Document 10948360

advertisement

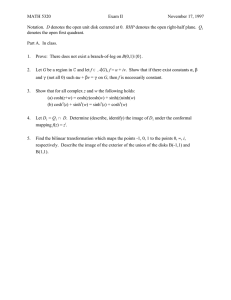

Hindawi Publishing Corporation Mathematical Problems in Engineering Volume 2010, Article ID 898720, 17 pages doi:10.1155/2010/898720 Research Article Unsteady Flow and Heat Transfer of a Dusty Fluid through a Rectangular Channel B. J. Gireesha, G. S. Roopa, and C. S. Bagewadi Department of Studies and Research in Mathematics, Kuvempu University, Shankaraghatta, Shimoga, Karnataka 577 451, India Correspondence should be addressed to B. J. Gireesha, bjgireesu@rediffmail.com Received 3 August 2010; Accepted 30 December 2010 Academic Editor: J. Jiang Copyright q 2010 B. J. Gireesha et al. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. The present discussion deals with the study of an unsteady flow and heat transfer of a dusty fluid through a rectangular channel under the influence of pulsatile pressure gradient along with the effect of a uniform magnetic field. The analytical solutions of the problem are obtained using variable separable and Fourier transform techniques. The graphs are drawn for the velocity fields of both fluid and dust phases under the effect of Reynolds number. Further, changes in the Nusselt number are shown graphically, and, on the basis of these, the conclusions and discussions are given. 1. Introduction The concept of an unsteady flow and heat transfer of a dusty fluid has a wide range of applications in refrigeration, air conditioning, space heating, power generation, chemical processing, pumps, accelerators, nuclear reactors, filtration and geothermal systems, and so forth. One common example of heat transfer is the radiator in a car, in which the hot radiator fluid is cooled by the flow of air over the radiator surface. On this basis many mathematicians were attracted by this field. Saffman 1 has formulated the governing equations for the flow of dusty fluid and has discussed the stability of the laminar flow of a dusty gas in which the dust particles are uniformly distributed. Datta et al. 2 have obtained the solution of unsteady heat transfer to pulsatile flow of a dusty viscous incompressible fluid in a channel. Heat transfer in unsteady laminar flow through a channel was analyzed by Ariel 3. Ghosh et al. 4 have made the solution for hall effects on MHD flow in a rotating system with heat transfer characteristics. Ezzat et al. 5 analyzed a space approach to the hydromagnetic flow of a dusty fluid through a porous medium. 2 Mathematical Problems in Engineering Some researchers like Anjali Devi and Jothimani 6 have discussed the heat transfer in unsteady MHD oscillatory flow. Further, Malashetty et al. 7 have investigated the convective magnetohydrodynamic two phase flow and heat transfer of a fluid in an inclined channel. Palani and Ganesan 8 have discussed the heat transfer effects on dusty gas flow past a semi-infinite inclined plate. Attia 9 has investigated an unsteady MHD Couette flow and heat transfer of dusty fluid with