\">Hv)

advertisement

\">Hv)

0^CMtr*^,

4>

^ (librariesI ^

L1.I.T.

LIBRARIES

-

DEWEY

/

Ii4>

Dewey

Massachusetts

Institute of

Technology

Sloan School of Management

Working Paper

Deciding between Sequential and Parallel

Tasks in Engineering Design

Robert P. Smith

Steven D. Eppinger

October 1995

Working Paper Number 3858

Contact Addresses:

Prof. Robert P.

Smith

Department of Industrial Engineering

University of Washington

Seattle,

A 98195

Prof. Steven D.

W

smith

Eppinger

Sloan School of Management

Massachusetts Institute of Technology

Cambridge,

@ ieng.washington.edu

MA 02142-1347

eppinger@mit.edu

MASSACHUSETTS INSTITUTE

OCT

2 4 1995

LlSnAR.'ES

Abstract

It is

generally desirable to complete design tasks in parallel in order to reduce

However, completing tasks in parallel may

sometimes increase the total amount of rework that must be done, thereby

increasing the total engineering effort, the development cost and the lead time. The

technique described in this paper helps to decide between serial and parallel

the overall development time.

scheduling of multiple tasks in a two-stage design process. Using information about

task interdependencies, this method calculates the amount of time and the amount

of effort (in engineer-weeks) required for any suggested assignment of tasks to the

two stages. The paper suggests an approach for minimizing time, or effort, or both

by adjusting the schedule of which tasks should be completed at which time. The

method is applied to data from a computer workstation design problem.

1.

Introduction

Concurrent engineering has become increasingly important in recent years.

Concurrent engineering

issues simultaneously

is

a philosophy that suggests the

need

to consider

where they may have been considered sequentially

past [Nevins and Whitney 1989,

Susman

1992].

design

in the

The division between sequential

design phases arose historically because one set of design issues (typically product

performance

issues)

were considered

design space was considered

first.

of greater importance,

The secondary

set of

manufacturing process design) were considered only

issues

had been decided ('throw

it

over the

design process has been considered

typically leads to a greater

its

after the initial set of

design

In recent years the sequential

wall'.)

type of design process

cost,

the overall profit generated

and lower

by the design.

broadest definition does not only consider

issues, but

environmental impact, service,

historically neglected in the

portion of the

design issues (typically

inefficient, since this

which lower

performance and process design

reliability,

this

development time, greater development

overall design quality, all of

Concurrent engineering in

and

many

other

testing,

product design phase.

2

life

and so

cycle issues (such as

forth)

which have been

Yet the division between design phases arose for valid reasons.

industries at

some times

there

was

The inclusion

the value be responsible for creating the design.

issues

would

in the

design process.

many people and

lead to too

It

is

difficult to

among

achieve complete consensus

who

have only those

a benefit to

many

too

of

In

some

created most of

any other design

concerns being involved early

organize complex design processes, and to

all

of the players

may

be inefficient and

expensive.

Development time

is

an important determinant of eventual success

in the

market [Blackburn 1991, Smith and Reinertsen 1991]. One of the primary reasons

that concurrent engineering has

concurrent engineering

product and bring

We believe

environment.

able to lessen the

is

that in

to

most cases

In this

method

The model

is

a

amount

paper

it is

movement

of time

it

is

we

is

takes to develop a

offer a

model which can help engineers and

way

is

appropriate in their design

based on the work transformation matrix

in a

to calculate the

amount

Our

analyze the eigenstructure of the matrix

of

earlier

in

work completed during an

paper describes

how

on the idea of the design structure matrix (DSM) which

are

is

a tool

done during every

effects of not

is

used

and coupled design tasks [Steward 1981, Eppinger and others

earlier

it is

in turn

iteration, the intent of the current

in

every

iteration.

paper

We

is

based

to identify

1994].

paper [Smith and Eppinger 1995b] assumes that

completing every task

possible to

order to determine important properties

about the design process. The work transformation matrix concept

Whereas the

(WTM)

previous paper [Smith and Eppinger 1995bl. The

engineering design iteration process.

serial

because

beneficial to separate the design process

what extent concurrent design

model, which was developed

WTM

a significant

to market.

it

into multiple phases.

managers decide

become

all

tasks

to look at the

demonstrate here

that

the

WTM can also be used

to

examine the

sequentially during a design process,

scheduling of tasks

Design

is

is

which can

assist in

deciding

when

concurrent

appropriate.

complex process of many

a

doing tasks concurrently or

effect of

interrelated tasks.

