2013 Job Skills Program July 1, 2012 – June 30, 2013

advertisement

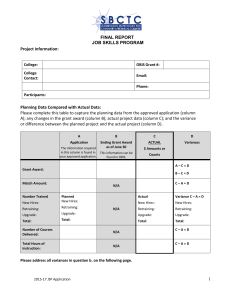

2013 Job Skills Program July 1, 2012 – June 30, 2013 Report to the Legislature December 2013 State Board for Community and Technical Colleges Workforce Education Department 1300 Quince St SE; P.O. Box 42495 Olympia, WA 98504-2495 306-704-4400 www.sbctc.edu Table of Contents Preface ................................................................................................................................ 1 Executive Summary ............................................................................................................. 2 Program Overview ........................................................................................................... 2-3 About the Job Skills Program .................................................................................. 2 Job Skills Priorities ................................................................................................... 2 Shared Investments ................................................................................................. 2 Workforce Training Customer Advisory Committee ............................................... 3 Increasing Efficiencies through Lean....................................................................... 3 Scoring High in Customer Satisfaction………………………………………………………………….3 Project Results and Program Data ...................................................................................... 4 2012-2013 Job Skills Projects at a Glance ……………………………………………………………………….5 2012-2013 Distribution of Grants by Educational Sector.............................................................................................. 6 by Region................................................................................................................. 6 by Employer Size ..................................................................................................... 6 by Industry............................................................................................................... 6 2012-2013 Individual Project Descriptions and Outcomes ............................................ 7-20 2013-2014 Job Skills Projects at a Glance ......................................................................... 21 i PREFACE Job Skills Program Legislation The Washington State Legislature finds that it is in the public interest of the state to encourage and facilitate the formation of cooperative relationships between business and industry and educational institutions which provide for the development and expansion of skills training and education consistent with employment needs. Since 1983 the Job Skills Program (JSP) has funded customized training designed to meet the needs of business and industry and to provide or retain gainful employment opportunities for new hires and incumbent workers. Purpose of This Report This Job Skills Program report is submitted by the State Board for Community and Technical Colleges (SBCTC) to the Washington State Legislature in fulfillment of 2011-13 2ESHB 1087 Sec. 605(2) which reads in part: The state board [SBCTC] shall make an annual report by January 1st of each year to the governor and to the appropriate policy and fiscal committees of the legislature regarding implementation of this section, listing the scope of grant awards, the distribution of funds by educational sector and region of the state, and the results of the partnerships supported by these funds. Program Funding The Job Skills Program (JSP) was funded at $2,725,000 from the state general fund for FY 2012 and FY 2013 of the biennium, for a total of $5,450,000 million. $2,725,000 of the general fund--state appropriation for fiscal year 2012 and $2,725,000 of the general fund--state appropriation for fiscal year 2013 are provided solely for administration and customized training contracts through the job skills program. 1 EXECUTIVE SUMMARY Washington State’s economy continued its slow but steady growth in 2012/13. Talent is a top economic driver in the state, and Washington’s strategic industries require an increasingly sophisticated skill-set from both new and incumbent employees. The Job Skills Program provides assistance to businesses by funding industry-specific training, while building capacity for the state’s community and technical college system. Ninety-five percent of the 2012/13 JSP projects funded training for the state’s manufacturers, including those in aerospace, medical devices, and automotive sectors. As businesses saw an increase in production and hiring, many sought to upgrade their current employees’ skills to prepare them for promotion into positions of leadership, and others cross-trained workers to increase businesses’ adaptability in the changing economy. While most of the funds went towards retraining incumbent employees, a positive trend of training new hires began to emerge in 2010/11 and continued through 2012/13. PROGRAM OVERVIEW About the Job Skills Program Attracting, developing, and maintaining a skilled workforce is a challenge faced by many employers in Washington’s targeted industry clusters. Washington’s Job Skills Program (JSP) serves to develop the skills of new or existing workers, retain and grow living wage jobs, and help companies improve their competitiveness to strengthen Washington’s economy. Job Skills Priorities Industry clusters are supported by the Job Skills Program whenever possible, and awards are spread to all corners of the state, including rural areas. Job Skills resources are also concentrated: where there is a shortage of skilled labor to meet businesses’ needs; where upgrading employee skills is necessary to avoid layoffs; where training incumbent workers for advancement creates new vacancies; where new businesses or industry clusters need a skilled labor pool; and in economically disadvantaged communities with high unemployment. Shared Investments JSP is a dollar-for-dollar matching