Document 10974517

advertisement

CHEMISTRY OF THE SULPHITE PROCES S

VIII . Studies of the Acid Hydrolysis of Woo d

By

R . N . :fille r

Chemist in Forest Product s

an d

W . H . Swanso n

Assistant Wood Technologis t

The species of wood which serves most commonly a s

the raw material for the manufacture of sulphite wood pul p

is white spruce . Balsam fir and hemlock are also used, an d

other species in smaller quantities .

The composition of spruce wood, as recorded in th e

literature, varies considerably with the :methods employed i n

the analysis . Practical agreement is found as to the mai n

constituents, but Tlot as to their exact grouping . A typical

analysis by Klason- gives : Cellulose free from pentosans ,

53 per cent ; hemicellulose, 15 per cent ; lignin, 30 per cent ;

fat, resin, and proteins, 2 per cent .

Johnson and Hove y

find cellulose, 50 .33 per cent, lignin, 24 .44 per cent a s

constants for balsam fir . The methods of Schorger_ at the

Forest Products Laboratory show as a typical analysis o f

spruce wood : Cellulose, 55 .4 per cent ; lignin, 28 .3 pe r

cent ; pentosans, 11 .8 per cent ; soluble in 7 .14 per cent

sodium hydroxide, 18 .55 per cent ; soluble in 1 per cent

sodium hydroxide, 8 .8 per cent ; soluble in ether, 1 .24 pe r

cent . From these results it can be seen that while the distribution of constituents may vary, spruce wood may be take n

to consist of a more resistant carbohydrate called cellulose ,

certain less resistant carbohydrates (called variously hemicelluloses, pentosans, etc .), lignin, and extractives, whic h

1Svensk Pappers Tid ., 26, 319-22 (1923) .

-Paper, Vol . 21, 40 {1918) .

3J . Ind . Eng . Chem ., Vol . 9, 556 (1917) .

R33

latter class may be defined as materials consisting of resinous and fatty bodies soluble either in a mixture of benzen e

and alcohol or in ether .

The analytical methods employed in the presen t

study were : (1) Schorger's modification of Cross and Bevan' s

chlorination method for cellulose ; (2) lignin determination

by means of 72 per cent sulphuric acid ; and (3) Allihn'smodification of Fehling's method for determination of reducing sugars . It is appropriate to note here that when th e

terms cellulose, lignin, etc ., are used in connection wit h

experimental results, they refer only to the material as

defined by the analytical methods used .

Cross and Bevan- and Cross and Engelstadt6 hav e

advanced the idea that sulphurous acid is the active chemica l

in the sulphite process . More commonly the view is held ,

however, thet the part of the cooking liquor known as "free, "

that is, all acid in excess of a monosulphite compound of th e

base, is the active constituent . The concept of the reaction s

of the sulphite pulping process that has at times seemed t o

the authors of paramount importance is that it is, from on e

point of view, essentially an acid hydrolysis of wood . Th e

reaction from the standpoint of hydrolysis has therefor e

been made the subject of special study in the work reporte d

here, and the results are interpreted from that point of vie w

throughout .

The behavior of wood toward hydrolytic attack a s

been studied under a variety of conditions by Kressmann, L

Sherrard and Blanco, . Haggland,

Klason,?G and others .

Generalizing from their results it may be stated that spruc e

wood when subjected to hydrolytic attack will yield a variet y

of reducing sugars with more or less marked reduction in th e

amount of stable cellulose, and with little or no change i n

the lignin content of the wood except in the presence o f

sulphurous acid and bisulphites .

4J . Assn . Off . Agr . Chem ., pp . 107-108, (1916) ; see als o

Leach, Food inspection and analysis, 4th ed ., p . 633 .

- A Textbook of Papermaking, 5th ed ., p . 73 .

-J . Soc . Chem . Ind ., 43, 253T-357T ; also Paper, Vol, 34 ,

No, 18, Aug ., 1924 .

-U . S . Dept . of Agric . But . 983 .

J . Ind . and Eng . Chem ., Vol . 15, No . 6, p . 611, June, 1923 ,

gSvensk . Kern . Tids ., Vol . 35, pp . 2-24 (1923) .

--Paper, Vol . 35, No . 1, Oct . 23, 1924 .

R33

-2-

Hydrolysis of Wood with Hydrochloric Aci d

It seemed rather desirable at the start of thi s

study to establish a conception of the acid hydrolysis o f

wood in terms of the analytical methods to be employed an d

under a range of conditions, as re7,ards destruction of cellulose, comparable with those obtaining in bisulphite cooking .

To this end hydrochloric acid in a graduated series of wea k

concentrations was selected as the hydrolytic reagent, an d

white spruce, ground to pass an 80-mesh but to remain on a

100-mesh screen and extracted with a mixture of benzene an d

alcohol in proportions of 2 to 1, as the wood to be hydrolyzed .

The hydrochloric acid was prepared in a series o f

concentrations ranging from 0 .05 to 3 .00 per cent . Five gram samples of the finely ground wood were heated wit h

100 cc . portions of the acid in a water bath at 96° 0 . ,

under a reflux condenser, for 5 hours . The loss in weigh t

suffered by the wood was determined and the residue Was examined for cellulose .

The extract from the wood was divided into tw o

parts . In one the reducing sugars were determined directly .