variable physical properties. Unsteady hydromagnetic flow and heat transfer from a nonisothermal stretching sheet immersed in a porous medium was discussed by Chamkha 10. Mishra et al. 11 have studied the two-dimensional transient conduction and radiation heat transfer with temperature-dependent thermal conductivity. MHD flow and heat transfer of a dusty viscoelastic stratified fluid down an inclined channel in porous medium under variable viscosity was analyzed by Chakraborty 12. Shawky 13 has investigated the solution for pulsatile flow with heat transfer of dusty magnetohydrodynamic Ree-Eyring fluid through a channel. Gireesha et al. 14 have obtained the analytical solutions for velocity fields using variable separable method for an unsteady flow of dusty fluid through a rectangular channel under the influence of pulsatile pressure gradients and in the absence of a magnetic field. In continuation of this paper and with the help of the above cited papers we have studied an unsteady flow and heat transport in a dusty fluid through a rectangular channel under the influence of a pulsatile pressure gradient in the presence of uniform magnetic field and viscous dissipation term. Further, heat transfer analysis and the effect of Reynolds number, Prandtl number, and Nusselt number have been considered. This paper presents three methods of solution, namely, perturbation technique, Fourier decomposition, and finite Fourier transform, to obtain useful results on the problem. Finally, the graphical representation of velocity fields of both fluid and dust phases and changes in the Nusselt number are drawn for different values of Reynolds number and Prandtl number. 2. Equations of Motion The governing equations of motion and energy for two phases are given by 1 the following. For fluid phase, − ∇ ·→ u 0, − − σB02→ f → 1 ∂→ u → − − − − − u ·∇ → u − ∇p ν∇2→ u v −→ u − u, ∂t ρ τv ρ − → ∂E → − u · ∇E Q → v −− u · F k∇ · ∇T Φf . ρ ∂t 2.1 For dust phase, − ∇ ·→ v 0, − − 1 → ∂→ v → − − v v ·∇ → u −→ v , − ∂t τv ∂Ep → − −Q − Φd . N v · ∇Ep ∂t 2.2 Mathematical Problems in Engineering 3 We have following nomenclature. E cp T , Ep cm Tp , Q Ncp Tp − T /τT is the thermal − − interaction between fluid and dust particle phases, F N→ v −→ u/τv is the velocity interaction force between the fluid and dust particle phase, τv m/6πaμ m/K is the velocity relaxation time of the dust particles, τT mcp /4πak is the thermal relaxation time of the dust particles, k∇. ∇T is the rate of heat added to the fluid by conduction in unit volume, − u, ρ, p, ν, T , cp , and Φf and Φd are the viscous dissipation of fluid and dust particles. → k are, respectively, the velocity vector, density, pressure, kinematic viscosity, temperature, − specific heat, and thermal conductivity of the fluid, → v , N, Tp , cm , and m are, respectively, the velocity vector, number density, temperature, specific heat, mass concentration of dust particles, K 6πaμ is the Stoke’s resistance coefficient, and