Activity costing: twenty years on J. George Staubus

advertisement

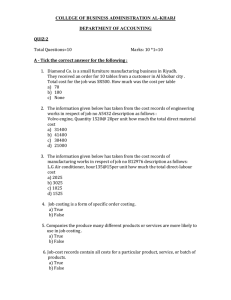

Management Accounting Research, 1990, 1, 249-264 Activity costing: twenty years on George J. Staubus This paper reports on a review of the extent to which the activity costing model (Activity Costing and Input-Output Accounting, G. J. Staubus) has been accepted in practice and in accounting education. Activity costing is a model of cost accounting in which the objects of costing are activities instead of products, e.g. the process of making a product rather than the product made. It incorporates a fundamental economic definition of cost, emphasizes the cost of using resource inputs, recognizes each significant resource rather than three cost elements, treats increments in activity as objects of costing and costs those increments, and attends to asset holding costs and the costs of using plant assets. Evidence of acceptance of those ideas varies from moderate to none. The method called 'activity-based costing' can be interpreted as a rejection of the conventional treatment of overhead in favor of identifying specific services (resources) being put into the processes (activities) being costed. Also, a bit of acceptance of the idea that materials holding costs should be loaded onto materials acquisition costs is found. Otherwise, activity costing has not been a great success in the 'market place'. The unhelpful explanation for lack of acceptance of activity costing is that 'consumers' perceptions of the prospective costs and benefits of adopting activity costing have been weighted more heavily on the cost side. Further inquiry has identified several types of costs: direct costs of operating the cost system (or two cost systems), cognitive and educational costs, emotional costs, and dislike of the results because the model yields higher and more variable costs than conventional costing. Introduction Accounting practitioners a n d teachers have shown more interest in changing cost accounting in the last six o r seven years than in the preceding decade o r so. Terms such as 'activity-based costing', 'activity accounting', o r 'activity costing', appear frequently in the related literature, Cooper and Kaplan [I], D r u r y [2]. M y assignment is to review those developments in relation to a n earlier exposition of 'activity costing' [3].' For those interested in the circumstances surrounding the birth of activity costing, only a few words are offered here. M y selection of the term may have been stimulated by W. J. Vatter's [4] passing reference to Eric Kohler's use of the term 'activity accounting'. Unfortunately, neither of them followed through with a development of activity costing. I had become interested in the decision-usefulness approach to accounting in the 1950's [5] a n d had developed m y thoughts on that approach to *Walter A. Haas School of Business, University of California, Berkeley, CA 94720, U.S.A. Unless otherwise indicated, I use 'activity costing' to mean the system described in my 1971 and 1988 publications. ' Received 25 May 1990; accepted 25 July 1990. 0 1990 Academic Press Limited 250 G. J. Staubus accounting to investors [ 6 ] . After a few years of empirical testing of those ideas, I turned to what I viewed as the next task: developing decision-useful managerial accounting. Activity Costing and Input-Output Accounting was the result. Like A Themy of Accounting to Investors, it was unabashedly normative, based on the decisionusefulness objective. If you want to maximize this, you need that information, which should be gathered according to such-and-such principles. That approach began to bear fruit on the Financial Accounting Standards Board's conceptual framework tree in 1978, just 25 years after it was planted (in the dissertation submitted in December 1953). Is acceptance of activity costing progressing on a similar timetable? This paper is organized as follows: a digest of the essential points in the activity costing view of cost accounting is presented first. The evidence of acceptance of those points in practice or in the literature is then reviewed; that evidence is sparse. The limited degree of acceptance of activity costing begs an explanation; some conjectures are discussed in the next section. A few comments on the role and potential value of cost accounting round off the paper. The activity costing framework I start with the five fundamental ideas in activity costing. 1. The activity focus This is a natural consequence of adopting the decision-usefulness paradigm. Decisions are taken to do or not do something-an activity. Economic actions are based on economic analyses, i.e. costlbenefit analyses of prospective actions. The activity focus contrasts with a product focus that emphasizes the static picture: things that exist. The prospective aspect involves a future orientation, which plays down (but does not ignore) some qualities of financial accounting that are prized, viz. objectivity and verifiability. To serve in costlbenefit analysis, much valuable costing is done outside of the double-entry framework in a style characterized by estimates, round numbers, informality, timeliness, and efficiency. Activity costing includes both systematic and unsystematic cost calculations. 2. Objects of costing Economic activities have objectives-an accomplishment or output aspect. An object of costing (or cost objective) is what one wants to know the cost of doing, stated in rather specific, operational terms. In a loose sense, objects of costing often are synonymous with activities. Specifications related to the unit of measurement (of the output), scope, period, and other circumstances convert an activity to an object of costing. Word processing is an activity in many offices. 'Typing' a double-spaced, standard page of verbal material is an object of costing. The value of cost accounting depends on identifying objects of costing that are of interest to managers. Failure to recognize the importance of objects of costing was a serious weakness in J. M. Clark's [7] otherwise outstanding contribution to costing in which he emphasized 'different costs for different purposes'. That emphasis led generations of accountants on a fruitless quest for different meanings of cost-instead of different objects of costing. Examples of objects of costing are: clearing a cheque (in a bank), servicing a guest room (maid service, in a hotel), paying an employee (in a payroll department). In manufacturing, the unit cost of making a particular product (or Activity Costing 251 part, or operation on a product) might be calculated based on (a) this week's rate of output (level of capacity), (b) a year's production, or (c) a product's life cycle, i.e. costs of designing, producing and marketing a product over a planned life of n months or years (e.g. products with fashion or fast-moving technological characteristics). Thus, several versions of objects of costing related to the same activity could be costed by a combination of systematic and ad hoc procedures. 