grant program, and at least 50% of training expenses are covered by the business through cash and/or in-kind payments. Lasting working relationships develop between the business and the educational institution as both parties engage in the development and implementation of a training plan. In FY 2013, employers provided the equivalent of $1.39 in match (cash and in-kind) for every $1.00 spent in Job Skills grant funding. At the forefront of in-kind matches are the wages paid to employees while they are in training. In economic terms, these wages represent opportunity costs to the employer, who must either forego the productive contributions of those employees while they train, or hire substitutes to maintain production during training activities. Other in-kind employer contributions 2 include materials, training supplies, management and supervisor time spent planning and coordinating the training, and specialized equipment and supplies contributed for training. Workforce Training Customer Advisory Committee The State Board for Community and Technical Colleges (SBCTC) utilizes the Workforce Training Customer Advisory Committee made up of representatives from business, labor, and public and private educational institutions to guide program decisions. A Job Skills sub-committee meets via conference calls to review, provide input, and recommend applications for Job Skills grants. A representative of the Department of Commerce also participates in the review process. Increasing Efficiencies through Lean Lean manufacturing has been the most requested type of training in the JSP for several years, and 2012/13 continued the trend. Lean principles were originally designed for the manufacturing environment, but have been adopted by a variety of industries, including health care, service providers, and education. In October 2012, The State Board for Community and Technical Colleges applied Lean principles to evaluating the Job Skills Program, and redesigned the application process to condense steps, remove non-value-added elements, and decrease rework. Ultimately, the new procedures reduced time spent on the application process by 14% for college staff, and by 23% for the State Board staff. The increase in efficiencies has led to colleges and businesses receiving funding decisions sooner, and starting projects on time. Scoring High in Customer Satisfaction The Job Skills Program served as a case study in the report produced by the Washington Economic Development Commission (WEDC) - an independent non-partisan organization, charged by the Legislature with the mission of creating a comprehensive statewide strategy to guide investments in economic development - that assessed Washington’s economic development system. The WEDC conducted interviews and surveyed the JSP participants to collect data on the program and its results. The inquiry found that the program is very well-regarded and that over 90% of the respondents would use it in the future1. Another WEDC analysis, detailed in the Innovation Sources, Practices, and Economic Development Programs Serving the Needs of Businesses Survey, showed that 90.2% of the surveyed participants indicated that the Job Skills Program was important (very: 33.5%, frequently: 23.9%, critically: 19.6%, or occasionally: 13.1%) to their business’ overall performance. 2 The JSP also had one of the highest awareness rates for state-funded economic development programs among the surveyed businesses. The above findings confirm the efficacy of the program and its contributions to the State’s economic vitality through investment in businesses and human capital. 1 Washington Economic Development Commission. (2012). Economic Development Programs and Investment: Review of Evaluation Practices in Washington State. Retrieved from http://www.wedc.wa.gov/Download%20files/Evaluation_Practices.pdf 2 Washington Economic Development Commission. (2013). Innovation Sources, Practices, and Economic Development Programs Serving the Needs of Businesses: A survey of Businesses and Recommendations. Retrieved from http://www.wedc.wa.gov/Download%20files/WEDC_SURVEY_OF_BUSINESSES.pdf 3 Project Results and Program Data Each Job Skills project identified desired outcomes and provided information on those outcomes after the completion of training. Outcomes are unique to each project, quite varied, and often the complete results of training are not fully realized until well after the reporting period. Details on individual projects can be found on page 8. Comparison of Final FY 2011, 2012 and 2013 2010-2011 2011-2012 2012-2013 Final Final Final Total Requests Made: $3,149,555 $1,935,152 $2,329,585 Total Awards Made: $2,759,900* $1,734,711 $1,982,816 Total Number of Projects: 34 33 27 Total Number of Companies: 71 42 40 Total Awards Spent: $2,388,600 $1,675,777 $1,899,710 Total Private Investment (Match): $3,591,048 $2,442,876 $2,637,223 Number of Trainees: 3043 2667 2009 Retrained Workers: 2225 2085 1575 New Hires: 75 135 149 Skills Upgrades: 743 447 285 State Investment per Trainee: $784.95 $628.34 $945.60 Private Investment (Match) per Trainee: $1,180.10 $915.96 $1,312.70 Total Investment per Trainee: $1,965.05 $1,544.30 $2,258.30 *Awards exceed $2,725,000 when unspent funds are re-awarded to other projects. Fiscal years 12 and 13 saw a reduction in the amount of project funding awards. Several internal and external factors contributed to the decline: Colleges experienced additional budget cuts at the same time as student enrollments grew dramatically. Many colleges decreased their business and industry outreach to concentrate their efforts on better serving the increased number of students on their campuses. Affected by the recession, many Washington businesses scaled back their staff. As the economy began to recover in 2011-12, companies were trying to maintain their market shares and were not able to pull employees from production for training purposes. Training had to be postponed in order to concentrate on staying competitive while cutting expenses and keeping up with the demand. Of the businesses that participated in JSP training, most requested a lower funding level than in previous years, engaged fewer employees and focused on small-scale projects. As student enrollments have slowed and the economy rebounds, applications for JSP funding are increasing. Five months into the 2013/14 fiscal year, the Job Skills Program has funded 33 projects, exceeding a year’s total for 2012/13. The trend also points to a reduced focus on Lean and other process improvement trainings, and increased interest in leadership and supervision education that prepares supervisors and production workers for promotional opportunities. The list of projects for 2013/14 year can be found on page 22. 