t is the time. 3. Formulation of the Problem Consider an unsteady flow of an incompressible, viscous, electrically conducting fluid with uniform distribution of dust particles through a rectangular channel. It is assumed that the flow is due to the time-dependent pressure gradient and applied uniform magnetic field. Both the fluid and the dust particle clouds are supposed to be static at the beginning. The dust particles are assumed to be spherical in shape and uniform in size. The number density of the dust particles is taken as a constant throughout the flow. The flow is taken along z-axis, and it is as shown in Figure 1. For the above described flow the velocities of both fluid and dust particles are given by → − → − 3.1 u u x, y, t k, v v x, y, t k. 4. Solution of the Problem The governing equations from 2.1 and 2.2 can be decomposed as follows. For fluid phase, σB02 f u, v − u − τv ρ Ncp N ∂T ∂2 T ∂2 T 2 ρcp Tp − T v − u k ∂t τT τv ∂x2 ∂y2 2 2 ∂u 4 ∂u . μ 3 ∂x ∂y 1 ∂p ∂u − ν ∂t ρ ∂z ∂2 u ∂2 u ∂x2 ∂y2 4.1 For dust phase, ∂v 1 u − v, ∂t τv 2 ∂Tp cp μp 4 ∂v 2 ∂v , cm T − Tp − ∂t τT N 3 ∂x ∂y where u and v denote the velocity of the fluid and the dust phases, respectively. 4.2 4 Mathematical Problems in Engineering y x=d x = −d y=h x z y=0 Figure 1: Schematic diagram of dusty fluid flow in a rectangular channel. The boundary conditions of the given problem are taken as u 0, v 0, T T0 at y 0, u 0, v 0, T T1 at y h, u 0, v 0, u 0, v 0, 4.3 at x −d, T T2 T T3 at x d. Since we have assumed that the pulsatile pressure gradient has influence on the flow, we have that − 1 ∂p A 1 eiωt , ρ ∂z 4.4 where is a small quantity and A and ω are constants. To make the above system dimensionless, introduce the following nondimensional variables: u ξ Pr x , h μcp , k uω , A η v y , h Re vω , A ψ ωh2 , ν z , h t tω, p Rep θ p , Aρh ωh2 , νp T − T0 , T1 − T0 θp Ec Tp − T0 , T1 − T0 ω2 c 4.5 A2 , p T1 − T0 where h is the distance between plates, Ec the Eckert number, Pr the Prandtl number, Re and Rep the Reynolds numbers of fluid and dust phases, x and y the space coordinates along and perpendicular to the plates, θ and θp the dimensionless fluid and dust phase temperatures, μ the viscosity of fluid, and νp and ρp the kinematic viscosity and density of the dust particles. Mathematical Problems in Engineering 5 Using the above nondimensional variables in 4.1 and 4.2 and dropping the bars, one can get that ∂p 1 ∂2 u ∂2 u ∂u fαv − u − βu, − ∂t ∂ψ Re ∂ξ2 ∂η2 ∂θ ∂2 θ ∂2 θ 1 α1 β1 θp − θ αβ1 Ecv − u2 ∂t Re Pr ∂ξ2 ∂η2 2 Ec 4 ∂u 2 ∂u , Re 3 ∂ξ ∂η 4.6 ∂v αu − v, ∂t 2 ∂θp γEc 4 ∂v 2 ∂v , γα1 θ − θp − ∂t Rep β2 3 ∂ξ ∂η where α 1/ωτv , β σB02 /ρω, α1 1/ωτT , β1 N/ρ, β2 N/ρp , and γ cp /cm . The dimensionless boundary conditions are u 0, v 0, θ 0 at η 0, u 0, v 0, θ 1 at η 1, u 0, u 0, v 0, v 0, θ Ta at ξ −r, θ Tb at ξ r, 4.7 where Ta T2 − T0 /T1 − T0 , Tb T3 − T0 /T1 − T0 , and r d/h. The nondimensional form of pressure gradient is given by − ∂p 1 eit . ∂ψ 4.8 Now assume the solutions of the velocities and temperature of both fluid and dust phases as u ξ, η, t u0 ξ, η u1 ξ, η eit , v ξ, η, t v0 ξ, η v1 ξ, η eit , θ ξ, η, t θ0 ξ, η θ1 ξ, η eit 2 θ2 ξ, η e2it , θp ξ, η, t θp0 ξ, η θp1 ξ, η eit 2 θp2 ξ, η e2it . 