The other part was rehydrolyzed by boiling again under a

reflu condenser for 3 hours with 3 per cent hydrochlori c

acid, -L2- and the reducing sugars were determined as before .

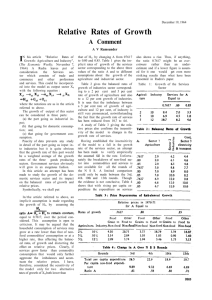

The results obtained in both treatments are shown in Table 1 .

The loss in weight suffered by the wood under th e

primary hydrolytic treatment increases decidedly as the aci d

concentration is increased, until 0 .75 per cent is reached .

From that point on the loss in weight becomes nearly enoug h

constant to suggest either a marked decrease in the rate o r

reaction or else a complete cessation . The latter is unlikely ,

as it has been shown that mineral acids may bring about complete resolution of the carbohydrate material of wood upo n

treatment at high concentrations . Rather, an acid concentration of 0 .75 per cent seems the point of differentiatio n

between two parts of the carbohydrate material with respec t

to their resistance to such hydrolytic conditions as ar e

represented in the experiments .

11

--The quantities marked with an asterisk (*) in Table I

(fourth column) were obtained with 1 .5 per cent and 2 pe r

cent hydrochloric acid respectively and are therefor e

somewhat low .

R33

-3-

Table 1 .--Hydrolysis with hydrochloric aci d

(All results are expressed as percentages o f

the weight of the original wood . )

Con- : Weight : Reduc- ; Reduc-- ; Cellu- : Lignin : Cellu- : Mate cen- : loss :

ing

ing :lose in :

in

lose : rial

tra- :

on : sugar : sugar :residue :residue ;

loss : enac tion : hydro- : formed : after

on :counte d

of : lysis : during :rehydro- :

hydro- :

for

HC1 :

: hydro- : lysis .

. lysis .

. lysis .

Per

cent :

0 .05

.10

.15

.25

.50

.75

1 .00

1 .50

2 .00

2 .50

3 .00

Per .

cent

Original

9 .88

:

12

.72

.

: 14 .67

: 14 .75

: 18 .33

: 20 .13

: 20 .16

: 18 .78

: 19 .28

: 20 .17

: 20 .95

Per

cent :

wood

2 .31

:

3 .50

4 .54

:

7 .32

: 12 .52

: 16 .15

16 .37

: 14 .12

: 15 .24

: 16 .37

: 17 .54

:

:

:

:

:

:

:

:

:

:

:

Per

cent

: r Per

cent

6 .59 :

8 .57 :

12 .07 :

13 .15 :

16 .28 :

19 .00 :

18 .05

17 .34* :

17 .48** :

18 .67 :

19 .40 :

58 .88

51 .18

50 .96

50 .08

50 .89

49 .06

48 .31

48 .61

48 .74

48 .62

48 .79

48 .70

*Rehydrolyzed with 1 .5 per cent HC1 .

**Rehydroly

with 2 per cent HC1 .

.

:

:

:

:

:

:

:

:

:

:

:

:

Per

cent :

28 .55

28 .55

28 .55

28 .55

28 .55

28 .55

28 .55

28 .55

28 .55

28 .55

28 .55

28 .55

Per : Pe r

cent : cent

:

:

7 .70 :

:

7 .92 :

:

8 .80 :

:

7 .99 :

:

9 .82

: 10 .57

: 10 .27

: 10 .14 :

10 .26 :

: 10 .09 :

: 10 .18 :

12 .5 7

13 .6 8

11 .9 2

9 .3 0

7 .41

66 .1 1

4 .1 4

4.7 9

5 .3 7

5 .35

3 .9 9

3 .35

The determination of reducing sugars (column 3 )

shows a reduction in rate of their formation at about th e

The de

same point as the reduction in rate of weight loss .

e

rehydrolysis

of

th

termination of reducing sugars after

4)

show

s

extract with 3 per cent hydrochloric acid (column

y

an approach to constancy quite comparable to that shown b

the loss in weight of wood ; not only so, but the reducin g

sugars now fall but little short of accounting for the whol e

loss in weight . From these results it seems that the carbohydrate material of wood most subject to removal by the mil d

acid hydrolysis represented is, in part at least, removed a s

a nonreducing body and is further broken down by the rehydrolysis .

This is in cc;formation of earlier observations of

Sherrard and Blanco . The values for cellulose in the residue (column 5 )

show a slow decrease in the earlier range of the hydrolysis .

The highest of the figures after hydrolysis is, however, i n

marked reduction from the initial value, 58 .88 per cent, obtained on the unhydrolyzed wood, and shows that part of th e

carbohydrate material included in the cellulose determination

in wood, as performed at this Laborato4y, is much more susceptible to hydro tic attack than the rest .

Similar effect s

are noted by Dore

and also by Johnson and Hovey in thei r

work on the analysis of wood . The former includes, in hi s

analytical summary, determinations of material soluble in 5

per cent caustic, besides mannans, galactans, and unaccounted for pentosans . The latter investigators provide a preliminary hydrolysis with acetic acid and glycerine as one ste p

in the determination of cellulose in balsam fir .

s

From the foregoing analysis of the data, it is evident that the carbohydrates that are removed from wood b y

acid hydrolysis of varying intensity, within the range examined, come from at least two different sources or groups o f

bodies, and with different degrees of reluctance .

