a

ift>l.

Wjj(z)}

nondecreasing function of

denote the set of

all

(15)

vectors

X

z.

satisfying (12), (13), and (14).

-

11

(16b)

Observation

2:

For a given value

z

e [LB, UB], the vector Y(z) obtained using equations (16a) and (16b)

the smallest element of Q' with an objective value of at least

and Y(z) < Y'

for

any other vector Y' e Q' with f "(Y) >

z, i.e.,

Y(z) e

equivalently define yjt(z) for

= min

yj,(z)

(Xj,:

z

t

=

<

Note

that, instead

f '(Y(z)) >

z,

z.

This observation stems from the monotonicity property of each function

proven using a contradiction argument.

ii',

is

fjj(),

and can be

of using equation (16b),

we can

p, as

1

fj,(Xj,), Xjj

=

yj

,_,(z),

yj

j_,(z)+l,

....

(16c)

Ujj}.

Observation 2 and the monotonicity of the resource-usage functions G"(X) defined by (11)

enable us to perform binary search to find an e-optimal solution to problem [ARP'].

algorithm before justifying

state this

its

procedure to evaluate Wjj(z) (defined

in

validity.

We

The algorithm contains an embedded search

equation (15)).

We

refer to this procedure as the

evaluation subroutine.

Bisection algorithm for

Step

Step

0:

ARP problem

:

Initialization

P <— 0;

{initial

vector of lower bounds on Y(z*)}

Y<— U;

(initial

vector of upper bounds on Y(z*)}

LB

<r- f'(0);

(initial

lower bound on z*}

UB

<r-

(initial

upper bound on z*}

1:

Search process

r(U);

REPEAT

z <-

(LB + UB)/2;

Compute W(z) in

FORj = l, ...,n.

[P,Y];

(call

W-evaluation subroutine}

Set yjQ(z) <- Wjq(z);

FORt=l,....

p.

Set yj((z) <-

max

wjj(z)};

|yj ,_i(z),

IF Y(z) satisfies constraints (11)

THEN

set

LB

<- r(Y(z)) and p <- Y(z);

ELSE set UB <- z and Y <UNTIL (UB - LB) < e;

Y(z);

-

first

12-

(z

< z* and Y(z) < Y(z*))

(z

>

z* and Y(z*) < Y(z)}

W-

Step

e-optimal solution

2:

FORj=l

Set

n.

= yjo(LB);

qjo

FORt=

1,..., p,

Setqj, = yj,(LB)-yj,_,(LB);

Q

=

e-optimal.

(qj() is

W-evaluation subroutine To compute

:

FORj =

FOR =

0,

<

...,

X

Initialize

IF z

j

and

t.

n,

1

t

wjj(z) in [^^, y^] for all

p.

<r-

and

pj^

\) <r-

Yjp

<

{pj,

Wjj(z)

<

Yjt}

fj,(X)

THEN

setv<r-X;

ELSE

REPEAT

Set u <-

IF z

<

L(A.

+

a))/2j;

fjt(u)

THEN

set\><-u;

ELSE

set

A.

{Wj,(z)<u}

<— u+1;

(u

<

Wj,(z) implies

u+1 < Wjj(z)}

UNTIL X>\);

Set Wjj(z) <—

X);

Starting with

(LB+UB)/2,

constraints

LB =

for all

( 1 1 ),

j

we

r(0) and

and

t;

update

UB

Y(z) =

let

LB

<—

=

f'CU), the algorithm

(yj((z)).

r'( Y(z));

computes

yjjCz),

these values satisfy the resource capacity

If

otherwise,

we

set

UB

<—

z.

We also

and lower bounds on the optimal values of \^ (thus narrowing the search

We

for

(UB - LB) <

repeat this procedure until

We

problem [ARP'].

each period

release quantities (given by the solution

yj,(z),

quantity for product

j

we

at

first

time

equations (16a) and (16b).

t

t

interval for Wjj(z)).

At termination, the solution Y(LB)

Y(LB))

in

periods

t

and

determine the smallest value Wjj(z) of the cumulative release

to achieve the objective function value z,

and then apply

is

The parameters

not necessary

Pj^

and

y-^

if

we can

U:,.

