Numerical Modelling of Geometrical Parameters of Textile Composites Piotr Szablewski

advertisement

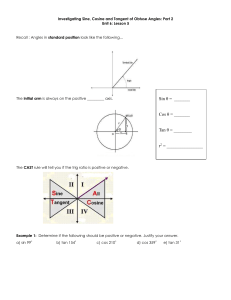

Piotr Szablewski Technical University of Łódź Department of Technical Mechanics and Informatics ul. Żeromskiego 116, 90-924 Łódź, Poland Phone: (48) (42) 636 14 29 E-mail: piotr.szablewski@p.lodz.pl Numerical Modelling of Geometrical Parameters of Textile Composites Abstract This paper describes a simple sinusoidal geometrical model of textile composites. On the basis of this model, how to obtain certain geometrical parameters that fully characterize the geometry of the composite structure will be presented. Using geometrical considerations, it is possible to obtain from this model basic mechanical parameters that are very useful for further strength analysis. Such mechanical considerations and a method for calculating mechanical parameters will be presented in future articles. On the basis of the above-mentioned theoretical considerations, a special computer program was developed. The method of calculation presented in this paper can be applied to more complicated models of textile composites. Key words: textile composites, textile mechanics, numerical methods, woven fabric, unit cell model. textile composites. A symmetric plain weave unit cell configuration was studied to evaluate the performance of the procedure. The stress results were compared with those from other analyses. Introduction Textile composites represent a class of advanced materials that are reinforced with textile preforms for structural or load-bearing applications. In general, composites can be defined as a select combination of dissimilar materials with a specific internal structure and external shape. The unique combination of two material components leads to particular mechanical properties and superior performance characteristics not possible with any of the components alone [1-4]. Many authors in their works have discussed the classical textile studies performed by Peirce, Kawabata and Leaf. Scida and others [5] presented a micromechanical model called MESOTEX for the prediction of the elastic behaviour of composites reinforced with non-hybrid weave (plain weave, satin weave and twill weave) and hybrid weave (hybrid plain weave and hybrid twill weave) fabrics. By using the classical thin laminate theory applied to each woven structure, this analytical model takes into account the strand undulations in the two directions and also integrates the geometrical and mechanical parameters of each constituent (resin, fill and warp strands). Woo and Whitcomb in [6] analysed macroelements for detailed stresses of woven Lomov, Gusakov and others [7] used a mathematical model of the internal geometry of 2D and 3D woven fabrics as a unit cell geometry preprocessor for meso-mechanical models of composite materials. The model computes a spatial placement of all the yarns in a fabric repeat for a given weave structure (a special coding algorithm is employed) and the given warp and weft yarns’ geometrical and mechanical parameters. In [8], Jiang, Tabiei and Simitses presented a stress and strain averaging procedure for local and global analysis of plain weave fabric composites. Osada, Nakai and Hamada [9] considered the final fractures of composites to be caused by cumulation of the microfractures, so that the initiation of a microfracture, namely, the initial fracture, is an important factor of which to know the mechanical properties. Microfracture behaviours in textile composites were decided by the geometry of the textile fabric quantitatively. First, in order to investigate the geometry of the textile fabric, the crimp ratio and aspect ratio were measured. Tensile testing was performed and the knee point on the stress-strain curve was identified. The arrangement, properties and structure of the fibres within the yarn and the yarns within the fabric generate a complex mechanism of deformation. Therefore, Turfaoui and Akesbi [10] developed a theoretical model of the mechanical behaviour of the plain weave. The modelling of textile structures by the finite element method was a new approach based Szablewski P.; Numerical Modelling of Geometrical Parameters of Textile Composites. FIBRES & TEXTILES in Eastern Europe January / December / B 2008, Vol. 16, No. 6 (71) pp. 49-52. on the combination of geometric and mechanical models. The finite element method permits a construction and representation of fabrics by taking into consideration the yarn undulation, the existence or not of symmetries in the basic cell and the type of contact between the warp and weft yarns. The modelling of textile structures was also considered by Milašius in [12] and [13], where considerations are presented concerning the principles of woven fabric 3D structure formation and cross-section shapes. Kobza [14] presented the bending theory of multi-layered composites filled with soft materials. The range of applications for composite materials appears to be limitless. Textile composites can be defined as the combination of a resin system with a textile fibre, yarn or fabric system. They may be either flexible or quite rigid. This paper will present how to build a simple geometrical model of textile composites and how to obtain from this model certain geometrical and mechanical parameters that are very useful for further strength analysis. As a novelty, in this study, the validity and limitations of the presented geometric model will be studied carefully. Besides, the usability of new iterative procedures in the Mathematica environment will be tested to extend the range of applications. The geometrical model of textile composites Let us consider a balanced plain weave textile composite in which the warp and fill yarns contain the same number of fibres n, with all the filaments having the same diameter df , and with the warp and fill yarns having the same yarn 49 t (1) z w ( x) = sin(π x / Lu ) , − Lu / 2 ≤ x ≤ Lu / 2 . 2 t (1) z w ( x) = sin(π x / Lu ) , − Lu / 2 t≤ x ≤ Lu / 2 . 2 ) = sin( π x / Lu ) , z− (x Lu)/ are 2 ≤ x ≤ Lu / 2 . of function The trigonometric functions of the angle β wz win( xterms w 2 t z w ( x) =of the sin(angle π x / Lβuw) ,in− terms Lu / 2 ≤ofxfunction ≤ Lu / 2 . z w (x) are The trigonometric functions 2 −12/ 2 z w (x) are The trigonometric functions of the angle β w in terms of function ′ ′ ′ , π xs/inβ , = = tan β dz dx z (2) = + cos β w = [1 +z( z(′wx))2 =]−1t/ 2sin( z [ 1 ( z ) ] w w w. (1) Lu )w, − Lwu / 2 ≤ xw≤ Lu / 2 . w 2 −1 / 2 2 −1 / 2 2 tan β w = [π t (2 Lu )]cos( tanwβ=c cos( π+ x( z/ ′wL)u )], of the tan β w β= dz dx = of z ′w function . , β trigonometric , angle t cosπ β wx =L[1u )+, ( z ′w ) but ] tan sinβ z ′w [1functions w = w in terms z (x ) are (2) The w 1/ 2 ( x) = sin(π x / Lu ) , − Lu / 2 ≤ x ≤ Lu / 2 . ′ ′w [1 +w ( z ′w ) 2 ]−1 / 2 , tan β w = dz ,β = tan = z(1) cos β wL= )[1, + ( z ′wbut ) 2 ]−tan sinββw cos( w dx = z w . 