3. Cost The concept of cost that fits most neatly into the costlbenefit analysis context is the simple, intuitive, unadorned one: an economic sacrifice. In financial terminology, it is an outflow of wealth; in accounting terms, a sacrifice of asset value or an incurring of liability value. Why would one want anything different on the cost side of a costlbenefit analysis? The further specifications that are needed are supplied by identification of the object of costing and by breakdowns of the costs of that object (an activity, remember). Thus, costs are incurred in acquisition (of resources) activities, holding (assets) activities, production (in the broad economic sense) activities, and disposition activities (e.g. cost of sales). Modifications of the basic concept are likely to cripple it. For example, if costs are viewed as incurred only in 'transactions' between the firm and external parties, one is likely to end up with a measure that is not logically matchable with the benefits provided by actions. A resource might be assigned an old price, or be omitted altogether, as usually happens in the case of services of capital funds. 4 . Costs of using N resources Resources are the substance of inputs to activities-the goods that are needed to do the job. It is difficult to analyse and manage activities if one cannot identify the resources that are used. It is difficult to cost an activity if one does not know the costs of the resource inputs. Certain resources used in an activity may come directly from another entity, as in the cases of purchased materials, labour and power. Other resource inputs may be transferred from other in-house activities in which they were 'produced' or 'synthesized' by combining various inputs. Examples of synthetic resources and possible measuring units are: a purchase transaction service; a square-foot-month of floor space; a disbursement transaction service; an hour of machine service (including machine holding costs, maintenance and perhaps power and operator labour); personnel department support services for an hour of labour. Each of these synthetic resources is an output of one activity and an input to another(s). The inputs, and costs, required to obtain each of these resources typically include labour, supplies, electricity, and a variety of other raw and synthetic resources, including others on the above list. Several steps are involved in finding the costs of using a resource: (a) identify the resource input in question as clearly as is feasible. In some cases it may include a loose bundle of services, such as 'personnel department support services for an hour of labour'; 252 G . J. Staubus (b) select a physical unit for measuring the resource input, if possible: pounds, hours, yards, square feet, transactions, etc. (c) measure the usage of resources in physical units. (d) price those units according to the supply adjustment rule, i.e. identify what other action will be caused by using those units (reduce sales, reduce use elsewhere, or, most commonly, add to future acquisitions), then price them accordingly [net realizable value, value in other use, or, most commonly, current cost (including fringe acquisition costs and holding costs)]. Costs of using resources fit into systematic activity costing as unit prices of the activity inputs. They are also viewed as the fundamental building blocks to be stored in a cost data bank for ready use by managers making optimization decisions such as those relating to output volume, technology (input mix), and vertical integration (make-orbuy). Obvious examples include cost per mile for operating a vehicle or airplane, cost per hour of labour service, and cost of an hour's service of a valuable facility such as an assembly line. Strangely enough, textbook cost accounting systems do not yield such information. On the contrary, two typical features of textbook systems are distinctly inconsistent with the costs-of-using-N-resources view: the emphasis on three cost elements (direct materials, direct labour, and overhead) and the use of an amorphous pool of indirect costs (overhead, burden). 5. The cost-benefit test of cost accounting This principle, which was underemphasized in the original exposition of activity costing, must now be listed as fundamental. An accountant should not be caught in the hypocritical position of advocating the cost-benefit test for all other decisions without accepting its rule in accounting. Unfortunately, it is much easier to teach high-benefit costing than cost-effective costing, because the benefits of alternative methods e.g. inclusion vs. omission of the cost of one resource, using current or old prices, may be ranked (but not measured) on the relevance criterion in the class room. In practice, however, the lower-benefit method may be cost effective. Because the costs of accounting are so case-specific, little can be taught about that side of cost-benefit analyses of costing methods in the present state of the art. All we can do is admonish students: be sure to consider the costs. Derivative features of activity costing A few ideas that grow out of the basic notions reviewed above are mentioned here. Because they are of less significance and are quite straightforward to one who is familiar with the above basics, they will be skimmed lightly. 6. Incremental costing Objects of costing are increments in activity, so increments in cost are sought. One chooses the increment in activity when helshe chooses the object of costing. If one chooses to emphasize short-term control uses in designing a system, a small increment in activity output based on the current level of activity may be appropriate. Costing small increments in activity could be labelled marginal, direct, or variable costing. Associated with small increment costing is the concept of variable rate costing: Activity Costing 253 calculating alternative costs of using a resource at different levels of utilization, e.g. with idle capacity and at full capacity. For product pricing, the increment that is of most interest may be large, e.g. a year's or product life cycle's output. 