How

these tasks are

divided and organized has a significant effect on the eventual outcome and success

of the process [Alexander 1964,

effectively

is

not easy, but

its

von Hippel

success

is

Managing the design process

1990].

important to the long-term health of

technology companies [Whitney 1990, Clark and Fujimoto 1991].

The model

tasks

to

in this

paper addresses the issue of scheduling coupled design

by decomposition. This problem

complex design

several methods.

removed which

projects,

acknowledged

is

and has been addressed

These methods include

result in

'tearing',

to

be of practical importance

in the research literature

where

a set of feedback tasks are

an uncoupled ordering [Steward 1981, Kusiak and

1993]; the sequential iteration

by

Wang

model, where coupled tasks are placed in a sequential

ordering in order to minimize the expected amount of time taken to complete the

entire process [Smith

total length of

and Eppinger

1994a];

and

a

model intended

to

minimize the

feedback chains in coupled multi-disciplinary optimization design

problems [Altus and others

1995].

There are other recent models which address the problem of determining the

appropriate amount of parallelism in the product development process.

model explore the case where

[Hoedemaker and others

level the time taken for

a project

1994].

As

the

is

where

divided into a number of identical tasks

number

of tasks increases

communication between tasks

time for completing the project increases.

One such

An

increases,

alternative

beyond a

and the overall

model presents

tasks have a probabilistic need for repetition [AitSahlia

critical

and others

a case

1995].

Under these conditions

scheduled

in parallel in

it

is

desirable to limit the

order

to

number

of tasks

which are

minimize the cost of completing the design

project.

Both of those papers on the sequential/parallel task scheduling decision rely

on simpler mcxiels of the structure

how

asymmetrical interconnectedness between tasks, and

affects the

that interconnectedness

scheduling of tasks. Another recent paper (Krishnan and others 1995]

models the overlapping (parallelism) of two

development process

to

activities

of the

asymmetry

within a product

determine the optimal overlapping conditions based on the

nature of the information coupling the pair of tasks.

some

They do not explore the

of the design process.

of the Krishnan

Our

current paper retains

model while extending

to the multi-task

two-stage case.

The remainder

Work Transformation

of the paper

is

laid out as follows: Section 2 describes the

Matrix as given in the earlier paper [Smith and Eppinger

1994bJ. Section 3 describes

how

the

WTM can be used to describe a

two-phase design

process. Section 4 looks at the two-phase process as an optimization

suggests

some

heuristic algorithms.

Section 5 applies the

problem and

model and optimization

algorithms from sections 3 and 4 to a computer workstation design problem.

Section 6 describes

how

this

model can be extended

to

more than two-stage

design.

Section 7 contains the discussion and conclusions.

2.

Review and Extension

of the

Work Transformation Matrix Method

The design structure matrix, the precursor of the

WTM,

identifies the tasks

involved in the design process, and shows the ways that information

between tasks [Steward 1981, Eppinger and others

corresponding column

in

1994].

is

transferred

Each row and

the matrix concerns the information flows (inputs

outputs) of a design task. Each off-diagonal entry on the

row

of a given task

and

indicates the other tasks

the

column

of a given task indicates the other tasks to

information.

parallel,

from which that task needs information, and each entry on

The

DSM

method

is

used

which

that task gives

which tasks can be done

to identify

which tasks can be done purely sequentially, and which tasks have

in

cyclic

information flows and therefore require iteration to be completed.

The

WTM

information.

is

The

an extension

to the

DSM

which contains additional numeric

WTM contains two separate sets of matrix data.

There

is

a off-

diagonal matrix which contains the numbers which indicate the amount of rework

done during the

iteration process.