If the

in the interval

directly evaluate the

respectively denote the current lower

and upper bounds on the optimal value of the cumulative release quantity

=

e-optimal

(t-1).

The W-evaluation subroutine employs binary search

inverse of the functions fJ).

Yj,

is

equal to the difference between the cumulative

[PjpYjJ to determine Wjj(z). This subroutine

and

update the upper

recover the e-optimal solution to the original problem [ARP] by

setting the release quantity in

To compute

e.

with z =

Xjj.

Initially, Pj,

=

solution Y(z) at a particular iteration satisfies the resource constraints (11),

13

then Y(z)

Therefore, z* >

a feasible solution to [ARP'j.

is

z,

and since the productivity

functions fjj() are nondecreasing, the problem must have an optimal solution

> Y(z). Hence, we

(1

X* <

D),

bound

increase the lower

we reduce

Y(z) and

the upper

(3

to Y(z).

bound y

Otherwise

to Y(z).

and updating scheme, the lower and upper bounds

(if

Notice

X*

satisfying

X*

Y(z) does not satisfy

with this initialization

that,

satisfy the following condition at every

iteration:

Pj,t-1

We

emphasize

-

^"'^

Pjt

Yj,

^

for all

Yj.,-1

that, since the release quantities

j

must be

=

1. ...., n,

and

integral, the

t

=

1, ...,

p.

W-evaluation subroutine

finds the exact value of Wjj(z).

The

validity of the bisection

Proposition

ARP

For the

method

rests

upon

the following result:

3:

problem with nondecreasing resource-usage functions, a

function value z

is

a lower bound on the optimal value z*

if

equations (16a) and (16b), satisfies the resource constraints,

trial

and only

i.e., iff

if

objective

Y(z), defined by

G"(Y(z)) <

S.

Proof:

Let

X*

is

be any optimal solution to [ARP'] with optimal value z* = f'(X*).

X*

nonnegative, integral, and satisfies the resource capacity constraints

coupling constraints (12) and upper bounds (13).

equal to z*.

By observation

2,

Y(z)

constraints (12), (13), and f'(X)

G"()

is

nondecreasing and

G"(Y(z)) < G"(X*) < S,

X*

i.e.,

suppose for a given value of

>

z;

is

[ARF], z* > f '(Y(z)) >

Computational

To

trial

value z

therefore, Y(z)

< X*. Since

difference of

more than 21

limited by

two

satisfies the resource constraints,

Y(z) <

X*

less than or

X

satisfying

implies that

the solution Y(z) satisfies the resource constraints.

z,

well as the

By

Y(z) satisfies the resource constraints (11).

Since z < r(Y(z)) and Y(z)

is

Conversely,

definition, Y(z)

a feasible solution

z.

effort:

(i.e.,

number of repeats

probabilities,

in

Step

I).

-2 < fXO) - r(U) <

iterations are required.

memory

is

solution

the resource-usage function

most log2((r(U)-F'(0))/e)

find an e-optimal solution, the bisection algorithm requires at

"major" iterations

(I I) as

the smallest nonnegative, integral vector

also satisfies constraints (12), (13), and (14).

to

Suppose the

The

As problem

2.

Since each service level difference

Therefore,

if

size increases, the

rather than speed.

14-

e

is

the

= 2"^^ = 1/1,048,576, no

method

will likely

be

At each

iteration, the

method

most

calls the

W-evaluation subroutine n(p+l) times. Each

We

evaluation requires

at

search effort

W-evaluation subroutine by modifying the overall algorithm as follows.

each

in the

iteration in

Step

we

first

yjj(z) values,

sequence,

max{yj

we

log2(Yjt~Pit) iterations within the subroutine.

instead of

1,

Observe

bound of

(15)).

t

=

p in

1

the search interval for the W-evaluation subroutine as

that the values returned

directly correspond to the yj((z) values

At

evaluating aU the w-j(z) values before computing the

evaluate Wjq(z), and set yjo(z) = Wjq(z). Subsequently, for

specify the lower

t_i(z). Pjt)-

first

can reduce the

by the W-evaluation subroutine

they are not the Wjj(z) values

(i.e.,

defmed

in

now

equation

Since the search intervals are shorter, this modified method has lower computational

effort.

