9 . f 2321 3 FOREST PRODUCTS LABORATOR Y

advertisement

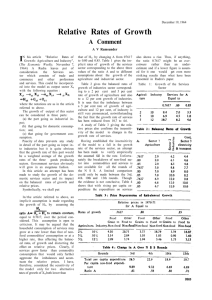

9 . f 2321 3 U. S. Department of Agriculture, Forest Servic e FOREST PRODUCTS LABORATOR Y In cooperation with the University of Wisconsin MADISON, WISCONSI N CHEMISTRY OF THE SULPHITE PROCES S II. Chemical Properties of - Pulps Prepared By Indirect Coi+rl'i gt By MARK W . BRA Y Chemist in Forest Products an d T . M . ANDREW S Associate Chemist in Forest Products , Published i n PAPER TRADE JOURNAL January 18, 192 3 Vol LXXVI, No .' 3 . Reprinted in Pap er trade journal, January 18, 192 3 CHEMISTRY OF THE SULPHITE PROCES S El,. Chemical Properties of Pulps Prepared by Indiredt Cooking ' This study of sulphite pulp was undertaken in order to deter mine the nature of product obtained with different periods of cookin g and to show, if possible, the factors influencing the character of th e product at various stages of the reaction . Such an investigation i s possible only by following the process at regular stages from the ra w condition to the end of the cook . With this end in view a detaile d chemical study was made of pulps at definite intervals of cooking, al l conditions of temperature and pressure being maintained as closely a s possible on a standard curve . Met a s of an l_ysi s Considerable dLfticulty has been experi , eced in finding a dependable method of analysis for pulps . A modified. Coss and Bevan method has proved most satisiactory for the determination of the cellulose content . The alpha-, beta-, And gamma-celluloses were g determine d . Certai n by the method developed at the Forest Products Laboratory pulps especially the raw cooks, appear to be oxidized by the chlorin e 1 2 Presented at the fall meeting of the Technical A .ssociation of the Pul p and Paper In d ustry at Detroit, r'ich ., October 9 and 10, 1922 . Chemist in forest products, Forest Products L a b oratory, Madison, Wisconsin . 3Associate chemist in forest p roducts, Forest Products Laboratory, Vadison , Wisconsin . 4 1 . w. Schorger, J . Ind . Eng . Chem ., Vol . 9, p . 556 (1917 ) 5 An Improved Method for the Determination of Alpha-, Bota-, and Gamma Cellulose . Presented by the authors at the sixty-fourth meetin g A . C . S . (September, 1922) . R47 treatment and hence give a corres p ondingly high solubility in the [ercer' s solution (17 .5 p er cent YaOH) used. in the separation of the stable alpha cellulose from the unstable beta-, and gamma-celluloses . However, by careful manip ulation this oxidation can largely be avoided, in most instances . The moisture, hot-water-soluble, and lignin contgnts have been determine d by the ordinary methods used at this laboratory . E merimentalivitsche_rlich Sul phite Cook s The pulps used in the investi gations were made in a 50-poun d capacity digester at the Forest Products Laboratory, thereby permittin g the cooking conditions to be observed in detail . 7 The various factors o f pressure, temperature curve, strength of cooking acid, both free an d combined S 2 are that furnished . These conditions combined with a detailed chemical study i:urr:J.oh a basis for determining the relation of pulp s of this series and show the way to a new and im p roved series of cooks . As it is impossible to obtain representative samples of pulp s during the process of coeki .ng, cooks were blown at definite periods fro m the raw stage to a well-coobred product . All these cooks followed a s nearly as possible the ware curve, p ermitting the data from the separat e cooks to be a pp lied at any similar period durin_e a single cook . • The spr, , ce woad used in these melee analyzed 53 .4 p er cen t Cross and Bevan cellulose an . 