RFIC Test System

advertisement

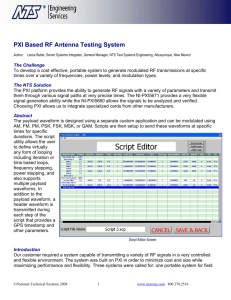

RFIC Test System Test Solution for Power Amplifier and Front End Module Characterization System Features • Support for 802.11a/b/g/h/n/ac, UMTS, LTE, and LTE-Advanced technologies • Getting started LV, C and .NET example programs for DPD, Power Servo and Envelope Tracking • Measure harmonics up to 26.5 GHz Envelope Tracking Reference Solution • Industry leading baseband-to-RF synchronization • Customizable Vcc waveform shaping • Advanced digital synchronization with DUT DPD Reference Solution • Measure AM-AM and AM-PM using modulated waveforms • Implement both lookup table (LUT) and memory polynomial model (MPM) DPD algorithms Characterization & Manufacturing Test Solutions • FPGA-based power level servo • 5x to 10x improvements in measurement speed versus traditional instruments RFIC Test System The demands of emerging wireless standards such as LTE Advanced and 802.11ac in conjunction with RF power amplifier (PA) technologies such as envelope tracking (ET) and digital pre-distortion (DPD) are creating new test challenges for today’s engineers. NI PXI offers complete solutions for PA testing from initial product design to manufacturing test. Benefits of NI PXI solutions include: • Best-in-Class RF Measurement Performance • Industry-Leading Measurement Speed • Reduced Cost of Test Modular Instruments PXI modular instruments including RF signal generators, RF signal analyzers, high speed digital I/O, source measure units (SMUs), switches, high-speed digitizers, and arbitrary waveform generators (AWGs). Application Software Embedded PC NI instrument soft front panel and reference example software provides an easy-to-use interface to modular instruments and is powered by LabVIEW As an embedded PC, a PXI controller is the heart of the PXI system and contains a highperformance multicore processor, deep memory, and multiple hard drive options. RFIC Test Soft Front Panel Customizable Example Programs TestStand Example Sequences Interactively characterize ET and DPD PA’s using measurements such as EVM, ACLR, and harmonics. Customize your RFIC test system more quickly by modifying ready-torun LabVIEW example programs. Transition test plans from initial design to automated characterization and production test using TestStand example sequences. www.ni.com/pa System Architecture DPD, Envelope Trackin for WiFi and Cellular Devices DPD, ET, and Power Servo LabVIEW / .NET Reference Examples RFIC Measurement Example Programs RFIC Test Soft Front Panel NI RFIC Test System includes a combination of software and PXI modular instruments. The system includes an instrument soft panel along with LabVIEW, C, and .NET example programs. In addition, NI TestStand example sequences allow you to easily automate PA testing with test executive software. TestStand Sequences for Characterization & Manufacturing NI-RFmx Measurement Driver Software Hardware PXI System Vector Signal Analyzer PXI Controller Source Measure Unit High-Speed Digitizer Arbitrary Waveform Generator High Speed Digital I/P Vector Signal Transceiver www.ni.com/pa DPD Solution Overview Digital pre-distortion (DPD) is a popular technique to correct for signal distortion and improve PA metrics such as ACLR and EVM. Testing a PA under DPD conditions involves four key operations: characterizing device behavior, model extraction, model inversion, and application of predistortion to baseband IQ samples. When testing DPD enabled PA’s and front end modules, the RFIC Test Soft Front Panel allows you to interactively apply DPD models and observe device behavior. This solution supports three DPD models, the memoryless AMAM/PM lookup table (LUT), the Memory Polynomial Model (MPM), and the Generalized Memory Polynomial (GMP). In addition, the included LabVIEW example programs allow you to automate device testing. Because these example programs use the same underlying measurement IP as the soft front panel – you can more easily correlate results from the interactive and automated use case. Performance Visualization Harmonics Measurements Observe improvements in spectral regrowth and modulation quality in real time. Measure harmonics up to 26.5 GHz using the high performance 5668R Vector Signal Analyzer PA Linearity Measurements PA Performance Metrics Observe AM-AM and AM-PM response of the PA with and without DPD. Use metrics such as ACLR, EVM, power, and RMS memory to characterize PA performance. www.ni.com/pa DPD Solution Hardware Configuration For DPD testing, the RFIC Test System combines multiple instruments into a single system including the NI vector signal transceiver (VST), precision power supplies, and high speed digital I/O. The NI VST is a key element of the measurement configuration and combines an RF signal generator and RF signal analyzer into one module. Tight synchronization between RF signal generator and acquisition enables you to accurately measure AM-AM/PM using modulated waveforms. NI PXI has the added benefit of