7. Holding costs Explicit accounting for holding costs follows from two of the above basics: holding assets is likely to be identified as a decision-relevant activity in its own right, and associating holding costs with acquisition costs is necessary to obtain the cost of using a resource. Cost of capital typically is the largest holding cost. 8. Plant asset costing Plant asset services often are expensive resources used in an activity. Costing the services of plant assets (which replaces depreciation accounting) is approached as if one were estimating costs on which to base a rental price. The fundamental concept of cost is critical in costing holding activities and plant asset services. 9. Costs not associable with resources are expenses After associating any fringe acquisition and holding costs with labour services, materials, and plant asset services and having identified other resource inputs such as power, set-ups, engineering and production control, the amount of remaining costs may be quite immaterial. Whether immaterial or not, if they cannot be associated with resources being put into an activity, they are not charged to such an activity according to activity costing reasoning. They are 'drained off'--out of the activity network into an expense account. 10. Input-output accounting Accounting for the inputs to and outputs from an activity may be worthwhile for two reasons: (a) the output may be an important resource input to a subsequent activity in a sequence; and (b) the activity itself may justify the accounting. Ideally, an accounting system would provide information for evaluating the performance of every activity and its management. If an activity's output can be measured independently of its inputs by reference to a market price, a profit or loss is calculable. Otherwise, the activity output may be measured at standard cost and variances may be computed and used in performance evaluation. 1 1. The activities network Carried to its logical end, all of an entity's activities are accounted for and related to each other. One activity's outputs typically are inputs to another or others. All are connected in a network that would include some loops. An equation for the current, standard unit cost of using each activity output is seen as the prototypical accomplishment of the cost accountant. The creation and maintenance of a full set of such equations might be viewed as an ideal, even though development of the system to a matrix of thousands of equations is unlikely to be cost-benefit effective. But that way of thinking about cost accounting might be helpful. If nothing else, one should become accustomed to recognizing that a given resource typically is an output of one activity and an input to another or others. 254 G. J. Staubus Evidence of acceptance of activity costing Taking activity costing to mean application of the 11 fundamental ideas laid out above, acceptance might be assessed by reviewing today's cost accounting practices together with descriptive and prescriptive statements regarding cost accountants' observations and beliefs. The results of such a review1 can be summarized succinctly at the outset: activity costing is not widely accepted. It is not even narrowly accepted, except with respect to the idea of abandoning the three-cost-elements approach in favour of the N resources view. I shall commence with that point. Cost of using N resources Activity costing's emphasis on the 'cost of using N resources' was described (above) in four steps. At this point, the four steps may be divided into two sets: (1) identifying the key resources that are 'put into' an activity, selecting a physical unit for measuring those inputs, and performing the physical measurements, and (2) pricing each resource on a 'what-difference-will-it-make' basis. The second part can be dealt with quickly here: I know of no examples of its application in practice, nor even of its discussion in the new wave of cost literature. The N resources approach to identification of activity inputs and outputs has (implicitly) received much more attention. One movement that suggests an interest in ascertaining the cost of using specific resource inputs is the modest trend towards full costing of materials and labour inputs. In the case of materials, this trend appears to take the form of assigning a pool of materials-related costs to products on the basis of direct materials quantities or costs. This practice is recommended by the National Association of Accountants (NAA) [8], p. 6 and is described in reports of systems revisions by two West Coast electronic equipment manufacturers. In the case of labour, the NAA has taken the position that fringe labour costs, such as health insurance, vacation pay, and pension costs, should be included in direct labour, thus striking a blow against one of the most scandalous gaps in traditional American cost accounting textbooks: the failure to teach the computation of the cost of using an hour of labour services. These modest movements towards full costing of materials and labour inputs are steps towards recognition of the 'N-resources' view of activity inputs rather than adherence to the 'three-cost-elements' tradition. Another modest trend away from the three-cost-elements approach is the merger of direct labour and a pool of relatively direct overheads into one conversion rate per hour, as exemplified by a glass products manufacturer and two firms involved in motor vehicle and/or parts manufacturing and as recommended by a well-known management consultant Seed [9], p. 39. This technique is especially appealing when a worker and hislher machine are constant companions, e.g. a motor vehicle and driver, a bulldozer and operator, a piece of office equipment and operator. The work being performed may be viewed as a separate activity receiving labour and machine service inputs and producing an output that might be measured in hours, miles, cubic yards, pages, or whatever. Activities such as those just mentioned, together with many others, may be subject to the 'charge-back' or 'charge-out' method of assigning their costs to 'users' of their services. Techniques that meet this description are recommended by the NAA [lo] for assigning information systems costs and are required by the U.S. Cost Accounting ' I apologize for relying almost entirely on observations of North American practices and views. Activity Costing 255 Standards Board (CASB) for assigning home office expenses to segments in connection with government contract costing CASB [ll], pp. 252-253. A large forest products company is reported to make heavy use of charge-backs. The 'buzz term' of 1990 in product costing is 'activity-based costing' (ABC). The term may be a poor one, as it does little to help the reader visualize the operations involved. It typically is applied to a process of assigning costs conventionally classified as overheads to products. In