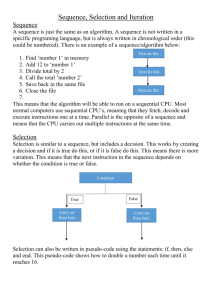

the times for each task. Figure

1

There

is

also a diagonal matrix

shows an example two-task

which contains

WTM containing both

rework and time data. (Because of the complementary structure of the two types of

data

it is

also possible to write both types of data in

A

(a)

Rework matrix

done completely 20% of task

Example

1.

40%

of

A

needs

to

takes 4 units of time to complete,

are linear factors, so doing

40%

doing 20% of rework on task

A

The assumptions made

All tasks are

(b)

done

its

WTM

Every time task

be redone. From Figure

A

generates

A

work redone. Likewise, when

and task B takes 7

of task

B

Time matrix

in Figure 1(a) are interpreted as follows:

completely, task B needs to have

•

A

B

Figure

The data

one matrix.)

1(b)

we

is

task B

is

see task

A

units of time to complete. These

requires 1.6 units of time (=0.4x4),

8%

(=0.4x0.2) of

in constructing the

in every stage.

6

done

rework

and

for task B.

WTM model are as

follows:

Rework performed

•

is

a linear function of the

work done

in the

previous iteration

stage.

The work transformation parameters do not vary with

•

time.

Discussion of the vahdity of these assumptions can be found

in the earlier

paper

[Smith and Eppinger 1995b]. The model described in Section 3 below explicitly

relaxes the

first

assumption above.

Each iteration

much

of each task

vector of

Is,

is

is

characterized by a

worked on

which indicates

first iteration.

that

work

vector

in the t-th iteration.

all

work needs

During each iteration work

to

u,

.

The

how

This vector indicates

work

initial

be done on

all

vector u^

is

a

tasks during the

created for the next iteration according

is

to the linear rule

m,„=Am,

where the matrix

The

the

all

total

work

A

is

the rework matrix from Figure 1(a) above.

amount

of

work done during

total

work

vector

U

is

is

is

U, the

sum

the vector of

amount

= t^i.

of

W

is

(2)

W in order to get the total amount of time

multiplied by

spent on each design task, where

R

the iteration process

vectors.

U

The

(1)

a diagonal matrix of task times (Figure 1(b)).

of time spent

on each task during the

iteration process.

R = WU = WY,u,

(3)

(=0

which can also be written as

R = wf^A'u„

(4)

(=0

or,

if

the

maximum

matrices, see Smith

can be simplified to

eigenvalue of

A

is

less

and Eppinger [1995b]

than

1

(these are

known

as stable

for a discussion of this issue), equation (4)

R = W{I-A)-'u,

The

total

(5)

time spent to complete the design process

The time spent on each

for each iteration stage.

T

is

the

sum

of the times

iteration stage is the longest time

taken for any task in that stage.

T = £max[WM,f

where

[]*'

the f-th element of the vector within the brackets.

is

Under worst-case conditions T may be

is

(6)

no closed-form expression equivalent

The convergence

calculated explicitly.

magnitude of the

eigenvalue of

A

maximum

is

a difficult quantity to calculate. There

summation must be

to (5) for T; the

rate of the infinite series

(positive) eigenvalue of A.

sufficiently less than unity

it is

If

the

is

controlled

by the

maximum

possible to approximate

T

to

reasonable accuracy using only a few terms of the infinite series.

Effort

amount

the total

is

the design process.

It is

the

sum

of engineering time (in engineer-weeks) spent

of

all

the time spent

on the individual design

£ = IR'"

on

tasks.

(7)

1=1

The quantities time

the design process.

while effort

is

Time

(T)

is

and

effort (£) are

important quantities in managing

an important determining

an indicator of the development

cost.

factor of time-to-market,

Formulas

in calculating these quantities for the fully parallel case.

the concept of a serial structure of the process

to calculate time

3.

Using the

and

effort

(6)

and

(7)

are useful

The next section introduces

and develops the formulas necessary

under those circumstances.

WTM to Describe Two-Phase Design Processes

We now

work on some

assume

that the coupled design process

is

to

be structured such that

of the coupled tasks can be delayed until later in the process.

WTM can be extended to consider multiple-phase design processes.

8

The

The simplest

version (and the one which

the design process,

and

more than two design

on

It is

two

that there are

(See Section 6 for including

sets of tasks.