4 2012–2013 Job Skills Projects at a Glance College 1 2 Big Bend CC Clark College 3 Clark College 4 5 6 7 Clover Park TC 8 Green River CC 9 Green River CC 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 Green River CC Green River CC Green River CC Green River CC Green River CC Lake Washington IT Lower Columbia C North Seattle CC North Seattle CC Pierce College Pierce College Renton Skagit Valley South Puget Sound South Seattle Tacoma CC Wenatchee Valley Yakima Valley CC Grays Harbor C Green River CC Business Award Spent Match SGL Automotive ControlTek Consortium #2/Green Belt: Adalis, nLight, Sagetech, SEH, Smith-Root Craft Brew Alliance General Plastics Cosmo Specialty Fiber Carlisle Interconnect Technologies Consortium #1: GM Nameplate, Microscan Systems, Mold Rite, The Box Maker, TECT Aerospace, Sonosite Consortium #3: BE Aerospace, Heatcon, IDD Aerospace/Zodiac, Microscan Systems, Mold-Rite, Precor, Skills, Inc., Spacelabs Healthcare, ThyssenKrupp,Tri-Tec Manufacturing Labinal, Inc. Onamac Industries, Inc. Skills, Inc. TECT Aerospace Toray Composites Jamco Bennu Glass Vaupell (Phase 1) Vaupell (Phase 2) Red Dot PnJ Machining Allpak Trojan KLW Manufacturing Sealy Mattress, Inc. Khan Machine Tools Carlile Transportation Souriau PA&E Tree Top $189,150 $67,853 $266,857 $76,781 $36,273 $13,773 $26,768 $24,077 $27,900 $68,541 $18,438 $26,894 $24,077 $36,896 $52,687 Totals: # of Co’s Trainees 1 1 5 60 137 1 1 1 1 28 83 18 137 91 $156,736 6 22 $99,900 $157,553 10 38 $63,500 $29,734 $73,900 $44,300 $24,300 $58,318 $115,000 $145,711 $157,755 $69,770 $34,433 $37,231 $20,766 $359,213 $7,380 $18,879 $59,149 $41,990 $122,285 $29,734 $81,035 $57,833 $43,138 $83,548 $197,680 $184,910 $186,814 $69,895 $34,545 $42,953 $23,515 $412,908 $8,404 $31,283 $124,469 $69,501 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 61 36 107 114 12 129 54 145 158 85 19 113 20 89 11 23 146 73 $1,899,710 $2,637,223 443 2009 C = College, CC = Community College, TC = Technical College, IT = Institute of Technology 3 4 of the companies (Mold-Rite, Skills, Inc., TECT Aerospace, and Microscan) are counted twice due to participation in multiple projects. Individual company count is 40. 5 2012-2013 Distribution of Grants Distribution by Educational Sector Job Skills grants may be awarded to eligible post-secondary institutions, which include community and technical colleges; public and non-profit universities and regional colleges/universities; and licensed private career schools and colleges located in Washington. In 2012-13, all JSP applications were made through community and technical colleges. Distribution by Region (2012-2013) Region Number of JSP Projects in Region Percent of JSP Projects in Region Number of JSP Trainees by Region Percent of JSP Trainees in Region 19 70% 1285 64% $1,018,856 51% 5 3 27 19% 11% 100% 445 279 2009 22% 14% 100% $654,810 $309,150 $1,982,816 33% 16% 100% Puget Sound (King, Pierce & Snohomish) Balance of State – West Balance of State – East Total JSP Funds Awarded by Region Percent of JSP Funds Awarded by Region Distribution by Employer Size (2012-2013) Employer Size by Number of Employees in Washington Number Percent Companies Companies Served Served Small (1-50) Medium (51-250) Large (251+) Total 6 18 16 40 Percent of Washington Employers of Same Size 15% 45% 40% 100% 4 Percent of Number of JSP Trainees Percent of JSP Trainees 101 844 1064 2009 5% 42% 53% 100% 96% 3% 1% 100% Washington Workforce Employed in 4 Same Size JSP Funding Awarded 40% $168,402 26% $1,022,103 34% $792,311 100% 1,982,816 Distribution of Companies by Industry (2012-2013)* Manufacturing 38 companies - 95 % of grant funding Aerospace 15 companies Packaging and Branding 4 companies Food Production and Processing 2 companies Other Manufacturing 13 companies Medical Equipment 3 companies All Other Industries 2companies 5 % of grant funding Transportation/Logistics 1 companies Retail/Wholesale 1 company Automotive 1 company * 27 JSP projects included 40 separate companies, including three JSP consortia projects that trained employees from 21 companies. Some of the consortia participants also engaged in individual projects. 4 Source: Washington Employment Security Department 6 2012–2013 Individual Project Descriptions and Outcomes Twenty seven projects were completed between July 1, 2012 and June 30, 2013, training 2009 employees in a wide range of topics and skills. Following are brief descriptions of each project along with the number of trainees, state and business investments, and select outcomes taken from the projects’ final reports. Projects are listed in alphabetical order first by college and second by business name. Big Bend Community College Grant County Grant: $189,150 Spent: $189,150 Match: $266,857 SGL Automotive Carbon Fiber LLC January 2013 – June 2013 Trainees: 60 New Hires 25 Retraining 0 Upgrade 35 SGL Automotive is a growing manufacturer of carbon fiber, used in production of automobiles. The purpose of this project was to provide equipment and process training for 25 new production operators, as well as upgrade the skills of the incumbent employees. The grant allowed for cross-functional training and for training team members who would not otherwise have had the opportunity to increase their skills. Having the JSP grant offered us the opportunity to be proactive and identify the needs of our team members and company for future growth. Annette Herup Manager, Human Resources SGL Automotive Outcomes: 25 FTEs were hired and trained, increasing total employee count to 77. Achieved a low turn-over rate with only one termination since the start of the grant. 