SKU Segmentation Strategy for a Global Retail Supply Chain

By

Huiping Jin

MS Finance, Case Western Reserve University, 2013

Master of Business Administration, Tongji University, 2012

SMASSACHUSE[TSINSIJE

OF TECHNOLOGY

JUL 17 2014

And

LIBRARIES_

Brad Gilligan

B.S. Business Administration, Colorado State University, 2010

Submitted to the Engineering Systems Division in Partial Fulfillment of the

Requirements for the Degree of

Master of Engineering in Logistics

at the

Massachusetts Institute of Technology

June 2014

02014 Bradley Michael Gilligan and Huiping Jin. All rights reserved.

The authors hereby grant to MIT permission to reproduce and to distribute publicly

paper and electronic copies of this thesis document in whole or in part in any medium now

known or hereafter created.

Signature of Author ............................... Signature redacted

Master of Engineering in Logistics Program, Engi eering Systems Division

Signature redacted

Signature of A uthor ...................

May 13, 2014

.....

. ...........................................

Master of Engineering in Log~tics.Pr.g.,.giermn Systems Division

May13,2014

Signature redacted'

C ertified by .................................................

Signature

Accepted by .................

r

.........................

Edgar E. Blanco

Thesis Supervisor

Principal Research Associate

Executive Director IT S ALE Network Latin America

redacted MIT Center for Transportation & Logistics

........................................................................

Prof. Yossi Sheffi

Professor, Engineering Systems Division

Professor, Civil and Environmental Engineering Department

Director, Center for Transportation and Logistics

Director, Engineering Systems Division

W

1

SKU Segmentation Strategy for a Global Retail Supply Chain

By

Brad Gilligan

And

Huiping Jin

Submitted to the Engineering Systems Division in Partial Fulfillment of the

Requirements for the Degree of

Master of Engineering in Logistics

at the

Massachusetts Institute of Technology

ABSTRACT

The concept of using different supply chain strategies for different products or product families

is a fairly simple component of supply chain management. This practice, known as SKU

segmentation, is widely used by many companies. However, most research and success stories

involve a relatively stable portfolio of brands and products, and products with easily identifiable

attributes such as profit margins and demand. This thesis attempts to determine if and how a

SKU segmentation can be conducted when product mix is constantly changing and many key

variables used in traditional segmentations are not known in advance. To explore this problem,

we analyze one year of purchase order data and shipment data provided by our sponsor company.

The objective is to use data from purchase orders to predict which items are candidates for

different supply chain configurations (i.e. an expedited supply chain for time-sensitive products

or an efficient supply chain if there is opportunity to reduce cost and still meet demand). We start

by mapping the current supply chain process using historical data and interviews with employees.

The key piece of the process we want to understand is how early or late products arrive at

destination in relation to when those goods are expected in retail stores (a metric we refer to as

"destination dwell time"). We then use visualization and statistical analysis to determine what

PO information is related to the destination dwell time. After testing various multi-factor

regression models to predict the length of this dwell time, we conclude that a neural network

regression model predicts this time most accurately. We then assess whether or not it is feasible

for the sponsor company to use this model to "speed up" or "slow down" the supply chain for

different products as needed.

Thesis Supervisor: Edgar Blanco

Title:

2

ACKNOWLEDGEMENTS

On behalf of Brad Gilligan:

I thank the entire faculty and staff of MIT's Center for Transportation and Logistics for

designing and managing this challenging and rewarding program. I thank my classmates for

enriching this experience with their insight and support, and my thesis partner Huiping Jin and

advisor Edgar Blanco for their contributions to this project. I thoroughly enjoyed working with

such brilliant people and learned so much from both of you.

I thank the many helpful partners at our sponsor company for making this project possible. We

appreciate you taking the time to teach us about your business, arranging tours, and providing

data. It was a pleasure to work with all of you.

I thank my parents, Tim and Jill Gilligan for always challenging me to better myself. You taught

me the value of education and hard work, and none of my achievements would be possible

without you. I also thank Leslie Herring for being by my side throughout this hectic year. Your

love and support made this experience more manageable and enjoyable than I could have

imagined.

On behalf of Huiping Jin:

First of all, I would like to express my deepest appreciation to our thesis advisor, Dr. Edgar E

Blanco, for his support and motivation. His guidance helped me in completing this research and

his enthusiasm in supply chain management really encouraged me to fully commit myself to this

area.

I would also like to give my special thanks to Dr. Bruce C. Arntzen for his guidance in getting

my graduate study at MIT started on the right foot and at the right direction. In addition, my

thanks also go to Jennifer Ademi and Allison Sturchio who had provided endless care to my life

at MIT and valuable advice on my career. You are the ones that made my life at SCM an

enjoyable experience.

I am also indebted to all the faculty members at MIT ESD SCM program for giving me a lot of

insights and help in completing my study and research.

I would like to thank my thesis partner, Bradley M. Gilligan, who has made tremendous

contribution in completing this thesis. I really enjoyed working with you in completing this

research.

Finally, and most importantly, I would like to thank my wife Yefei Gu, my father Yong Jin, and

my mother Lianfeng Tang. It is your support and love that made me this far. I greatly appreciate

for everything you have done for me.

3

CONTENTS

A BSTRA CT....................................................................................................................................

2

A CKN O W LED G EMEN TS.....................................................................................................

3

CON TEN TS.....................................................................................................................................

4

TABLE O F FIGU RES....................................................................................................................

6

TA BLE O F TA BLES .....................................................................................................................

8

1 Introduction..................................................................................................................................

9

1.1

Company-Specific Challenges of SKU Segmentation................................................