that context, it has been contrasted with 'volume-based allocation, meaning use of one of the traditional allocation bases. Of course, ABC is just as firmly based on volume, in the sense of the number of units of a base, but the range of permissible bases is extended, e.g. to include number of transactions (orders, receipts, set-ups, etc.). A related buzz term is 'cost drivers' which usually is not defined, an exception being Drury's [2], p. 61 'the forces behind overhead costs'. As indicated by its sudden popularity, 'cost drivers' is an appealing, somewhat colourful, term. Perhaps it represents progress when compared with the old attempts to explain allocation of overhead costs, which typically invoked a cause-and-effect relationship. Unfortunately, 'cost drivers' is only a more colourful term for causal bases of allocation. If you agree that overhead allocation is the most hated and confusing feature of conventional costing, you may doubt whether the ABC-cost drivers movement is in a progressive direction? I think it is, in spite of the poor choices of terms. One versed in conventional cost accounting may see a system described as ABC as involving more careful tracing of overhead to products, perhaps using multiple bases (e.g. materials cost and machine hours) for allocating costs from the same pool to products. Also, a wider range of allocation bases may be used with a number of cost pools in a manufacturing plant, including several number-of-transaction bases, such as orders handled, machine set-ups, or requisitions filled. In other words, ABC could be viewed as more refined application of familiar principles. But there is more to it than that! A number of the ABC systems outlined by its advocates' could be described in genuine activity costing terms: identify activities and their outputs; measure those outputs, trace costs of resources inputs to the activities, divide to get the unit cost of output, then record the transfer of those outputs to final products or subsequent activities treating the unit cost as the transfer price. The output may be a hard product (a machined part) or a soft product (a set-up, an order processed, or an hour of service). Thus, ABC may be interpreted as a hybrid of (1) the traditional search for an overhead base(s) that relates a pool of relatively homogeneous costs to products, and (2) an activity costing system emphasizing resource inputs and product outputs with those outputs typically serving as resources put into subsequent activities, until the final product is done. In my opinion, an organization can gain from thinking of and describing cost assignment methods as the processes of identifying, costing, and tracking resource inputs and activity outputs rather than as allocating direct and indirect costs to products. 'A primary objective of a cost management system is to measure the cost of resources consumed in performing the significant activities of the business' Berliner ' Professors Robert S. Kaplan and Robin Cooper of the Harvard Business School clearly are the leaders of the ABC movement. A close follower is George Foster at Stanford and the leading corporate practitioner: Hewlett-Packard. A giant automobile manufacturer is experimenting with ABC at 17 of its many plants. A 'CAM-I' report by Innes and Mitchell [lo] describes eight other applications. Computer Aided Manufacturing-International is a research and development consortium based in Arlington, Texas, with a European office in Poole, England. 256 G.J. Staubus and Brimson [ll], p. 85. The resource focus is more consistent with an operations orientation, as opposed to the book keeping orientation of cost allocation. Furthermore, costing of resources, such as labour hours, equipment services, a pound of material A used, provides a lot of information for technology and volume decisions, and they may be a mme valuable set of uses than final product pricing. Costlbenefit test of cost accounting Among the main ideas in activity costing, the one that has received the second most attention in the last 20 years is the costlbaefit test of a procedure that is in use or proposed for use. Quantitative tests still are not feasible, but recognition of the propriety of a costlbenefit judgment-+ heightened awareness that systems should not be designed to achieve maximum accuracy in associating costs with objects of costing-is detectable in, for example, the pronouncements of the NAA and the CASB, as well as reports on the development of ABC in several companies. I found several references to the acceptability of rough approximations and the potential for further improvements when circumstances warrant them. To some extent, this could be a change in the rhetoric rather than a change in the underlying thinking of practitioners who have always been cost conscious; American academic accountants have been the last to 'get the word' on the role of information as a commodity that is subject to economic laws. 'Taking into account the cost of information in relation to accounting is not a new phenomenon. It was an understated and natural feature of the environment at the London School of Economics and Political Science (LSE) in the 1930s when and where so much progress was made on economic measurement concepts' Staubus [13], p. 20. Prominent contributors to those developments were Ronald Edwards [15], and Ronald Coase [16]. It is encouraging to see a resurgence and spreading of that notion, especially at a time when data processing costs appear to be falling, thus making more careful tracing of activity costs feasible. Other features of activity costing Evidence of the acceptance of the other basic ideas in activity costing is difficult to find without a microscope. Consider the activity focus. It is doubtful if the popularity of the term 'activity-based costing' represents any increased attention to activities, but perhaps it does in some cases. One well-known academic gives explicit attention to activities as a focus of costing Shillinglaw [17, 181, but does not carry it to the point of building a system based on the measurement of activity inputs and outputs. The notion that objects of costing are activities-doing things--rather than products does not permeate any cost accounting system to my knowledge. Thus, the object of costing notion, or cost objective, or cost object, has gradually picked up some recognition, but it has not been carried to its logical implications for systems design. The most general acceptance of the activities focus that I have found is in the CAM-I book [14] 'Accounting is responsible for measuring the inputs (costs) required to perform an activity. . .' (p. 16). Also, 'Activity accounting is the