NAVY TRAINING SYSTEM PLAN NAVAL AVIATION OXYGEN SYSTEMS N88-NTSP-A-50-8603C/A SEPTEMBER 2002

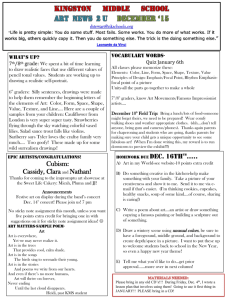

advertisement