14 promotions occurred since the start of the grant. Clark College ControlTek October 2012 – April 2013 Trainees: 137 New Hires 0 Retraining 137 Upgrade 0 ControlTek designs, manufactures, and tests products for consumer and industrial use, semiconductor, medical, and other industries. Training focused on Lean Manufacturing for all employees. Outcomes: On-time deliveries increased by 6% to 93%. Sales increased by $1 million. Clark County Grant: $67,853 Spent: $67,853 Match: $76,781 ControlTek’s entire staff has been given the unique opportunity for training in Lean Manufacturing. Through this opportunity, the basic level of Lean manufacturing techniques have been raised to where employees now integrate Lean in most aspects of their jobs. This integration of Lean techniques brings an increased level of efficiency to our workplace. Our employees are using their newly learned skills in many aspects of their jobs […] This attention to efficiency has a direct impact on the company's bottom line Stacey Smity Vice President of Human Resources & Marketing ControlTek 7 Clark College Consortium # 2/Green Belt: Adalis, nLight, SEH, Smith-Root, Sagetech January 2013 – June 2013 Trainees: 28 New Hires 0 Retraining 28 Upgrade 0 Five manufactures participated in the Six Sigma Green Belt training. This short-term, industry-endorsed training equipped workers and companies with strategies to reduce error, waste, and turnaround times, while increasing productivity and responsiveness to customer needs. Clark County Grant: $36,273 Spent: $36,273 Match: $68,541 Engineers who attended the Lean Green Belt training report using the techniques they learned to improve a number of processes. Examples include using techniques to design a better packaging operation that will create fewer errors to the end customer, and using techniques to isolate variables in high yield loss situations to target root cause and resolve issues. Natalie Pacholl Training Program Specialist SEH America Sample Outcomes: Participants reported improved skills in Quality Control and R&D, increased efficiencies. On target to reduce scrap by 15%. New process documented and stress-tested, leading to reduced redundancies. Clover Park Technical College Craft Brew Alliance October 2012 – March 2013 Trainees: 83 New Hires 0 Retraining 75 Upgrade 8 Craft Brew Alliance formed when Widmer Brothers Brewing, Redhook Ale Brewery, and Kona Brewing Company merged. Beer produced by the Alliance is sold nationwide. Employees received supervisory and management training to support a projected growth rate of over 300% in the next three to five years. Pierce County Grant: $13,854 Spent: $13,773 Match: $18,438 The Job Skills Program has allowed us to take action on our commitment to our company values and key initiatives in several ways […].The impact has been so profound; we have started to roll out these programs to our locations outside WA State Melissa Orgrodowski HR/Development Manager Craft Brew Alliance/Redhook Outcomes: Participants have a greater understanding of concepts relating to personal accountability, embracing change, communication, and teamwork. Curriculum, customized to the specific needs of the beverage manufacturing industry, will support the rapid growth of the Alliance. 8 Clover Park Technical College General Plastics Manufacturing January 2013 – June 2013 Trainees: 18 New Hires 0 Retraining 18 Upgrade 0 Pierce County Grant: $26,800 Spent: $26,768 Match: $26,894 General Plastics is an aerospace supplier, manufacturing high-density rigid polyurethane foams used in aircraft composite applications. The training project focused on Lean techniques and problem solving. Outcomes: GP employees’ supervisory and management skills have risen, allowing them to better manage their staff and time. Grays Harbor College Cosmo Specialty Fibers November 2012 – May 2013 Trainees: 137 New Hires 0 Retraining 0 Upgrade 137 Established in 2011, Cosmo Specialty Fibers produces high-quality dissolving wood pulp. The pulp is used by many manufacturing, pharmaceutical, and food processing firms, creating products such as cellophane, LED screens, rayon fabric, and filters. The JSP funding focused both on soft and technical skills. Grays Harbor County Grant: $75,789 Spent: $24,077 Match: $24,077 Training received through the JSP has supported Cosmo’s goal of achieving higher quality product and process controls that will allow it to introduce new, higher value products in order to achieve long term sustainability. Cosmo Specialty Fibers Outcomes: Trainees achieved higher-level skills related to managing work within teams, leadership, communication, and organizational effectiveness. Productivity and product quality improvements were reported from both the leadership team and the operators. Employees understand how waste water treatment plants operate. Wastewater treatment (activated sludge) and hazardous waste handling training supports the mill’s ongoing efforts to meet environmental responsibilities. 