collection of financial and operational performance information about significant activities of the business' (p. 6). Other examples of recognition are in the NAA Statements and one or two of the descriptions of ABC systems. An interesting and firm expression of opinion relevant to the choice of an object of costing related to the production of final products is: 'Almost all product-related decisions-introduction, pricing, and discontinuance-are long-term decisions' [I], p. Activity Costing 257 224. This judgment contrasts sharply with the marginal-variable-direct costing view that a small increment in output over a short run is the best choice for product costing. In activity costing, the choice of size of increment in production, e.g. a tiny increment, a month's production, a year's production, or output over a product life cycle, is a choice of object of costing. The notion that costing generally means incremental costing--that decisions generally focus on changes (some small, some large) from the present course of activities-has received no noticeable recognition, but at least expressions of devotion to either inflexible position in the variable costing/full costing argument seem to be less frequent now than they were 20 years ago. How about acceptance of the cost concept advocated in activity costing? I find no evidence of its acceptance in practice. A few textbook writers, notably Horngren and Foster [19], p. 20 and Deakin and Maher [18], p. 23, have made a sacrifice of resources the heart of a definition of cost, but in each case they abandon that concept immediately in favour of a conventional view of cost, such as 'monetary units that must be paid for goods and services' [19], p. 2 1. The idea that asset holding costs are a component of the cost of using a stocked resource has fared better than some of the activity costing ideas. The NAA (Statement 4E, p. 6) [8] has taken the position that 'material storage costs prior to purchased material entering production' should be allocated to cost objects on the basis of some measure of direct material quantity or cost-a step towards the activity costing view. A stronger position was taken by the Cost Accounting Standards Board (Part 414): 'The purpose of this Cost Accounting Standard is to establish criteria for the measurement and allocation of the cost of capital committed to facilities as an element of contract cost'. One of the companies associated with ABC says that it uses a type of 'material burdening' that includes carrying costs of components along with acquisition cost as an element of product cost. The CAM-I group also take a firm position: 'Recognize holding costs as a non-value-added activity traceable directly to a product' [ll], p. 13. The approach to costing the services of plant assets (in lieu of depreciation) that fits activity costing generally has been ignored. Only three authorities, to my knowledge, have suggested one or more steps in that direction. The Cost Accounting Standards Board (Part 409) has taken a position contrary to the American Institute of Accountants' notorious approach to depreciation accounting [21]-rational and systematic allocation of cost-by asking that contractors attempt to choose a time pattern of depreciation that fits the pattern of consumption of services over the life of the asset. That position seems to be consistent with the idea that the acquisition cost of a plant asset is the cost of a stock of services and that those services should be costed out as consumed. The other hint is Seed's [9] recommendation that other companies apply the equipment rental concept that is used in the construction industry. An equipment cost centre would 'rent' equipment to production cost centres at rates that would cover repairs and maintenance and holding costs in addition to depreciation. But Seed has found no applications of this approach to equipment costing in manufacturing. The CAM-I group, once again, shows interest: they recommend a current cost adjustment and inclusion of plant asset financing cost in product costs [14], pp. 115-19. The treatment of costs not reasonably associable with zdentifid resource inputs is not easy to describe here. The spirit of activity costing is to search for resources that are put into activities and find outputs of those activities that are transferred as inputs to other activities or are sold to outsiders. Clearly some resources acquired-public relations services and officers' services may be example-re not identifiable as inputs to other 258 G. J. Staubus activities. 'Draining them off into expense, rather than forcing them through the activity network, is recommended as costlbenefit effective in many instances. It is difficult to say whether this view is more, or less, widely accepted than it was 20 years ago. Perhaps the most accurate assessment is that practices vary. The input-output view of activity evaluation does not seem to have caught on. The ideal of measuring each activity's contribution to the success of the firm by comparing its outputs and its inputs is not readily applied in most activities. Independent (non-cost) measurements of outputs of activities in integrated firms are difficult; when they are made in practice those measurements usually are referred to as transfer prices. The more frequently feasible evaluation approach is to measure outputs at standard costs and look at variances as evidence of activity performance. Finally, the activity netwmk view of a cost accounting system as based on a system of standard cost equations with many interdependencies-a large matrix to be solved simultaneously-is only a conceptual model (comparable to complete and perfect markets). One would not expect to find it in practice. Whether it is useful in thinking about, and teaching, cost accounting is difficult to say. In sum, a survey of evidence of acceptance of activity costing in the last 20 years yields a score of roughly 10 to 1 against the home team. Speculations on resistance to 'Reform' Evidence presented in preceding paragraphs shows that activity costing has not been an overwhelming success in the 'market place'. Perhaps something can be learned from an effort to identify reasons for such limited acceptance. Viewing choices of cost accounting systems as economic choices, one is inclined to take a costlbenefit view of the matter. The activity costing model presented at the beginning of this paper and elsewhere can be characterized as ambitious and idealistic; it has not been feasible to temper the positive side of it with firm-specific constraints. The start-up and operating costs of a new costing pattern applied both systematically and informally can be discussed in generalities