accelerating measurement speed through NI-RFmx measurement software. This software takes advantage of multicore processors for highly mathematically complex algorithms such as the memory polynomial DPD model. PXI Chassis PXI Controller High Speed Digital I/O & PPMU MIPI RFFE Control Digital I/O Precision Source Measure Unit DCout Vector Signal Transceiver RFout Stimulus PA Vector Signal Analyzer RFin Response DPD Solution Features & Specifications DPD Models Supported Signal Types • Memoryless AM-AM/PM LUT • Memory Polynomial Model • Generalized Memory Polynomial • Measurements Included Products • • • • • • • AM-AM/PM Power EVM ACLR SEM RMS Memory (Phase) Harmonics • • • • • • • UMTS (WCDMA, HSPA, HSPA+), LTE / LTEAdvanced, GSM / EDGE, TDSCDMA, CDMA2k and EVDO WLAN 802.11a/b/g/h/n/ac NI PXIe-1085 18-Slot PXI Chassis NI PXIe-8135 Embedded Controller NI PXIe-5646R Vector Signal Transceiver NI PXIe-4139 Source Measure Unit NI PXIe-6556 High Speed Digital I/O NI PXIe-5668R Vector Signal Analyzer www.ni.com/pa Envelope Tracking Solution Overview Envelope tracking (ET) is an increasingly popular technique to improve the efficiency of power amplifiers for modern wireless signals with a high peak to average power ratio (PAPR). PA efficiency is highest when a PA nears compression, an ET Power Supply (ETPS) is used to dynamically vary the power supply in conjunction with the amplitude of a modulated wireless signal. Envelope tracking keeps a PA near compression as often as possible – thus improving overall efficiency. For ET testing, the NI RFIC Test Soft Front Panel transforms multiple instruments into a single measurement experience. Instruments include the NI Vector Signal Transceiver (VST), arbitrary waveform generator (AWG), and high-speed digitizer. The GUI provides an easy-to-use interface for synchronizing all of these instruments and also supplies UMTS and LTE waveforms. The system also features LabVIEW, C, and .NET example code that you can customize for automated test applications. DPD Algorithms Apply DPD algorithms to ET PAs to correct for AM-AM and AM-PM distortion. PA Performance Observe AM-AM and AM-PM behavior of PA under envelope tracking conditions. Envelope Control Applies envelope shaping and real-time control of VSG-to-AWG delay. PA Performance Metrics Use metrics such as ACLR, EVM, power, and RMS memory to characterize PA performance. www.ni.com/pa Envelope Tracking Solution Hardware Configuration A critical challenge for ET PA Testing is synchronization and stable alignment of RF and Vcc signals supplied by a vector signal generator (VSG) and arbitrary waveform generator (AWG). The RFIC Test System is based on NI PXI instrumentation and features shared trigger and timing bus resources. This implementation produces synchronization jitter between RF and Vcc signals that is less than 20 ps. In addition, by routing timing signals on the PXI backplane, these results are stable and repeatable. The software includes the NI Fast ET Align measurement which rapidly estimates RF and Vcc alignment. Finally, the envelope tracking software can simultaneously apply DPD to the stimulus signal. PXI Chassis PXI Controller Precision Power Supply DCout Shaped Envelope Vcc Out Arbitrary Waveform Generator High Speed Digital I/O & PPMU High Speed Digitizer MIPI RFFE Control Digital I/O Ch0 Splitter Ch1 Vector Signal Transceiver Power Modulator PA RFout Measure PA Behavior Vector Signal Analyzer RFin Envelope Tracking Solution Features & Specifications Synchronization Included Products • AWG-to-VSG Jitter: < 20 ps • AWG-to-VSG skew resolution: 1 ns • • • • • • • • Supported Signal Types • UMTS (WCDMA, HSPA, HSPA+), LTE / LTE-Advanced, GSM/EDGE, TDSCDMA, CDMA2k and EVDO • WLAN 802.11a/b/g/h/n/ac NI LabVIEW System Design Software NI PXIe-1085 18-Slot Chassis NI PXIe-8135 Embedded Controller NI PXIe-5646R Vector Signal Transceiver NI PXIe-5451 Arbitrary Waveform Generator NI PXIe-4139 Precision Source Measure Unit NI PXIe-5162 High Speed Digitizer NI PXIe-6556 High Speed Digital I/O www.ni.com/pa Power Amplifier Characterization Solution Overview The emergence of new wireless technologies and multi-mode power amplifiers are increasing the demands on automated power amplifier testing both in characterization and in high-volume manufacturing test. NI PXI automated test systems deliver best-in-class RF measurement performance with test times that are typically 5 to 10 times faster than traditional instruments. The NI approach combines high-performance modular instruments with highly innovative measurement software. Typical automated PA test systems include a combination of modular instruments and test automation software and test PAs that use technologies such as: GSM/EDGE, UMTS (WCDMA/HSPA/HSPA+), LTE/LTE-A, CDMA2000/EV-DO, and 802.11a/b/g/h/n/ac “ ” With NI PXI, we were able to reduce the characterization time of new parts from two weeks to about a day. Gary Shipley, Senior Engineer Qorvo Fast Power Level Servo Technology A unique technology of the NI power