9 Green River Community College King County Grant: $27,900 Spent: $27,900 Match: $36,896 Carlisle Interconnect Technologies May 2013 – June 2013 Trainees: 91 New Hires 0 Retraining 91 Upgrade 0 Carlisle is a manufacturer of wires, cables, and interconnectors. While the Kent facility’s primary product is seat cables for the aerospace industry, the company is expanding into the medical field. Training was aimed at ensuring that current employees have the skill sets necessary for a smooth transition into the new market. The ESL class built confidence in our employees to speak up when they didn’t understand a concept (such as more than or less than). The Quality class provided a thorough overview of reliability, acceptance, and quantitative methods which expanded the quality knowledge of our employees and hence has benefitted our customers. Becky Wright PHR, Recruiter Carlisle Interconnect Technologies Outcomes: Year-to-date, 82% of all vacancies have been filled internally through promotion, exceeding the pre-training benchmark by 40%. The Excel classes have increased productivity by teaching students effective software shortcuts. The ASQ course provided a solid baseline for ASQ Quality Standards. ESL classes increased verbal communication and the understanding of terms on the production floor. Green River Community College Consortium # 1/Six Sigma Black Belt: The Box Maker, Sonosite, TECT Aerospace, Microscan, Mold Rite, GM Nameplate September 2012 – October 2012 Trainees: 22 New Hires 0 Retraining 0 Upgrade 22 Six organizations formed a training consortium in order to receive Six Sigma process improvement training. Outcomes: King County Grant: $53,000 Spent: $52,687 Match: $156,736 The course material was detailed, highly useful, and understandable. The team projects helped us solidify the concepts taught in the course. Kyle Desautels 22 participants were cross-trained Lean Manager The Box Maker in Lean Six Sigma; within individual companies, 2-4 people from each company learned skills that will be shared with other employees. Trainees passed both Green Belt and Black Belt exams at 80% or higher to demonstrate knowledge of Six Sigma principles. 10 Green River Community College Consortium # 3/Six Sigma Black Belt: BE Aerospace, Heatcon, IDD Aerospace/Zodiac, Microscan Systems, Mold-Rite, Precor, Skills, Inc. Spacelabs Healthcare, ThyssenKrupp, Tri-Tec Manufacturing. King County Grant: $99,900 Spent: $99,900 Match: $157,553 February 2013 – June 2013 Trainees: 38 New Hires 0 Retraining 38 Upgrade 0 This project was built to produce Six Sigma practitioners and help 12 businesses create an infrastructure of Six Sigma experts. Very well organized. Appreciated the opportunity to apply concepts to real life examples. Manufacturing Manager Zodiac Sample Outcomes: Participants passed both Green Belt and Black Belt exams at 80% or higher. Very helpful and effective – lots of information I can Participants produced detailed project use. charters in the Green Belt portion of the Manager class. BE Aerospace All participants showed skill improvement in the classroom through practical demonstration of concepts in small groups and individual projects. Green River Community College Everett Community College Snohomish County Labinal, Inc. Grant: Spent: Match: November 2012 – June 2013 Trainees: 61 New Hires 0 Retraining 55 Upgrade 6 Labinal, Inc. is a world leader in electrical wiring solutions for the global aerospace and defense market, encompassing engineering, manufacturing, and installation services. In this Phase II project, Labinal engaged staff in Catia V5, Excel, Finance, Management, and other training topics. Outcomes: 11 new employees were hired during the grant period. Turnover rate was reduced by 5%. 24 people earned promotions. Wages increased 4.8% due to merit and promotions. $63,500 $63,500 $122,285 The JSP training grant allows Labinal to offer development opportunities to our employees that we otherwise would not be able to offer. Our employees have taken leadership and project management classes that allowed them to perform at a higher level. Classes in Microsoft Excel and Project have also allowed our employees to provide a better work product. Edi Dirkes HR Manager Labinal, Inc. 11 4 new contracts for new programs were secured during the grant period. 2 employees were promoted into leadership as needed for new programs. Sales increased by 4.2%. Green River Community College Everett Community College Snohomish County Grant: $31,500 Spent: $29,734 Match: $29,734 Onamac Industries April 2013 – June 2013 Trainees: 36 New Hires 0 Retraining 36 Upgrade 0 Onamac Industries, Inc. produces high mix, low volume precision aerospace, commericial, and military components. The company sought training in Management, Leadership, Supervision, Project Management, IT, and CAD in order to create wage progression and improve communication with vendors. The training we received through the grant and EVCC was very beneficial to us as a company. We have already used several of the aspects taught to our personnel with regards to Root Cause and Corrective Action, as well as Next Level Supervision. The instructors used to deliver the material were very knowledgeable and presented themselves very well. Outcomes: Workforce headcount increased by 8 in 2013. Maintained turnover rate at less than 1%. Established a training matrix so that all skills are identified and tracked. Established standards of work for bottlenecked and troubled areas. Green River Community College Skills, Inc. September 2012 – June 2013 Trainees: 107 New Hires 0 Retraining 107 Upgrade 0 Skills, Inc., an aerospace manufacturing company supporting Boeing, Airbus, and Gulfstream, participated in Phase II of a project that began in FY 11/12. The training was undertaken as the company anticipates massive production increases. Outcomes: Workforce headcount increased by 9%. Turnover was reduced by 5% 25 employees were cross-trained Jay Andersen Supervisor Onamac King County Grant: $73,900 Spent: $73,900 Match: $81,035 By receiving this grant for a second year we were able to capitalize on our initial year of Lean training by digging deeper into our processes. This allowed us to run even more Lean events than we had in the past year. We tackled our Maintenance department in the biggest, most expansive Lean project to date. We removed three 40 cubic yard containers of trash, four 20 cubic yard containers of scrap and reclaimed over 7,000 square feet of outside work area. Mike Nielsen Training Supervisor Skills, Inc. 12 to work in more than one department. Reduced rework to 76 orders from a high of 267 orders. Accidents reduced by 20% from prior year. Participated in 6 career fairs