Again, if it is assumed, as is done throughout thi s

paper, that the hydrolytic action does not alter the inerti a

of the cellulose toward the manipulations of the cellulos e

determination, it is interesting to observe that the reduction in cellulose in the experiment with the weakest aci d

is approximately equal to the reducing sugars formed, an d

that the reduction in cellulose does not increase greatl y

with the more drastic treatments . From Table 1 it can b e

12

T . Ind . and Eng . Chem ., 15, 1166 (1923) .

13

--J . Ind . and Eng . Chem ., 12, pp . 264 and 476 .

R33

-5-

seen that the material unaccounted for, obtained by addin g

together the analytical results for lignin, cellulose, and

reducing sugars after rehydrolysis, and subtracting from 100 ,

decreases slowly as the strength of the acid increases . The

loss in cellulose reaches a slow rate of change early in th e

series, whereas the reducing sugars in the rehydrolyze d

extract increase at a rate comparable to the reduction i n

amount of material unaccounted for .

It is, therefore, possible to conceive of the carbohydrate materials of wood a s

existing in three groups :

(1) Those most resistant to hydrolytic attack and, (2) those least resistant, both of whic h

are grouped as cellulose by the analytical method ; and ( 3 )

a class of intermediate resistance, referred to by variou s

writers as pentosans, carbohydrates other than cellulose ,

etc .

Hydrolysis with Sulphite Cooking Aci d

Next, for the investigation of the acid hydrolysi s

of wood under conditions related to the foregoing but als o

favorable for the removal of lignin, that is, with sulphit e

cooking liquor, a special apparatus was contrived and a technique developed .

Apparatus

An autoclave of bronze, capable of withstandin g

high pressures and the solvent action . of the cooking acid ,

was the digester used . Details of its construction are shown

in the accompanying sketch (fig . 3) . It was heated in a well insulated bath of oil .

Heat was supplied by two "Simplex st

electric imi ersion heaters of 440 watts capacity, operatin g

at 110 volts . One, the primary heater, was connected throug h

a rheostat with the source of current . This heater was use d

constantly, and with proper adjustment of the rheostat woul d

maintain the oil within 2° or 3° of the desired temperature .

The secondary heater, furnishing the heat required to maintai n

the bath at the exact temperature, worked intermittently .

It

was connected to the source of current through a relay circui t

breaker actuated by an adjustable mercury thermoregulato r

immersed in the oil .

Temperatures up to 150° C . could thu s

be maintained within +0 .5° C . of that required .

Eodifications of procedure were made to correct fo r

irregularities that appeared in the preliminary runs, and th e

experimental procedure as now used may be described in detai l

as follows :

R33

-6-

.r

4

r

l

F

5c&€~. f-inc h

BRONZE

AUTOCLAVE

FoR

SULPHITE COOKING

1

Preparation of Woo d

Spruce ground to 40--60 or 60-80 mesh size was th e

material cooked . It was extracted with a 67 per cent benzene ,

33 per cent alcohol mixture for 6 hours in a Soxhlet extracto r

in order to remove resins and waxes . Also, the wetting of th e

wood was thus enhanced . The sample for cooking was weighe d

approximately into a weighed aluminum can . Can and content s

were then dried at 105° C . for 5 hours, cooled in a desiccator ,

and weighed to determine the oven-dry weight of the charge .

About 15 grams of wood made a convenient portion . The woo d

was then transferred to a 250 cc . tall form pyrex beake r

cut off just below the lip, making a size which fitted conveniently within the autoclave .

•

41,

Liquor Preparatio n

The cooking liquor was made up in 250 cc . quantities, which amount was sufficient for one cook . Stock solu tions of sulphurous acid and sodium bisulphite make a satisfactory source, respectively, for the acid and salt used i n

the liquor making . The two solutions were analyzed in th e

usual manner with N/16 iodine solutio to determine the tota l

sulphur dioxide . The Sander analysisl4 was used to determin e

the oisulphite in the bisulphite solution . Five per cent

total sulphur dioxide for the sulphurous acid and 7 per cen t

for the bisulphite solution were convenient strengths for th e

stock solutions . From the analysis the correct quantities o f

each solution necessary to produce the desired concentratio n

of cooking acid when diluted with distilled water to 250 cc .

were calculated . After the acid was made up, its compositio n

was checked by analysis .

Two hundred cubic centimeters of the acid wer e

siphoned into the beaker containing the wood, and 40 cc . mor e

were poured into the autoclave around it .

A lead disc wa s

placed over the beaker, after which the autoclave cap wa s

tightened on .

Cocking

The oil bath having been brought to a temperatur e

8° to 10° C . above that at which cooking was to be carrie d

on, the autoclave was immersed, and when the temperatur e

had dropped to the desired point, usually in about 5 minutes ,

the thermoregulator was adjusted to maintain it there . The

time at which the desired temperature was reached was take n

. See Miller and Swanson, Paper . Trade J ., April 13, 1922 .

R33

-7-

as e starting point of the cook . When the autoclave ha d

`., 'e; ' -, been in the oil for the intended length of time, it was

withdrawn and cooled in a bucket of water .

was the n

ate ' opened, the beaker and contents were removed, and the pul p

was separated from the liquor on a filter folded to fit a

•_« ' Buchner funnel . The paper had previously been dried a t

.•. 105°

C . and weighed in a covered aluminum dish .