7 4 .7 per cent aapgin,-, 5 .7 per cent beta- , and 14 .2 per cent mamma-cell"ioeo, ac shown in Tdhle 1 . As would b e exeected_, the hat-water sole 'le and the 1 eel- cent sodium hydroxid e soluble contents are considerable amounts, which taken with a ligni n content of 2 8 . per cent partly account for there being only 58 .4 pe r cent cellulose as determined by the Cross and Bevan method . Yet eve r this yield is not equaled in commercial cooking . With the result s of the different cooks it is possible, perhaps, to show some of th e causes, or at least the stages, of the disintegration or changes tha t wood undergoes during continued treatment with hot sulphite cookin g liquors . 6 7 S . A . Yarood and D . E . Cable, J . Ind . Eng . Chem ., Vol . 14, No . 8, pag e 727 (August, 1922) . Cooking data supplied by R . Y . miller and W . F . Swanson, Paper Trad e Journal, April 13, 1922 . Technical Association Paper Series V (1922) , pp . 69-74 . R47 TABLE 1-ANALYSIS OF EXPERIMENTAL MITSCHERLICH SULPHIT E PULP S Basis of Wood Cook No. Spruce wood Sample No 52 . . . . . . . . . . . . . . . . . . . . 630-I 51 . . . . . . . . . . . . . . . . . . . . . . 629.1 44 . . . . . . . . . . . . . . . . . . . . . 626-I 37 . . . . . . . . . . . . . . . . . . . . . . 625-I 63 . . . . . . . . . . . . . . . . . . . . . . 634-I 62 . . . . . . . . . . . . . . . . . . . . . . 633 .1 53 . . . . . . . . . . . . . . . . . . . . . . 631-1 61 69 . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . .. . 632-I 636-I Cook duration Hrs, Hot Water Sol . % 5.6 5.1 2.2 Yield % 7 9 10 80 .8 62.8 64 .0 51 . 0 5 0.6 1134 12 1 .9 0.6 0.5 0.0 51 .2 1234 1331 51 .6 47 .1 48 .4 15 0 .8 0.2 1% NaOH Sol 1%NaOH Sol. Corrected for Water Sol . Lignin 15.1 9 .5 9 .7 9.1 6 .5 6.7 5 .3 14 .8 11 .2 8.4 7 .3 5 .7 5.6 5 .9 5 .3 5 .3 28.3 20.9 12.0 10.6 3 .9 4.6 3.8 2.5 5 .1 5 .9 4.5 28 .4 35.8 36 .7 38 .5 37 .3 46 .7 42 .7 43.1 Sample No 52 51 44 63 37 62 53 61 69 . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . .. . Chips Cook No. oven dry 630-1 629-I 626-I 625-I Lbs. 101.6 634-1 633-I 631-I 632-I 636-I 97.5 90.6 92 .3 98.9 99 .0 102.0 95 .9 88.3 Cook No . 630-I 629-1 626-1 633-I 634 .1 633-I 631-I 632-I 636-1 H O in chip s Gal. 3.4 0 3 .3 0 3 .08 3 .1 8 3.3 3 3 .3 6 3 .48 3 .24 .3.28 cooking Hrs., 7 9 10 11 1135 Moisture % 2 .4 3 .3 5 .1 4 .1 5.1 1234 0.9 2.9 2 .6 2 .3 40.0 37 .5 36 .9 1 .5 Basis of Cellulose 15 Hot Water Sol . % 6.3 3.5 2.9 1 .2 0.9 00 7 4.9 5 .1 1354 % 14. 2 8. 9 6. 5 6. 2 4. 7 4. 4 5. 5 5. 2 4. 3 5. 0 2.4 Basis of Pulp Time of cellulose % 5.7 8.3 9.7 7.7 31 .7 45 .1 Gamma- cellulose % 34 .7 44.2 0.9 Beta- cellulose 43 .7 3.0 5 .1 Alpha- Cellulose % 58.4 50 .2 45.9 45.2 1 .7 0.7 1% Ns OH Sol. % 18 .3 17 .9 13 .1 14 .3 11 .2 10 .9 11 .8 11 .1 12 .7 1% NaOH Sol . Corrected for Water Sol. Lignin % 11 .9 25.9 14 .4 19.1 10.2 16.6 13.1 7 .6 9.1 10.4 9.9 7.4 11 .8 5.1 9 .4 6.3 12 .0 1 .8 Beta- Alphacellulose Cellulose % 62 .0 % 63 .2 61 .8 71 .9 83.9 87 .2 82 .6 83 .6 87 .7 86 .8 73.1 76 .9 35 .8 87.4 87,9 92.7 89 .9 94.4 1 Gamma- cellulose cellulos e 16 .5 21 .1 17. 9 14. 3 12.5 % 15.6 5,5 1 .9 6 .4 5.4 5 .4 2.8 % 10.8 10. 0 12. 2 10. 9 10. 1 11 . 0 TABLE 2-COOKING DATA FOR EXPERIMENTAL PULP S Cooking Max- Time to Bleach liquor per imam maximum Cook Yield of Yield of Yield of I00 lb. O . D . temComb unsereened screen- screened 35% availterndunTotal Free able chlorine Acid woad perature perature lion SO, SOs pulp ing pulp SOa Gal. Gal . °C . Hrs. Hrs. % % % 59.5 Not bleached 61 .9 133 7 7 3 .78 2.37 1 .4 1 80.8 Nit screened 80.8 57 .0 62 .2 145 834 9 3.82 2.42 1 .4 0 62.8 Not screened 62 .8 Not bleached 55 .0 64 .9 145 L36 1 .38 64.0 0.70 63 .3 Over 30 834 10 3 .74 Over 30 57.0 65 .1 145 854 11 3 .81 2 .40 1 .4 1 51 .0 0.70 50.3 .0 2 .58 1 .08 49 .5 Over 30 57 61 .0 145 835 1195 3.80 2.38 1 .4 50 57 .5 61 .5 145 3.79 2.39 1 .42 51 .20 0 .00 51 .2 Over 30 834 12 50.4 Over 30 56 .5 58 .8 145 834 1234 3 .82 2.42 1 .4 0 51 .60 1.20 58 .25 64a 145 2.41 1 .4 1 47 .05 0.75 46.3 Over 3 0 8$4 1 334 3 .82 0 .13 48.3 1S 58 .5 70.0 137 15 15 5.60 4.46 1 .1 4 48 .43 TABLE 3-PHYSICAL TESTS OF EXPERIMENTAL PULP S Ball Mil l Machine Run • Cook No . 