with local colleges. Green River Community College Everett Community College Snohomish County TECT Aerospace Grant: Spent: Match: March 2013 – June 2013 Trainees: 114 New Hires 0 Retraining 114 Upgrade 0 TECT Aerospace produces structural components and assemblies for wings, fuselages, interiors, landing gear, and doors for commercial, business, general aviation, and military aircraft. The company is in a growth phase, and pursued Phase II training to follow up on the successes of a 2011-12 JSP project. Employees participated in Green Belt, CATIA V5, Blueprint Reading, Supervision, and Excel training. $44,300 $44,300 $57,833 The funding that TECT Aerospace has received from the Job Skills Program, coupled with the support and assistance provided by Everett Community College, has had a significant positive impact on our business. This training has provided new tools to our team members to apply to the challenges of today’s marketplace. This investment in our team members will be invaluable in retaining and recruiting the talent that we need to grow. Tom Winkelmann Vice President and General Manager TECT Aerospace Outcomes: Great response from trainees translates into 90% and above retention rate. Company reached the goal of retaining employees and avoiding dislocation of incumbent workers by keeping the current employee count, and expects to grow by 2% within two years. All participants improved skills and knowledge in Blueprint Reading, CATIA V5, Six Sigma, Management, and Excel. Green River Community College Toray Composites April 2012 – June 2012 Trainees: 12 New Hires 0 Retraining 12 Upgrade 0 Toray Composites is a leading producer of high quality advanced composite prepreg materials serving the needs of recreational, aircraft, and industrial markets. Twelve trainees participated in Green Belt Six Sigma training. King County Grant: $24,300 Spent: $24,300 Match: $43,138 The Six Sigma instructor provided in-depth explanations of how, when, and why, and enabled the students to go beyond the use of the tools and move forward with a working knowledge of the Six Sigma material. The material presented is invaluable in learning new methods and techniques to solve problems, establish and track performance excellence, and make decisions that are beneficial to the organization. Mark Haller 13 Capacity and Lean Manufacturing Manager Toray Composites Outcomes: Trainees acquired skills to perform basic statistical analysis using MS Excel. Employees translated Lean Six Sigma analyses into recommendations for improving their workplace processes. Apply statistical and non-statistical control tools to sustain the gains from improvement projects. Lake Washington Institute of Technology Jamco America November 2012 – May 2013 Trainees: 129 New Hires 0 Retraining 129 Upgrade 0 King County Grant: $66,977 Spent: $58,318 Match: $83,548 Jamco America, located in Everett, is the American headquarters of Jamco Japan. The company produces airplane interiors, including seats, closets, and dividers. The project was intended to provide upgrade training to 129 Jamco employees, working with them on gaining skills through cross-training and on incorporating Lean enterprise practices. Outcomes: 124 employees cross-trained. Cross- training allowed employees involved with product lines that saw a slow-down to retain their jobs at Jamco by transferring to new product lines. Streamlined process for root cause analysis. Lower Columbia College Bennu Glass LLC July 2012 – March 2013 Trainees: 54 New Hires 33 Retraining 21 Upgrade 0 Glass bottle produciton is a new manufacturing sector for the CowlitzWahkiakum area. Most Bennu employees were hired without the specific skills needed to work in the industry, and required training in all areas of glass production. Cowlitz County Grant: $115,000 Spent: $115,000 Match: $197,680 As a new facility with limited startup funds, the educational grant that was offered to us gave our employees a great jump start to learning our equipment and process to ensure a successful beginning and a solid future. We were very grateful for this opportunity Jeff Green Maintenance Manager Bennu Glass Outcomes: Bennu Glass went from 43 to 96 total employees, with 53 new hires during FY 12/13 Having no previous glass container manufacturing experience, employees acquired high-level skills necessary to perform successfully in their jobs. Production of wine and beer bottles started on August 1, 2012. 14 North Seattle Community College Vaupell Northwest Molding and Tooling (Phase I) July 2012 – June 2013 Trainees: 145 New Hires 0 Retraining 145 Upgrade 0 Vaupell is a full service manufacturing company that produces plastic injection molded parts for commercial, aerospace, defense, and medical industries. This Job Skills project focused on Lean principles to aid in re-design of the shop floor and facility relocation. King County Grant: $145,800 Spent: $145,711 Match: $184,910 I was able to reset my lines to better fit the process that had evolved over time […]. Allowing the operators to have a great deal of input in the orientation and flow of cells allowed them to have a better sense of ownership of their parts, faster pace, and more comfortable working environment. William Hardwick Vaupell Outcomes: 97 new jobs added. Revenue increased by $10 million. On-time delivery to customers also increased to 94%, a 5% increase. Productivity measurement of Sales per FTE employee was $144,599, up 12% over the previous period. North Seattle Community College Vaupell Northwest Molding and Tooling (Phase II) February 2012 – June 2013 Trainees: 158 New Hires 0 Retraining 158 Upgrade 0 Phase II of the JSP project focused on line balancing of all production lines within the Ballard and Everett facilities to optimize production throughput/revenue and improve product deliveries to customers. King County Grant: $157,828 Spent: $157,755 Match: $186,814 The line balance project helped reduce task time by evaluating each step of the process. Oanh Bahena Vaupell Outcomes: Revenues increased by 7% over the previous six-month period. Productivity measurement was up 8% over the previous grant period. On-time delivery was 96%, up 2% from the previous grant period. 