2 ( ) [ ] π π π tan β = t 2 L cos( x x / L ) , w u of the angle u β in terms of w function cz w (x) are u The trigonometric functions w tan β w 1). = [π t (2 L )]cos(π x Lu ) , but tan β = tan β cos(π x / L ) , where β c is the so-called crimp angle (see cos Figure β w = [1 + ( z ′w ) 2u]−1 / 2 , sinβ w = z ′w [1 + ( z ′w )w2 ]−1 / 2 , c tan β w = dz uw dx = z ′w . β in terms of function z (x ) are e trigonometric functions of the angle w w where β is the so-called crimp (see 2 )−]1cos( /Figure 2 π xthe tan β = t( z(2′w )L x 1). Lβuw) = , dz wbut β c cos(of / Lpath. ) , These lower and upper c ′ [πangle portion = zβ′w .w = tan dx tan , π tan cos β = [1 + ( z ′ )c2 ]−1 / 2 , sinβ u] u (2) w =wz wβ[1 + where (3) tan β c = tan β w ( x w= 0 ) = π t w(2 Lu ) . c is the so-called crimp angle (see Figure 1). shown in Figure 2. The parametric equations o −1 / 2 π x L ) , tan β w= =z ′[π[1t+ ((2z ′L)u 2)]]cos( tan= βzw′ .= tan β c cos(π x / Lu ) (2) , s β w = [1 + ( z ′w ) 2 ]−1 / 2 , sinβ w wL dx w w wtan β = w tan β (, x =tan (2but ) . (3) π =t dz 0 )u=βwhere c w u β c is so-called crimp angle (see Figure 1). t the ) . x ≤ofL the β w (πx x=/ 0L) =) ,π−t L(2portion L2u ≤ path. These lower and upper curves n β w = [π t (2 Lu )]cos(π x Lu ) , but tan β w = tan β c cos(πtan . zxw (/βxLc)u==) ,tansin( / / 2 x ( x ) = x + ( t / 2 ) sin β x z1 ( x) = z win( xt ( ) , are depicted u u 1 w where β c is the so-called crimp angle (see2 Figure 1).u shown in Figure 2. The parametric equations of the lower and upper c x 2 ( x) = x − (t / 2) sin β w ( x) , z 2 ( x) = z w ( x tan β c = tan β w ( x = 0 ) = π t (2 Lu ) . ere β c is the so-called crimp angle (see Figure 1). portion of the path. These lower upper arez1depicted in xof )= x + (tand sinterms β w (curves x)of, function ( x)z w(3) =(xz w) (are x) the − (t detail / 2) cosof β wthe ( x) undu , β/ 2w )in functions the angle . trigonometric tan β c = tan β w ( x = 0 ) = π t (2 Lu )The 1 (x Using eqs. (1) to (3) and setting in the first of shown in Figure 2. The parametric equations of the lower and upper curves are: portion of the path. These lower and upper x 2 ( x) = x(3) − (t / 2) sin β w ( x) , z 2 ( x) = z w ( x) + (t / 2) cos β w ( x) . cur (x = 0) =1.πCross n β c = tan β w Figure t (2 Lsection u ). 2the −1 /warp 2 2 shown −12. / 2 Geometry Figure of an undulation region of the representative unit cos cellβ(RUC) along yarn. in Figure 2. The parametric equations of the root of the equation = z ′win tan dz depicted dx . the detail , path. , curves = z ′wlower ( z ′ ) ] of the sinβThese [1 + ( z ′wand ) ] portion portion upper are of the of βthe path. These lower and upper cu w = w = [1 + x1 ( x) = xw + (t / 2) sin β w ( x) ,w z1 ( xalong ) = z wthe ( x) warp − (t / 2yarn. ) cos β w (wx) , Figure 2. The parametric equations of lower and upper curves are: shown in2the Figure 2. The parametric equations ot x ( x ) = , it ca eqs. (1) to (3) and setting in the first of eq. (7) 0 ofπthe These lower upper curves are depicted in the detail of ] π tan β w = [π shown t (2portion Lu )in cos( x Using Lpath. ) , but tan β = tan β cos( x / L ) , −1 / 2 u β ( x) , 2 (xxa))+=c(tan tc /cos( 2path. ) sin z11and (2xa()φ=aupper portion These lower cu−0 )]zare: 1. + tanupper β c cos = x 2 ( x) = shown x − (t / 2in) sin β w (u x2.) ,The parametric z 2 ( x) =wz wxequations txof / +2of )β(the cos 1(φ w ( x) wφ(ax))[w Figure theβ lower and curves the root of the equation Figure 2. The path. are packing density pd. The yarn packing where βc is thex1so-called angle ( xparametric ) , , b =in−zthe (1 x(upper x)φx−acurves βudepicted x(. xdetail ) )==zzww(of x( x)of)t+ (portion x) = x +ofcrimp (t the / 2) sin β w These x) , lower z1 ( xand )xshown =where zx)w)=(= xin ((see +(=t(t/π2/ x2) acos )sin sin βwwand /L x2za(1equations 2x w ( x) x where1). β c is theshown so-called crimp2.angle (see Figure 1). in Figure The parametric equations of the lower and upper curves are: (7) density is defined as pd = n · Af /A, where Figure lower uppv ,βit Usingxeqs. / path. 2β x ((1) x) =tox(3) + (tand 2)setting sin xcos( (x= x2)eq. (x+xx−)(12t−(((of 2−sin )10cos βcan ().x,)be, shown ) ,theφfirst )/sin β w β(2xwβ)(c,in za )2 [(1zx1+)of cos (xwx,)These (z=xw2portion )β(z(7) =x)cos t/x(2/ata2))/the )= z ( xthat )and = zthe 2 ( x1) = x − (t / 2φ ww(0 w ( x) a + tan xtan =wc the x + (path. t φ/ Figure 2))]sin β= xlower z12(upper x) =equatio zcurve ) , parametric Af = � df2/4 is the cross-sectional area of 1 ( x )shown w ( The w ( x) in 2. portion of These and portion of the path. These lower and upper curves are depicted Using eqs. (1) to (3) and setting in the first of eqi the root of the equation (xxπ)),,x / L zzand (xx)0)=)==xxπ+−t((t(twhere 2))sin sinββ (3) = zz=w(−(xxx))−+. ((tt//22))cos cosββ w((xx)), . w(= 2 (xx))= tan β c = tan β w x(xx12(= /2/2L the filament. The cross-sectional area of aw in a u2.1 ( u ). φ shown The w x −a(t 2. x 2 ( xxin )b =Figure / 2equations ) sin βparametric , the equations z 2 ( x)and = zof ( xth) shown Figure The parametric lower w (wx )of wuppe the root of the equation x ((3) xa )and = 0setting , it can in bethe shown eqs.(RUC) (1) to (3) andthe setting the Using first ofeqs. eq. (1) (7) to first that of e Figure section of the representativeUsing unit cell along warpinyarn. 2 the yarns is given by1.ACross 2x ( x ) = x − (t / 2) sin 2 β ( x )2 , −1 / 2 2) sin ) ,= xz1w( (xx) )=+x(t+/ 1(2t)/cos β w β( xw)( .x) , (8) z1 ( x) = z f = (� df n)/(4pd). wcos (φ )] z 2 (=x0 φa + tan β2 c cos( φthe [equation 1fibres +to tan(3) βand a )(1) c the a x ( x ) = , it can be shown t Using eqs. setting in the first of eq. (7) 0 the root of the root of the equation The volume fraction of the in Figure 1. Cross section of the representative unit cell (RUC) along the warp yarn. xβ) w=( xxx)eqs. +2, x(t) /(1) β 1( x)zsin (22x))the = zzfirst )aw,(setting The representative unit cell (RUC) is a x1 ( xof2) =thex +representative (t / 2)xsin x2β)βw− /,in β−w21w/((2(xxx=))of )−=0, e(,z 1 (Using to ( x(zt)1warp =2)xzsin 2 (β (φcos φwarp cos( φ1−(a(x(3) )t)[1/w=2+and tan Figure 1. Cross section unit (RUC) along the yarn. where and . φ π = x / L x = − x a + tan ccell c cos a )] The volume fraction of the fibres in the RUC is given by ( 4 ) /( 4 ) V = p A l a H . For the yarns, RUC is by . a a u b a the root of the equation f d rectangle consisting of two warp yarns the (the xeqs. x(1) teq. / 2(3) )(7) sin βx = xza)w),(=x0)2 +, in ( x)be = zshown ( ((xsetting