4.9 Substituting 4.8 and 4.9 in 4.6 and equating the coefficient of the similar powers of on both sides, then we obtain the following set of equations. 6 Mathematical Problems in Engineering Steady part coefficient of 0 : 1 ∂2 u0 ∂2 u0 fαv0 − u0 − βu0 −1, Re ∂ξ2 ∂η2 4.10 αu0 − v0 0, 1 Re Pr 4.11 ∂2 θ0 ∂2 θ0 Ec 4 ∂u0 2 ∂u0 2 2 α 0, β − θ Ecv − u θ αβ 1 1 p0 0 1 0 0 Re 3 ∂ξ ∂η ∂ξ2 ∂η2 γEc 4 ∂v0 2 ∂v0 2 γα1 θ0 − θp0 − 0. Rep β2 3 ∂ξ ∂η 4.12 Unsteady part coefficient of : 1 ∂2 u1 ∂2 u1 fαv1 − u1 − β i u1 −1, 2 2 Re ∂ξ ∂η 4.13 αu1 − v1 − iv1 0, ∂2 θ1 ∂2 θ1 1 α1 β1 θp1 − θ1 2αβ1 Ecv0 − u0 v1 − u1 Re Pr ∂ξ2 ∂η2 2Ec 4 ∂u0 ∂u1 ∂u0 ∂u1 − iθ1 0, Re 3 ∂ξ ∂ξ ∂η ∂η 2γEc 4 ∂v0 ∂v1 ∂v0 ∂v1 − iθp1 0. γα1 θ1 − θp1 − Rep β2 3 ∂ξ ∂ξ ∂η ∂η 4.14 4.15 Unsteady part coefficient of 2 : 1 ∂2 θ2 ∂2 θ2 α1 β1 θp2 − θ2 αβ1 Ecv1 − u1 2 2 2 Re Pr ∂ξ ∂η Ec 4 ∂u1 2 ∂u1 2 − 2iθ2 0, Re 3 ∂ξ ∂η γEc 4 ∂v1 2 ∂v1 2 − 2iθp2 0. γα1 θ2 − θp2 − Rep β2 3 ∂ξ ∂η 4.16 4.17 Mathematical Problems in Engineering 7 Now, the corresponding dimensionless boundary conditions are as follows: u0 0, v0 0, θ0 Ta at ξ −r, u0 0, v0 0, θ0 Tb at ξ r, u0 0, v0 0, θ0 0 at η 0, u0 0, v0 0, θ0 1 at η 1; u1 0, v1 0, θ1 0 at ξ −r, u1 0, v1 0, θ1 0 at ξ r, u1 0, v1 0, θ1 0 at η 0, u1 0, v1 0, θ1 0 at η 1; 4.18 4.19 θ2 0 at ξ −r, θ2 0 at ξ r, θ2 0 at η 0, 4.20 θ2 0 at η 1. By substituting 4.11 in 4.10, one can get ∂2 u0 ∂2 u0 − β Re u0 − Re. ∂ξ2 ∂η2 4.21 To solve 4.21, we assume that the solution is in the form u0 ξ, η X ξ, η Y ξ. 4.22 Substituting u0 ξ, η in 4.21, then we obtain that ∂2 X ∂2 Y ∂2 X − β ReX Y − Re. ∂ξ2 ∂η2 ∂η2 4.23 ∂2 Y − β Re Y Re 0, ∂η2 4.24 ∂2 X ∂2 X − β Re X 0. ∂ξ2 ∂η2 4.25 so that 8 Mathematical Problems in Engineering The corresponding boundary conditions will become u0 −r, η X −r, η Y −r 0, u0 ξ, 0 Xξ, 0 Y ξ 0, u0 r, η X r, η Y r 0, u0 ξ, 1 Xξ, 0 Y ξ 0. 4.26 By solving 4.24 and using the method of separation of variables to 4.25, we obtain the solution in the form ⎡ ⎤ ∞ β Re ξ cosh sinh A1 η − 1 − sinh A1 η 1⎢ nπ ⎥ 2 ξ sin u0 ξ, η ⎣1 − ⎦ β β n1 r sinh A1 cosh β Re r ⎧ ⎫ ⎨ 1 ⎬ β Re nπ n × − , − −1 ⎩ nπ r 2 A2 cosh ⎭ nπA21 β Re r 1 v0 ξ, η u0 ξ, η , 4.27 % where A1 β Re r 2 n2 π 2 /r 2 . Here one can observe that the velocity of steady part of the fluid and the dust phases is the same. In a similar manner, by the method of separation of variables, the solution of 4.13, and using the boundary conditions 4.19, one can obtain that ∞ sinh B η − 1 − sinh Bη 2 Re coshQξ nπ Re ξ 2 sin u1 ξ, η 2 1 − coshQr r sinh B Q Q n1 1 nπ Q2 × − 2 2 − −1n , nπ r B coshQr nπB2 α v1 u1 , αi 4.28 where Q2 Refαi/α i β i and B Q2 r 2 n2 π 2 /r 2 . We define the finite Fourier sine transform of θ and θp as &r nπ Fs θ ξ , θ ξ, η sin r −r F s θp &r nπ ξ . θp ξ, η sin