-,

a

se.

After filtration and washing with hot water th e

~x<< ,

pulp was air dried for 16 hours, oven dried for 5 hours a t

105° C . in the aluminum weighing dish, cooled, accuratel y

f

weighed, and the yield thus calculated . The pulp was the n

analyzed for lignin and cellulose in the manner noted earlie r

e-,. .* ;

in this paper .

.4

It

The results of the analyses are recorded in Table 2

and are shown graphically in Figures 1 and 2 . The figure s

for yield, or residue after cooking, follow a descendin g

curve with increasing time, but at a decreasing rate of chang e

that becomes quite slow in the later stages .

The curve showing the removal of so-called cellulose material (as define d

by the application of the Cross and Bevan method) indicate s

a rapid onset followed by a slow continuation in the late r

stages of the reaction . The rate of removal of lignin i s

- steady up to about the twelfth hour but decreases thereafter .

The relts confirm those previously obtained on a large

scale . The reaction involving the removal of carbohydrat e

material from the wood shows certain similarities to that i n

, the previous series in which hydrochloric acid was used . The

reduction in amount of material determined by the application

of Cross and Bevan's cellulose method to the residue after

cooking is, as just stated, rapid at first and reaches a

slowly changing value early in the series .

The quantity o f

so-called cellulose showing a resistance to prolonged aci d

eatment at the higher temperature used is very close t o

at which in the previous series showed resistance to in creased concentration of acid . That the resistance is no t

perfect is shown by the lower values appearing, especially ,

. 'With further reference to the analysis of wood acrding to Dore, or the results of Klason, attention is agai n

rected to the group of poorly defined materials of carbohydrate nature which are not included in the part often re ' erred to as cellulose . 7 In the first1 series of experiment s

'd

4-3

o

0

cd

to

d

I

a) 4-1

w o k

.' o

'd

1b

a) -p

r

s~

o

~•,

1-4

H

O Fi

r-1

all

co 0 o tA? r-1 ad '

O

N o

. ra 0]

p:, cd

ri O

. . . . . . .. .. . . . . . .

a)

C)]

a)

u) ''d •H

H 0] + 3

o as w Cd o

H

rd 41

r I Q)

O A q •H

w

r-1

ECG r4 a)

r1 a)

•H r-r k

a)kO

k0 p7.

0 0

H

u)

rq

o

0

I

to

fl

.H

k

4-4

a)

I

a)

1

I

k

111(11 LON Lf1 H f- tf N

to al O [t1 t+ rrO c\

J

CU 150

t r. CV CV r-4 CU

H

a)

1 p,

..

.. . .

1

0

1

k

I

1

'do

s

4s

I +3

1 G

1

a]

o

a)

1

r

l

1..1 rja H r- C7! O 150 '60

ry-N_- r- N N sN■.D ■..0

r

C r-150 CNCT 0

HHHH N

a)

k

•

• Lr)lo Cn o

t ,o L▪f 1 - ■.o

LC'1r~10 r-1 H tv r-

+3

q O 'd

In

,o

. .

. .

. .

1

a

'J+

01■.A rr 1LO l0 0 0 1

i.n■.o

LD r-i ■.D Q

5o CV 0 I~ LC1 C7O r-l r-1

Lr1~D r- r-tO 60 ON O N

E

to

4-4 a

1)

I k

t-locor-4P

o w

r-i q d o 0 'CI Q- I P< 0

r 1

I.

..

•

H

.p

• d •rI [d f~

I

r1 a) CF2

•ri a)

1 a5

1~ q cd

s~ w

1 q

taf) o ,o c i

bU Q)

I

O •*a .H k

1 F-1

4-4 a)

f••1 H R

I a)

F< O

O

I P.

•

•H

•r 1

~..,

'd

r

+3

co 4-i (I) o k l

•

- Q ,O q O rd

I P+

o

..

0

to to C1. 1

OH

01N 0■ .D H

r

■

▪

rnCl1rfoNoCV

o

r-r N ■ .C] 150 150 CSr C7-N

ou O - Lh r-i'- In ON ~Q MD \-0 0

■

. ■ .

IS1 r-I \-0 O LC1 N1 CU CU

CV C1.1 r-i r- i

X50 ,-r LC1r0 [1J C7r r \ N

1•rr\ H tO H tO H O

▪ f- ts-N r- ova if1 r n

1

CV (\I o) 1 r'I

-H

4-3

w 4i N ~+ H

Fi 0

o p

)

Q O' d P . 1 R. C

..

.

4-s r+

I +-'

oHSM 0%-t

s~

'd 0

'd 'd

r a)

w r o

1 q

b l

O

r•-l 0 0.. . H

•

r i '~

ad

I a)

• 0 o IP- F

+3

1

I

ttO

P.

•rt 4-4 a) r-+ i cd

w o Fi t F- +

▪

Cab fo

1 0

. . . . . . ..

I w

I

trd

„` C

1 H

Fi o 4-i o

.H o o

1 o

Q +3

q

4-3

I w

bit b s~

I E

a) Oo k

1 k

q 'd I o

OR

Sd

q 0

I

C.)

