Draft Gum-Thickener Study— Drop Test, Marana, AZ, 2005 United States

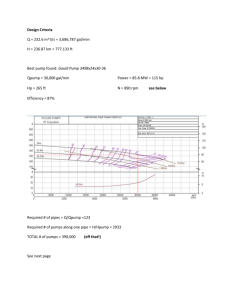

advertisement