1.2

Hypothesis.....................................................11

1.3

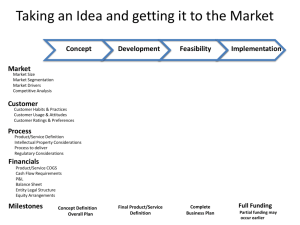

A pproach ........................................................................................................................

11

2 Literature Review ......................................................................................................................

12

10

2.1 Purpose of Stock K eeping U nit (SKU) segmentation ......................................................

12

2.2 SK U segm entation dim ensions........................................................................................

12

2.3 SK U segm entation practice for fashion retail industry ....................................................

14

3 M ethods .....................................................................................................................................

15

3.1 D ata Collection ...................................................................................................................

16

3.2 Initial A nalysis of D ata and Supply Chain Process ........................................................

17

3.3 Quantitative A nalysis......................................................................................................

20

4 D ata A nalysis and Results.........................................................................................................

21

4.1 Initial D ata Statistical D escription...................................................................................

23

4

4.1.1 M easuring Tim ing Attributes....................................................................................

24

4.1.2 D efining and M easuring Dw ell Tim e ......................................................................

28

4.2 H ypothesis ..........................................................................................................................

29

4.3 M odel Construction ............................................................................................................

33

4.3.1 Ordered-Probit M ethod.............................................................................................

34

4.3.2 N eural N etw ork M odel.............................................................................................

38

4.4 Tests and Results ................................................................................................................

45

4.4.1 Ordered-Probit Model...............................................................................................

45

4.4.2 N eural N etw ork M odel.............................................................................................

46

4.5 Potential A pplication of M odel (Proof of Concept) ........................................................

48

5 Conclusion .................................................................................................................................

51

A ppendix I - Ordered Probit Model Output:.............................................................................

54

Appendix II - M atlab script for neural network m odel.............................................................

56

References.....................................................................................................................................

57

5

TABLE OF FIGURES

Figure 1 - Initial Understanding of Supply Chain Process and Terminology ...........................

18

Figure 2 - PO Lead Time Histogram ........................................................................................

19

Figure 3 - Lead Time Components..........................................................................................

22

Figure 4 - PO Attributes and Descriptions...............................................................................

24

Figure 5 - PO Create Date to Header Date Statistics (in days)..................................................

25

Figure 6 - Lead Time Components with Statistics ...................................................................

27

Figure 7 - Dwell Time Statistics (in days).................................................................................

29

Figure 8 - A scatterplot showing the days between PO Create and Cargo Receipt on Y-axis, and

Destination Dwell Time on x-axis. Different colors identify different departments, and size of

circle represents order quantity.................................................................................................

31

Figure 9 - Figure 8 has been modified to show a department with more variability than normal.

......................................................................................................................................................

32

Figure 10 - Figure 8 has been modified again to show a department with stable timing.......... 32

Figure 11 - Ordered Probit Model Output Summary...............................................................

36

Figure 12 - Ordered-Probit Prediction Evaluation....................................................................

37

Figure 13 - Model Training and Validation...............................................................................

42

Figure 14 - Error Distribution Histogram.................................................................................

42

Figure 15 - Regress Predicted Value on Actual (In-sample test) ............................................

43

Figure 16 - Regress Predicted Value on Actual (Out-of-Sample Prediction for 100 POs)..... 44

Figure 17 - Predicted Result VS Actual Dwell Time (Out-of-Sample Prediction for 100 POs).. 44

Figure 18 - Performance Sensitivity Relative to Change of Model Size (Number of

prediction= 1,000 PO s)..................................................................................................................48

6

Figure 19 - Histogram of Actual Cargo Receipt to First Keytrol.................................................

50

Figure 20 - Histogram of Actual Dwell Time for 100 POs ..........................................................

51

Figure 21 - Histogram of Improved Dwell Time for 100 POs .....................................................

51

7

TABLE OF TABLES

Table 1 - Factors influencing supply chain segmentation ........................................................

13

Table 2 - Ordered Probit Model - Test Result for 1,000 POs .................................................

45

Table 3 - Test Results without updating the model (model size=3,000, gap=3,000)...............

47

Table 4 - Test Results with updating the model (model size=3,000, gap=3,000)........................

47

Table 5 - Model Parameters Used in the Application Example ...............................................

49

Table 6 - Segment Predicted Dwell Time into Predefined Categories......................................

49

Table 7 - Example Strategies for Supply Chain Segments........................................................

50

8

1 Introduction

Before describing SKU segmentation, it is important to clarify what is meant by the term "SKU".

SKU is an abbreviation for Stock Keeping Unit and refers to a specific product within a

company's catalog. As consumers, we see SKUs every day in the form of barcodes. If you walk

through any large retail store, you will realize there are thousands of different SKUs, and each

one can have very different characteristics such as size, price, and demand. A SKU segmentation

is a simple concept that suggests there is a benefit to handling certain products differently.

To illustrate this concept, consider the way you may buy and care for a suit or dress for a special

event, and compare it to the way you buy socks. You would likely spend a lot of time shopping

around for the suit or dress and try on several different products. You would make sure to hang it

safely in your closet and would have it cleaned by a professional dry cleaner. When buying

socks, you would grab the product that is easiest to find and reasonably priced, and store them

and clean them with little care. The advantage of these different approaches is that you get a

quality suit or dress and you do not waste too much time or effort worrying about socks. This

exact same principle applied to an organization can tell them which products they should focus

on and which can be handled with little effort. The advantages are satisfying customers while

minimizing supply chain costs.