r −r 4.29 Eliminating θp0 from 4.12, we get that 4 ∂u0 2 ∂2 θ0 ∂2 θ0 ∂u0 2 , H1 3 ∂ξ ∂η ∂ξ2 ∂η2 4 ∂v0 2 Ec ∂v0 2 θp0 ξ, η θ0 − , Rep α1 β2 3 ∂ξ ∂η where H1 Ec Re Pr β1 /Rep β2 − 1/ Re. 4.30 4.31 Mathematical Problems in Engineering 9 Applying the finite fourier sine transform to 4.30 with respect to the variable ξ and to boundary conditions, one obtains that ∞ d2 Fs θ0 n2 π 2 nπ 4H1 8π 2 β Re n − 2 Fs θ0 Tb − Ta −1 r 3 dη2 r β2 n1 β Re r n × 2 4n2 π 2 β Re r cosh β Re r n1 ∞ 2 sinh ⎞ ⎛ 4.32 β Re −1n ⎟ nπ ⎜ 1 − ×⎝ − ⎠ nπ r 2 A2 cosh nπA21 β Re r 1 sinh A1 η − 1 − sinh A1 η , × sinh A1 Fs θ0 ξ, 0 0, Fs θ0 ξ, 1 0. 4.33 The temperature of fluid is obtained by solving 4.32 with the help of boundary conditions 4.33 as ⎡ ∞ ∞ 32π 2 β ReH1 n2 ⎢ r n Fs θ0 ⎣ Tb − Ta −1 nπ 3β2 β Re r 2 4n2 π 2 n1 n1 ⎞⎤ ⎛ n sinh β Re r β Re −1 nπ r2 1 ⎟⎥ ⎜ − × 2 ⎝ − ⎠⎦ 2 2 nπ 2 A1 r 2 − n2 π 2 cosh nπA β Re r r A1 cosh β Re r 1 nπ 1 − cosh nπ/rη nπ η sinh η × cosh r sinhnπ/r r ∞ ∞ 32π 2 β ReH1 r n2 n − Tb − Ta −1 nπ 3β2 β Re r 2 4n2 π 2 n1 n1 ⎞ ⎛ n β Re r β Re −1 ⎟ nπ r ⎜ 1 − × 2 ⎝ − ⎠ 2 2 2 nπ r 2 A2 cosh A1 r − n π cosh nπA21 β Re r β Re r 1 2 sinh sinh A1 η − 1 − sinh A1 η . × sinh A1 4.34 10 Mathematical Problems in Engineering Now taking the inverse finite Fourier sine transform to 4.34, one can obtain that ⎧⎡ ⎪ ∞ ∞ 2 ⎨⎢ 32π 2 β Re H1 r n θ0 ξ, η Tb − Ta −1 ⎣ r⎪ nπ 3β2 r1 ⎩ n1 sinh β Re r n2 r2 × β Re r 2 4n2 π 2 A21 r 2 − n2 π 2 cosh β Re r n1 ∞ ⎞⎤ n β Re −1 nπ 1 ⎟⎥ ⎜ − ×⎝ − ⎠⎦ nπ r 2 A2 cosh β Re r nπA21 1 ⎛ 1 − cosh nπ/rη nπ nπ η sinh η × cosh r sinhnπ/r r ∞ ∞ 32π 2 β Re H1 r n2 n − Tb − Ta −1 2 2 nπ 3β β Re r 4n2 π 2 n1 n1 sinh β Re r 2 sinh A1 η − 1 − sinh A1 η r × 2 sinh A1 A1 r 2 − n2 π 2 cosh β Re r 4.35 ⎞⎫ ⎪ β Re −1 ⎟⎬ nπ nπ ⎜ 1 − ξ . ×⎝ − ⎠ sin ⎪ nπ r 2 A2 cosh β Re r r nπA21 ⎭ 1 ⎛ n The temperature of dust θp0 is obtained by substituting θ0 in 4.31. Using 4.15 in 4.14 and boundary conditions 4.19, with the help of finite fourier sine transform technique, one can get the solution for θ1 as θ1 ξ, η ∞ ∞ 2 16 Re π 2 H3 1 n2 1 sinhQr 2 2 2 2 2 2 r 3β Q n1 A1 − q1 Q r 4n π coshQr r1 ⎛ ⎞ n β Re −1 ⎟ nπ ⎜ 1 ×⎝ − − ⎠ nπ r 2 A2 cosh β Re r nπA21 1 ∞ β Re 1 n2 2 2 Q n1 B − q12 β Re r 2 4n2 π 2 nπ Q2 −1n 1 − − × nπ Q2 r 2 n2 π 2 coshQr nπB2 1 − cos hq1 × cosh q1 η sinh q1 η sinh q1 β Re r cosh β Re r sinh Mathematical Problems in Engineering ∞ n2 1 16 Re π 2 H3 1 3β Q n1 A21 − q12 Q2 r 2 4n2 π 2 ⎞ ⎛ n β Re −1 ⎟ sinhQr nπ ⎜ 1 − ×⎝ − ⎠ nπ r 2 A2 cosh β Re r coshQr nπA21 11 1 % ∞ β Re sinh A1 η−1 −sinh A1 η 1 n2 × sinh A1 Q2 n1 B2 −q12 β Re r 2 4n2 π 2 nπ Q2 −1n sinh β Re r 1 − − × nπ Q2 r 2 n2 π 2 coshQr nπB2 cosh β Re r sinh B η − 1 − sinh Bη nπ ξ . sin × sinh B r 4.36 Using θ1 , we get the expression for θp1 as θp1 ξ, η 2γEc γα1 4 ∂v0 ∂v1 ∂v0 ∂v1 θ1 − , γα1 i ∂η ∂η Rep β2 γα1 i 3 ∂ξ ∂ξ 4.37 where . q1 H2 α1 β1 i i , γα1 i α1 β1 γ α 1 . − Rep β2 γα1 i α i Re n2 π 2 , r2 H3 2 Ec Re P r H2 Re Pr 4.38 Similarly, the solutions of 4.16 and 4.17 using boundary