Process-Based Cost Modeling of Tool-Steels Parts by Transient

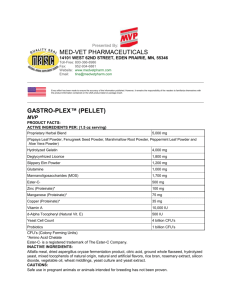

advertisement