630.I 629-I 628 .1 624-I 634-1 633 . 1 631 .1 632-I 636-I Strengt h Weight Mullen factor per test points ream Llu. Lbs. Lbs. sq. in . per ream . . . . . . . . . . . Pulp raw-not tested . . . . . . . . . . . Pulp raw-mot teste d 56 .6 32 .2 0.5 7 . . . . . . . . . . . 51 .9 46 .8 0 .90 .. . .. .. .. .. .. .. .. .. .. 51 .0 36 .1 0 .72 35 .9 0.76 47 .0 . . . . . . . . . . 46 .0 28 .5 0 .62 . . . . . . . . . . . 48.1 34 .9 0 .72 . . . . . . . . . . . 53 .8 40 .0 0 .74 Tempera. Breaking length Stretch % 5 , 960 6 ,41 0 1 .7 Meters 2.1 2.7 6,030 5,450 5,830 6,080 6,120 2.1 1.8 2.1 2.5 Double folds No . 58 389 271 426 223 363 283 Humid - tore of ity of testteatin$ room ing room F. % 65 69 66 71 64 .5 65.0 65 .5 65 .0 68 70 65 .6 65 .0 81 Max- Time imum to max. strength strength Lbs. sq . in . Min. 65 .0 119 109 80 60 99 109 98 85 95 60 60 60 60 60 Tear . ing force Time to max. tear Min . 1 .5 2.3 40 40 20 40 1,030 730 20 1,500 1 .220 Lba. 1 .8 2.2 1 .9 2,5 1 .8 40 80 Double folds No. 670 700 910 Time t o minimum fold s Min . 60 40 40 60 80 40 40 TABLE 5-COMMERCIAL MITSCHERLICH PULP S Res:rd No . P176 P188 P206 P187 P18S P186 P213 P207 P175 Moisture Description of wood used % Unbleached spruce and balsam 4 .9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 .5 Unbleached spruce and balsam _ . . 4 .5 Unbleached spruce Unbleached spruce Unbleached spruce Unbleached hemlock Bleschei spruce snd balsam Bleached spruce and balsam 4 .3 4 .4 3 .3 4 .3 3,9 4 .6 Hot H,O 1% NaOH % 0 .9 1 .6 0 .6 1,2 0.6 % 10 .5 12.5 12 .4 soluble 1 .7 0.5 0.5 0.0 soluble 11 .4 9 .8 12 .7 14,2 13 .9 11 .6 1% HaOf i sot . corrected far water sal . % 9.6 10.9 11 .8 10.2 Lignin Cellulose Alphacellulose % L6 5.2 % % 96 .1 13.7 7 .C 6.2 7.8 1 .4 95 .3 95 .3 94 .6 94.8 90.8 92.4 11 .6 0,5 97.1 9.2 ILO 13.4 1 .3 0.9 98.4 R2 .1 82 .8 86.6 82.2 92.8 83.7 83.8 84.5 81.4 Betacellulose % 3 .2 5 .1 2.1 3 .4 3 .2 1 .4 3.3 4.1 3 .6 Gamma . cellulose % 13. 8 14 . 1 12. 7 13 .9 13. 8 13. 7 13 . 9 11 . 6 13 .2 Yield and Quality of Pulp s The shorter cooks of this series naturally were raw and afforde d samples of pulp well without the range of mill conditions as far as rea l pulp is concerned . Those samples obtained between the seventh and nint h hours showed a gradual pulping action, but it was not until ten hours o f cooking that a pulp was obtained that could be screened and made int o sheets . All the cooking data, such as temperature, t-i,R . .of cooking , strength of acid, free and combined, yield, bleaching qualities, an d machine-run and ball-mill tests are g iven in Tables 2 and 3 . The elevenhour cook had good strength and color and though not of as high qualit y as good commercial 1,itscherlich pulp was the best product obtained i n this series , Cooking -ith Tecreased Strength of Acid at Decre .sed Ten .eratur e In order to sec-are for chemical study an experimental pulp whic h had physical properties more nearly identical with those of commercia l Mitscherlich pulp a cook was made under conditions somewhat modified fro m those used in the series . The free 80 2 was increased to 4 .46 per cen t and the cooking time to 15 hours, while the maximum temperature wa s reduced to 1370 0, ilade these conditions the yield of p ulp was 48, 4 per cent, based on the d_~y we i ght of the wood_ . This pulp compared favor ably with the eleven--ho,h cook of the series in