conditions 4.20 are obtained as θ2 ξ, η ∞ 2 r1 r ∞ ∞ 1 8Re2 H5 4π 2 H6 n2 1 r− 3 2 2 2 2 2 Q n1 Q 3 n1 Q r 4n π B − q22 Q 1 nπ Q2 −1n 1 sinhQr − − × coshQr nπ Q2 r 2 n2 π 2 coshQr nπB2 sinh B η − 1 − sinh Bη 1 − cosh q2 sinh q2 η cosh q2 η sinh q2 sinh B nπ ξ . × sin r 4.39 Mathematical Problems in Engineering 10 10 5 5 u0 (x, h) u0 (x, h) 12 0 −5 0 −5 −10 −10 300 200 h 400 100 200 0 0 600 300 200 h x a 400 100 0 0 200 600 x b Figure 2: Variation of fluid velocity u0 ξ, η with ξ and η for Re 1 and Re 10. From 4.17, one can get that θp2 ξ, η γα1 γEc 4 ∂v1 2 ∂v1 2 , θ2 − γα1 2i ∂η Rep β2 γα1 2i 3 ∂ξ 4.40 where . q2 H5 − H4 Ec Re P r αβ1 α i2 2iα1 β1 2i , γα1 2i α 2 α1 β1 γ 1 . H6 Ec Re Pr − Re Rep β2 γα1 2i α i n2 π 2 , r2 H4 Re Pr , 4.41 5. Results and Discussion Figures 2, 3, 4, 5, 6, 7, and 8 represent the velocity and temperature fields, respectively, for the fluid and dust particles, which are parabolic in nature. Here we can see that the path of fluid particles is much steeper than that of dust particles. Further, one can see that if the dust is very fine, that is, the mass of the dust particles is negligibly small, then the relaxation time of dust particle decreases and ultimately as τv → 0 the velocities of fluid and dust particles will be the same. Also we see that the fluid particles will reach the steady state earlier than the dust particles. Further, one can observe the impressive effect of Reynolds number on the velocity fields. It means that the Reynolds number is favorable to the velocity fields, that is, the velocity profiles for both fluid and dust particles increases as the Reynolds number increases. The graphs are drawn for the following values: ω 0.5, N 0.4, β 2, σ 1, Ec 0.02, Pr 0.72, T0 0.5, T1 1, T2 1.5, T3 2, τv τT 0.15, and γ 1.4. Mathematical Problems in Engineering 13 2 5 1 v0 (x, h) v0 (x, h) ×10 4 10 0 −5 0 −1 −10 −2 300 200 h 400 100 0 0 200 300 600 200 h x 400 100 0 0 a 200 600 x b 5 800 4 600 u1 (x, h) u1 (x, h) Figure 3: Variation of dust velocity v0 ξ, η with ξ and η for Re 1 and Re 10. 3 2 400 200 1 0 300 200 400 100 h 0 0 200 0 300 600 200 h x 400 100 0 0 a 200 600 x b 5 800 4 600 v1 (x, h) v1 (x, h) Figure 4: Variation of fluid velocity u1 ξ, η with ξ and η for Re 1 and Re 10. 3 2 400 200 1 0 300 200 h 400 100 0 0 a 200 x 600 0 300 200 h 400 100 0 0 200 x b Figure 5: Variation of dust velocity v1 ξ, η with ξ and η for Re 1 and Re 10. 600 14 Mathematical Problems in Engineering 6 4 Re = 1 5 Re = 1 Re = 3 4 Re = 3 3 3 2 Re = 5 Re = 5 Nu0 Nu0 5 1 −1 1 Re = 1 Re = 3 Re = 5 0 0 0.2 0.4 2 Re = 1 Re = 3 Re = 5 0 0.6 0.8 −1 1 0 0.2 0.4 0.6 ξ, η 0.8 1 ξ, η Varies with ξ Varies with η Varies with ξ Varies with η a b Figure 6: Steady part of the Nusselt number Nu0 versus ξ and η for ξ r and η 0 and ξ −r and η 1. ×10−3 ×10−3 6 6 Pr = 3 4 Pr = 2 3 Pr = 3 2 Pr = 1 1 Pr = 2 0 −1 Re = 5 5 Amplitude of Nu1 Amplitude of Nu1 5 4 Re = 3 3 2 Re = 5 Re = 3 Re = 1 1 0 Pr = 1 0 0.2 0.4 0.6 0.8 1 −1 Re = 1 0 0.2 0.4 ξ, η Varies