Notice

that, unlike

some

linear

programming-based methods, the bisection method does

not introduce cumulative floating point errors.

value of z* but only want to

know

if

z* >

levels for all products in all periods), then

Finally,

(i.e.,

we can

if

we

whether we

are not interested in the exact

Ccin

achieve the target service

terminate the procedure as soon as

LB

becomes nonnegative.

The next two

sections consider

two types of generalizations of

the

ARP

model, namely,

precedence constraints and part substitutability, that the bisection method can solve.

4.

Model Extensions

ARP

The

problem

is

I:

Precedence-constrained resource allocation

a constrained version of the basic resource-allocation model [P],

containing the additional coupling constraints (12) to ensure that the cumulative release in a

period equals or exceeds the cumulative release in the previous period.

Let us

now

broader class of "precedence" constraints that generalize the coupling constraints.

development leads

to

our next generalization, (20) below, which

is

consider a

Our

initial

applicable to multistage

production settings.

Suppose the production context requires

at time

t

that the

cumulative release quantity of a product

must equal or exceed the cumulative release quantity of product

must add constraints of the following type

ordered product-time index pairs

xjj

>

to formulation

j'

at

time

t',

i.e.,

j

we

[ARP'] for a prespecified subset IP of

<(j',t'),(j,t)>:

Xj-f

for all <a',t'). (j.t)>

15

e

IP.

(17)

6

If <(j',t'), (j,t)>

IP,

we

say that

(j'.t) 's

a predecessor of

We

(j,t).

will refer to discrete resource-

allocation problems with precedence constraints (17) instead of the coupling constraints (12) as

precedence-constrained resource-allocation problems.

PG

Let us define a precedence graph

to

encode the required relationships specified

This graph has one node for each product-time index

set IP.

from node

(j',t')

DC. To

circuit

necessarily set

N(DC)

to

node

(j,t)

for every pair

(j,t)

= min

DC, we can reduce

in the circuit

{fjt(X[)c): all

we

eliminate

(j,t)

fjt(Xjj)

for

e N(DC)}. Note

all (j,t)

substitution corresponds to contracting

all

the nodes

in the

transformed graph.

By

Since

(j.t) all its

PG

We

predecessors occur before

it

analogous to the node indexing scheme for

computations, where

lEl is

the

in

for all

and

j

=

1,

n,

and

t

=

p,

we

N(DC)

node DC;

are incident to node

manner, we obtain

graph to be connected.

nodes such that for each node

its

networks, requires O(IEr)

We

will refer to

can easily modify the bisection method

these precedence constraints as follows:

...,

in

PG; see Lawler [1976].)

We

problem by

(This node sequencing operation,

PERT/CPM

such a sequence S as a y-evaluation sequence.

accommodate

this

sequence.

number of edges

if

resource constraints

all circuits in this

we can sequence

in the

Thus,

In the precedence graph, the

any node

to

do not require

contains no directed circuits,

in the

value.

in the circuit into a single

successively eliminating

a circuit-free precedence graph PG.

same

we must

that this substitution preserves the

(j,t)

N(DC)

arcs originally incident from nodes not in

DC

contains a directed

e N(DC) and instead introduce

monotonicity of the resource-usage and productivity functions.

all

PG

the size of the

e N(DC) by a single variable, say, \^q

(11); in the objective function,

^DC^'^DC^

Suppose

IP.

the variables corresponding to the circuit's nodes to the

all

for every

X:j

and contains a directed edge

(j,t),

precedence constraints (17) implied by the circuit

satisfy all the

denotes the set of nodes

replacing

g

<(j'.t'). (j,t)>

in the

in

consider the indices

Step

after

1,

(j,t) in

computing W(z)

to

in [p.y]

the y-evaluation sequence S,

set:

= max

yj((z)

The remaining

[wjj(z),

max

{yj.t.(z): all (j'.f)

steps of the algorithm are unaltered.

from the nondecreasing property of

For our

ori ginal

<(j,t-l), (j,t)> for all

ARP

j

=

and

t

=

in

1, ...,

p.