Our research explores how this concept can be utilized by a global retailer that procures and sells

a wide range of products in multiple regions. To simplify this project we focus only on items that

are procured in China for sale in the USA, but the intent is for this approach to be scalable and

repeatable to be applied to other parts of the business. We start by looking at their existing

product mix and supply chain process, then identifying which SKUs might need to be handled in

a more proactive and responsive manner, and which SKUs could be handled more economically.

9

1.1 Company-Specific Challenges of SKU Segmentation

A SKU segmentation can be very straightforward and useful for companies with a mostly static

product base. For example, a company with a very high-cost high-margin product line with

volatile demand would obviously benefit from a flexible and responsive supply chain. They can

afford to spend more on transportation in order to meet demand. On the other hand, a company

that sells a low-cost everyday item with stable demand can utilize a slow and economical supply

chain to control costs. In the real world, these segments of SKUs are not always so easily

identifiable. What if the company's product mix changes and they do not know in advance what

their margins and their demand will be? What if some SKUs are inherently more difficult to

handle and require additional time in the supply chain regardless of traditional attributes? These

are questions difficult to answer while working with a company that has a unique business

model.

Currently, our sponsor company treats every single product the same in terms of procurement,

transportation, and storage. This approach can result in high-value products being delivered to

stores late and missing sales, while low-value items could be delivered too early and

consequently take up valuable space in a distribution center. The company sells a large variety of

products, with price points that range from under ten dollars to several hundred dollars and

annual sales between a single unit and over one million units. This wide range of products

suggests there is definitely potential to customize the supply chain process for different SKUs,

but the company's business has some unique complexities that make this segmentation

challenging.

To begin, the company has a very dynamic product mix and an equally dynamic pool of

suppliers. Their business is seasonal, and consumer preferences change quickly and frequently. It

10

is very rare for them to sell the same SKU more than once, and their product assortment changes

constantly. The supplier market is highly fragmented and competitive, so they are constantly

working with new suppliers depending on where they can get products at the best value. Because

a SKU segmentation relies on the attributes and behavior of suppliers, products, and customers

over time, this volatility makes the process much more difficult.

1.2 Hypothesis

Even with the challenges presented by this business model, there is potential to identify SKUs

which can be handled differently to achieve improvements in cost and/or service. Because the

products and suppliers are constantly changing, we will look at higher level attributes of SKUs

such as merchandise departments, order sizes, and origin locations rather than lower level

attributes such as specific suppliers and styles, the most traditional segmentation attributes.

1.3 Approach

We used a combination of qualitative and quantitative analysis to identify when and how this

company could treat certain SKUs differently. The qualitative piece involved working with

stakeholders to clearly understand and map out their supply chain process from procurement to

store delivery. The quantitative piece involved statistical analysis to predict lead times and

demand for products based on SKU attributes. The deliverable is a model that could tell this

company which SKUs should be expedited in order to meet demand, which could be held or

processed differently to reduce costs, and which fit the current process.

11

2 Literature Review

SKU segmentation is not a new or innovative idea. Research on the topic is readily available, and

the technique is already used by many companies to improve supply chain performance.

However, because every company has a different mix of SKUs and different feasible supply

chain configurations, every segmentation requires a unique approach. Our sponsor company's

business model proved to be an exception to many of the conventional rules used to segment

SKUs.

In this literature review, we will discuss the history and purpose of SKU segmentation, the

typical and widely used methods, and industry-specific considerations. We will then describe

how the traditional approach to segmentation did not work for our sponsor company.

2.1 Purpose of Stock Keeping Unit (SKU) segmentation

A segmentation strategy is a systematic method of separating products into different buckets for

a certain purpose, which can include maximizing market share, minimizing risk, improving

efficiency, etc. The approach to SKU segmentation is usually to group SKUs based on criteria

that indicate which supply chain management strategies can be used to maximize a firm's value.

It can also be described as a process of understanding the nature of the demand for different

SKUs and devising supply chain strategies that can best satisfy that demand (Fisher, 1997).

2.2 SKU segmentation dimensions

SKUs can be segmented based on many dimensions. The most traditional way is the ABC

classification method, which is to segment the SKUs based on the dollar sales volume. The

underlying theory of this segmentation method is the 20-80 Pareto principle, which suggests that

12

20% of the SKUs account for roughly 80% of total revenue, and those 20% should deserve the

most attention from management.

The benefits of using the ABC segmentation method are that it is very easy to implement and

there are many established inventory control strategies based on it, such as continuous review (s,

Q)

inventory strategy, period review (R, S) inventor strategy, order-up-to (s, S) inventory

strategy etc. The shortcoming of this method is that it utilizes only one dimension to segment the

SKUs. Under ABC segmentation method, SKUs within the same bucket can still have very

different characteristics. For example, two SKUs may have similar dollar value contribution, but

one may have high unit value but low demand, and the other may have low unit value but high

demand. Obviously, it is not appropriate to apply the same strategy to both SKUs.

Due to the limitations of the ABC method, many other dimensions have been used for

segmentation. Additional product characteristics include profit margin, volume, demand

volatility, etc. Anthony Lovell summarized these dimensions as shown in table 1. (Anthony,

2005)

Table 1 - Factors influencing supply chain segmentation

Group

Product

Market

Factor

Life cycle

Variety within product group

Product type: functional or innovative

Handling characteristics

Shelf life

Physical size and weight

Value

PVD

Demand location/dispersion

Demand level (throughput)

Demand variability

Service expectations

Limitations on raw material

Source

Economies of scale

13

Production flexibility

Lead-time

Geographic and commercial environment

Existing infra-structure

Transport mode availability

Customs/duties/trade areas

Legislation

In addition to introducing new dimensions, SKUs can be segmented using multiple dimensions

instead of just one or two. A common approach is to first segment the SKUs based on two

dimensions, then add another dimension as a new axis to further slice the SKUs. An example

could be segmenting the SKUs based on volume ani volatility first, then adding profit margin as

the third axis to form a 3-dimensional segmentation.