15 Pierce College Pierce County Grant: $69,770 Spent: $69,770 Match: $69,895 RedDOT Corporation October 2012 – March 2013 Trainees: 85 New Hires 0 Retraining 81 Upgrade 4 RedDot Corporation designs and produces heating, ventilation, and air conditioning systems and replacement parts for vehicles. The company serves heavy duty, commercial, and international markets. This project improved the skills of four employee groups – production leads, production supervisors, on-the-job trainers, and resistance spot welders. During the Fall/Winter of 2012 and Spring of 2013 RedDOT Corporation offered a menu of leadership learning opportunities to our manufacturing supervisors and leads. […]In looking at the total package one can now see a smoothing of communication which resulted in improved productivity and quality of work throughout the production and assembly process Bryan Price HR Lead RedDOT Corporation Outcomes: The classes succeeded in giving each leader a more complex toolbox for use in interactions with peers and subordinates. Pre and post skills assessments show that leadership skill level of employees at RedDOT has risen. Supervisors are able to better manage their staff and time. Pierce College PnJ Machining October 2012 – June 2013 Trainees: 19 New Hires 0 Retraining 19 Upgrade 0 PnJ Machining produces components and assemblies for the aerospace manufacturing industry. The company is AS9100 certified with Boeing as their primary customer. The purpose of this project was to provide training for managers, supervisors, and leads to support a managed twenty percent-ayear growth model. Pierce County Grant: $34,480 Spent: $34,433 Match: $34,545 I have definitely observed improved interdepartmental teamwork. I have seen them laughing and talking with each other and they look at each other as ‘wow, we are really one company and share one common goal’. It is a huge difference. Loretta Cherry HR Manager PnJ Machining Outcomes: The pre and post skills assessment results indicate that employees have improved their understanding of supervisory and management skills. HR staff has seen a marked improvement on 360 evaluations of managers participating in the training. One manager went from a score of 3.2 to 4.5. 16 Renton Technical College Spokane Community College Allpak Trojan March 2012 – June 2013 Trainees: 113 New Hires 0 Retraining 113 Upgrade 0 This partnership between Renton Technical College and Spokane Community College served both Renton and Cheney locations of Allpak Trojan, a manufacturer of print, packaging, and displays. Trainees participated in Electrical Training, Preventative Maintenance, Communication, Lean, and computer classes. King County Spokane County Grant: $37,231 Spent: $37,231 Match: $42,953 Thank you again for helping us with this grant […] I’m really thrilled we are able to bring this terrific training to our Maintenance Technicians. I think it will really upgrade their skills, benefit our operations by lowering costs and is a retention tool for me, too. Mary Merten Training Manager Allpak Trojan Outcomes: Pre and post training assessments showed skills increase in all areas. 21 machine operators increased their preventative maintenance scores from 28.9 to 98.6, and 13 technicians improved their electrical skills from 82.6 to 100. Operators and leads improved their communication and team building skills, leading to higher productivity. Internal and external customer service skills improved for Verbal Communication training participants. Skagit Valley College KLW Manufacturing April 2013 – June 2013 Trainees: 20 New Hires 2 Retraining 18 Upgrade 0 KLW provides fabricated components for various industry markets, such as audio, telecommunications, power conversion, and aerospace. The project provided employees with a sound understanding of Lean manufacturing. Outcomes: Production Supervisor promoted from within and his position was backfilled with a new hire. Incumbent employee was promoted Skagit County Grant: $21,431 Spent: $20,766 Match: $23,515 […]The benefits from the training and follow-on implementation far outweighed the time investment. In a relatively short period of time, the employees accepted ownership for their areas and began to make improvements in those areas. Soon they were making suggestions and helping out in other areas. When we moved to the new facility, the principles learned in the training were put into action, resulting in a highly efficient work place. Because they now understand the concepts and have been empowered, they seem more highly motivated. Larry Webber CEO KLW Manufacturing 17 to Machine Shop Manager. Incumbent employee was promoted to General Manager. Achieved a 40% reduction in lead time. Labor and materials costs were reduced by 6%. South Puget Sound Community College Sealy Mattress, Inc. January 2012 – May 2013 Trainees: 89 New Hires 89 Retraining 0 Upgrade 0 Sealy Mattress Company opened a new manufacturing and assembly plant in Lacey, WA in December of 2012. Newly hired employees received training in skills specific to mattress manufacturing. Outcomes: 89 out of 101 total new employees were trained with the JSP grant. 