I

LC1 LC1 1• r1■..0 rrN ON 0

fi4 rr1 C31■,0 0 H O 0nioO;CJ\Or-;Hi 0

ON r 6 0 o tD L LC) LC' LC)

.

tO 60 150 LSN'60 e ^E r- a

N -\ CU Li-) HA- r-\ID 0

Lnr` CL' 150

r+' I

oHLrf . 0to

▪ ('U C] ON t5) 150 1` fHH H

r-! T41\0 0 CU 11\150 H

r I r-I H CU

t.ovd- a . to H

H -1- Kr. r--.-l- 'AD

m r~ r-10 to to o r`

0000OHH O

Lfl UN LC\ 111 LC \ LIN LC1 L f

H H H H H H r-I r- 1

hhlD o10 150 t- L[ l

E- r- r~ r` 150 r- r- f-9 -

..

rd

r

a)

•rl

!~

N

0

0

•

•rl a) a) q

to r-i U o o 0

fw Fs fi F c

•

ID

a) G.)

.0

0

PL1

a)

0

E

° 000 0

.

•

O

1-‘N

nir-r-i

to

o to

n.1

150

tO

0

CJ]

to•

CV

0

o

q

on 0 c

rn0 w

Fi

H

•r-1 Ca

•

a) cd to ,P a )

+3 a) E. O

co

to

014 q m

q

r-1

a)

E ' IT, rJ

-H

c-I

w

1-1

U r

4

•d

-•

r- r

to •H

cd

to

'd H 'd

tt3 •ri r ~

o

•

•

•

'

•

1

r

ZtI~1°

t

o

-

,

Q

tu

LL

0'

oQ

~. ( o,

4o

I

I

I

iza

r

_

N

1

F

a

ca.

4

O

Lt.

(

°

'

q V

-4

_

$

N

.

Uj

v

Qe

tt.i

e

C

Lt.

O

k

Q

#

r

4

V.)

m

ftti

_

_

w

w

N

W

C

ii ow ~~I 1 N~.7

b1Zcy

(Table 1) considerable proportions of these ordinarily unaccounted for substances were left in the wood residues afte r

hydrolysis . In the second series the more complete degradation of the wood has been accompanied by their more nearl y

complete removal . (See Table 2, last column . )

In the first series it was shown that a part of th e

carbohydrate material defined as cellulose by the analytica l

treatment was very susceptible to mild hydrolytic attack ,

and that the materials unaccounted for in the analytica l

methods used, and frequently defined as pentosans, are mor e

resistant .

The same conditions can be seen to exist in th e

second series . The values for cellulose based on weight o f

original wood show an immediate initial drop, while the portion of the residue unaccounted for in the analytical method s

used shows a continuous decrease, but without reaching zero .

The latter fact hould occasion no surprise, as it has bee n

shown by Sieber t and others that sulphite pulps always contain a portion of furfural-yielding bodies .

Of especial interest is the fact that the part o f

the cellulose most susceptible to hydrolytic attack is re moved so easily, with or without accompanying lignin removal .

or does there seem to be any interdependence whatever between the removal of lignin and that of the carbohydrate s

other than cellulose, the latter having been reduced practically

minimum before the lignin had been remove d

even to the extent of one-half .

to the

The general similarity of the results obtained i n

the two series of experiments indicates that the reactio n

upon the carbohydrate materials of the wood remains unaltere d

by the presence or absence of lignin ,

RelativeEffects of Acid Concentratio n

and of Temperature upon Cooking Tim e

The idea of a differentiation between more and les s

stable carbohydrate material in the wood having been forti fied by the results of the study thus far, it seemed desirable to examine the reactions under different but comparabl e

conditions of temperature, acid concentration, and time o f

,poking .

To this end the series of cooks, results for whic h

are tabulated in Table 3, was performed . The aim in all instances was to reduce the lignin to between 1 and 2 per cen t

of the weight of the wood .

0

ra q

a)

cdR

0

r-I

7 q

0

d~HH

cDp)

HI

•

rd

•

r--I

HI

a)

•.

• r1

•r

d o

• . •• a . ••

I

a)

p4

S

■

j

H

q

co

1

d

I

ca

+3

0

N-'D 0 x1150 UN ri 01 rr t~}

t1J . f 150 '60 P'-1 r-1f1 CV .- a• r\ 1w 1 Q

.■ .■

■• •

1E0 1.0 L0Eq ~D L \r--N-CO'-0u-1

1''-') LC')

r-r-P r\{-'15O ro f-II10 Pr\

O~ U' W 0 .••I bQ .•-I 0 CV - t r~1

H

• • •

.

•

I G) ID 4' .- LC1 LC\LO r+1 L0 Lf 1 11140 ‘ .I) CV

p4 U ON Oti ON ON ON ON O\ ON ON ON ON O N

I

H > ■Pr . C7

r -I a) co q

H4

a) ca rd

'd

0 0 A 4-I p,,

ri

q

H

a)

•0 W

I

150 HLO .-4 r-a1NlCV . E.0150 I 4 LQ O10150 r. 1•- CV CV I-150 0

a

■

• • a ■

LO Q1150 01 o1 p to \D a7 . a cu

ri r•i r••! HI HI CV Hi HI r-1 H H CU

0

U

i I

I

q H?.'d

G`

O 4A4a~

H 0

rI

S

I

I

a] p.