with ξ Varies with η a 0.6 0.8 1 ξ, η Varies with ξ Varies with η b Figure 7: Unsteady part of Nusselt number Nu1 versus ξ and η for ξ r and η 0 and ξ −r and η 1. Now we discuss the heat transfer at the vertical walls, so we consider the Nusselt number Nu of the fluid as / ∂θ // Nu − / ∂ξ at ξr or ξ−r dθ1 dθ2 dθ0 5.1 eit 2 e2it − dξ dξ dξ at ξr or ξ−r − Nu0 eit Nu1 2 e2it Nu2 . at ξr or ξ−r Mathematical Problems in Engineering 15 ×10−4 Re = 1 Re = 1 Re = 3 Re = 3 Amplitude of Nu2 Amplitude of Nu2 ×10−4 Re = 5 1 Re = 1 Re = 3 Re = 5 1 Re = 1 Re = 3 Re = 5 0 0 0.2 0.4 Re = 5 0.6 0.8 1 0 0 0.2 0.4 ξ, η 0.6 0.8 1 ξ, η Varies with ξ Varies with η Varies with ξ Varies with η a b Figure 8: Unsteady part of Nusselt number Nu2 versus ξ and η for ξ r and η 0 and ξ −r and η 1. Next to discuss is the heat transfer at the horizontal walls, so we consider the Nusselt number Nu of the fluid as / ∂θ // Nu − / ∂η at η0 or η1 dθ1 dθ2 dθ0 eit 2 e2it − dη dη dη − Nu0 eit Nu1 2 e2it Nu2 5.2 at η0 or η1 at η0 or η1 , where Nu0 , Nu1 , and Nu2 denote the Nusselt number for steady part, unsteady part for coefficient of , and unsteady part for coefficient of 2 , respectively. The graphs of steady part of Nusselt number Nu0 against ξ and η at η 0 and ξ r or at η 1 and ξ −r has been drawn in Figure 6. It shows that for different values of Prandtl number, Nusselt number increases with increase in ξ and η. Figure 7 shows the unsteady part of amplitude of Nusselt number Nu1 against ξ and η at η 0 and ξ r or at η 1 and ξ −r. It reveals that for different values of Prandtl number, amplitude of Nusselt number increases with increase of ξ and η. The unsteady part of the amplitude of Nusselt number Nu2 against ξ and η has been drawn in Figure 8. Here, one can see that the amplitude of Nusselt number increases with increase of ξ and η for different values of Prandtl number. 16 Mathematical Problems in Engineering 6. Conclusions A detailed analytical study has been carried out for the unsteady flow and heat transfer of a dusty fluid through a rectangular channel. Here, one can see that the flow of fluid particles is parallel to that of dust. Further, one can see that the fluid particles will reach the steady state earlier than the dust particles. From the graphs the impressive effect of Reynolds number on the velocity fields of both fluid and dust phases is evident. It is clear that the effect of Reynolds number on velocity fields is favorable, that is, the velocity profiles for both fluid and dust particles increase as Reynolds number increases. Further, one can observe the changes in the steady and unsteady parts of amplitude of Nusselt number. It is clear that for different values of Prandtl number steady part of Nusselt number Nu0 increases with increase of ξ and η. In the same manner unsteady parts of amplitude of Nusselt number Nu1 and Nu2 increases with increase of ξ and η for different values of Prandtl number. Acknowledgments The authors wish to express their thanks to DST Department of Science and Technology, india for granting a Major Research Project no: SR/S4/MS: 470/07, 25-08-2008. They are also grateful to the referees for useful comments. References 1 P. G. Saffman, “On the stability of laminar flow of a dusty gas,” Journal of Fluid Mechanics, vol. 13, pp. 120–128, 1962. 