16 of the new hires were promoted and trained into higher positions during the grant period. The new plant began operating in April, as scheduled. South Seattle Community College Khan Machine Tools Co, Ltd. January 2013 – February 2013 Trainees: 11 New Hires 0 Retraining 11 Upgrade 0 Khan Machine Tools is a small precision machining and sheet metal manufacturer for the aerospace industry, with the majority of their work supplying Boeing. Training in Lean and Business helped the company transition to new clients and product markets. Thurston County Grant: $359,895 Spent: $359,213 Match: $412,908 The JSP grant provided Sealy Mattress Co. the necessary assistance to properly train and develop employees from the Lacey and Olympia area. The designed tracking tools provided a documented approach to measure progress of the employees and the new operation. These metrics provide a baseline for productivity improvements, safety, and quality Roy Finke West Region Vice President - Finance Tempur Sealy International, Inc. King County Grant: $7,380 Spent: $7,380 Match: $8,404 Khan Machine would have never even attempted this training without the direct financial support of the grant. This gave us an opportunity to train with one of the best Lean trainers in the country […] He had the ability to help us lay out a road map which will guide the company to move forward far into the future. Richard C. Bailey Quality Assurance Manager Khan Machine Tools Outcomes: During the grant period, the company was introduced to local groups and associations that are helping them with exposure to new markets. 18 Growth and quality goals have been set enabling the company to achieve Boeing Silver status through on-time deliveries and to increase sales to $3 million/year. Tacoma Community College Pierce County Grant: $18,915 Spent: $18,879 Match: $31,283 Carlile Transportation October 2012 – November 2012 Trainees: 23 New Hires 0 Retraining 23 Upgrade 0 Carlile is a private transportation services business providing a wide variety of transportation and logistics services. The purpose of this project was to align job descriptions with key performance indicators, improve business process flows, and increase project management and business writing skills. We had amazing results. Carlile is a growing company with lots of growing pains. Having this training for all staff up to and including ownership, was great. I cannot begin to stress how great the process and results were. Ted Klein Operations Manger Carlile Transportation Systems Outcomes: Employee’s agility in performing their job duties increased. Trainees developed potential for promotion. Training resulted in a more efficiently run operation in Washington State. Wenatchee Valley College Souriau PA&E December 2012 – June 2013 Trainees: 146 New Hires 0 Retraining 146 Upgrade 0 Souriau PA&E , Inc. is an integrated manufacturing company, specializing in technically demanding ceramic and metal components and assemblies for global leaders in defense, space, medical, and commercial industries. The company sought training in shop math, welding, print reading, among other topics. Outcomes: Retention rates increased by 5% to 90%. On-time delivery increased by 13% to 83%. Chelan County Grant: $59,400 Spent: $59,149 Match: $124,469 Through the Job Skills training program, PA&E has established a baseline training program for shop math and print reading. In addition, future progress was made in reducing cycle time to meet our customer demands […] This training has improved their skills, therefore increasing their value to the company and their marketability if they were to leave the company. Shaun McGuire Director of Engineering PA&E 19 Yakima Valley Community College Tree Top September 2012 – June 2013 Trainees: 73 New Hires 0 Retraining 0 Upgrade 73 Tree Top, a cooperative juice processor, employs over 700 people in Washington. The company participated in Lean process improvement training. Outcomes: Achieved a 35% of reduction in turnover. Exceeded the goal of cross-training 25% of plant employees by 5%. Trainees saw a 3% wage increase. Yakima County Grant: $60,600 Spent: $41,990 Match: $69,501 We’ve been very pleased with the further personnel developments that Lean brought to the table. Our people are much more knowledgeable and empowered and, with that, are driving constant improvements to our process and overall plant results. Jason Simpson, Plant Manager Tree Top 20 2013–2014 Job Skills Projects at a Glance Next Year’s Report As one of the state’s few tools to address new and incumbent worker training, the Job Skills Program remains in strong demand. By December 2013, the thirty three projects listed below have been awarded funding for FY 2014 (compared to 15 at this time in FY 2013). JSP 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 College Grays Harbor College Green River Community College Green River Community College Green River Community College Green River Community College Tacoma Community College Skagit Valley College North Seattle Community College Tacoma Community College Tacoma Community College Green River Community College Green River/Bellevue North Seattle Community College Big Bend Community College Skagit Valley College Big Bend Community College Tacoma Community College Clover Park Technical College Green River Community College Green River Community College Cascadia/Everett Green River Community College Green River Community College Green River Community College Green River Community College Green River Community College Cascadia/Everett Green River/Everett South Puget Sound Community College Centralia College Lower Columbia College South Puget Sound Community College Bates Technical College Business Little Green LLC Black Belt Consortium # 1 Carlson Paving Sound Sleep Norfil Re-marks Skagit Regional Health Quiring Monuments Niagara Bottling Simpson Lumber Carlisle Interconnect Booking.com Bodypoint REC Silicon KLW SGL Automotive McFarland Cascade Kuker-Ranken, Inc. Jamco Out of the Box Manufacturing Zetron ISO Consortium Canyon Creek Fluke Lean Consortium Award Metals Vertafore Charlie’s Produce H2O Jet Hampton Lumber Portco Packaging Diamond Technologies Interstate Distributors Grant Amount $41,665 $103,900 $99,300 $70,900 53,700 31,003 30,917 $76,613 $120,000 $33,173 $41,550 $158,800 $66,214 $102,199 $27,766 $243,660 $14,856 $56,315 $57,600 $31,500 $57,960 $66,800 $53,800 $37,600 $90,900 $46,900 $34,560 $73,100 $5,131 $37,540 $72,500 $31,973 $92,804 $2,163,199 # of Co’s 1 7 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 5 1 1 1 1 1 1 1 1 1 1 1 43 Trainees 36 36 72 58 28 12 82 38 40 105 111 258 34 200 18 100 18 21 30 19 111 39 115 115 43 16 25 188 7 48 47 14 40 2124 21