<(j',t'),0,t)>

e IP)].

Again, the validity of

the resource-usage

problem (described

1, .... n,

such that

this

(18)

method stems

and productivity functions.

Section 3), the set IP consists of index pairs

Observe

that the

precedence graph

PG

for this

special case of precedence-constrained resource allocation consists of n "line" subgraphs, one

corresponding to each product; the adjacent nodes on each line

-

16-

j

correspond to release

quantities for product

j

consecutive time periods.

in

The

does not require any further reduction.

satisfies the required

we use

identical if

Let us

now

is

j

natural sequence

this

how

consider

time

t'

parameter

h-^

and

t'

1, ...,n,

=

t

0,

p)

...,

j'

that the

might differ

if

the

for discrete resource-allocation

more general than

that are

an accessory board and product

(t

method

to adapt the bisection

is

the

mother board

bjj

:.j.

Suppose

constraints (17).

for a personal computer.

cumulative release of product

equal or exceed a certain (nonnegative) proportion

at

=

j

sequence as the y-evaluation sequence S.

The production policy might specify

j'

for

((j,t)

and

circuit-free,

is

precedence property; the original and enhanced bisection methods are

problems with precedence constraints

product

This precedence graph

j at

time

t

must

of the cumulative release of product

two board types have

assembly lead times). The

different

might be based upon the relative yields of the two board types, spare parts

•^>

Modeling

requirements, and so on.

adding precedence constraints of the

this policy requires

form:

Xjj

A

>

for all <(j,t),

bjt j.f Xj.j.

more general version of these forcing constraints

where product j

is

a subassembly that

lead time for subassembly

per unit of final assembly

is

j

is

used

k time units,

in final

b::.

(19)

IP.

arises in multi-stage

assemblies

jj, J2,

assembly settings

If the

...., j^-

assembly

denotes the number of units of product

and Lq represents the

j',

6

(j'.t')>

inventory of product

initial

j,

then

needed

j

we

require:

"jt

"^

^jO

-

''jji

''ji.t+k

+

+

''jjr '^jr.t+k-

This constraint specifies that the cumulative release of subassembly

j

at

time

t

plus the opening

inventory must equal or exceed the cumulative requirements of this subassembly to meet the

final

assembly release quantities. In general, the precedence constraints might contain a

(nonnegative) weighted combination of several variables of the form:

where the parameter

The

variable

x-^

right-hand sides.

e-^ is

unrestricted in sign, but the coefficients

b-^

•^•

in the

as a predecessor of

let P:,

be the set of

every

(j',t')

e

all

indices

such that

(j'.f)

Xj.^.

right-hand side of at least one constraint of n(j,t).

(j,t).

The precedence graph PG

one node corresponding to each product-time index

<(j'.t'),0.t)> for

are all nonnegative.

Let n(j,t) denote the subset of precedence constraints (20) that contain the

with positive coefficient

(j',t')

:.j.

might be governed by several such precedence constraints, each with different

variable Xj^ in the left-hand side, and

refer to

b^

P^^.

17

(j,t);

node

for this

(j,t)

occurs

We

enhanced problem has

has incident arcs

To

apply the bisection method for resource-allocation problems with the general

precedence constraints (19) or (20), we will assume

PG

that the

corresponding precedence graph

(With constraints (19) or (20), we cannot always make the

contains no directed cycles.

precedence graph acyclic using the successive substitution procedure we described for

The

constraints (17).)

assumption. Since

that the index

y:j(z) in this

y:,(z) as the

(j,t)

PG

is

assumed

we

described earlier satisfies this

we can sequence

to be acyclic,

occurs after the indices of

We

predecessors.

all its

the product-time indices such

then determine the values

This version computes

sequence S using a generalized version of equation (18).

maximum

constraints in n(j,t).

values of

multi-stage assembly example that

By

for all

y:','(z)

of w-j(z) and the highest right-hand side value over

considering the variables

in the correct

the precedence

all

we

sequence,

ensure that the

e P^ are available before we compute the value of

(j',t')

We

yjt(z).

can

extend the same argument to handle even non-linear precedence constraints x^ > hjj(Yjj),

where Y:j =

{y:Y(z): all

(j',t')

e

Pj^} as

corresponding precedence graph

5.