During the

phases.)

a limited set of tasks.

tasks, including

explored here) assumes that there are two phases to

is

first

phase,

all

During the second phase, work

rework of the

and

first set

all

of the

of the

is

work

is

completed

completed on both sets of

work on

the remaining tasks.

possible to interpret a two-phase design process as corresponding to a

product design phase and a process design phase, but the model need not be limited

to that case.

where

The example given

the phases are product

Using the

WTM

in Section 5 discusses a

two-phase design process

and process design.

method,

it

is

possible to calculate the design time and the

design effort for a two-phase design process. The calculations are similar in

the calculation of time

Section

effort required

•

compare

The

on the

in the

design process described in

WTM do

amount

of time

and

assumptions:

not change as tasks switch from

first-

to second-

(or vice versa).

quality of final product

assignment of tasks

produced by the design process

assumption

constraints

is

reasonable

if

may

independent of

will not

not always represent design practice. The

the data are indicative of fundamental technical

and relationships between

dependency

is

to phases.

These assumptions are strong and

first

fully parallel

different serial divisions for the

we must make some

The parameters

phase

effort

2.

In order to

•

and

spirit to

tasks, in

which case the strength

of

change a great deal whether or not the sequence changes.

nature of the tasks changes

parameters remain constant

when an

is

ordering changes, then assuming that the

not realistic.

If

the

Both assumptions require that the information needs between the tasks be

order-independent, in the sense that the types of inputs

The work required

by a

to

task should not

and outputs are comparable.

complete a task and the type of output information produced

change depending on the order of the

For example, suppose that an engineer

a fan necessary to cool electronic

is

components

tasks.

attempting to determine the size of

in a

A

computer.

separate engineer

is

determining the size of the power supply. Both of these are routine design choices,

however these

tasks are coupled.

will be chosen after,

process used to

If

the

power supply

make

Whether

a selection of size of either

a parallel

either design task

specified

and then the power supply may have

coming

design structure

the

first,

work

is

that

to

then the fan

first,

be changed. The

component involves

the total load (thermal or power) of other elements

device.

is

calculating

and choosing an appropriate

chosen, or a sequential structure with

must be completed during any one

undertaking of a task would not change, the amount of rework created for the other

task

would not change, and the

independent

would not change. These

is

exemplified by two tasks such as choosing a material for

computer case and choosing the manufacturing process used

These are coupled

first.

are order-

tasks.

The converse case

a

final result

tasks, yet

we have

the opportunity to

make

to

make

the case.

either design choice

This choice will strongly constrain the range of options available to the other

design task, and therefore affects the amount of time taken and the amount of

rework created on subsequent

iterations.

Given these assumptions,

process.

During the

first

we

These are order-dependent

can build a model of the two-phase design

phase, only the indicated subset of tasks

These tasks create work for each other as described

need

to find a

companion equation

tasks.

to (5)

above

10

is

worked

in Section 2 above.

We

on.

therefore

for the total time vector of the first

We

phase.

need

to consider only a restricted portion of the matrix A.

we mtroduce

calculate the total time vector

specify the portion of

vector of the

first

A which

phase

is

K. is

''

1 if

K

/

=

/

known

is

which were not done

on any

task,

whether

k^^

and the

total

(8)

such that

Jth task is in the first

phase

a

it is

work

is initial

in the first phase.

first

to

Iterative

be completed only on the

rework may need

to

be done

or a second phase task.

R„=W{I-Ar\l-K)u,

The time

each of which

is

for the

two-phase process T

calculated as

shown

is

a

sum

(10)

of the times for the

for the fully parallel

WTM

two phases,

(see section

2).

T = J^max[WKA'Ku,,f^ + J^max[WA' {I - K)u^f

(=0

The

total effort

time

as a division or state of the system.

During the second phase there

tasks

The

phase.

to

otherwise

[0

of matrix

first

used

is

=W(/-K^K)"'Kmo

defined with elements

f

The value

considered during the

which

is:

R,

the matrix

the division matrix K,

order to

In

(=0

'

(U)

'

E of the two-phase process

is

a

sum

of the efforts in each of the

separate phases.