itzt2can Using and 2 eqs. (1) to x(3) /= 2( x 2(to root of the )−0,of xtan ) =2xsetting −cos (tUsing / 22in )xsin β−)1wfirst (and βw−w1(/(x2x)=)+.0th 2 the 2= 2/φ φH x azequation Lxau))1wwarp xyarns, =β c−(cos x/a 2.2)(cos ,cell φa the + tan βarc φa ) [12by +(of βrepresentative Forthe thefibres warp yarns, the is givLu 2 tan β. π cos( [and 1along + tan φyarn. volume fraction of in RUC is length given ))]φ/( V p d (Aφof a(7) the a )= b the c cos( c ( 4first alwhere a 4+ cFor a )] interlaced with two fillThe yarns with resin f = Figure 1. Cross section the unit (RUC) warp 2 eq. x (x ) = 0, it can be shown thefibres equation eqs. firs fraction ofof is 2given by /(4and ) . For in =a (4(1) p Atol )(3) a Hsetting thethe warp 2 the 2 −Using 1 / 2 V1a the arc length given by portion l = 2 ∫of 1 + (The z ′w ) 2 volume dx + 2(Lawhere −the L )root . aUsing this integrating, we ,π (where )]have 0f is φ and )in [1 +the tanRUC β xc acos φavalue = . the = πβ cxcos( φ2(1) = x a / droot Lu and x2b =equa− x a2 . matrix filling the isremaining u 2 φ au +φtan −1 / 2 a / Lu aand xb = −that the of the aof Using eqs. to (3) and setting in the first of eq. cos ( )] φ + tan β cos( φ ) [ 1 + tan β φ = Lu 2 eqs. 2unit cell Figure 1. Cross section of the representative (RUC) along the warp yarn. x ( x ) = , 0it( Using (1) to (3) and setting in the first of eq. (7) 0 the root of equation a c a c a L 2 − 2 a en l = 2 fraction 1 + ( zof′wφ2)the dxπfibres +x2(/aLin −L this and we have a. For1 the the arc is given byvolume the volume. Its dimensions arelength 2a × u2a 2Using −by 1 / 2 integrating, u ) . RUC 2x a2given where and . = x = − The the is ( 4 ) /( 4 ) V = p A l a H warp tion ∫ a a u b f d , cos ( )] 0 φ + tan β cos( φ ) [ 1 + tan β φ = ′ ( zcw )equation dx where +root −φthe La u=) equation .π Using we hy the arc length is given by l =the the a2 root a2( aof and and x a / Lu this xb =integrating, − xa . for is the volume fraction: − Lu 2 a the warpc yarn. ∫ 2 1of+ the Figure 1.itsCross section ofdenoted the representative andrelationship thickness by H. Theunit cell (RUC) along Lu 2 2 2 2 2 −1 / L − u The volume fraction for of the in fraction: the RUC is given 4a− xHa .) . Forφthe =/ L(4 pand A lx) /(= warpβyarns, + tan where φ a by = πVxf ahave c cos(φ a ) [·1 + tan β c cos (φ a )] relationship the fibres volume Using and integrating, other parameters are denoted and shown l = 2 u∫ adre12+ (b z ′w ) 2 dx + 2(a 2−a 2Lu ) . Using this the arcthis length given bywe 2 and integrating, 2 −1 / 2 we h 2 − 1 / 2 relationship foristhe volume fraction: Lu 2 β(4) cos( φ=a )]− x . = 0 , 2 , xb((9) φa− L+u tan β cos(φφaa·)+ [1tan + tan cβ c0cos where φφa a=)(φ[π1a+)] x atan / Lu=βand [1 −the ] , Vlationship V f =of[ A /( a t hshows ( Luidealization / ais) ggiven c cos in Figure 1,pwhich e volume fraction the in RUC 4a volume = (4 p Afor l ) /(the H ) . Forfraction: the warp 2yarns,c a dfibres r )]the 1 (β c )by ((zβ′w ))2] dx + 2(a − Lu ) . Using this andwhere integrating, we have a x =(4) the arc length is pgiven by)]l[1=−f 2( L∫ / a1d) + and . = x / L − x φ π V = [ A /( a t h g , where φ a = π x a / Lu anda xb = −ax a . u of the real model. LThe idealizations arer b a relationship 2u u 2 f2 d 1 for c 2 the volume fraction: g 1 (β c ) = 1 + 2 1 + tan β c E (2m) / π , m = tan mu ≤/ a1) g1for 1 p+dtan , ([10−≤( L (5) V − Lβ /( a tβh )] (β c )]0, ≤ β c ≤ π 2 ), u=2 c[ A 1 +most ( z ′w ) warp dx + and 2(a − Lu 2) . f Using this andcr integrating, we2 have a arc lengthrelatively is given by l = 2because simple 2 ∫ relationship for the volume fraction: 0 ≤ m ≤ 1 for 0 ≤ β ≤ π 2 ), (5) g ( β ) = 1 + 2 1 + tan β E ( m ) / π m = tan β 1 + tan β , ( , 2 2 2 1 c c Using (4) − Lu 2 weft yarnsh are nominally straight. The ≤ m ≤ 1 for consid0 ≤ β c ≤ π 2 ), ) =p1d +/(layer) tan βLcuc E πβ c,)]cm β c 1complicated + tan β cof, ( 0cmathematical [1 − (E(m) Vg (=β [ A a2 t h1r+)]and / a(is )mg)a1/(complete , = tan where elliptic integral r = 1 + t r /( 2 t ) ( t r is the thickness off1thec resin erations, we can obtain the relationship ationship forthickness the volume fraction: of the yarn along the centreline Figure 1. Cross section of the representative unit cell (RUC) along the warp yarn. Figure 2. Geometry of an u where E(m) is a complete elliptic integral of ( is the thickness of the resin layer) and h = 1 + t /( 2 t ) t 2 2 2 the second kind. V f = [ A p d /( a t hrr )] [1 − (rLu / a ) gwhere (4)≤ 1isofafor marea 0 ≤the β celliptic ≤ π 2 integ βcc ))] ,=hr1=+12+ t1r + E (the m) /thickness π , m = tan ), β cthe 1 +cross-sectional tanlayer) β c , and ( 0 ≤E(m) acomplete tip of 11r((β offor the resin /( 2tan t ) (βt rc is of the yarn path is denoted by t. If the fithe second kind. fill yarns A in the undulating region, 2 2 2 2 tipπ 2 ), kind. volume [1 − ( Lufraction = [ A p d /( abre t hr )] / a )gg1 (1β(βcspecified (4) ≤ in m(5) ≤ 1 RUC 0given ≤Using βlayer) )c )=] ,1 + 2 for 1 + the tan unit β c E (mwhere )the / π second mh ==tan , ( 0thickness , volume complicated consideratio The fibres the isresin by (4(5) 4a H ) . For Vand p d Aismathematical l )a/(complete the warp c ≤ f = E(m) (oft r the isβ cthe offor theFigure elliptic integ 1 +fraction t rβ/(c 21t + ) tan r determined by integration using the func2. Geometry of an undulation region along cell2.1. is too small, it is necessary to add an A in the undula area of a tip of the fill yarns L 2 2 2 2 theβundulation region tip u π 0 ≤ m ≤ 1 for 0 ≤ β ≤ 2 (β c ) = 1 + 2 1 + tan The β c Egeometry (where m) / π , hm =of ), (5) =1tan 1 + tan β , ( the second kind. tions in eqs.integral (7) to (9) c c thickness of the resin layer) ofthis and integrating, we +The t r /( 2cgeometry t r is the ttr)to( the additional resin layer ofr2.1. thickness ′w ) 2 dxgiven = 2E(m) 1is+a( zcomplete +given 2elliptic (a −inLeqs. arcundulation length is given by land ofthe the region (7) to (9): u ) . Using ∫ complicated mathematical considerations, we can obtain the r 2.1. The geometry of theUsing undulation region unit cell. The geometry of the path of the the second kind. − Lu 2 a constant normal the we can determine the equationsL of ere hr = 1 + t r /(On is a complete integral ( t r basis is theofthickness of thickness the resin layer) andtoE(m) 2 t )the where hr =centreline 1+ tr /(2t)path, (tr elliptic isFigure the thickness Lu 2along the Lu warp 2 u 2 in region 2. aGeometry undulation yarn. Atip the undulating region, determined area of tip of of theoffillanyarns warp or fill yarn is modelled using two relationship fornormal the volume fraction: curves of the yarn in the cross section of the RUC along the can undulating the basis of warp a constant thickness tothe the path, we the equations ofz ( x)(dx / dx) dx E(m) is acentreline complete of thethe resin layer) and 2.1. The geometry of undulation region second kind. the lower and upperOn Atipdetermine = ∫ z1 dx + Figure z dx = On basis of a constant thickness normal to the centreline path, we can determine the 1 2 2 1 1 equatio 2. Geometry of an und ∫ in eqs. (7) toof (9): assumptions: 1 – the centreline of the the lower and upper elliptic curves integral of the warp in given the cross section the RUC0 along the∫0 undulating of theyarn second kind. xa along for Using complicated mathematical considerations, we can obtain the relationship the cr the lower and upper curves of the warp yarn in the cross section of the RUC the undu 2.1. The geometry of the undulation region yarn path consists of undulation portions Figure 2. Geometry of an undulation region along the warp yarn. Figure 2. Geometry of an un L 2 L 2 L 2 L 2 V f the = [area A p d of /(ofaatatip hconstant − ( Lfill / ayarns ) g1 (βuAcnormal )] , u u On basis tou the centreline path, we can determine the equatio r )] uthickness region, determined by integration using of[1the tip in the undulating Using complicated mathematical considerations Now, the area and straight portions, with the centreline Atip the =Figure z1 dx12. +Geometry zin2 dx z1 (undulation xcross-sectional )(dx1 / of dx)the dx +RUC z1 (of x)(the dx1fill / dxyarn, ) dx . of∫an region the warp yar the lower and of upper curves of warp yarn the section along the undu 1. The geometry of the undulation region 2 =cross ∫20considerations, ∫Aalong 2 The the undulation the ofthe a2 tip of( 0the fill yarns On the basis described of a constant centreline can of Figure 2. Geometry of in (7) to π an ≤m ≤ 1 for 0in≤consideration β c ≤undulatin 2for g 1 (geometry β cnormal )given = 1 +Using 2toeqs. 1the +complicated tan β c(9): E (mpath, )region / π ∫0,we ),unt m= tandetermine β carea 1Finally, + tan βequations mathematical can obtain the Using mathematical xacomplicated xa tiprelationship c3,we of the undulating portions by thickness the 2lower and upper curves ofOnthe in cross of the RUC along the undulating thewarp basisyarn ofLu aUsing nor2. Geometry ofof undulation region the yarfu given in (7) to can (9): the undulating region, determined integration area of the a tip thesection fillFigure Athe in thewarp undulat area a tip ofwe the fill yarnsalong 2 constant Luof 2thickness Lyarns Luan 2eqs. sine function, – the cross-sectional u 2 tipby complicated mathematical considerations, obtain relationship 3is the basis ofthea constant thickness normal to the centrelinewhere path, we equations ofAtipofinthe Now, the cross-sectional area of( the fill yarn, which the same asinte th isdx the thickness resin layer) and E(m) is a. )]complete elliptic hr centreline =can 1 + tdetermine 2 tpath, )+ ( t r zthe Using complicated mathematical consideration mal to the we can deterr /( A = z dx = z ( x )( dx / dx ) dx + z x )( dx / dx ) dx Figure 2. Geometry A = a t [ 1 − ( L a ) g ( β g (β , where area and the thickness of the yarn normal L 2 L 2 L 2 A in the undulating region, determined by integratio area of a tip of the fill yarns 1 in1 eqs. 2the 1 1tip lower and upper curves of the warp yarn in the cross section oftip the RUC along undulating given to2 (9): given ∫uin 1eqs. (7) u 1u to (9): 2 c u 2 of ∫0Using ∫0 (7) ∫x upA in the undulati area of a tip of the fill yarns complicated mathematical considerations, we can obtain the relationship fo the second kind. mine the equations of the lower and tip Finally, xa z dx + Figure a to its centreline are uniform along the arc A z dx 2.= Geometry z ( x)(dxof / an dx)undu dxalo + Figure 1Geometry 1 1region tip = ∫L2. Lu 2in eqs. (7) Lu 2 to (9): Lu 2 given Lu 2 of 2an undulation Lu 12 ∫ ∫ u 2 Lu 2 region, the undulating determined by integratio area of ayarn tip ofin the fill yarns Atip in given per curves of the warp the cross in eqs. (7) to (9): Using complicated mathematical consider 0 0 (10) for Axa in eq. (4), we can r length of the centreline. The centreline of Substituting eq. dx =− (the (Now, dx(1βthe / dx )=dx∫+is z u+ (same / the dx )=dx A z1where dx zarea (fill x)( dx Now, Athe cross-sectional which the warp yarn, is/ dx 2. A 2 1 + A Larea 2t [ 2x )( 2u a 21of 1dx tip = 2as 2 )= 1G 1β tip =zto a2x))(gyarn, 1∫the −.zconsiderations, (φtipdx )A/ π)=und ,cross-sectional ∫0 inzL1udx ∫0 Using ∫LzuL1ufill ∫gdx of the(7) undulating 2 mathematical c )]complicated 23(β cfill 2A a ,in c the ofx∫a1L1tip of the Using givenalong eqs. (9): Lmathematical Lyarns complicated considerations, obtain thw the warp yarn path in an undulating re- section of the RUC Lu / area aL:u)02dx u 02 ux 2 we can xa a aof Now, the cross-sectional area the fill yarn, wh A = z dx + z dx = z ( x )( dx dx + z ( x )( dx / dx ) dx . 2.1. The geometry of the undulation region Finally, yarn, which is the same the yarn, 1 lower 1 2 up2 1 area 1 a tip 1 as 1warp tip These portion of the path. and A in the undulating of of the fill yarns ∫ ∫ ∫ ∫ tip A in the undulating region, determin area of a tip of the fill yarns Atip =given z1 dx z 2 dx = ∫ z1 ( x)(dx1 / dx) dx + Lu 2 Lu 2 in1Leqs. to2 (9): gion is specified by 3Luxa2 tip u+2 ∫(7) ∫which 0 0 xa Agiven =Finally, 2 yarn, AA +the t(a – Lto Substituting (10) for in (4), we can rearrange thefill result as Now, the cross-sectional area ofis the fill isuz). the same asx)athe yarn, is waA Now, cross-sectional area ofwarp the yarn, per curves are depicted indxthe detail of=eq. tipdx 0eq. 0(Finally, in eqs. (7) (9): A = z + z dx z ( x )( dx / ) dx + x )( dx / dx given in eqs. (7) to (9): L 2 L 2 L.u 2 1 1 2 2 1 1 1 1 tip ∫ ∫ ∫ ∫ u u φ π A = a t [ 1 − ( L a ) g ( β )] g ( β ) = 1 − G ( , β ) / whereto the . dx On the basis region of a constant thickness determine the equat ushown 2 in 2 ccentreline2 path, a cwe can t LucFigure a, : normal the undulation 2. Now, the cross-sectional area of the fill yarn, which is the same as the warp yarn, i 0 0 x x Finally, Finally, a a 2 (1) z w ( x) = sin(π x / Lu ) , − Lu / 2 ≤ x ≤ Lu the 2the 2RUC A +(β ∫the zLu2area dx = ( x)( dx(1βund / dx Lh L in 2Now, 2( L lower and upper theLu cross section along the cross-sectional the w 2 Lof tipLu = g/ 12g.parametric g1 + g 2curves )(Lu ofa )of + 1the −lower V fwarp u 2 / p yarn u 2where gyarn, )Lu ∫0uLzu 1a2dx) g12of ∫ z1fill 2 (Lu a ) − ( equations r d = 0 u. A = a t [1 − c )] , 2 c (1 The the 2 t (1) 0 x Finally, (10) Acan =dx =same z+1 as ( x)( / equation dx dx +) di∫ a( x t z(4), + the z1+ (L− x∫)(Gzresult dx /2dx ) )] dx zdx )( dx)1yarn, 1which 2 dx 1warp cross-sectional of fill yarn, is the ∫ =z1dx)∫(1) Substituting eq. rearrange 1 dx1we 2A 1φ 1where tipin=)] ∫0tipzFinally, u / 2 .upper curves A Now, = are: a t [eq. 1the − (10) (L afor ) gAA )∫a/,πquadratic ,∫ area where . ∫the −= (1the (, βas g/ dx (1) ( x) = sin(π x / Lu )z,w−( xL)u=/ 22 ≤sin( x ≤π Lxu/ /L2u .) , − Lu / 2 ≤ x ≤ Land 2 (β cprocedure 4 g=220a(βt c[1parameters u0 a2)(g 2 (β cx L2a u . c xa Equation (11) is used in theu iterative to determine 0 xa xa 2 L a : Now, area thecan fill rea ya Substituting (10) eq. (4),ofwe Finally, sin(π x / Lu ) , − Lu / 2The ≤ xtrigonometric ≤ Lu / 2 . u of functions of the angle β w in terms Afunction = a t [1 − (zLwu(x(1) a) )are g (β c )] , g 2 (β cthe )eq. = 1cross-sectional − G2for (φ a A, βin where c ) /π . The function of the crimp angle defined byNow, G2 2is the Au =athe a: area tcross-sectional [1 −of ( Lthe ) g 2 yarn, (βarea g 2whic (βas where of the fill yarn, The trigonometric functions of the angle L u afill c )] ,which c) Now, cross-sectional is the same t Finally, Substituting eq. (10) for A in eq. (4), we can rearrange the result as a quadratic equa Substituting eq. (10) for A in eq. (4), we can re L /2. in(x terms ofAfunction z( L (x)a )2are −1 / 2 2 −1 w4 (1) (terms xThe ) = trigonometric sin( πthe x / angle Lu )z,2functions − Lw/ u2are / 2terms ≤ xof≤the Lu function /angle 2 . Gβ w((1) β in of z ) are e utrigonometric of φ π = a t [ 1 − g ( β )] g ( β ) = 1 − G ( , β ) / , where . φ , β ) = I − ( I + I )( 1 + tan β ) + I ( 1 + tan β ) , where βw zinwfunctions of function (x) − 1 2 − 1 / 2 w 2c c c 2 a c w ] ca :2 2+ (az ′ )c ] L1, a :tan 2 β 3 = dzu Finally, 4 Finally, L ′ ′ ′ 2 , = dx z . (2) = + = cos β [ 1 ( z ) s inβ z [ 1 eq. u Substituting w w terms of function w z (x w ) are w w (10) for w A in eq. (4), uwe can rearrange the result as a quadratic eq β w in ometric (1) w − Lu / 2 functions ≤ x ≤ Lu / 2of. the angle w Substituting can re A = a t [eq. 1 − (10) ( Lu afor ) g 2A(βinc )]eq. g , (4), we where 2 )−]1cos( /2 2φ −1 tan / ,2 β Lcutan a β: πI 2=x=/dz− φ I = 2 cos 2 F ( , m ) ( [ β = t 2 L tan β = cos( L ) , π π 2 −1 / cos 2tanβ 2x −s1L / u2 ) , = z ′but ′ ′ ′ , , = dx z ., A in eq. A(4), (2) = + + [ 1 ( z ) ] inβ [ 1 ( z ) ] a a 1 w u w u L a wzare w tanwβ = dz w w w (10) w : Substituting eq. for we can rearrange the result as a quadratic eq ′ ′ ′ function z ww(x= ) ngle = a t [ 1 − ( L a ) g ( β )] g ( β ) = , where (12) , w sinβ , = dx z . (2) + s β w β=w[1in+ terms ( z ′w The ) ]oftrigonometric [ 1 ( z ) ] u 2 c g 2 (β c ) = 1 − G 2 (φ a2 , β cc ) / π w w the angle β w w of function w z w (x) are A = a t [1 − ( Lu a ) g 2 (β c )] , u where functions of w in terms 1/ 2 ′wbut ′w) ,(.=φ atan ,βπ x=tan β = dzbut +β( z ′w=)[2π]−t1 / (22, L )]cos( sinβ ) 2 ]−tan Idx =/=[L2βz4E , m)βL+cu 2cos( m) − 2 m sin 2φ a (2 − m +Substituting m cos 2φ a ) −1 / 2eq. ] (m − 1)for , A in eq. (4), we(1c a(m: π− 1x)/FL(uφ)a ,(2) tanπwβxw= =Lz ′w[π)[1,t+ ((2z L Ltan tan wπ 3x (10) u )]cos( u ) w,β cos( w ntions βwhere in terms of function z (x ) are w of the angle u u w c u w w crimp angle (see Figure 1). theβso-called 4 /2 2 c is 2tan Substituting eq. (10) for A in eq. (4), rearra x, βLutan )=, [β1 w+β=(but = tan β cos( x / L ) , πzt′w [(12+L(uz)′w]cos( π L a : −dx 1 / 2w 2 − 1 / 2 ′ (2) = dz z . (2) ) 2 ]−π1cos Substituting (10) m for((2) thecan result [(1β− m )(1 − m + m cos atan[ 1A−u in m)eq. cos(4), φa ] we [(1 -can m) rearrange 1− m ] . we c u I′4 = m cos ′ ′ φa )] + meq. , φ a tan z ′w )w ] , w sinβ w w = z w [1 + ( z w ) ] w = dz w dx = z w . 4 L a : 4 where β is the so-called crimp angle (see Figure 1). L a 2 − 1 / 2 : u here isβ the (see 1). = but = so-called tan cos( ) ),]tan π xc(/2Langle u ′w [1ββ+cwtan w , but βtan βπw )Figure scinβ (=z ′w[crimp cos( x==dz Lπutw) ,(dx x / Lu ) , π(2) w = ztan (3) βπ)c t]=(see tanL,u uβFigure 2 Lu )z.′w . tan β w = tan β c cos( w ( x = 01). s the so-called crimp angle of the first and second kind. F (φ a , m) and E4(φ a , m) are the incomplete elliptic integrals 4 s(π x Lu ) , but tan β w = tan β c cos(π x / Lu ) , Set of Equations 12. 2 tan β c = Ltan) .β w ( x = 0 ) = π t (2 Lu ) . (3) β c = Figure tan β w (1). xwhere = 0) = en (see to the (3) volume fraction equation (4) and the ya Assuming u so-called crimp angle (see Figure βπct is(2the 1). that 40 ≤ β c << 1 , we obtain approximations (3) n β w ( x = 0 ) = π t (2 Lu ) . 2 and4January higher in the/ Bseries shape equation (10). We neglect terms of order β c Europe FIBRES & TEXTILES in Eastern / December 2008, Vol.expansions 16, No. 6 (71) to obtain 50 (see Figure 1). ed crimp angle 4 final(3) results: (3) tan β c = tan β w ( x = 0 ) = π t (2 Lu ) . 4 π t (2 Lu ) . t = A p /(V h a)(3) , L = a (1 − V h / p ) / (1 − 2 / π ) . (1 a. If 0 < βc ≤ π / 4, then STOP. Convergence of the geometric parameters 1 1 z/t t, L u and tr has been achieved and the geometry of the RUC is estab0,5 0,5 lished. 2x / Lu 2x / Lu b. If βc > π / 4, then set βc = π / 4 and -1 -0,5 0,5 1 -1 -0,5 0,5 1 assume that the specified value of the -0,5 -0,5 spacing is incorrect. Solve εfor 2g. Calculate the yarn difference in the a iterates using the measure = (β c ) i − (β c ) i −1 t, L , t and a in steps from 3c to 3f. 2h. If , then increase the index . ε > tol i → i + 1 -1 u r -1 to step 2a, else, if i > imax , then STOP and print a 2i. If i ≤ imax c., then Set tgo r = 0 or hr = 1 and solve the quadmessage. ratic equation (11) for the two roots 2j. If ε < tol , then the fixed point iteration is judged to have converged to Figure 3. Geometry of an undulation region along the warp yarn calculated numerically: β c = (β c ) i . Lu /a. a) βc ≤ π/4 – model is valid, b) βc > π/4 – model is not valid (a cusp forms). Take the positive real root for the ratio 3. Check the constraintofonLthe crimp angle. u /a. , then Convergence of the geometric parameters t, L 3a. If 0 < β c ≤ /40 Table 1. The output data. d.