physical properties, wa s more readily bleached, aad closely resembled Mitscherlich pulp . Discus -i.on. of Analytical Della In Table 1 are given the chemies3 data for this series of cooks . The curves for yield, cellulose, alpha-, beta-, and gamma-celluloses , lignin and 1 per cent sodium hydroxide soluble are show in Figure 1 . It appears that during the early part of the cook there is a removal o r destruction of nearly equal parts by weight of cellulose and lignin . With awns" itewr* of treatment these losses are 8„2 and 7 .4 per cen t (based on weight of wood.1, respectively, as shown in Table 4 . Durin g the remainder of the cooking period the lignin loss becomes larger tha n that of cellulose and the above ratio is not maintained . However, th e ratio of lignin lost to cellulose lost ran g es from 1 .60 to 2 .17, or a n average of 1 .77 . This value holes over a range of time from eleven t o fifteo]a hours ; and the va ric+ ;^ .. from the mean is 0 .11, with the exception of the one instance where it varies 0 .4 . Those results are substantiated by three other series of cooks by the alkaline p rocess, a full discussion of which will be given in a subsequent publication . This would indicate that by none of the present commercial methods o f cooking is i,t possible to obtain a higher yield than approximately 45 pe r R47 -3- T- T 7 .- . ..Ll _,_ t _ r. I k-:1 0 .4 - ` ! ft- - tr * w4-1 I -. -- - 4-4- 1- --A- if ;I .-- 41- . 10 - ---- - - -'- - - 4! P -th l Ob - i I L. .._ p. I r 1 I1 ._~'- " i _ .. I. _1 v_ vi :i - .. - .. 41 --I- i --I/ 1 t _1 .4 _fl i I - i .L_ ---I-r----I i it * I -1 S . ---f- -Tv. - - -1- - 1 -..: . 1, 11 L, ; -t - - -kr I ., ,c. --I- ! 1 __ i , -.-, ‘4 '-i I) II-- -.I , L ■. •Z, cent of cellulose as nnlp, although the rood contains annroxirnatel y scent cellulose . Since the cookin g conditions in this series are constant, tim e being the only variable, it is to be expected that the quality of the pul p will steadily app roach a ma rimnm, while the lignin content will graduall y tend toward a rinimum . In the seven-hoar cook, which was very raw, th e yield is very high and only a small part of the . lignin has been removed . Compared with the cellulose based on bone-dry wood there is a loss o f 8 .2 per cent cell"lose in this period of cooking . An additional two hours of cooking removes 8 .9 per cent li g nin with an adr'i.tional loss of. 4 .8 :-p e r cent in cellulose material . The next two hours a ppear to cause the greatest change in the ;nature of the pulp both physically and chemically . Mtn the ninth hour of cooking the cellulose percentage in th e pulp has increased but slightly . From the eighth to the eleventh hou r this value in the p ulp increases 25 .7 per cent to 8 .8 per cent with a lignin content of 7 .6 per cent . However, the yield of cell„lc .ee materia l is 25 .2 per cent less ten the theoretical, due to the sc lubil i ty an d decommosition of t is material under the drastic cooking .;onwi_tions . An hour and a half of ad'_it_Lonal treatment improves the cellulose conten t of the pulp by 6 .9 per cent with an increase in the yield of cellulos e of 3 p er cent based on the wood, The latter is unexple-nable at present . Under ordinary co_litienan increase in the cooking tame taro es a n increase in the cellulose content of the pulp produced Baeea on wood , however, the actual yield of cellulose is usually less the longer th e period of cooking . Table 4 . --17titschoriich Lignin and Cellulose Looses in Experimental Cooks . Cook ITo . ?Pond r R47 : Colin- : . : Hours 0 . 7 . 629-I 634-1 625-I 9 : . 11-1/2 . 11 623-I 633-I 632-I . 11-3/4 . 47 .3 : 12 . 45 .1 : 13-1/4 . 42 .7 : 15 : Lignin : Cellu- : Lignin : lose lost lost . Per cent 58 .4 : 28 .3 50 .2 : 20 .9 45 .9 12 .0 4 .6 4 4 .2 . 