E=

'^(R]-^ + R<;')

r

Using equations

split

between

(11)

and

(12)

we

and second-phase

first-

can find the time and effort for any suggested

tasks.

For any set of coupled tasks, any subset of them

constitute the

first

calculate the time

(12)

=l

may be

considered to

phase of the design process. Given that choice,

and

effort for that division

it is

using equations (11) and

possible to

(12).

It is

desirable to simultaneously minimize both the time and effort for any given

process.

However,

it

is

not necessarily possible to lower both for

11

all

design projects.

Therefore,

we must sometimes

We

the effort, or vice versa.

divisions for

must therefore attempt

to identify a set of

good

any one design matrix, where goodness indicates superior performance

on one or both

4,

attempt to lower the time at the expense of raising

Finding these good divisions

criteria.

the focus of Section

is

4.

Considering the Two-Phase Division as an Optimization Problem

It is

desirable to lower both the effort

described in Section

we have

3,

the tasks to complete in the

As

phase.

As

such, this

is

and the development

control over these quantities

first

time.

As

by choosing which

of

phase, and which of them to delay until the second

a two-criteria combinatorial optimization problem.

a first attempt at looking for optimal points,

minimum-time and minimum-effort

solutions.

we have examined

The remainder

of this sections

discusses finding solutions which are locally or globally optimal on one of the

criteria.

4.1.

Minimizing Time and

Finding

minimum

known

Effort

optimal solutions

effort) is difficult.

We

which finds such solutions short

discuss

some

(in

the sense of

have not been able

to

of exhaustive search.

heuristic algorithms

which

minimum

time or

determine an algorithm

In the next subsection

we

find locally optimal solutions, although

they are not guaranteed to be globally optimal.

4.2.

Heuristic for Finding Locally Optimal

One simple

Time and

(but effective) heuristic solution

current best

known

phase. This

is

solution

does quite well

when

far

attempt to improve the

to

by switching one task of the division

not a sophisticated algorithm, and

optima which are quite

is

Effort Solutions

may be

from the global optimum. In

the optimization criterion

12

is effort,

to the other

trapped finding local

practice, this algorithm

but not as well when the

optimization criterion

is

For discussion on the effectiveness of this heuristic

time.

on an industrial example see Section

5.

Heuristic Algorithm (1-opt)

Generate a random starting division.

Switch one task from the phase in which it is to the other phase.

3.

Evaluate the current division to see if it is an improvement (on either

time or effort, whichever we are considering), if not then switch that

task back to its previous phase.

Step 4. Go back to step 2 until there are no more improvements available.

Step

Step

Step

A

1.

2.

(slightly)

counterpart. That

more complex version

is its

2-opt

replace step 2 with:

is,

Improved Heuristic

of the previous algorithm

(2-opt)

Step 2a. Switch two tasks from the phase which they are to the other phase.

The 2-opt algorithm

global optimal value, but

the global optimum.^

solutions

is

still

more

likely to find solutions

with values close to the

can be fooled into finding local optima which are not

Again, evaluating the time criterion

is

more

likely to find

which are not the global optimal values than when looking

for effort

solutions for our example problem.

Changing the

of time

and

effort

criterion of interest in Step 3 to incorporate linear

would allow

other changes to the algorithm

combinations

the finding of other Pareto-optimal solutions.

would be

No

required.

^As an example of a matrix where the 2-opt heuristic does

consider the case where

is the identity matrix and

r\ot

always terminate on the global optimum

W

0.7

A

0.1

0.2'

0.6

0.6

=

0.1

0.5

0.3

0.2

When

using the effort criterion there are two matrices

depending on the

initial starting state.

13

K

at

which the 2-opt

heuristic

may

terminate,

5.