In general, segmentation dimensions are industry specific or company specific. There is no

universal list of attributes that can be applied for all companies and all situations. Therefore,

when developing a segmentation strategy for our sponsor company, it becomes very important to

understand their industry and business model.

2.3 SKU segmentation practice for fashion retail industry

The retail fashion industry, from a supply chain management perspective, is usually described as

a perishable-goods industry. It is assumed that all the goods purchased during the period will be

sold out by the end of the season. This assumption is quite reasonable because the industry is

highly seasonal and excess inventory is usually sold via mark-downs. Therefore, the supply

chain model is often characterized as a single-period model. A classic example of this is the

newsvendor model, which assumes that every unit of supply will be sold or salvaged by the end

of a given time period with known demand distribution and fixed cost.

14

Based on this model, SKU segmentation for this industry has focused on lost sales, demand

patterns, margin, lead time, and holding cost.

Different supply chain strategies are then

developed to manage the flow of the goods from suppliers to retail stores. The goal is to balance

the tradeoff between lost sales due to stock outs and the cost of excess inventory.

On a higher level, those supply chain strategies can be categorized into several groups, such as a

"responsive" supply chain focused on reacting quickly to changes in demand, or an efficient

supply chain that aims to use the most economical transportation and storage options.

Our sponsor company's suppliers and product mix are constantly changing. This prevents us

from using many traditional dimensions used for segmentation such as demand variability.

Another caveat that made the segmentation even more challenging was that the sponsor company

requested that price and margin be excluded from the analysis because product availability is a

critical component of their strategy, regardless of profitability.

In order to segment their products, we will look at patterns and trends in the import process for

different categories of products. They currently treat all items in their supply chain equally, but

because they know that some items sit in their distribution centers for extended periods while

others are delivered late to retail stores, they believe that certain products have more urgency

than others. The objective of this thesis is to identify groups of SKUs that may warrant a

different supply chain process in order to reduce costs or better meet customer demand.

3 Methods

A traditional Stock Keeping Unit (SKU) segmentation begins by segmenting products based on

cost, profit margin, and the volume and variability of demand. Because the sponsor company did

not want to consider the cost of an item, and because they rarely sell the same SKU more than

15

once, we could not utilize profit margin or historical demand. This segmentation started by

identifying items that had abnormally long lead times, then working backward to find out what

characteristics could be contributing to those lead times. This process involved gathering data

from the sponsor company and learning about its supply chain through site visits and interviews,

plotting data to identify patterns and trends, and then building a regression model and

simulations to test and validate the correlation of variables.

3.1 Data Collection

The first step was a face-to-face meeting with the key stakeholders of this project (VP of

International Logistics and Trade Compliance and VP of Logistics Development) at their

corporate headquarters. This meeting served as an introduction to the company's supply chain

process and provided an opportunity to ask questions to determine which variables could be

relevant to the project. The next step was to tour facilities that receive and ship goods, in order to

see the supply chain in action and observe the physical flow of materials. These facilities

included a third party deconsolidator (crossdock) and a company distribution center.

After developing an understanding of the company's end-to-end supply chain, we then looked at

one year of historical data. In order to narrow the focus of the project, we looked at only data for

shipments from China to the US. The data included 298,754 records (rows) and 48 fields

(columns). Each record represented one shipment of one SKU. Shipments that contained

multiple SKUs were listed in more than one record, and multiple shipments of a single SKU

were also listed separately. The data included 491 unique suppliers, 38,306 unique Purchase

Orders, and 33,566 unique SKUs.

16

3.2 Initial Analysis of Data and Supply Chain Process

Once we received the data, we tried to tie each element of data to the specific supply chain

processes that were explained by the company and witnessed at their facilities. We also clarified

when each element of data was created and how it was generated (i.e. the PO Quantity is

generated at the time the PO is created by the buyer). After validating the source and meaning of

the data, we then attempted to validate the actual dates and numbers. After identifying records

with missing and incorrect data, we made revisions before continuing the analysis. An overview

of the supply chain process and definitions of key dates and terms is shown in Figure 1 on the

following page.

17

ORIGIN LEAD TIME

Supplier

PO Create Date = Sponsor company agrees to buy goods.

Start Ship Date = Sponsor company agrees to accept shipments of this PO.

Book Date = Supplier arranges shipment of goods.

Con Can Date = The last day the sponsor company will accept shipments of this PO.

Consolidator (accepts shipments on behalf of sponsor company and arranges ocean shipping)

Cargo Receipt Date = Goods are received by the consolidator.

Consolidation Date = Goods are in an ocean container and ready to be shipped.

Origin Port

ETD = Estimated time of departure. This is the date the goods leave the port.

OCEAN TRANSIT TIME

DESTINATION LEAD TIME

Destination Port

ETA = Date the vessel reaches US port.

Deconsolidator (receives containers and ships goods to sponsor company distribution centers)

Arrive Decon = Goods received by deconsolidator.

Distribution Center (DC)

1st Keytrol Date = Goods received by distribution center.

IRetail Store

LP Date = Goods expected in store.

Figure 1 - Initial Understanding of Supply Chain Process and Terminology

The next stage of the qualitative analysis entailed looking for high-level patterns and trends in

SKU lead times. We used a range of visualizations to reveal patterns and found histograms, boxplots, and scatter-plots to be the most useful. The analysis started by looking at the total lead

time from the creation of a purchase order to distribution to retail locations. The following

histogram shows the distribution of this lead time.