but can only be weighed against prospective benefits in specific contexts. In the following general discussion, benefits are dealt with briefly, as they have received substantial implicit or explicit attention previously, and costs are interpreted broadly to include perceptions of prospective adverse impacts on personal interests. First, the benefits. The central benefit expected to result from application of activity costing is better decisions, where 'better' means greater contributions to entity objectives, and 'decisions' include those involved in control as well as all of the other choices made by entity managers from among alternative courses of actions they face. Activity costing is premised on economic behaviour, i.e. behaviour based on costlbenefit analysis. Therefore, cost data are relied upon. There is some finite probability that a different cost number will result in a different decision that will yield a different outcome in relation to an entity objective. Thus, substitution of cost of acquiring a resource for the cost of using it, of an out-of-date cost number for an up-to-date number, of a unit cost number excluding the cost of one resource for an all-inclusive cost number, of a crude number based on pooling and allocating a heterogeneous set of costs for costs of several specific resources-any and all such practices yield different cost numbers that can lead to different decisions, some of which will not achieve the desired outcome. Activity costing is designed to minimize such 'mistakes'. Activity Costing 259 A possible benefit of activity costing that might be interpreted as a means to the above end is its educational value. Entities that apply the activity costing philosophy might enjoy the value of a cost-conscious staff. Both accountants and non-accountants might understand costs better if cost accounting is changed from a mysterious ritual to familiar economic reasoning. Similarly, the teaching and learning of cost accounting in universities surely would become more satisfying to both parties if the relationships between cost numbers and entity objectives were visible. The image of cost accounting might be improved in both educational and practical settings. Now, the costs. Application of activity costing in the degree of detail that was described in 1971 is almost certain to be w e costly (in direct operating costs) than the typical cost accounting system. Having conceded that point, I should hasten to add that I believe activity costing is especially well-suited to incremental application. Ideally, one would start with those features that have the highest benefitlcost ratios, then proceed to add other features in benefitlcost order until the breakeven point is reached. While that is easier said than done, surely an intent to proceed in such an economical order is reasonable. A general reason to believe that many firms would find serious consideration of such a plan worthwhile is the set of changes in the operating environment that have occurred since the conventional cost accounting model was developed more than 50 years ago (see Table 1). In particular, reductions in the relative cost of data processing is especially pertinent to the cost of accounting factor. But note Kaplan's [22], p. 195 contrary assessment: 'Thus, complex and not easily modified Table 1 Implications of environmental changes since the conventional cost accounting model was developed -- Circumstances no longer extant Practices that might be obsolete 1. Fringe labour costs were immaterial 2. Indirect costs were low relative to direct labour 3. Costs of using plant assets were relatively low Treatment of fringe labour costs as indirect with respect to products Pooling of heterogeneous costs for assignment to product per one base Uniform treatment of those costs regardless of output rate relative to capacity 4. Few non-manufacturing enterprises accumulated unit cost data 5. Theory of finance and cost-of-capital Concept were not well-developed Focus on tangible products as objects of costing 6. Data processing Costs were relatively high Omission of cost of capital and value orientation from cost measurements Practices with little to recommend them except economy, e.g. one overhead pool and rate Alternative practice to be considered Loading fringe costs onto nominal wage rates Pooling costs by resource inputs Treat costs as activity costs if resource is scarce; charge directly to period expense if not Focus on activities as objects of costing Treat services of capital funds as a resource input to activities. Measure costs of using resources per economic sacrifices Various, e.g. calculate costs of using n significant resource inputs to an activity 260 G . J. Staubus computerized accounting systems provide a barrier to innovative and adaptive changes in the firm's managerial accounting system'. The two-sets-of-books factor may be a deterrent to adoption of activity costing in certain cases. If other cost principles are mandated by financial accounting standards, tax authorities, contracting parties, or compensation agreements, the additional cost of operating an activity costing system may be hard to justify. Cognitive costs may carry substantial implicit weight. Consider the costs implied by concern for understandability and complexity. Some may challenge the suggestion that accountants are unaccustomed to thinking in wealth and income terms, but the economic reasoning embodied in activity costing may be a handicap to its adoption by some of the old timers who would be affected by a changeover. The cost of educating entity personnel may be affected by activity costing's conflicts with financial accounting principles and by the cost accounting that has been taught in higher education. To one who sees substantial potential benefits from activity costing, the dearth of related instruction in institutions of higher education burdens society with costs for which accounting educators are to blame. Another type of cost of adopting activity costing that might be worth separate recognition may be described as emotional costs: loss of comfort, damage to the egos of those who were pleased with their knowledge of costing, costs of overcoming resistance to change. Elusive as these matters may appear, their role in preventing change should be recognized. While conflicts of interests may be related to the above points, a more specific conflict could arise from the probable tendency of managerial perfmance reports based on activity costing to show higher costs of operations. Inclusion of the cost of capital and current costing are specific features of the theory that would tend to increase reported operating costs. Considering