Application

We

to

Workstation Design

have previously modeled workstation design

which are

different tasks

related in a

WTM

be composed of 45

to

[Smith 1992]. The dependencies and task

times have been suggested by engineers from the project. The

list

of tasks

and

their

corresponding times are given in Appendix A. The dependencies are shown in

Figure A.l. In the text of the paper

Using the equations

strategy,

where

all

tasks will be referred to

all

and

effort for the

The workstation design process

design phases: product design

appropriate

better

ways

weeks and

way

numbers.

tasks are attempted from the beginning of the design process,

parallel design strategy has time 51.597

(all

their

in Section 2 for describing the fully parallel design

possible to calculate the time

process design

by

(all

to divide the

to divide

it.

workstation design process. The fully

weeks and

effort 319.98 engineer-weeks.

as described

tasks with task

tasks beginning with A2).

it is

is

naturally divided into

number begirming with

We wish

to

two

Al), and

analyze whether this

is

an

design process into two phases or whether there are

The product/process two-phase solution has time 55.590

effort 234.45 engineer-weeks.

This division has greatly reduced the effort

while slightly increasing the time.

The product /process two-phase solution

improvement, but there

may be

still

is

therefore potentially an

better solutions.

We

have attempted

such solutions using the heuristics described in subsection

4.2.

the structure of the best found two-phase solutions for time

discuss

how

effective the

two

and

effort

first

discuss

and secondly

heuristics are at finding such solutions.

The best minimum-effort solution found

is

given in Appendix

vector which corresponds to the minimum-effort solution

from the matrix K. All entries with

indicate second-phase tasks.)

We will

to find

It

is

the

a 1 indicate first-phase tasks,

B.

(The

main diagonal

and

entries with

has an effort of 134.59 engineer-weeks and a time of

14

17.060 weeks.

This

a significant

is

as well as the product /process

second phase (11 of the

a

low

the product design

effort

it

Both the

anomalous

if it is

makes sense

it

minimum

results,

is

given

is

in

Appendix

B.

It

section

The

3.

tasks

in the

minimum

effort solution).

important to minimize the amount of time spent

begin more tasks earlier in the project.

to

time and the

minimum

some

effort divisions give

such as delaying choosing the architecture (task Allll) until the

do not

Even though there are feedbacks

it

performed

A11333

after task

To handle such

in

one phase or the

constraint

is

(logic

it

other,

and timing

which cannot

difficult to

feasibly

tasks,

then

it

tasks.

If

there

would be

to explicitly require certain tasks to

and then reapply the

have

is

heuristic.

Adding

this

type of

implement. The search space considered

would simply be

their schedule

Another alternative would be

between the

example) the task of choosing the

validation).

would be possible

2 (or step 2a) of the heuristic algorithm

tasks

to (for

not meaningful to suggest that this task could be

cases,

would not be

in the

the definition of order-independent tasks as described in

fit

product architecture,

be

until

has a time of 14.746

second phase. The anomalies arise because of errors in specifying the tasks

matrix.

to

engineer-weeks. Only nine of the design tasks are

effort of 151.59

design process,

expect to see in

substantially complete.

is

This matches intuition that

a

we would

in the

complete the process design

to

delayed until the second phase (as opposed to 16

on

design tasks

criterion for the design process

makes sense not

The minimum time solution

weeks and an

of tht

design tasks, which

an important

If

either the fully parallel solution

two-phase solution. Mo'^t

16) are process

total-effort process.

minimize engineering

improvement on

to

in step

restricted to exclude those

changed.

change the weights of the interdependencies

a strict ordering relationship

between two

(or

more)

possible to increase the magnitudes of the feed-forward

15

dependencies, and decrease the magnitudes of any feed-back dependencies. The

iteration

model and scheduling algorithm

will then

be compelled

to

schedule the

tasks to reflect the effective ordering structure.

The

effort

minimization problem

very well behaved for the two heuristic

(Appendix B contains the values of

algorithms tested.

the heuristics

is

came

to rest, as well as the

number

local

it

was

run, starting from

optima have

effort

within

found the best known solution

generated

initial

randomly generated

1%

all

27 times

was

On

on which

the given

solution 14 out of the 20

initial conditions.

solution.

The other

six

The 2-opt solution

run, again starting from

randomly

conditions.

The time minimization problem

opt solution found the best

(starting

it

known

known

of the best

of the solutions

of times observed.)

45-task example, the 1-opt algorithm found the best

times

all

known

from randomly generated

is

also algorithmically well behaved.

The

1-

time solution eight out of the 23 times run

initial conditions).

The other

fifteen local

optima have time within 9.5% of the best known solution. The 2-opt solution

found the best known time solution

all

24 times executed.