2 N. Datta, D. C. Dalal, and S. K. Mishra, “Unsteady heat transfer to pulsatile flow of a dusty viscous incompressible fluid in a channel,” International Journal of Heat and Mass Transfer, vol. 36, no. 7, pp. 1783–1788, 1993. 3 P. D. Ariel, “Heat transfer in unsteady laminar flow through a channel,” Applied Scientific Research, vol. 47, no. 4, pp. 287–300, 1990. 4 S. K. Ghosh, O. Anwar Bég, and M. Narahari, “Hall effects on MHD flow in a rotating system with heat transfer characteristics,” Meccanica, vol. 44, no. 6, pp. 741–765, 2009. 5 M. A. Ezzat, A. A. El-Bary, and M. M. Morsey, “Space approach to the hydro-magnetic flow of a dusty fluid through a porous medium,” Computers & Mathematics with Applications, vol. 59, no. 8, pp. 2868–2879, 2010. 6 S. P. Anjali Devi and S. Jothimani, “Heat transfer in unsteady MHD oscillatory flow,” Czechoslovak Journal of Physics, vol. 46, no. 9, pp. 825–838, 1996. 7 M. S. Malashetty, J. C. Umavathi, and J. Prathap Kumar, “Convective magnetohydrodynamic two fluid flow and heat transfer in an inclined channel,” Heat and Mass Transfer/Waerme- und Stoffuebertragung, vol. 37, no. 2-3, pp. 259–264, 2001. 8 G. Palani and P. Ganesan, “Heat transfer effects on dusty gas flow past a semi-infinite inclined plate,” Forschung im Ingenieurwesen, vol. 71, no. 3-4, pp. 223–230, 2007. 9 H. A. Attia, “Unsteady MHD couette flow and heat transfer of dusty fluid with variable physical properties,” Applied Mathematics and Computation, vol. 177, no. 1, pp. 308–318, 2006. 10 A. J. Chamkha, “Unsteady hydromagnetic flow and heat transfer from a non-isothermal stretching sheet immersed in a porous medium,” International Communications in Heat and Mass Transfer, vol. 25, no. 6, pp. 899–906, 1998. 11 S. C. Mishra, P. Talukdar, D. Trimis, and F. Durst, “Two-dimensional transient conduction and radiation heat transfer with temperature dependent thermal conductivity,” International Communications in Heat and Mass Transfer, vol. 32, no. 3-4, pp. 305–314, 2005. 12 S. Chakraborty, “MHD flow and heat transfer of a dusty visco-elastic stratified fluid down an inclined channel in porous medium under variable viscosity,” Theoretical and Applied Mechanics, vol. 26, pp. 1– 14, 2001. Mathematical Problems in Engineering 17 13 H. M. Shawky, “Pulsatile flow with heat transfer of dusty magnetohydrodynamic Ree-Eyring fluid through a channel,” Heat and Mass Transfer, vol. 45, no. 10, pp. 1261–1269, 2009. 14 B. J. Gireesha, C. S. Bagewadi, and B. C. Prasannakumar, “Pulsatile flow of an unsteady dusty fluid through rectangular channel,” Communications in Nonlinear Science and Numerical Simulation, vol. 14, no. 5, pp. 2103–2110, 2009.