Model Extensions

In Section 4,

some

substitutability

product

is

acyclic.

is

Part substltutablllty

we showed how

to

problems with general

discuss modifications to incorporate another complicating

electronics assembly environments, namely, part substitutability.

we mean

not available.

using a designated alternative part (or parts)

Allowing substitution yields risk-pooling

achieving desired service levels; however,

quality and reliability.

it

may

if

it

is

benefits,

Our approach

to achieve service levels.

parts

and contributes to

also increase product costs

more

desirable to allow no

By

the preferred part for a

Products with substitute parts, although functional,

thoroughly as the nominal design. Thus,

needed

method extends

the bisection

We now

precedence constraints.

feature of

II:

long as the functions h U) are non-decreasing and the

and reduce product

may

not be tested as

substitution than

incorporates this preference,

i.e., it

is

exploits the

risk-pooling benefit of substitutability while maintaining cost, quality and reliability objectives.

For any desired (and achievable) service

minimum

substitution necessary by solving a

Suppose we can replace

the products.

part

i

with

we minimize

the total

i.e.,

one

unit of a part

commonality, provides

risk

i'

i,

some other

e

i.e.,

RB(i)

(or cost) of

part without affecting the functionality of

=

(i":

R(i) replaces

pooling benefits.

amount

cost network flow problem.

Let R(i) be the index set of parts that can replace part

of parts that can be replaced by part

substitution,

level,

If part

18

i

€ R(i")}.

one unit of

i

is

i,

and

We

part

i.

let

RB(i) be the

set

assume one-for-one

Part substitutability, like

not available in stock,

we can

still

assemble products

by using an alternate part from

that require this part

Rothblum [1993] developed an

aigonthm

efficient specialized

Klein, Luss, and

R(i).

to solve linear,

continuous

resource-allocation problems with substitutions.

Let us

formulate the assembly-release planning problem with part substitutability,

first

APS

which we abbreviate as the

quantity of product

bjQ be the

periods

j in

initial availability

through

of part

i

in

period

t

before,

for

t,

=

j

1

denote the cumulative release

let x-^

and

n,

...,

,

=

1, ...,

p, let bjj

0,

...,

in

i

For every

p.

period

part

=

and

Sjq,

=

h^^

Sjj

let

i,

plus the

be the number of units of part

In terms of our previous notation, bjQ

t.

=

t

opening inventory of part

(i.e.,

quantity received in period 0), and for

received

As

problem.

-

i

Sj j_[ for

=

t

t

1,

...,

where

p,

cumulative availability of part

Sj^ is the

i

period

in

Note

t.

that Sjj

=

Z

bjj.

for

t'=0

all

i

and

t.

As

=

before, \x^

For simplicity, we

equal or exceed

min{LSjj/ajjJ:

i

will consider the simple

for every product

x- j_|

we

version of the bisection method that

j

such that

aj:

>

0}

a valid upper bound on

is

precedence constraints (12) specifying that

and periods

t

=

The model and

p.

1

x-^.

x-j

must

the modified

describe later can also incorporate the more general

precedence constraints (19) or (20).

To model

...,

m,

i'

part substitutability,

e RB(i), and

during period

t.

t

=

0,

...,

p,

we

new

introduce

denoting the

"substitution" variables

number

The APS problem then has

of units of part

i

Vjji|,

for all

=

i

used to replace part

the following nonlinear, integer

1,

i'

programming

formulation.

[APS]

maximize

r(X) =

j

=

bj,,

+

min{fjf(Xjf):

and

n,

1

t

=

0,

(21)

p}

...,

subject to:

n

I

j=l

t

t

a'J

X-j

J'

+

I

I

Vij.

,

<

t=Oi'eRB(i)

Xjj

>

Xj

Xjj

<

Ujj

Xjj

>

Vjj.j

>

j_j

and integer

and integer

I

t

1

I

Vj,.;

,

f=Oi"€R(i)

t'=0

for all

i

=

I,

for all

j

=

1, ...,n,

and

t

=

forall

j

=

1, ...,n,

and

t

=

for all

j

=

1

foraU

i

=

1,

19-

...,

m, and

n,

....

m,

and

i'

=

t

t

0,1,

1

(24)

p,

0,1,

g RB(i).

