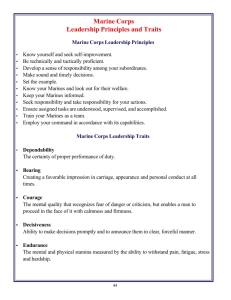

DEPARTMENT OF THE NAVY Headquarters United States Marine Corps 24 April 1998

advertisement