amplifier test solution is FPGA-based power level servo using the NI Vector Signal Transceiver (VST). Power level servo is traditionally a time consuming process. By performing the control loop entirely on the instrument FPGA you can achieve the fastest possible power level convergence. By decoupling the power level servo algorithm from the embedded controller and performing it on an FPGA, test software is able to exploit dramatic measurement parallelism. This results in significant reductions in test time and test cost. PXI Chassis PXI Controller CPU Memory Data Transfer FPGA Vector Signal Transceiver Digital I/O PA RFout RFin www.ni.com/pa From Characterization to Manufacturing Test The openness and flexibility of the NI RFIC Test System allows engineers to easily transition test systems from the R&D lab to the manufacturing floor. Although the RFIC Test System is designed for product characterization, you can duplicate the same physical hardware and measurement software for manufacturing test. R&D Test Bench Device Characterization Quickly validate PA behavior using instrument soft front panels or reference examples. Automate PA/FEM characterization through easy-touse example programs Manufacturing Test Re-use test equipment and characterization software such as LabVIEW code and TestStand sequences in manufacturing test. PXI’s combination of fast measurement speed and small physical footprint make it an ideal test solution for highvolume manufacturing. In addition, by re-using the same equipment and test software from initial product design through final production test, you can reduce development time and improve correlation of R&D and manufacturing test data. Deploying PXI in Manufacturing Test You can deploy PXI for manufacturing test either as a stand-alone system or as part of the NI Semiconductor Test System (STS). STS combines the NI PXI platform, TestStand test management software, and LabVIEW graphical programming inside a fully enclosed test head. PXI Chassis and Controller PXI RF and Modular Instrumentation NI RFmx Measurement Science and NI TestStand (Test Management) STS Standardized Docking and Cabling Interface NI PXI NI STS T1 NI STS T2 NI STS T4 The STS enclosure houses all the key components of a production tester including test instruments, device under test (DUT) interfacing, and device handler/prober docking mechanics. With the open, modular STS design, you can take advantage of the latest industry-standard PXI modules for more instrumentation and computing power to lower the overall cost of RFIC production test. www.ni.com/pa Hardware Specifications NI DPD and Envelope Tracking (ET) Reference Solutions are based on a standard configuration of PXI modular instruments. One can use these instruments with the LabVIEW Reference example code or as standalone instruments. PXIe-5646R Specifications (Signal Analyzer) Frequency Range 65 MHz – 6 GHz Bandwidth 200 MHz Amplitude Accuracy +/- 0.34 dB Average Noise Floor -161 dBm/Hz (1 GHz) 802.11ac EVM -45 dB LTE EVM -50 dB PXIe-5646R Specifications (Signal Generator) Frequency Range 65 MHz – 6 GHz Bandwidth 200 MHz Maximum Output Power +15 dBm 802.11ac EVM -45 dB LTE EVM -50 dB UMTS ACLR 65 dB NI PXIe-5646R Vector Signal Transceiver The NI PXIE-5646R VST combines an RF vector signal generator (VSG) and RF vector signal analyzer (VSA) into one module. The combination of wide bandwidth and high-quality RF measurement performance make the NI PXIe-5646R an ideal solution for RF power amplifier testing. Refer to PXIe-5646R Specifications Document for more details PXIe-55668R Specifications Frequency Range 20 Hz – 26.5 GHz Bandwidth Up to 765 MHz Phase Noise, Typ -129 dBm/Hz ( 1GHz) Amplitude Accuracy +/- 0.25 dB Average Noise Floor -167 dBM/Hz (1 GHz) Tuning Speed 3 ms (1 GHz step) Third Order Intercept +25 dBm (1 GHz) Refer to PXIe-5668R Specifications Document for more details NI PXIe-5668R Vector Signal Transceiver www.ni.com/pa Hardware Specifications (Continued) PXIe-5451 Arbitrary Waveform Generator Specifications PXIe-4139 Precision Source Measure Unit Specifications Max Sample Rate 400 MS/s Max Pulse Power 500 W Bandwidth 145 MHz Max Continuous Power 20 W SFDR (1 MHz) 98 dB Transient Response < 70 µs PXIe-5162 10-Bit Digitizer Specifications PXIe-6556 High Speed DIO Specifications Max Sample Rate 5 GS/s Clock Rates 800 Hz – 200 MHz Bandwidth (3 dB) 1.5 GHz PPMU Channels 24 Max Channels 4 Voltage Ranges -2 V to 7 V PXIe-1085 Chassis Specifications PXIe-8880 Embedded Controller Specifications PXI Express Slots 18 Processor Xeon Octal Core Total System Bandwidth 24 GB/s CPU Clock Rate 2.3 GHz Total Power Rating 925 W Memory Up to 24 GB www.ni.com/pa For more information on the RFIC Test system, email: rfic.test@ni.com ©2013 National Instruments. All rights reserved. LabVIEW, National Instruments, NI, ni.com, and NI CompactDAQ are trademarks of National Instruments. Other product and company names listed are trademarks or trade names of their respective companies. [20160729]