H a)

•

+3

a)

co

El

k

H

to d

•H

..

+yw

iC

0

4-i

#12I

+>

s~ 0

q {

p CI

a7, Cu LIN NA- 150 1 .I1tD 010 .4- A-Lf

•H .

bO r-1 •H a) I

+-2 180 (VA- I- r . CV 0 153 L0 t0 O CV '

QQ ci .

GO 1 H

• • • .

■

H w 7,1 ~

a) ! a)

l.n LCl LW L0 LC1_1- LD LO L0 O

•H 1) cd d •*-1 •H F-i I R . 0, ON 0\O1D1OA01Ol0101O 0101

r 7 f-1

,o

r-1 f:7. I

0O O• 04 •* 00 00 •0

0 . •0 00 •0 OO RD 09 "

0o •• WO 0 .0 •0 Oo •• • 0

•

a)) I

I

I

+a

LC1 LtV 0 C& 01\0 CV CV ti.f NC

'd

•

H HI CLI \0 0 0' H rO

Lf 1.f

tit] 0 rd a

0

,-o

..f

U

H

Hr-1r-IHI

HI HI HI OH CU

H

0 'd ,

Ip

H

• .0

S.

ca

I1

•r.I

•r•{0C

{

Q,

}i CV L.C1 CV 150 N-. LD N HI CV I- 01

s~ ~. a) 4 I C >%H

LIl CU H O N r,0

i ti s~ 0 ON O F4 N

b,O0cd ook

I ma)

••

• • • • •

•H

A

rd p.

rr1CV CV CV CV CL CV Iw1CV CV CV LC \

I 114 0

0

I

CH

4,

q H C 0 F-i

i

c

L0 • Lb Pr11;O NA- 0 CV O LC'\ O \

d 0 d d

CD

4 Hi ON CU H I'---4 r- r- :--I H r U

H ON150 Q

C R. 1~ 0

150 x101150 t0 '60 to

CL) 0 H GQ G.)

H

•H

cd P

a)

>-■ a P. . a

w

+a

I

I

0 .O 53 01 ON LC1 H N 1 CV 1:0 150 ON

ro

150 1505 H 0 0 LL-NO T.0 f- E0 LO LO

b[+4-a a)

p4- p1 t-L.D O L0 N- 0 Na

H

I

cd

P

r1 0 0 0 150 01150 H01I!OuD01

▪a

q 'd p.

• • • • • •

• •

I >~

•)

10

r- r• N-- ,,O LD ~D N-D LO

•0 00 00 •• 40 •0 •0 00 00 00 00. •• •

• ■ •0

V.

R

.

Im

0 0 0 0 0 LL"1 LC1 LC1 LC3 Lr1 O P r1

rd 0

0

I r~

0 O LI1Il10 r- CV CV

0 NrN

~+a 0 0

i o

Lnr+''CUCVCU H

0

-00ti

A

I x

CV r-a

ri H

4 •l •

1.

bO I sd a)

I o

0000000000 0

d p E i H

CV CV Cu rr1 N \ I +

Z

I!

Lf1 Lf1 LIl

o 'H 4) a] Id

HHIHrIrIrHHr-iHI

•

o

+' p •+'

I

•I

j

•

{

0

cd 4-)

10

0

• +s

•

I 1c 44 A

i

4 44 4 . 4 : ' a . .

I 1 m cu

+-J

o 0 do o o o oo o o

i ci ooQoo0o0000 0

. a O

1

0

C]

r--I CV Pr1 r{ CV tr 1 H CV N".H CV Prl

▪

1

I I

I

4-)

an !

I k

0 0 0 0 0 0 0 0 0 0 00

rr:l

-H

,s:) rd cV

o a)

0 0 0 0 0 0 0 0 0 0 0 0

to

a) 0

•

P-1

;r,

{

q

U

H r--aHrlr-IH HHriH r-!r H

d i r-i I O

■■ •

- •■

■ . •• 00 • •

I cd

I I~

a3 CV

I

+'

00000000000 0

d

11.1 0

0 0000000000 0

10n0i

[~w

CV▪ ref ni r CU trLf C

U

1 Ra U

▪ 00 00

00 . .

•.

0 0 0 0 0 0 0 0 0 0 0 0

I

1 cad N

} Fi I G

00000000000 0

I

i +'0

1m a

CY7

i P1 . U

r f Lf32* Lnr *r LC1 N Lr1

••

0 v . ■•

.• • .

HIriHIHHIHiLC1r-iraO0 0

+'

I

r m

0000001-0000 0

.~ 'd C

1:kO

0 a) >1

E

N•1 Pr 1 FIN M N N ti50 Pr1 r+l Pr1 M N1

0 0 H

I cdd

0

0 'd

i

HI r--I r-1 ra r I rH ri r+ r-r rI r-i r- I

..

.

64 *

q 0 I r` cu H N-Lc1 LI\010 H 0 .4- Aq Z I 4 M he\ Nl rr1 CU Tr \ L C 1 if 1_f LC1 r` r1

0

LQ

a~

0

N^

+3

0

cd

I

H

t.1

.H

0))

C

bd:

H

'P

0 r- i

a~

It may be remarked that the effect upon the rate o f

cooking shown by both temperature and acid concentratio n

change is in the direction which earlier exper gents on a

larger scale, already reported, had indicated _ The greate r

refinement of the later experiments, however, makes possibl e

a more exact estimate of the relative magnitude of the effect s

of temperature and acid concentration on the rate of cooking .