the resistance to proposals for use of current costs and price-level-adjusted costs in the context of 'inflation accounting' for external reporting, some of which appeared to be due to prospective negative impacts on reported earnings, one can predict that proposals to adopt costing techniques that would tend to yield higher reported costs would be received unfavourably by the managers involved. Finally, another potential concern regarding the suitability of activity costing numbers for performance evaluations should be mentioned. Certain features of the system can result in volatility of cost numbers. One of these is the variable rate costing technique, whereby the cost of using a resource is recognized as changing as its scarcity status changes. Thus, when a plant asset's services are plentiful (and idle capacity is observed) the cost of using services that would otherwise be lost may be very low, whereas when the facility is heavily utilized the cost of using its services for a specific activity might be very high. This is consistent with observed pricing practices under peak load and slack season conditions. When variable rate costing is followed, the costs of performing the using activity may swing widely from time to time. This might be disconcerting to the manager of the using activity and to those evaluating and rewarding that manager's performance.' Other flexible features of activity costing may contribute to variation in costs as well. Also, as noted above, activity costing puts less weight than conventional accounting doctrine on the reliability criterion of information value. While that reliability/relevance trade-off may be acceptable when use of the numbers in making technological and optimization decisions is paramount, it ' I am indebted to my colleague, Oliver Williamson, for bringing this point to my attention. Activity Costing 261 might be objectionable when they are used in performance reporting. There, the prospect for conflicts of interests makes reliability-especially verifiability and neutrality-relatively more important. In sum, one concludes that perceptions of the above-described costs-and perhaps others-typically have exceeded perceived benefits of activity costing to date. A question to be left for the reader is: which, if any, of the above cost or benefit factors are likely to be perceived differently in the near future? To the activity costing enthusiast, the potential is great. The embedded nature of cost accounting systems and the inexperience of managers at changing them may be the reason we find so few up-to-date systems in use, even though the need for better systems seems obvious to many managers and outside observers alike. [23], p. 117. [Tlhere is . . . considerable evidence that firms do not change their accounting systems easily, a n d . . .that existing accounting systems encompass other objectives not considered by those who favour such changes. [24]. Conclusions The above observations may be summarized in one sentence: perceptions of the prospective costs and benefits of adopting activity costing have prevented it from achieving any significant popularity among practitioners and academics. Neither the prospective costs nor the prospective benefits are easy to estimate. Like most accounting literature, that on activity costing tends to emphasize the anticipated benefits; costs are more circumstantial. One might hypothesize that accountants, who are in the business of producing, but not so effectively selling, financial information, have a positively biased view of the value of our products, especially if we are promoting something new. If so, that bias might be offset by the conservative policy of textbook authors who, under the influence of textbook selectors (teachers) who prefer to avoid changeover costs, continue to describe conventional systems. Under these circumstances, inertia prevails. Readers are invited to join in the game of speculating on prospects for changes in perceived costs and benefits of activity costing. A casual reading of the evidence from the history of cost accounting suggests that those who might be expected to use unit product cost numbers do not place a high value on them-at least not as high a value as producers of those numbers might like. If so, is that explained by (1) sloppiness in application of the conventional model, (2) differences between the conventional model at its best and a high-benefits model such as activity costing, or (3) unavoidable measurement failures, including those relating to departmental and divisional externalities, revenue interdependencies among several products in a product line, long-run effects of start-up 'losses', effects of product quality on firm reputation, and intangible investments such as human resources and intellectual property. A pessimist easily could find bases for predicting a decline in the values accorded accounting numbers and a diminution in the efforts devoted to cost accounting. Accountants would be (are?) foolish to expect others to value accounting products as highly as we do. Our products will have to earn their way in the market place. On the other hand, the value of the activity costing paradigm does not depend so heavily upon the quality of its accounting for final products. A key feature of activity costing is the calculation of the cost of using a unit of a resource in an activity. True, 262 G . J. Staubus one cannot determine the cost of using an hour of labour perfectly in the absence of human resource accounting, but perhaps substantial improvements in our estimates can be made at acceptable costs. Emphasis on the cost of using resources might encourage comparisons of costs of alternative technologies and make costlbenefit analysis a more natural feature of every decision-taker's work. One way to think about our dissatisfaction with conventional cost accounting systems (note the premise here) is to ask what 'we' do when the system does not produce a number that is judged to be at all relevant to a specific decision being faced. Many textbooks have a chapter on 'relevant costing' (which raises a question regarding the characterization of the material in the other chapters). Those who find the relevant costing, capital budgeting, and other decision model-oriented chapters more satisfying than the chapters on systematic cost accounting might ask why. Is it because they (a) have an action focus, (b) consciously identify an object of costing, (c) employ an economic concept of cost, (d) identify each specific resource required to complete the action (rather than three cost elements), (e) deal with the cost of using those resources now rather than the cost of acquiring them in