Finding one 2-opt solution using

hours of

CPU

time on a

10 minutes of

6.

CPU

Extension to

There

is

contemplated.

VAX

8800.

MATLAB

requires approximately three

Finding a 1-opt solution requires approximately

time on the same machine.

More than Two-Phase Design

no particular reason

It is

why

only two-phase design should be

possible to extend the ideas expressed in this paper to design

processes which have

more than two

phases.

process would involve:

Three-Phase Process:

Divide tasks into groups

I, II,

and

HI.

16

For example, a three-phase design

work on tasks in group

Second phase: work on tasks in groups

First phase:

I.

have

1

initial

bird phase:

We

I

and

but only the tasks in group

II,

II

work.

work on

but only tasks in group

all tasks,

must define two matrices

K,

with elements

III

have

initial

work.

and K„ with elements

k'

k'!

such that

[1 if

,

;

=

/

and the

zth task is in the first

phase

^/,=L otherwise

_...:....

(13)

*''

1

f

„

''

The

1 if

= / and the

/th task is in the first or

second phase

[O otherwise

work time

total

/

vectors for the three phases are calculated by:

Ri=W{I-K,AK,y'K,Ua

(15)

R,=W{I-K„AK,r\K„-K,)u,

(16)

R„=W{I-Ar\l-K,)u,

(17)

Calculating the total time and /or total effort for the three-phase process

to

is

analogous

using equations (11) and (12) for the two-phase process. Minimizing the

time or the

the

total effort of the

design project as a function of whether each task

second, or third phase leads to an optimization problem which

first,

complex than the one which

As

the

number

is

discussed in Section

of phases

on the

total

time

the effects through analysis of the

best possible two-phase ordering.

would have

which minimizes the

number

the

The

effect of

problem under study.

We

minimum

total

parallel.

it is

We

in

more

work

an increase

in the

necessary to determine

observe

in the

example

has a longer development time that the

would not expect

time.

is

4.

difficult to predict;

is

in section 5 that the fully parallel strategy

strategy

is

of phases increases, the total effort will decrease, since

becomes increasingly sequential rather than

number

total

that a fully sequential

Therefore finding the

number

of phases

time requires restructuring the problem to allow the

of phases be an independent variable.

17

7.

Discussion and Conclusion

We

when

to

have given an

do design

explicit representation to the difficult

Our model

sequentially rather than in parallel.

work transformation matrix (WTM) model

able to suggest sequential

and

parallel orderings of tasks

we

set,

is

based on the

The model

of product development.

product development time and lower development

For our example data

problem of deciding

which lead

to

is

lower overall

effort.

believe that the divisions suggested by this

system do indicate ways in which the time or

suggested by the algorithm seem in

many

effort

can be reduced. The divisions

respects reasonable.

therefore be useful in identifying advantages

The method may

and disadvantages of

serial or parallel

tasks in the design process.

In our experience, the data required to build this

The engineers involved with design

collect.

the information needs of the tasks with

model are not

have

projects typically

a

which they work as well as

difficult to

good idea

of

task times.

Polling each of the people involved with a design project creates a complete set of

WTM data, which can then be used

The assumptions required

strong.

Further investigation

less restrictive

is

in the

manner

of the

model

in order to build the

underway

to build

in the paper.

in this

paper are

more general models based on

assumptions.

The simple

heuristic algorithms

used

in this

paper seem to do a good job of

finding locally optimal solutions for the example data

solution techniques

The

model

may

More

exploration of

be required for poorly behaved or larger problems.

class of design projects to

the class of projects with

set.

which

this

type of analysis can best be applied

which an organization already has

from similar products. This

is

a large class, as

many

significant experience

design organizations have

experience working with the technologies being used in their

18

new

products.

is

Computer workstation design

project

it is

falls into this class

of design projects.

For this type of

reasonable to assume that the data from previous projects can be used

with useful predictive value.

If

the designers had

no experience working with the

technology involved in the project, then any estimates of task times and

dependencies are

likely to

be inaccurate and the model would lose

its

predictive

utility.

The problem

design

is

interesting

of determining parallel or series division of tasks in engineering

and important. Shortening the lead time

is

a major source of

competitive advantage in design, and concurrency has a strong effect on this score.