π If < LSTOP. u /a ≤ 1, then go to step 3e, else, achieved and the geometry of the RUC is established. if L /a > 1, then set Lu /a = 1 and solve 3b. If β c > π / 4 , thenu set β c = π / 4 and assume that the specified value of the n a, mm t, mm Lu, mm βc, deg No. of iterations eq. (11) for hr. a in steps from 3c to 3f. incorrect. Solve for t, Lu , t r and 2000 1.4110 0.0857 0.5869 12.90 4 e. Because βc =the1,quadratic we determine from equation (11) for the two roots 3c. Set t r = 0 or hr = 1 and solve t = (2/π) (L /a)a. Substieq. (3) that 10000 1.4110 0.4727 0.7812 43.54 6 u Take the positive real root for the ratio of Lu a . this expression for t into the vol14000 1.6260 0.5804 0.9117 45.00 23 3d. If 0 < L / a ≤tute 1 , then go to step 3e, else, if Lu a > 1 , then set Lu a = 1 and u ume fraction equation (4) and solve hr . for the new yarn spacing to obnew that determine from eq.a(3) 3e. Because tan β c = 1 , we t = (2 π ) ( Lu a ) a tain From the small crimp angle equations Substituting eq. (10) for A in eq. (4), we expression for t into the volume fraction equation (4) and solve for the new (13), compute the initial values oftothe can rearrange the result as a quadratic obtain a new = π d p A[1 − g1 (β c ) ( Lu a )] [2 ( Lu a ) V f hr ] , where β c = π thickness t and length Lu. The initial equation in the ratio of L / a: u 2 3f. For anew from step 3e, compute Lu = ( Lu a ) ⋅ a new , t = (2 π ) Lu and t r = 2 t g1 g 2 (Lu a ) − ( g1 + g22 )(Lu a ) + 1 − V f hr / p d crimp = 0 . angle (β ) is computed from where βc(11) = π/4. g1 g 2 (Lu a ) − ( g1 + g 2 )(Lu a ) + 1 − V f hr / p d = 0 . c 0 (11) f. For a eq. (3). new from step 3e, compute (11) 2 Equation (11) is used in the iterative L . procedure to determine parameters u − ( g1 + g 2 )(Lu a ) + 1 2− V f hr / p d = 0 . (11) Numerical Lu = (Lu /a)·anew, t = (2/π)Lu and 1 g 2 (Lu a ) + Lexample . (11) used inL thea )iterative procedure parameters g1 Equation g 2 (of a )crimp − ( gis21 + V h1 p d h= /0p.to determine , Vf = – Inputtodata: duf = 0.007 tmm = 1.411 mm 0.64 r−/ V ) +f Begin gL1ugthe − (gg2 1)(+ L+u1 −a2. (11), pd = 0.75 , tol = π 4 ⋅10 −6 , im The function by Gu2g 2is)(defined 1)., a(11) iteration loop: for imax 2 (L u a ) angle f the r d = 0. r = 2t(h r The function of the crimp angle is defined by G L . quation (11) is used in the iterative procedure to determine parameters Equation 11 is used in the iterative proce2 2 − 1 / 2 2 − 1 − ( g1 + g 2 )(LuGa()φ+ 1, β− V) f=hIr / −p d( I= +0 .I )(1 + tan β ) (11) u in steps ofc )determine one. +2Iprocedure tan βto , where Lu . (11) used in the in iterative parameters a Equation c 2 1 2 is 4 (1−+ 2 LuInput . Equation iterative parameters determine parameters Gangle =(11) I31 − (is.I 2used +byI 3 )(c1 the + tan ) 1 / 2procedure β1c and ) −1 , where he function dure of thetocrimp defined Gc2) is No. of dataa,dmm V = 0.64, a = 1.411 2 (φ a , β tr+=I 40(1or+ tan hrto=determine forOutput the crimp a.β cSet f = 0.007, data: n t, mm f Lu , mm β c , deg The function ofdetermine crimp angle by G2 −1isLdefined . is defined is used in the iterative procedure parameters The function of the crimp angle is defined 2 to −I1the / 2=of 2) angle uangle = 0.75, tol = π/4 · 10–6, imax = 30. iterations I = 2 cos , − 2 F ( , m , φ φ The function the crimp by G mm, p ) solve the quadratic equa(β 2 + I (1 + atan β ) , where 2 G2 (φ a , β c ) = I1 −1 ( I 2 + I 3 )(Ia1 += tan β ) d c i–1 4 −22cFβ(φ)a−,1m φcIa ,−50). / 2) , 2 2000 1.4110 0.0857 0.5869 12.90 4 Equation 12 2 + I(11) of the crimp by angle by φ1 aG,(see β2 cos ) =page )(I1+2 +=I tan tan β ctwo ) −1 2, roots G2 Gis2 (defined where −1 / 2) −1 ,of The output data is presented in Table 1. the the ratio ctan tion β1c−) 1=()IF I21(+φ−aI(,3Im 1m+sin βa c()2−4−1 /(21m+ +for Im + tan β where 10000 1.4110 0.4727 0.7812 43.54 6 I 3 = [22 E (φ−a1,/ 2m )2+c(φ2a(,m 2 2 φ + cos 2 φ ) − 1 ) , (12) c ] (m 2 ) − 3 )( 4 (1 1 / 2 − a ,h1 +/ ptan =β0I .2) I=3 −=2+[F2I (Eφ(1(aφ,+m )m,)2+β2)(−m1 ,−where 1) F (φ a , m) −Lu 2/ a. m sin 2φ a(11) (2 − m + m cos 2φ a ) ] (m − 1)14000 , (12) 0.9117 1 = 1.6260 0.5804 45.00 23 a ,tan −)2(+Icos Ia3f)( −φV c c 1a 21 + 4 r d I1 φ=E(φ 2 cos ,)( = −2 φ 2 F)(]φ+a2, m , , m)−,1m φm) F(φ , m) and are I 4 a= m cos [(a1, − 1 −athe m +incomplete mI 2cos m2)(If ) cos φ a ] [(1 1 − m ] . For n = 14000, a maximum crimp angle / 2 (1 − mreal 2a)m cos Fcos φatan[ /- m) aφ exists, )+ 2 (mintegrals − 1)IFa4 (=Iφ1am= ,m −φ aφfirst 2[(m,1sin (2mI−2a+m=m+−cos mb. (m − 1)m, (root cos −and m2)(φ1second φaa2)φno ]a+) positive m]atan[ 1 − mL) ucos ] [(1(12) - m) 1 − m ] . a− 3 = [ 2 E (φ a , m elliptic of the −1 / 2a I = − 2 F ( , m ) , φ = [2I E=(φ[a2,parameters m ) + 2 ( m − 1 ) F ( φ , m ) − 2 m sin 2 φ ( 2 − m + m cos 2 φ ) ] ( m−1− (12)spacing /a21) , condition, the yarn a I 3determine 2 L . iterative procedure to a is recomthen STOP the program and write a a a 2E (φ , m) + 2 (um − 1) F (φ , m) − 2 m sin 2φ ( 2 − m + m cos 2φ ) m − 1) , crimp angle condition, (12) a m) cos φ ] [(1 - m) a 1 − m ] . For n = a14000,]a (maximum 3m cos φ )a] + m atan[ m (1 − kind. the yarn spacing a is recomputed. 1(−φ m, )( 1) −and m +E −1 / 22elliptic 4 = m cos φ a [( a are the incomplete a message. puted. ( , m ) integrals of the first and second kind. F m φ warning m ) + 2 ( m − 1 ) F ( φ , m ) − 2 m sin 2 φ ( 2 − m + m cos 2 φ ) ] ( m − 1 ) , (12) ngle G2 is defined a a [(1 − m )(1 − m + m φa )] +2 φ m)elliptic m (1 − m)of φmaFigure ] [(1and m ]kind. . calculated shape of the undulation region along the warp a a byI 4 = a cos In numerically integrals F (mφI acos ,=mφm ) aand cos φE (φ[(a1, m − )mare )(1 −the m +incomplete m ]atan[ + smallest m atan[ m (cos 1 −the )first cosroot, φ-3,aa)m) ]a second [(11-−m) 1− m] . c. cos Takea the positive real 2 −1 Assuming / 2Assuming 2 4 0 −≤ 1 β 2 <<a1 , we two cases: model is valid (the π / 4 ), b) model is not valid because a cusp forms i β c ≤yarn 2 that we obtain approximations to the volume fraction equation (4) and that 2 obtain +[( tan β ) I ( 1 + tan β ) , where c 1 − m )( 1 − m + m cos φ ) ] + m atan[ m ( 1 − m ) cos φ ] [(1 m) 1 − m ] . c incomplete approximations to the volume fraction equation (4)3,anda the yarn Assuming that 0 ≤elliptic β c << integrals 1 , wea obtain a the ofand the first and second kind. (φ a , m) cand E (φ a4, m) are In Figure numerically multiply the root by the yarn spac). region close to the end of the undulating region ( β c > π / 4calculated 2 approximations theWe fraction and Evolume (φ aneglect , m) are the incomplete elliptic integrals ofthe theseries first and second kind. F (φ a , mto )(10). and higher in expansions to obtain the shape 2equation terms of order β 2 c shape of the undulation region along and E ( , m ) are the incomplete elliptic integrals of the first and second kind. F ( , m ) φ φ ing aoftoorder obtain aequation newhigher value of the unand in the series expansions to obtain the equation (10). terms β , wethe obtain to the volume fraction (4) and the yarn 1and −ssuming 2 F (φ a , mthat ) equation , 0 ≤ β c << a yarnapproximations aWe neglect c (4)shape shape equation E (φ a , m) arefinal the incomplete elliptic first andapproximations second kind. we obtain the volume fraction equation (4) yarn and the yarn for two cases: a) Assuming that 0integrals ≤ β c2 <<of 12,the results: the equation warp is and shown dulation Ltoexpansions 2 u. /02 ≤ β β<< −1order final results: obtain to the to volume (4) the yarn Assuming that 1, , we neglect terms of order and higher in approximations thelength series obtainfraction the hape neglect terms of (φ a , mequation )2− 2(10). m(10). sinWe 2φWe ( 2 − m + m