the past, and (f) address the cost of capital (or return on investment)? If so, they like activity costing. Why not introduce some of those features in the cost system and in the basic model of cost accounting in textbooks, instead of treating those features as variations from the real cost accounting? Or, if those features of activity costing are viewed as not acceptable in the basic cost accounting system, give more emphasis to them by placing them 'up front' in the text for the benefit of the non-accountants who will be forced into do-it-yourself cost analyses throughout their careers. The less useful the products of the basic accounting system, the more important become ad hoc analyses (extra-system calculations), so the more people in an organization need to feel comfortable with costlbenefit thinking. In short, if one appreciates the features of activity costing listed above, the activity costing paradigm surely would be their choice of models for teaching costing to enterprise practitioners as well as to students. Like other general models in accounting, e.g. matching costs and revenues, the activity costing model may be worthwhile even if application in its pure form is not feasible. Before closing, an observation somewhat independent of the above notes may be of interest. In the context of emphasis on the importance of quick responses to market conditions in the high-technology, global market, changing-tastes world, one might expect an increasing emphasis on the economics of speed (or time). Because asset holding costs have a special connection to time, those concerned with the economics of speed might well become more aware of holding costs and more insistent on accounting for holding costs-even as shorter product life cycles and faster inventory turnover decrease the relative weight of holding costs. Finally, a point that has arisen recently in connection with developments in the economics of the firm associated with names such as Coase [25 and elsewhere] and Williamson [26 and elsewhere]. We are beginning to recognize what I call 'the role of accounting in the integrated firm', i.e. all firms as we know them. The integrated firm removes selected interactivity transfers from the domain of market transactions and places them in the domain of intrafirm decisions. Actors engaging in market transactions are informed by-use as information inputs to their costlbenefit analysesobservable market prices. By contrast, actors engaging in intrafirm transfers have no 'setting-specific market prices' [27] to observe, so depend on accounting numbers as measures of the costs of using inputs to an activity and the benefits of producing Activity Costing 263 activity outputs. Activity costing is designed to serve this 'role of accounting in integrated firms' [28], pp. 250-251; Coase [29], p. 9 . References 1. Cooper, R. and Kaplan, R. S. How cost accounting systematically distorts product costs. In Accounting and Management: Field Study Perspectives, Boston: Haward Business School Press, 1987, pp. 204-228. 2. Drury, C. Activity-based costing, Management Accounting 67, 60-63, September, 1989. 3. Staubus, G. J. Activity Costing and Input-Output Accounting. Homewood, IL: Richard D. Irwin, 1971. 4. Vatter, W. J. Tailor-making cost data for specific uses, NACA Bulletin, Confmence Proceedings, p. 1697, 1954. 5. Staubus, G. J. An Accounting Concept of Revenue, Ph.D. Dissertation, University of Chicago, 1954; New York: Arno Press, 1980. 6. Staubus, G. J. A T h e w of Accounting to Investors. Berkeley, CA: University of California Press, 1961. 7. Clark, J. M. Studies in the Economics of Overhead Costs, Chicago: The University of Chicago Press, 1923. 8. National Association of Accountants Management Accounting Practices Committee, Statements on Management Accounting, No. 4E, Definition and measurement of direct material cost. Montvale, NJ, 1986. 9. Seed, A. H., 111, Cost accounting in the age of robotics, Management Accounting ( U S ) , 66, 39-43, October 1984. 10. National Association of Accountants Management Accounting Practices Committee. Statements on Management Accounting, No. 4F, Allocation of information systems costs, Montvale, NJ, 1987. 11. Cost Accounting Standards Board, Cost Accounting Standards. In Code of Federal Regulations, &Accounts, Washington, D.C.: U.S. Government Printing Office, 1980. 12. Innes, J. and Mitchell, R. Activity accounting case study summaries, Cost Management Systems Phase 111 Research, Arlington, TX: Computer Aided Manufacturing-International, 1989. 13. Staubus, G. J. The development of accounting in firms. Unpublished manuscript, University of California, Berkeley, 1990. 14. Berliner, C. and Brimson, J. A. (Eds), Cost Management for Today's Advanced Manufacturing: The CAM-I Conceptual Design, Boston, Harvard Business School Press, 1988. 15. Edwards, R. S. The rationale of cost accounting. In Plant, A. (ed), Some Modern Business Problems. London: Longmans, Green, 1937, pp. 275-299. 16. Coase, R. H. Business organization and the accountant, The Accountant, October 1December 17, 1938. 17. Shillinglaw, G. Managerial Cost Accounting, 5th ed. Homewood, IL: Richard D. Irwin, 1982. 18. Shillinglaw, G. Managerial cost accounting: present and future, Journal of Management Accounting Research, Fall, 33-46, 1989. 19. Horngren, C. T. and Foster, G. Cost Accounting: A Managerial Emphasis, 6th edn, Englewood Cliffs, NJ: Prentice-Hall, 1987. 20. Deakin, E. B. and Maher, M. W. Cost Accounting, 2nd edn. Homewood, IL: Irwin, 1987. 21. American Institute of Accountants. Review and resume, Accounting Terminology Bulletin, No. 1, 1953. 22. Kaplan, R. S. Accounting-lag: the obsolescence of cost accounting systems, Califmia Management Review, Winter 174-199, 1986. 23. Bruns, W. J. Jr. A field study of an attempt to change an embedded cost accounting system. In Bruns, W. J. Jr. and Kaplan, R. S. (Eds) Accounting and Management: Field Study Perspectives, Boston: Haward Business School Press, 1987, pp. 97-1 18. 264 G. J. Staubus 24. Bromwich, M. and Bhimani, A. Management Accounting: Evolution not Revolution, London: Chartered Institute of Management Accountants, 1989. 25. Coase, R. H. The nature of the firm, Economical, pp. 386-405, 1937. 26. Williamson, 0. E. The Economic Institutions of Capitalism: Firms, Markets, Relational Contrating, New York: The Free Press, 1985. 27. Staubus, G. J. The market simulation theory of accounting measurement, Accounting and Business Research, Spring 16, 117-132, 1986. 28. Staubus, G. J. Activity Costing for Decisions, New York and London: Garland Publishing, 1988. 29. Coase, R. H. Accounting and the theory of the firm, Journal of Accounting and Economics, 12, 1-11, January 1990.