We know

that other

models of design-task sequencing and scheduling are

and we suggest our model as

a starting point in building other

models

feasible

of this

important problem.

References

AitSahlia, Farid, Eric Johnson, and Peter Will, "Is Concurrent Engineering Always a

Sensible Proposition?," IEEE Transactions on Engineering Management, Vol. 42,

No.

2,

pp. 166-170, 1995.

Alexander, Christopher, Notes on the Synthesis of Form, Harvard University Press,

Cambridge, 1964.

M. Kroo, and Peter J. Gage, "A Genetic Algorithm for

Scheduling and Decomposition of Multidisciplinary Design Problems," 21st ASME

Design Automation Conference, 1995.

Aitus, Stephen

S.,

Ilan

Blackburn, Joseph D., Time-based Competition: The Next Battleground

Manufacturing, Business One Irwin, Homewood, 111., 1991.

Kim

in

American

and Takahiro Fujimoto, Product Development Performance: Strategy,

Organization, and Management in the World Auto Industry, Harvard Business

Clark,

B.,

School Press, Boston, 1991.

Whitney, Robert P. Smith and David A. Gebala, "A

Model-based Method for Organizing Tasks in Product Development," Research in

Engineering Design, Vol. 6, No. 1, pp. 1-13, 1994.

Eppinger, Steven D., Daniel

E.

19

Hoedemaker, Geert M., Joseph D. Blackburn, and Luk N. Van Wassenhove, "Limits

Owen School of Management Working

to Concurrency," Vanderbilt University

Paper #95-33, 1994.

Krishnan, Viswanathan, Steven D. Eppinger, and Daniel

Whitney, "A ModelBased Framework to Overlap Product Development Activities," M.I.T. Sloan School

of Management Working Paper no. 3635, forthcoming in Management Science, rev.

September 1995.

Kusiak, Andrew, and Juite

Wang,

"Efficient

E.

Organizing of Design Activities,"

No. 4, pp. 753-769, 1993.

International Journal of Production Research, Vol. 31,

L., and Daniel E. Whitney, Concurrent Design of Products and

Strategy for the Next Generation in Manufacturing, McGraw-Hill,

Nevins, James

Processes:

A

New

York, 1989.

Smith, Preston G., and Donald G. Reinertsen, Developing Products

Time, Van Nostrand Reinhold, New York, 1991.

Half the

and Steven D. Eppinger, "A Predictive Model of Sequential

Engineering Design," M.I.T. Sloan School of Management Working

Smith, Robert

Iteration in

in

P.,

Paper, 1995(a).

Smith, Robert P., and Steven D. Eppinger, "Identifying Controlling Features of

Engineering Design Iteration," M.I.T. Sloan School of Management Working Paper,

1995(b).

Smith, Robert P., Development and Verification of Engineering Design Iteration

Models, Ph.D. Thesis, M.I.T. Sloan School of Management, August 1992.

Steward, Donald V., "The Design Structure System: A Method for Managing the

Design of Complex Systems," /£££ Transactions on Engineering Management, Vol.

EM-28, No. 3, pp. 71-74, 1981.

Susman, Gerald I., Integrating Design and Manufacturing for Competitive

Advantage, Oxford University Press, New York, 1992.

von Hippel,

Eric,

"Task Partitioning:

An

Innovation Process Variable," Research

Policy, Vol. 19, pp. 407-418, 1990.

Whitney, Daniel

Design, Vol.

E.,

"Designing the Design Process," Research

2, pp. 3-13, 1990.

20

in

Engineering

Appendix A. Data from Workstation Design Example

Tciblf A.l.

Aim

Appendix

B.

Table

Best Oh>er\t'd Solutions for Effort

Task

15.1.

Results from Heuristic Algorithms

and Time

Table

T

B.2.

Locally Optimal Effort Solutions

2218

n o

I

Date Due

UHN.

)

4 49#

I

I .-

KA^^

i

20<-l<i

)

\'

iU>i^

tsai

^

2 1997

Stp.

SEP

1

3

19 ^7

:^iB

^'i'l

Lib-26-67

MIT LIBRARIES

3 9080 00939 8584