18

130K

120K

110K

100K

90K

80K

70K

60K

SOK

40K

30K

20K

10K

OK

Null

0

50

100

150

200

250

300

350

400

550

Days from PO Creation to Retail Store Distribution

Figure 2 - PO Lead Time Histogram

After looking at this total lead time, we focused on anomalies and looked at additional details to

determine which specific processes were contributing to the long lead times. For example, were

the long lead times a result of the time spent getting from the supplier to the origin port, or the

result of time spent at the company's DC in the destination country?

After identifying the outliers that could be causing unpredictability and unnecessary costs in the

supply chain, we looked for factors that these records had in common in an effort to determine

19

causality. We developed theories about product departments, seasons, and other variables that

could be correlated with lead time.

3.3 Quantitative Analysis

Using the variables identified during the qualitative analysis, we built regression models to

explore how well lead time could be predicted using specific variables. For instance, do products

in certain departments or products sold in certain seasons take longer to get from origin to

destination? To build the regression model, we focused on the top seventeen SKU categories by

order quantity, which account for 80% of total volume. We set lead time to be the dependent

variable and ran several iterations using different independent variables in order to identify those

that were most correlated with the lead time.

Once the regression model was working reasonably well, we used it to estimate lead times for a

sample of 100 SKUs. The advantage of an accurate estimation of the lead time is to give the

sponsor company more predictability in their supply chain. This predictability will allow them to

take advantage of opportunities to handle certain SKUs with more cost-effective supply chains.

For example, if they know a product will have a three month lead time, they do not need to

import it immediately and hold it in their distribution center. They can hold the item at origin and

use more economical storage and transportation options.

In order to demonstrate this value, we use our model to delay the export of shipment of SKUs

that we predict will have an abnormally long lead time. We can simulate the resulting time spent

at DCs and compare it to the actual time spent at DCs to predict potential savings.

20

4 Data Analysis and Results

We analyzed 2013 purchase order data for shipments from China to US. The analysis consisted

of four stages: 1) initial statistical data description; 2) hypothesis; 3) model construction; 4) tests

and results.

In the first stage, we looked at transit time statistics for shipments from China to US, including

averages, standard deviations, and distributions. Then, we broke down the total lead time into

several components in order to understand how each part behaved and contributed to the total

lead time, as shown in Figure 3.

21

i*

fD

P0 Create - Cargo Received

PO Creat Date Book Date

Confirmation Date

Month

PO CreateI Sail Date

Actual Receipt Date

lConsolidation Date

CY

Book Date

Con Can Date

CFS

Actual Receipt Date

Consolidation Date

Ui|

PO Create Datel

Itrt Shp Date

PROCESS DETAILS

ORDER DETAILS

ecpected at

ETD

Load Port

Origin Service

PO CreateDC Receipt

kI

Estimated Arrival

SaIlate -,

I

1

Estimate Arrival Deconsolidator Arrival

Delivery

BookedHeader Date

. .......

....

..

....

Destination Service

I

First KeyL Date -

Last Keytrol Date

DC Receipt

I

I

Deconsollor Date -

Last Header

Place of

Arrive Decon

Discharge Port

Store Ready

EFA

PO Create Date - Header Date

Actual Weight

Actual Measurement

Actual Packages

Actual Quantity

Vndor

The purpose of this study was to find out how different supply chain strategies can be applied in

order to reduce the dwell time at destination DCs and the relevant logistics costs. In order to do

this, the second stage of our analysis focused on hypothesizing on what attributes on a given

purchase order may help to explain why the dwell time at DCs behaved differently. Data

visualization is used to help to build our initial hypothesis. Based on the visualization result,

certain attributes are selected to be included in our hypothesis that can help to explain the

variation of the dwell time at destination DCs.

In the model construction stage, regression models are used to verify the correlation between the

ten attributes and dwell time at DCs. Specifically, two types of regression models are used to

carry out the analysis: multi-factor based regression model and ordered-probit regression model.

Finally, in the result and test stage, out-of-sample data are used to test the accuracy of the

regression models' predictions, and simulation is further used to test the effectiveness of the

segmentation strategy based on the regression results.

4.1 Initial Data Statistical Description

One year's Purchase Order data for shipments from China are given to perform the analysis.

There are total 298,711 specific order lines. Unlike traditional segmentation approach, which

typically used attributes such as profit margin, demand volume, demand volatility, value density

etc., the challenge for our study is to segment the SKUs using only the attributes on the Purchase

Orders. Figure 4 is the list of the attributes and their descriptions on a typical Purchase Order.

23

Dat

Element

Element Description

If N then only TJX po data; If Y then Damco shipment Data; APLL older PO Data

PO Shipped

Division

PONumber

)

Oracle

Agent Num

Date

UP

(M/Y

Po Create Date

Strt Shp Date

PO Merchandise Type

Pretkt ind

Prepk

Vendor

Numn

Po Page Num

Po Line Num

Nesting Code

Con Can

1Dte

ind

Style

Ladder

into

Sku

Indicator

Style

of set

Indicates if Item Is

Set Indicator

Arrive Decon

1st Keytrol

Last Header

Deconsoliator Date - DC Receipt

PO Create - DC Receipt

First Keytrol Date - Last Keytrol Date

PO Create Date - Header Date

PO Create -Cargo Received

PO Create -Sail Date

Sail date -Estimated Arrival

Estimated Arrival - Deconsolidator Arrival

PO Create Date - Book Date

Booked -DC Receipt

-Header Date

Booked

Equipment Number

Book Date

Confirmation date

Actual Receipt Date

Create

of

goods

received origin

origin

arrived

of arrival

at

umber

goods

is

of

Consolidation Date

ETD

ETA

Carrier

Service

Destination

Load Port Country

Load Port

Discharge Port Country

Discharge Port (Damco)