(23)

p,

0,1

=

(22)

...,p.

...,p,

t

=

and

0,1,

...,p.

(25)

(26)

Formulation [APS]

now

similar to our previous formulation [ARP'I except that constraints (22)

is

incorporate parts substitutability. and constraints (26) impose nonnegativity and integrality

on the new substitution variables \-^. Constraints (22) have

particular part

i

and period

"outflow" of part

and the

part

i

t,

period

in

total quantity

the following interpretation.

For a

the left-hand side of this constraint represents the cumulative

t

demand of products

both to satisfy the cumulative

of part

i

used to replace other parts

i'

e RB(i)

j

that use this

periods 0,

in

The

..., t.

right-hand side of the constraint represents the cumulative "inflow," consisting of the opening

inventory and cumulative receipts of part

i"

e R(i)

periods 0,

in

....

plus the

i

number of

units of part

replaced by parts

i

Constraints (22) specify that the cumulative outflow must not

t.

exceed the cumulative inflow for each part and every period. Formulation [APS]

is

clearly

feasible (set all variables to zero).

To

we

solve problem [APS]

search, a

trial

and (25) such

r(X) with

that

products

yjt(z) for all

X

= Y(z) =

quantities with substitutions permitted.

Y(z).

we

This step

we must

explain next,

APS

for the

more complicated

is

We

for

j

and periods

z,

and

the available parts can

i.e., if

required

satisfying constraints (23),

t

equals or exceeds

(yjt(z))

the desired release quantities yjt(z) are feasible,

of

minimum

value z of the objective function, (b) determining the

cumulative release quantities

(24),

will follow the previous strategy of: (a) selecting, via bisection

(c) verifying if

meet these release

refer to Step (c) as verifying the resource-feasibility

model [APS] than

for the basic

model [ARF]. As

solve a network flow subproblem to verify resource-feasibility of Y(z)

problem.

Given a vector

X

=

(x-^)

(= (yjj(z)) in our bisection method). Step (c) requires verifying

if

A

the partial solution

X

has a "feasible completion" in [APS],

nonnegative integer values for the variables

Xj,

and

=

we must determine

that satisfy constraints (22) after

we

if

there are

substitute

'^

A

Xjj in

if

Vjj.j

i.e.,

these constraints.

To

motivate the procedure for checking resource-feasibility of

so determining feasible v-values,

additional set of variables kj| for

all

i

=

let

X

us reformulate constraints (22) by introducing an

m, and

1

t

=

We

p-1.

will define these

variables via the following equations:

•^iO

=

bjo

+

.„

1

kit

=

2

Vi,.io

-

I

for all

Vij-o

i

=

1

m, and

(27)

m,t=l,...,H-

(28)

igRB(i)

gR(i)

^ + ^,t-l + .„^„,/i"it-.,

eR(i)

foralli=l

£,/ii't

lERfi(i)

1

Notice that using these k-variables,

we can

simplify constraints (22)

to:

n

Z

j=l

a:: Xj,

'J

J'

<

for all

k:,

-

20-

i

=

1

.

...,

m,

t

=

p-1.

(29a)

n

^

^p-^'^i,p-l+.„^,./np

I

.^,

eR(i)

foralli=l,...,m.

^ij^jp

^^

j=l

(29b)

"

A

X entails

Therefore, verifying the resource-feasibility of a given cumulative release vector

A

/\

determining a solution (V(X),K(X)) satisfying constraints (26) through (29) or proving

that no such solution exists.

We now

explain

how we can

and (28) as the familiar flow

interpret constraints (27)

conservation equations of a network flow problem, £ind constraints (29) as lower limits on the

A

A

flows on certain arcs. For a given vector X, consider a directed network G'(X) containing

nodes

corresponding to each product

(i,t)

network contains two types of

=

1

=

1,

m,

i'

G RB(i), and

m, and

....

=

t

can replace part

i,

.....