43 .7 . 3 .9 630-1 636-I L Cook dura- : lose tion : 43 .1 . . . Per cen t . . . 7 .4 8 .2 . 12 .5 : 16 .3 14 .2 23 .'7 14 .7 . 24 .4 4 .0 3 .8 11 .1 . 13 .3 24 .3 : 24 .5 3 .0 4 .1 : . 75 .3 . 24 . 2 15 .7 15 .3 . Rati o Lignin los t Cellulos e los t 0 .9 0 1 .3 0 1 .6 7 1 .6 6 2 .1 9 . . - r : - 4.8 4 6l 1 .70 The lignin in this series of cooks has shown a gradual decreas e up to 12-1/2 hours of cooking . Since the best pulp 7a s produced at the eleventh hour it is evident that factors other than lignin removal affec t the character of p"lp . kfter twelve and one-half hours there appears t o be a redisposition of lienin on the fiber instead of a continued removal . Mile the lignin percentaee has increased slip:tly tee cellulose content has diminished and the prlp is of poor quality . 'that portion of the wood which is soluble in one Der cent alkal i p ersists almost quantitatively in the pulp through the ninth hour of cooking. -Between the ninth and eleventh hour this material is 'removed ranidl y to abort 0 .6 of its oricinal quantity . Prom tic uil'vprlX Qtly a very slight further decrease is noted . In the earl* cooks the alpha-cellulose content is quite lee, . ?it'-_ longer periods of cooking, hoi-ever, the alpha-cellulose as fornd i n 00 pl-o and calc nlated. on the basis of wood shows an i .creases At th e 4u10 %ime Nip C` =L ►~ e shows a eradval decrease to an almost nog'M wki LI a ?'an ellei le very nearly constant . "he rodi ct s '.;crvL• . hard. to purify and -Ea chlorin e treatment ably causes * n of 11• e resinta_ t cellulose with a corresnorine Increase in t-:.e :~41~~`" ista z' }4rtion .`~ These cooks con tainirn a small amount of 1i=-'n1 Oda. canoeqrelatl-r easil-r Dnnified by th e chlorine-srlu p:ite method, time an igLI cell"lose content that is fa. rl v constant, var-ri-c bet-teen al .7 nor cent . is valve closely ap'L r p roximatee the al pha-cei .lugose content of -or1Ded cotton linters, which in o io case eras 88 .3 er ce_it, 9 Cooks lancer than eleven houre in the serie s appear tO be of inferior quality both c omicall T and in ap p earance . As 4 general conclusion, it se.Rae that w ith the conditions used in this series , *7.evea hours is the maximpm time for the production of a pulp apuroachin g co;: l qualiy, an Commercial Pulps r A ntmiber of commercial pulps were oietai-) .ed_ from differen t companies and used as a standard of comparison for the :laboratory coos .., The analntical data for these ruins is given in Table 5 . These sample s aka.a3 g a 64' ],lath bleat_ ed. and unbleached pulps and are sf high pnrit ;r and. good physical p roperties . The lignin content varies from 1.3 per cen t to 7 .8 ncr cent in the rnhleached and from 0 .5 per cent to 0 .9 per cen t in the bleached "yelps . In none does the cellulose content fall below 90 per cent and the purest 'leached pulp rrn .s 92 .4 per cwt cellulose . In the bleached. samp les the cellulose content is veru :high,, W ;. eft' '9,a _ per cent, and the li gnin value plus the celluloee.e totals 9'7 ..6 per cent 7 ' 1 to 99 .3 per cent . The cellulose value for unol.eached pzl.p~ is considerin from 90 .8p er cent to9x_er cent . 911''P'ag telr„ Influencing thhF 'Pro p erties of Toed Cellulose at. Jutted by th e &.1omi Lion .'et :.od" b e "ark Bra,* and. . Aoci'eorN I9 Co? i,ri, n of Mood Ced1ui.o e an-3 Cotton Cellulose, J . ha* , an•' Eng . Chem . , W p . 7'27 (Angu_s t 4 19 Ei . Yet, certain unbleached pulps are of a remarkable purity being as his h as 96 per cent cellulose and containing 1 .3 to 1 .6 per cent lignin or a total of 96 .6 to 97 .7 per cent for lignin and cellulose . The sodirm hydroxide-soluble content is fairly constant between the values 9 .2 t o 12 .4 per cent and in some cases slightly higher values were obtained . Alpha-cellulose is very constant in value for all these pulps, averagin g around 83 per cent, Beta-cellulose is within the range of 1 .4 to 4 . 