Place of Delivery

Ordered Quantity

Actual Quantity

Actual Packages

Actual Weight

Actual Measurement

Origin

Division Number

PO Number

PO Department Number

TiX

TJX Agent Number

PO Cancel date at freight forwarder

PO

Plan Month (expected at DC)

Date po was entered

mainframe

Earliest date Vendor can deliever the goods to consolidator

Po

Type

Preticket Indicator

PrePak

Vendlor

Number

Page on Po for style number

Line on PO for style number

Code for pack together

From ACT part a

Date the goods arrived atthe deconsolnoator (US)

First Date of cargo receipt at DC

Date that goods were worked at the DC

Timing: Arrival at Deconsolidator -Arrival at DC

Timing: Po Create date - Arrival at DC

Timing: First Date cargo receipt at DC - Date that goods were worked at the DC

date - Date that goods were worked at the DC

Timing: Po

Timing: Po Create date - date

were

at

Timing: Po Createe dat

e goods sailed from

Timing: Transit time for goods on the water

port - Date goods

at econsolidator

Timing: Date

Timing: PO Create date - Vendor booking date

Timing: Vendor booked date - Arrival DC

were worked at the DC

Timing: Vendor booked date - Date that

Container N

Vendor Booking Date

Date Damco confirmed booking

Actual cargo receive date

date that

Consolidation date cargo: CF the date the container stuffed, CY

the cargo has been received at the po

Estimated Vessel Departure Date

Estimated Vessel Arrival Date

ship

factory

Mode (Consolidated by forwarder

Destination Mode (Port Move

Door Move)

Export Country

ExportPort

Country discharge Port

Port Arrival

Final Destination on BL

Po Ordered Units

PO Shipped Units

PO Shipped Cartons

POShippedWeight(kgs)

Po Shipped Cubic meters

#

Dept Num

AP Vendor (Lawson

Service

line Carrier

Steam

Origin

of

vs

or

the

load)

of

Figure 4 - PO Attributes and Descriptions

We first wanted to understand how the different timing attributes behaved across the whole data

set and statistically measure the time spent in different stages of the supply chain process, along

with the variation and distribution of this timing. Most importantly, we wanted to understand

how dwell time at destination DCs varies across different Purchase Orders, since this is the

attribute we try to explain and predict in our analysis.

4.1.1 Measuring Timing Attributes

We first looked at the total time spent for moving shipments from China to US in the given data

set. We used PO Create - Header Date to measure this time attribute. This measure is equal to

24

the number of days between when a PO is created and when it is finished being processed at a

DC and ready for distribution to retail stores.

PO Create Date - Header Date

tMspwiofPO OatDt- HOdr Date

One Variable Summary

Mean

Variance

Std. Dev.

Skewness

Kurtosis

Median

Mean Abs. Dev.

Mode

Minimum

Maximum

Range

Count

m

117.00

34.14

112.00

34.00

630.00

3rd Quartile

Interquartilo Range

56.00

Ist Quartile

MO1I

baw0

596.00

284497

35660800.00

95.00

151.00

Sum

e g a m

125.35

186114

43.14

0.8370

4.0091

g

g

Figure 5 - PO Create Date to Header Date Statistics (in days)

As it is shown in Figure 5, the company spent an average of 125 days moving shipments from

China to US, with a median of 117, standard deviation of 43 days, minimum of 34 days, and

maximum of 630 days. So, its distribution is skewed to the right with a skewness of 0.837 and a

kurtosis of 4.

We then broke down this total lead time into several sub-components and looked at how they

behaved statistically, as shown in Figure 6. Because our study will be used to help the company

determine different supply chain strategies for moving future shipments, only the time attributes

that cannot be determined at the time of decision making are of particular interest. Those time

attributes are:

25

1) Estimated Time of Departure from origin port to Estimated Time of Arrival at destination

port (ETD to ETA)

2) ETA to Arrival at Deconsolidator Warehouse

3) Deconsolidation Date to receipt at company Distribution Center (DC)

4) Date goods received at company DC to date goods were processed at DC

Of these four attributes, the first three can be used as lead time distribution inputs in order to

simulate the outcome of using different supply chain strategies. The fourth element partially

captures the dwell time spent at destination distribution centers. Since destination dwell time

(days between arrival at a DC and actual demand at retail store) is the key attribute we tried to

explain and predict, our next focus is on how to define and measure this attribute appropriately.

Figure 6 on the following page quantifies the different lead time components that were identified

earlier.

26

II

a

I

rilli I

I

I

5|-|3

I

I

~I

-j

I~I

I

I

51 +;

2

II

'Ia

1;I I

2

I

II

611111

AI 'III

I

Figure 6 - Lead Time Components with Statistics

27

4.1.2 Defining and Measuring Dwell Time

Dwell time is the time difference between the goods received at DCs and the actual demand

window. In order to correctly measure the dwell time, we first need to understand when the

shipments were received at destination DCs and when they left. In the data set given, First

Keytrol Date (as shown in Figure 1) represents the time the shipments are received. To measure

the time shipments left a DC, our original thought was to use Last Header since this attribute

represents the last date that the goods were worked at DC. However, during interviews with the

company, we were told that the Last Header is not an accurate measure of the date a shipment

leaves the DC for two reasons. First, Last Header is the date the last item was processed at DC.

In many occasions, the majority of the inventory has already left the DC and any remaining

pieces, no matter how small the quantity, would lead to an unrealistically late Last Header date

for the entire PO. Second, the actual demand may happen before a shipment arrives at DC. In

other words, the shipment was late and the Last Header date will be beyond the actual demand

date.