=

i

1,

m, and every period

...,

from node

arcs: (i) "substitution" arcs

0,

from node

p; and, (ii) "k-arcs"

...,

=

t

can replace part

i".

Each k-arc from

node

node

to

(i,t)

The

p.

,

to

(i,t)

Figure 2 shows a portion of this network.

p-1.

while part

=

(i',t)

t+1) for

(i,

limit LLjj(X)

=

p) has a

for

i

=

1,

on

its

....

m

demand (minimum

lower

flow,

and

t

i.e.,

=

0,

minimum

the

p,

....

required flow on this arc

has a supply of

For

bjj units.

i

=

LLjj(X).

is

m, node

1

required extemal outflow) of

Z

a^jX:

(Since this node also

.

j=I

n

has a supply of

units, its net

bj

demand

Z

is

ajjX:

-

b-

.)

j=l

A

Consider the following y7ow/(?a.s/Z?j7/ry problem defined over the network G'(X).

A

Find a feasible flow on G'(X) satisfying the demand, supply, and

minimum

arc flow

constraints, or prove that no feasible flow exists.

The mathematical formulation of

this

flow feasibility problem contains flow conservation

A

equations

k-arcs,

at

each node, constraints imposing the

minimum flow

and nonnegativity constraints on the flow variables.

substitution arcs as the v-variables,

If

requirements LLjj(X) on the

we

interpret the flows

on the

and the flows on the k-arcs as the k-variables, then we see

that:

(i)

all

i

=

1

m are

for all

i

=

I, ...,

m, and

the flow conservation equations at nodes (i,0) for

the

same

as constraints

(27);

(ii)

the flow conservation equations at nodes

same

(iii)

(iv) for

i

(i,t)

t

=

1

p-1, are the

as constraints (28);

minimum

the

=

I, ...,

i

i'

n

(i,

i

A

2- a^: Xj^

(i,t),

all

In this figure, part

to (i,t+l) has a

(i,t)

for all

"

A

Every node

0,

t

i

flow requirements on the k-arcs correspond to constraints (29a); and,

m, the demand constraints

at

-

nodes

21

(i,p) are the

same

as constraints (29b).

Notice

that, if the

(assuming

network G'(X) has a feasible flow, then

the parameters a-

all

easily incorporate upper

and

are integral),

b|j

i.e.,

it

must have an

integral flow

constraints (26) are satisfied.

We

can

bounds on the substitution variables and k-variables; these upper

A

bounds become arc capacities for the substitution arcs and

k-arcs, respectively, in G'(X).

These observations establish the following lemma.

Lemma

4:

A

A

given cumulative release vector

X

has a feasible completion

if

and only

the

if

A

corresponding network flow problem defined over G'(X) has a feasible solution.

A

Note

that as

A

X

changes, only the

minimum

flow requirements LLjj(X) change; the node

A

supplies and

demands do not change, and

neither does the topology of network G'(X).

Any

algorithm used for checking feasibility of a transshipment problem can be used to determine

if

A

G'(X) has a feasible solution. Max-flow algorithms are commonly used for

max-flow problem can be solved very

the

number of nodes and edges

At each

in the

iteration, the bisection

efficiently in 0(INI ViEl) time,

where

this purpose.

INI

and

IE!

The

denote

network (Ahuja, Magnanti, and Orlin [1993]).

method applies

the

max-flow algorithm

to verify the

resource-feasibility of the cumulative release vector Y(z) corresponding to the current target

value

the

We

z.

restate this iterative step (Step 1) of the

APS problem

with general precedence constraints (20) (assuming these constraints satisfy

the acyclic precedence graph property).

are the

same as

modified bisection algorithm for solving

The remaining

steps and the W-evaluation subroutine

before.

Modified bisection algorithm for the

APS problem

with general

precedence constraints:

Step

1:

Search process

Construct a y-e valuation sequence S.

REPEAT

z f-

(LB + UB)/2;

Compute W(z)

FOR

successive

y:j(z)

= max

in [p,Y];

(j,t) in

[wjj(z),

{call

W-evaluation subroutine)

the sequence S, set

{max RHS value over

all