cos 2 φ ] (mc −and c 1) 2(12) a a ) to the model is valid (β π/4), b) model is not L ≤ a, then go to step 2e, else, d. If 0 < ,t we obtain approximations volume fraction equation (4) and the yarn t 0 ≤ β c << 1higher and obtainc ≤the shape equation (10). LWe neglect terms of) /order u 2β 2higher in the series expansions to (13) in the series expansions to obtain c = A p /( V h a ) , = a ( 1 − V h / p ( 1 − / ) . π d u f r d nal results: the series obtain the in the filaequation We neglect terms of/ porder t f=shape Ar 1p− h2 r φa) ],(10). −β c2 L /and (13)forms π )=. higher d /( d ) / (1set validexpansions because atocusp then a and in solve cos 2We φa )the ] + final m atan[ mV) βfcos [(1 - m) L1u−=ma](.1if− LVuf >hr a, u a final m results: results n+ m (10). neglect terms of (order c and higher in the series expansions to obtain the final results: ment in aofregion to the end of the eq. (11) hiterative = A p d /(V f hSmall Lu = a approximations (1 − V f hr /approximations p d ) / (1(13) − 2 /are (13)beginning π ) .used crimp angle in for the at the the close r. in the procedure r a) , (13)h are used procedure at the beginning of the t =Small A p d /(crimp V f hr aangle ), Lu = a (e. 1 −Determine V − 2 /thickness (13) π ) .iterative undulating region (β > π/4). f r / p d ) /a(1 new t from the calculations. c 6 the incomplete elliptic integrals kind. t = A of p d the /(V ffirst hr aand ) , second / (1 − 2 / π ) . (13) calculations. (13) L u = a (1 − V f hr / p d ) at crimp angle procedure beginning hmall Lu =approximations a (1 − V f hr / p d )(13) / (1 −are 2 / πused ) . in the iterative (13) (4). of the fibre volume fractionthe equation r a) , Small crimp angle approximations (13) are used in the iterative procedure at the beginning of the we obtain approximations to the volume fraction equation (4) and the yarn alculations. 2.2. Algorithm to crimp determine the architecture parameters f. Calculate a new crimp angle (βc)i from Small angle approximations (13) are used in the iterative procedure at the beginning of the 2.2. Algorithm to determine the architecture parameters calculations. Conclusions 2 angle crimp approximations (13) angle approximations arehigher used in the iterative procedure atobtain the beginning of the and in the series expansions to the eglect termsSmall of order β(13) eq. (3) using new L and t detercalculations. c u .2. Algorithm to determine the architecture parameters are used in the iterative procedure at the Input parameters: n, d f to , pdetermine , a, Output parameters: t, Lu , β ct,, tLr , , aβnew –presented new yarnmethod of analysis was The in steps 2c to 2e. dn, parameters: d f V, f p, dtol, ,the a, imax. Vmined Output parameters: Algorithm architecture f , tol, imax. parameters u c , t r , a new – new yarn beginning2.2. ofInput the calculations. 2.2. Algorithm to determine the architecture parameters o very useful for the modelling of textile g. Calculate the difference in the iterates ,parameters Vβ –imax. vol.o ofV¼– of the V yarn –L(13) vol. of the innew ¼ ofyarn the – vol. =V45, iftol, Vr RUC, nput n,the donly ,spacing pif ,βa, parameters: t,RUC, βyarn ayarns hm architecture c only vol. ofRUC, ¼ of the yarns in RUC, ¼ of the Vr – vol. Lu to =parameters: adetermine (1 − Vspacing u, V c , t– r , vol. newof –the c = 45 ,Output f hr / p d )f / (1 −d 2 / π ) . f composites. It can of course be applied using the measure Input parameters: n, architecd f , pd , a, V f , tol, imax. Output parameters: t, Lu , β c , t r , anew – new yarn o toindetermine Algorithm the of the resin ¼ of the RUC. of the resin in ¼ of the RUC. , V – vol. of ¼ of the RUC, V – vol. of the yarns in ¼ of the RUC, pacing only if – vol. β = 45 V , Input parameters: n, d , p , a, V , tol, imax. Output parameters: t, L , β , a – newmodels yarn (not only t for more complicated . .mations Calculate the the measure ε = ( β ) − ( β ) yarn d cdifference in the iterates using r f f u c r new o c i c i − 1 in theimax. iterative at of the the ––new ers: n, d(13) pare a,used V t,¼beginning Lof β c ,RUC, t r ,ofaVnew , V – ovol. vol. yarn of the yarns in ¼ with of thea RUC, spacing if Output – vol. β c =procedure 45parameters: V f ,ture f , tol, only d , parameters u , the yarn r centreline h. Ifofε¼>oftol, then increase the ofindex f. the of the RUC.spacing If resin then increase thecross-sectional index ε > tolin, ¼ i→ V – vol. the RUC, the yarns ¼ sinusoidal of the RUC, only if iβ+c 1area =. 45 A, of Vr – vol.of the yarn). 2 . Set .Onin yarn 1. Compute the A (π d 2f V )=r /(–(4π–vol. pdvol. . of yarn Compute cross-sectional area AnVyarn ) /(4 phrd )=.1Set hrthe = 1basis – vol. ofof¼1. of then,RUC, Va,yarn vol. of thethe yarns infrom ¼+ of the=from RUC, f β c = 45o , V the resin the RUC. Input parameters: dinf , p¼the V, –tol, imax. df )n of this model, certain geoiASTOP → ithe 1. d,of 2a, else, if , then and print a non-convergence If i ≤ imax , then go toofstep > i imax thet,crimp resin ofequations thenew RUC.(13), compute Output parameters: LA βcin ,angle tr¼ , crimp ayarn From theparameters small initial values ofvalues the thickness t and length metrical parameters imax, then go to step 2a, else, ifof the u, small new –from From the angleAequations compute the initial thickness t and lengthwere obtained. ¼Compute of the the RUC. of the the cross-sectional area =i. (πIfdi2f ≤n)(13), /(4 pthe mine architecture message. d ) . Set hr = 1 .2 . . Set A of the yarn from 1. Compute the cross-sectional area yarn spacing only if β = 45°, V – vol. of A = ( π d n ) /( 4 p ) h = 1 . The initial crimp angle is computed from eq. (3). L ( β ) These parameters fully characterize the i > imax, then STOP and print a nonc . The initial crimp angle is computed from eq. (3). L ( β ) f d r u the angle c 0judged If ε <the tolsmall , thencrimp fixed point iteration is have converged tothickness theA crimp cto0initial 2angle From equations (13), compute the of the length ) . Set h = 1 . A values of the yarn from 1.Vuyarn Compute the cross-sectional area = (πt dand 2in f n) /( 4 p d geometry r of the considered composite – vol. of the yarns ¼ of the RUC, convergence message. From the small crimp angle equations (13), compute the initial values of the thickness t and length . . Set A of the yarn from he cross-sectional area A = ( π d n ) /( 4 p ) h = 1 , danew – new pd L,βu a, , )tol, imax. t, Lufrom , fβ c eq. , t r (3). yarn =V(βf cinitial r crimp Output angle (βparameters: ) 0 is computed c. The i. ¼ the RUC, –cvol. of the resin the small crimp equations thepoint initial values structure. of the thickness t and length The method has shown that j. 1in If εimax > of tol, thencompute the fixed iterarFrom .VThe initial crimp