Therefore, in addition to the Purchase Order dataset, the company gave us the actual Ladder Plan

dates to represent the actual demand window. The dwell time at DC is then equal to the number

of days between the First Keytrol Date and the Ladder Plan Date. If the result is negative, it

means the shipment was delayed and failed to fulfill the demand on time.

28

First Key to LP

One Variable Summary Updated LP Date

Histogram of First Key to LP/ Updated LP

Variance

1.42

890.26

20OW

Std. Dev.

29.84

16M

Skewness

Mean Abs. Dev.

5.3008

46.7737

-2.00

15.85

Mode

-4.00

Minimum

-108.00

Maximum

399.00

507.00

Mean

Kurtosis

Median

"ane

Date

33O

1

M

LZM

0COO

WW

Figure 7 - Dwell Time Statistics (in days)

As shown in Figure 7, the historical dwell time averages about I to 2 days with a standard

deviation of almost 30 days, which indicates the historical dwell time is very volatile. Also, with

the median of -2 days, more than 50% of shipments failed to arrive before the actual demand

window. In the next section, we will build our hypothesis regarding which attributes can help to

explain this dwell time variation.

4.2 Hypothesis

There are many factors or attributes that may have some level of explanatory power of the dwell

time variation. In this study we are limited to the attributes on the purchase orders, and only the

attributes that are available before moving shipments from their port of origin can be used.

Attributes that are created after that are hind-sighted information and therefore cannot be used to

predict dwell time. The attributes that can be used for this study are listed below:

1) Division - The sponsor company operates multiple retail chains. Each one is a

considered a division in this data.

29

2) Department - Each item has a department number that represents the category of

item (i.e. shoes, menswear, etc.)

3) Vendor - Each supplier is assigned a unique ID.

4) Agent - Some products are sourced through agents, which are also assigned

unique IDs.

5) Start ship date - The date that suppliers are able to begin shipping product.

6) Con cancel date - The deadline for suppliers to arrange shipment of product.

7) Merchandise Type - Proprietary

8) Ladder Plan Month - The month that an item is expected to be for sale in retail

stores.

9) Place of Delivery - Destination location

10) Loading Port - Origin port

11) Style Ordered Quantity

12) Actual Quantity

13) Actual Packages

14) Actual Weight

15) Actual Measurement

16) Pre-ticketed - Whether or not an item has a price tag at the time it leaves the

supplier facility.

17) Pre-packed - Whether items are packaged for store delivery by the supplier, or

the company must repack them at their distribution center.

18) Time between PO create and Cargo Receipt at origin

19) Time between PO create and Start to Ship

30

.~

.....

....

...

...

.........

..

We then used data visualization to quickly identify which of those attributes can help to explain

the dwell time variation.

Sheet

1

Dept Num

101

102

400

103

109

350

112

113

C

300

114

115

C

110

*120

S124

geC

200

150

*120

128

U129

131

*133

0

235

CC...4.

50

100

236

6

238

*1A

150-

3500

2350

130

*362

*363

*366

PO Ordered Quantity

-100

0

50

100

150

200

PO to Cargo Received

250

300

350

4130

1000

147000

Figure 8 - A scatterplot showing the days between PO Create and Cargo Receipt on Y-axis, and Destination

Dwell Time on x-axis. Different colors identify different departments, and size of circle represents order

quantity.

For example, in Figure 8, we plotted the number of days cargo spent at the company DC (DC

receipt to ladder plan date) against the number of days between the date the PO was created and

the date the cargo was received at origin, based on Department Number and Ordered Quantity

attributes. Visually, we can quickly identify that it seems that as PO to Cargo Received time

increases, the dwell time will decrease. In Figures 9 and 10, we see that Dept 236 has much more

dwell time variation when compared to Dept 346.

31

Sheet

Dept Nun,

1

4W0

350

e.,

150

:

.

a

-

250

I

*

ON

*

IM

PO

100

Ordered Quantity

S500DO

50

100

200

PO to Cargo

250

300

350

1 OD0O

147000

400

Recoied

Figure 9 - Figure 8 has been modified to show a department with more variability than normal.

Dept Num

Sheet I

400

350

300

250

200

150

100

ME

50

ii

PO

Ordered Quantity

) 50000

50

100

20

150

PO

to Cargo Re ~e

250

300

350

400

1001

147000

Figure 10 - Figure 8 has been modified again to show a department with stable timing.

32

By using this data visualization approach, we narrowed down the original attributes to create the

following list:

1) Department (Binary Variable)

2) Merchandise Type (Binary Variable)

3) Ladder Plan Month (Binary and Numerical)

4) Place of Delivery (Binary Variable)

5) Dvision (Binary Variable)

6) Pre-ticketed (Binary Variable)

7) Pre-packed (Binary Variable)

8) Time between Cargo Receipt and LP month (Numerical Variable)

9) Time between PO create and LP month (Numerical Variable)

Our hypothesis is that these nine attributes can help explain the dwell time variation. In order to

test our hypothesis and understand the numerical relationship between these nine attributes and

dwell time, a numerical model must be constructed. In the next section, we discuss our model

construction and results.

4.3 Model Construction

In the previous section, we hypothesized that there are nine attributes that may help to explain

the dwell time variation. At this stage, we use various multifactor regression models to test this

hypothesis and determine the numerical correlation between the variables and the dwell time.

The company is particularly interested in segmenting future shipments into the following groups

so they can use different supply chain speed to improve on-time performance:

1) Late shipment: dwell time is less than negative 21 days

33

2) On time shipment: dwell time is between negative 21 days and 0

3) Early shipment: dwell time is greater than 0.