It has been hown, in this report, and also i n

earlier publicatiorfs, l2 that the removal of carbohydrat e

material from wood by sulphite cooking proceeds much mor e

rapidly than the removal of lignin . The factor controllin g

the rate of pulping, then, must be the rate at which ligni n

is removed . In the cooks here reported it is seen that a t

any particular acid concentration within the experimenta l

range (between I and 3 per cent excess sulphur dioxide) th e

rate of cooking is doubled by each successive 10° increas e

in temperature between 120 0 and 150° C .,1- with but sligh t

tendency toward greater loss of cellulose at the higher

acid concentrations . Also, at a particular temperature, a

change in acid concentration from 1 to 3 per cent is necessary to make an equivalent change in rate . As pointed ou t

in a previous paper, such a change in acid concentration i s

not possible in present commercial practice .

It is quite a fortuitous circumstance that the resistance of the desired fibrous carbohydrate material o f

wood to sulphurous acid hydrolysis should be such as to permit the removal of the lignin by the same reagent, and further remarkable that such a wide variation in cooking conditions should produce approximately the same amount of pul p

of approximately the same composition . The picture of th e

course of the sulphite pulping reactions that can be draw n

from the foregoing results is not that of a successive breaking down of the wood in various parts, but rather that of a

set of simultaneous reactions proceeding at different rates . $

l

Effect of Acids and Salts on Cooking Action

With reference to the changes that might be manifes t

in the qualities of the residual fibrous material as a resul t

of adding reagents to alter the rate of lignin removal, muc h

15 See Miller and Swanson, Paper Trade J ., Apr . 10, 1924 .

---Cf . R . Manisawa, Eng . Chem . Jour . (Japan), 1, 194-206 (1921) .

-$ See Sieber, loc . cit .

R33

- -12-

speculation has prevailed, and some experiments are on record .

The following cooks, the results of which are given in Table 4 ,

were performed to show the effects producible by the additio n

of a few simple chemicals to the cooking liquor .

As standards of comparison, the two cooks, Nos . 8 7

and 68, were made with 1 .05 and 0 .55 per cent excess sulphu r

dioxide, respectively . A 6-hour cooking period was allowe d

in all cases, and conditions were identical in all respect s

except for the addition or substitution of some reagent .

410

411

In cooks Nos . 63, 64, and 65 enough hydrochlori c

acid, sodium chloride, and acetic acid, respectively, wer e

added to produce 1/2 per cent concentration of each in a

cooking acid containing the usual 1 per cent combined sulphu r

dioxide and 1/2 per cent excess sulphur dioxide . The result s

in all three cases show a tendency toward the removal of mor e

lignin and cellulose than in cook No, 68 . The difference is

most decided in the case where hydrochloric acid was added .

Cook No . 71, in which sodium bisulphate was added, also show s

a tendency toward rapid removal of lignin and cellulose ,

while in cook No . 82 with sodium acetate, the same cellulos e

destruction is seen with less lignin removal . Cook No . 70 ,

with an extra 1/2 per cent of sodium bisulphate, is littl e

different from the control in cook No . 68 . In cooks Nos .

72 and 81 the only base present was that added as sodiu m

chloride and sodium acetate in amounts equivalent to th e

quantity of sodium bisulphate necessary to give 1 per cent

combined sulphur dioxide . In the case of cook No . 72 containing sodium chloride, a decided increase in the destruction of cellulose is•seen without accompanying acceleratio n

in lignin removal ; the pulp was decidedly burned . Coo k

No . 81, with sodium acetate, shows a decided and genera l

slowing up of the reaction .

It is unprofitable to generalize too widely o n

results with so small positive differences, but it may be observed that there is a tendency for strong acids and salt s

of strong acids to "speed up" the reaction ; while weak acid s

or salts of the same have a contrary effect, if any . Suc h

a generalization points directly to the theory of the pulpin g

process as an acid hydrolysis of wood, and to a consideratio n

of the influence of the concentration of the hydrogen ion

the pulping process . Results of experiments to establis h

e possible relation of hydrogen-ion concentration to th e

hite pulping process will be i .n _•_ d. in. a future pape r

-his ser s .

oCuIsor,rnH NH o

HA- r- N HA- to U r-t r . . . .

.

Na•0r-INNO0F r1iy1

Lr> LC Lc1 LCt I[1tn Iii Ln

▪

. . Of ►

n

0

r- r- ON-1- O O r-1 .z l~1

LD N LD Lfl 0 . 0 %.O

▪ f

F.+ I.C N rr\ at N

H

LD NLL]LD L O

• . ■. .. 0 n .

. . 00 00 oo ■ .0

•

..

00

. .

e

4-1

r7

00

. . 00 0

p.

4-1

.