computed from eq. (3). (βangle iangle =initial 1into¼ 2.ofBegin the loop: forthe imax steps one. 2.Luiteration Begin the iteration loop: for to in(13), steps of one. c )i0=is mall crimp angle equations (13), compute values of the thickness t and length – vol. of ¼ of of the the RUC. RUC, V yarn L– vol. ofinitial the yarns inangle ¼ of the RUC, Vr – vol. . The crimp is computed from eq. (3). ( β ) the presented model is valid only for a tion is judged to have converged to the u c 0 or and for the crimp angle ( β ) solve the quadratic equation (11) for the 2a. Set t = h 1 0 or and for the crimp angle ( β ) solve the quadratic equation (11) for the 2a. Set t = h = 1 0 tialthe crimp angle (on computed from eq.in(3). β )the r c i −1 rrimax r c i −1 ck constraint iangle. = 1 to for steps of one. 0 iscrimp C. Begin the iterationc loop: crimp angle of less than 45° (β crimp angle β = (β ) . cof c ≤ π/4). i = 1 c i 2. Begin the iteration loop: for to imax in steps one. roots of theroots ratioofLthe . geometric two L a. β c t≤r π , then STOP. Convergence ofaratio the parameters t, L and t r has . If2a.0 <Set (11)been for the = 0/ 4or htwo r = 1 and for the crimpu angle (β cu ) i −1 solve the quadratic uequation 1. Compute the cross-sectional area A of for Ifequation the crimp angle βc > π/4, the model is i = 1 2. Begin the iteration loop: to imax in steps of one. or and for the crimp angle ( β ) solve the quadratic (11) for the 2a. Set t = h = 1 0 c i −the 1 and i =the 1 If teration loop: for of to imax inis ofroot one.r Lreala root 2 positive 2b. Ifsteps no aCheck exists, then STOP program and writenot a message. warning message. ed the of the RUC no positive exists, STOP the program write a warning two roots ratio .restablished. . for Ageometry of the yarn from naland area ALu= dreal 40p doru) . Set h1r Land =u 1then the2b. yarn from valid because a cusp forms in the fil3. constraint the crimp thethe crimp angle (for βon 2a.a(πroots Set =the hrL= the f nt)r /( c )the i −1 solve the quadratic equation (11) for the two of ratio a . and for the crimp angle ( β ) solve quadratic equation (11) h = 1 u 4 / > , then set β = / 4 and assume that the specified value of the yarn spacing a is π π r. =If0 βor r c i − 1 a to obtain Take the smallest positive real root, and multiply the root by the yarn spacing 2c. Take the smallest positive real root, and multiply the root by the yarn spacing a to obtain a c If no positive c 2c. h = 1. 2b. real root L a exists, then STOP the program and write a warning message. ament in a region closeato the end of the angle. r gle equations (13), compute theu initial values the thickness length two roots ofof the ratio a . t and 2b.value Ifand no positive real root Lto aLLuexists, then STOP the program and write a warning message. oots of the ratio Lu for a .new L . new value of the undulation length . of the undulation length u 3f. t , L , a in steps from 3c incorrect. Solve t u u u r a to obtain a 2c. Take the smallest positive real root, and multiply the root by the yarn spacing le (β c ) 0 is computed from eq. 2b. (3). If no positive real root L a exists, then STOP the program and write a warning message. u root, to obtain the positive real and the by the spacing positive root L=u1the aIf exists, then STOP the and aelse, warning TEXTILES Eastern Europe January /≤December / B 2008, Vol. 16,write No. 6L(71) 2d. Ifa 0,length < Lsmallest then go step Lu message. >set a u,L then Lu solve = a yarn and eq.ah(11) for hr .a 51 LTake 0in2c. < then step 2e,to else, if2e, a ,ifmultiply then asetand eq. solve (11) for Lauto .,program value undulation or and solve quadratic equation (11) for the roots Set t rnew L au = . root =real h&2d. 0FIBRES u go u ≤the u >two r. r of 2c. Take the smallest positive real root, and multiply the root by the yarn spacing a to obtain a L . new value of the undulation length uspacing efor the smallest positive real root, and multiply the root by the yarn a to obtain a t from the fibre volume fraction equation (4). 2e. Determine a new thickness t from the fibre volume fraction equation (4). 2e.asteps Determine a new i = 1If to0 positive imax in ofgoone. 2d. < Lu ≤ , then to step 2e,thickness else, Take the real root for the ratio of LifuofLathe u. > a , then set Lu = a and solve eq. (11) for hr . new undulation length 2d.(β If)Lu0. < Lu ≤value a , then go to step 2e, else, LLu uthe >. a , then set Lu = a and solve eq. (11) for hr . length and of forthe theundulation crimp angle solve the quadratic equation (11)iffor 1value a) b) z/t undulating region. Using geometrical considerations, it is possible to obtain from this model basic mechanical parameters that are very useful for further strength analysis. Such mechanical considerations and a method for calculating mechanical parameters will be presented in a future article. Using the Mathematica environment [11], a special computer program was developed to calculate the geometrical parameters. References 1. Cox B. N., Flanagan G., Handbook of Analytical Methods for Textile Composites, Nasa Contractor Report 4750, Hampton, Virginia, March 1997. 2. Hull D., Clyne T. W., An Introduction to Composite Materials, Cambridge University Press, 1997. 3. Jones R. M., Mechanics of Composite Materials, McGraw-Hill Book Company, Washington, DC, 1975. 4. Tsai S. W., Hahn H. T., Introduction to Composite Materials, Technomic Publishing Co., Westport, CT, 1980. 5. Scida D., Aboura Z., Benzeggagh, M.L., Bocherens, E., Composites Science and Technology, vol. 57, 1997, pp. 17271740. 6. Woo K., Whitcomb J. D., Composites Science and Technology, vol. 60, 2000, pp. 693-704. 7. Lomov S. V., Gusakov A. V., Huysmans G., Prodromou A., Verpoest I., Composites Science and Technology, vol. 60, 2000, pp. 2083-2095. 8. Jiang Y., Tabiei A., Simitses G. J., Composites Science and Technology, vol. 60, 2000, pp. 1825-1833. 9. Osada T., Nakai A., Hamada H., Composite Structures, vol. 61, 2003, pp. 333339. 10. Turfaoui M., Akesbi S., Colloids and Surfaces A: Physicochemical and Engineering Aspects, vols. 187-188, 2001, pp. 439-448. 11. Wolfram Research Inc., Mathematica, Version 3.0, Champaign, Illinois, 1996. 12. Milašius V., Some Problems in Technical Design of Woven Textiles, Fibres & Textiles in Eastern Europe, vol. 5, 2(17), 1997, pp. 40-43. 13. Milašius V., Woven Fabrics CrossSection: Problems, Theory, and Experimental Data, Fibres & Textiles in Eastern Europe, vol. 6, 4(23), 1998, pp. 48-50. 14. Kobza W., Equilibrium of the Bent Soft Filled Laminate, Fibres & Textiles in Eastern Europe, vol. 9, 2(33), 2001, pp. 42-45. Received 2.04.2007 52 Reviewed 2.04.2008 FIBRES & TEXTILES in Eastern Europe January / December / B 2008, Vol. 16, No. 6 (71)