Achieving Business and Operational Excellence in... By Shonna Coffey

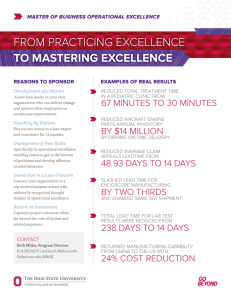

advertisement