•

°

-p

d a. I 1

a

p

0

q rn a'1 D

K.\ NLQr

N LC\LcLD Cti7n N

.■■ ■

▪

C7' - DSO O H at C~ H K.\

e--i

H CV H ri ri N N

f . . 00

f . •f ■■ 00 . .

r+

4O isa H 0 a' La CU '

HN LOA- .1:) Ch 0

LC% ri .- ...JD A- A- r-I CVit

CV CV NNNCUrr1 N

f

o L,D LD FA q r+1L.CZ r- gZ%. D

0 r-1 LO GO N CV t.0 (3 1

n

.■ .

▪

t• LC1LD LCl e- t 15O r+1 p1LID 1 f-LD r- t- a r- r-koL° W

p 0

Q.) q

!Sl

0

a)

Fa

1 4)

I C)

• cdd°C

(

0

q >~

d

a)

i f~

w

..

r~

-1-3

00

. .

n .

0000\9O0 CUL.q

I Ln LCl LCZ lCl_f !n I ti+O In

1 .

I

0I

NON

q0 00 •0 00 00 00 00 00 00 00 00 • 0

0

0

U •ri 41 a)

bl:l

d

C

S

I

. .

1114

n .

q O

4)

a3

I

I

.04

w

0

0

0

0

Q

or 00 et

t

CO

co

a)

I

1

W

0

0 CI)

a)

a

0

•

q

' -I

a

I a1 C V

I

~I

W

00

1

I

+3

H

f a) a)

C]

I 1

w 00

I

o

1 al 4)

Oct)

I G4 0

H

I

. . . . . . .. .. ..

. . ..

'cl 0

bA4-+ Q 4s >,

a) ° IW 0 s

..

06

..

.e

..

1 rA

1 L

o:l

▪ .. .0

. 0 . .0 00 00 00 0• ea 070 0

W\0 qq 0L,DOa.O0 • •

hlnLClLC)LC1r-w a'O 0

▪

■, .■ . n

r-1 ri ri ri ri ri ri r1 r-4 ri

00 0"0 0 00

000 00 0

00

. 00rr\ O O

Ln In LCl Lf 1 I.f 1 q L11 C)1 o 0

. . . . . . .

N N CV CV CV rn Cu N ri r i

q0 00 00 00 06 ea 00 00 pm 00 •0 0 0

art() to LO rl M Lt'') O CT N

LC

0A- LA r" r4 r---W e-I

LnT.O . r

ou'0I- O

r e\ at 0310-N 'LSO N W 5O LCl

'A- .- ■

.- A- LC\

HHri riH -r ir-i rira H

or

IS

i:O r

LClN 0 ri f-N H

VD L.D VD LD 6Q r- r-'.O r--14-

a)

p

GO

+~ td

.r• ~

4-3

il]

• O

•

tr,

m

0

r-4

•

r'-t

C

ref cd

Q

Cf)

-P

x

cd

Z (1)

U

4-3

qt

CV

l

r- I Q

o xz

- 00 0Z ~

z

Z

MZZZ

00 0 0 •• ■

n

n.

t

4

LC10 0 0 O 0 LC\ 0 O

;4 )ol

IntitInInLr Lc111%O q 0

I p4 0

0

rl 1- +

■ . . . . . ■

n.

q 0000 .- 0A0 0

q 000 q N001O 0

H1 0

W w

ri e-E H r-1 r•i ri H 0 0 C

r,

.

w

U

f-i

w

P.

G

IaO

.H

H

0

b

0

•rl

( re.%

0

K1 0

0 4i

rK". 'd

Cd a)

Z -P

p

•

q ri

4-i

.,

▪ .

n . 00 00 0 0 0 0 00 00 00 . .0

0 LD N f- at N O at Ln N LD

C') 0 L0 N re•\ r- t- t e ' LC

r` ►.n. .- 0 'ea N Pr%

0 w r+1 rr 1 r•I v] ~o Cu 0"1L 0

n

r-la'rtr-IN H0001t +• t

e1

rte-4r-1rIHH

ri. . .

. . ■ . I

I

.

.d

0

cd

oa

e

O

'60

}'

v

0

F-t

a)

P.

V

f-+

a)

a

q

'(O

CI) 0

q

0

a) LD

N to

o

[ II 0

•

▪

•rl

te)

a

Ga

a

a

q

1

w

q

H

r!

rl

0)

0

0

d

• 0

4- 4 }7

p

0

a)

4) a )

C) 0 C3

i

1

•

oa

A. a P.

•e i

m

'Go Cu .A

A

1

[mod C) r~ CU rel

0

Fr1

. HI NI r

a

Summar y

The results recorded in this paper show :

I.

That the same amount of carbohydrate material s

are removed from wood by mild hydrolysis with hydrochlori c

acid as are removed by sulphite digestion which reduces th e

lignin content of the residue below 2 per cent .

That the carbohydrate materials removed b y

2.

hydrolysis are, in part at least, removed as complex bodie s

that can be further hydrolyzed to reducing sugars .

410

3.

That the time of lignin removal by the sulphit e

reaction is reduced approximately one-half by each 10 0 inin temperature between 120° and 150° C .

4.

That a change in acid concentration from 1 t o

3 per cent is necessary to reduce the time of lignin removal

by one-half .

5. That the tendency of salts of strong acid s

added to the cooking liquor is to increase the rate of reaction, and for those of weak acids to decree the rate o f

reaction, suggesting a process dependent upon hydrogen-io n

concentration .

R33

-15-