1 per cent and gamma-cellulose varies very little, being between 11,6 an d 14 per cent . This gives a series of samples with varying chemica l analyses, yet all having the pro p erties of good pulp and affording a variety of standards each of waici meets some requirement of the pape r industry . Comparison of Experimental and CommercialPrl~ s Since the eleven hour cook is the best o the experimenta l series in its physical and chemical properties, it is ietereo} ;_n .g t o compare it with commercial unbleached pulps made -under eunilo .r conditions . This pelp has a cellulose content of 85,8 per cent and a ligni n content of 7 .6 p er cent . The a l pha-cellulose content is practically id atical with tha t of the commercial ?ripe . The some is true of the one n-->r cent sodium hydroxide soluble and the beta- and gamma-.-cellulo yea, 7:' .e c.e 3 lulos e content of the cocatercial pul p ., however, is con_sideraliy higher eve n though the stable and unetable celluloses are ap p roximately the sam e as those of the Laboratory pulps . 0 It would ap pear, therefore, that certain imn uri ties, thoug h present in small quantities, have great influence in determining th e physical quality of pulp . with any given pulp, even though it is withi n definite chemical limits, length of fiber, hydration, and all other suc h factors must be taken into account . Rather than any one factor deter mining the quality of a ;grip, it is evident that the ultirate produc t is the result of a combination of conditions . The single pulp, 533-I, cooked for fifteen hours with a greater concentration of free S0 9 and lower maximum temperature, i s even better than the eleven-hour cool : of the series . This pulp differ s but slightly from commercial unbleached Mitocherlich spruce pulp, havin g a cellulose content of 94,4 per cent as compared with 91 .6 per cen t to 95 .3 per cent for the latter and 86 .8 per cent alpha-cellulose a s against 32 .2 to 83 .6 p er cent . The lignin content of the experimenta l pulp is 1 .8 p er cent, a value corresponding closely to that found i n commercial pulps . Fifteen per cent bleach was consumed, indicating a product closely resembling good quality commercial pulp . Summarz 1. With all conditions constant except time, a series o f spruce sulphite pulps was prepared by indirect cooking . These pulp s were compared with commercial pulps made under similar conditions . 2. It has been found possible to compare such pulps by takin g into consideration the cellulose content . A high cellulose conten t appears to be necessary to produce a good pulp . 3. The percentages of stable and unstable cel1uloses are a n indication of the quality of tae pulp, the pulp with the greater amoun t of stable cellulose usually being of a superior quality . 4. The pulp dotoriorates with the overco>Thin g necessary t o remove all the lignin . 5. Until the ninth hour of cooking the cellulose and ligni n contents of the pulp are ver ;r nearly the same as those of the wood . 6. The first few hours of cooking Roes not affect the alkali-soluble material . In the latter -cart of the cook a larger amount o f this material is rc.moved . 7. While the llaracter of the cellulose an'' to lignin content are indicative of the quality of null) produced, other factors not wel l understood app ear to exert considerable influence . 8. Cellulose is always lost during the removal of lignin, an d it seems 45 per cent is about the maximum yield of cellulose by presen t commercial methods of sulphite 'cooking . • Y