Fiber to Waveguide Couplers for Silicon Photonics Trisha M. Montalbo

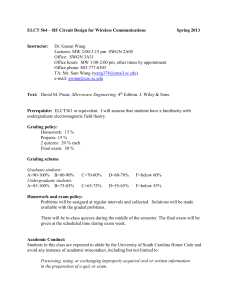

advertisement