The remainder of this section documents the development of an ordered-probit regression model

and a neural network regression model that proved to be most effective in identifying correlation

and predicting dwell time. We then provide an example of how a regression model can be used

to form a segmentation strategy for the purchase orders based on the predicted dwell time and

simulate the impact on on-time performance.

4.3.1 Ordered-Probit Method

Since our objective is to determine a method to segment future purchase orders into three groups,

we decided to use ordered-probit method to construct our model instead of using simple linear

regression method. We assumed this model would be more accurate and reliable because it

predicts the probability of dwell time falling in a given range rather than predicting an exact

number of days as in a linear regression. Unlike standard linear regression models where the

dependent variable needs to be numerical, an ordered-probit method is a technique used to

regress categorical values against the chosen attributes. Instead of a predicted value, the output

of a probit model is the likelihood of the occurrence of each category given a set of inputs. A

tyical ordered probit model can be described as follows (Chris Brooks, 2008):

=i

xi /3 + EL

Where ei are independent and identically distributed random variables, xi

is the independent

variable matrix, and 0 is the coefficient matrix. Then, yi is determined from yi* according to the rules

below:

34

if y* :5 y1

ify1<yt<y2

if yi* > Y3

1

yi =

2

(3

Then, the probabilities of observing each value y are given by:

P(yj = 11x,f, y) = F(y1 - xi' f)

F(y 1 - x i)

P(y = 21xi,f, y) = F(y2 - xi'

P(y = 31x,fl,y) = 1 - F(y2

- xi #)

The yi, the threshold values, and f , the coefficient matrix will then be estimated according to

the natural log likelihood function:

Maximize: L( 53, y)

ln(P(y1

=

= jIxi, fl,

y))

(yi = j)

i=1 j=1

is a logical value. If y = j is true it will take a value of 1,

In the above formula, 1(y =

j)

otherwise it will be 0. F( y

x' f

-

) is the

cumulative probability function of the error terms,

which is assumed to be normally distributed.

To build an ordered-probit regression model, the dependent variable - dwell timein this case - is

translated into three categorical ranges. Before running the model, we still have to transform the

original dwell time values into the categorical values, which are detailed as follows:

" Categorical value: 1, for dwell time <=-21 days

* Categorical value: 2, for dwell time >-21 days and <= 0 day

o Categorical value: 3, for dwell time > 0 day

Next, we constructed the model in EViews, which is an econometrics software. In choosing the

maximizing optimization method, the default Quadratic hill climbing method is used, the model

output is summarized in Figure 11:

35

Pseudo R-squared

Schwarz criterion

Hannan-Quinn criter.

0.364280

1.247907

1.237530

Akaike info criterion

Log likelihood

Restr. log likelihood

1.232705

-23118.32

-36365.56

LR statistic

26494.47

Avg. log likelihood

-0.614571

Prob(LR statistic)

0.000000

Figure 11 - Ordered Probit Model Output Summary

The correlation coefficient between the dependent and independent variables as well as the

significance level can be found in Appendix I. Since this is an ordered probit model, those

coefficients cannot be directly interpreted as how much the dependent variable will change by

changing one unit of the independent variables. Usually, marginal effects are calculated and used

to measure how much the probability of the dependent variables will change given a unit change

of the independent variables. Nevertheless, those coefficients can still be used to get a sense of

the relative strength in correlation with the dependent variables among the independent variables.

Specifically, the higher the coefficient, the higher is the chance that the dependent variable will

fall into category 3.

Regarding the model fitness, as indicated in Figure 11, the Pseudo R-squared value is 36%.

However, since this is an ordered-probit model, this R-square cannot be directly interpreted as a

measurement of goodness-of-fit. To better measure this model's predictability, the model

outcome should be compared to the constant probability in the original dataset. This is to

measure how the model performs in prediction relative to always choosing the category that has

the highest historical number of occurrence, which in our case will be category 2 that has 45%

occurrence in the past. Figure 12 shows the comparison of the model ability to predict the dwell

time:

36

Prediction Evaluation for Ordered Specification

Equation: EQ02PROBIT

Date: 04/20/14 Time: 11:15

Estimated Equation

Dep. Value

Obs.

Correct

Incorrect

% Correct % Incorrect

1

4233

1438

2795

33.971

66.029

2

17034

14570

2464

85.535

14.465

3

16350

13543

2807

82.832

17.168

Total

37617

29551

8066

78.558

21.442

Constant Probability Spec.

Dep. Value

1

2

3

Total

Obs.

4233

17034

16350

37617

Correct

Incorrect

4233

0

16350

20583

0

17034

0

17034

% Correct % Incorrect

0.000

100.000

0.000

45.283

100.000

0.000

100.000

54.717

Gain over Constant Prob. Spec.

Dep. Value

Obs.

Constant

Equation

% Incorrect % Incorrect Total Gain*

Pct. Gain**

33.971

1

4233

66.029

100.000

33.971

2

17034

14.465

0.000

-14.465

NA

3

16350

17.168

100.000

82.832

82.832

Total

37617

21.442

54.717

33.275

60.812

Figure 12 - Ordered-Probit Prediction Evaluation

Overall, this model achieves about 78% prediction accuracy. When compared to the constant

probability, the model improves prediction performance by 33%. However, the limitation of this

model is that it can only predict categories two and three with high accuracy. Its accuracy for

category one is only 33%. Moreover, since this model incorporates many binary variables, it will

frequently encounter multicollinearity problems, that were fixed in the final models, but could

resurface when running the model over new datasets.

37

4.3.2 Neural Network Model

Due to the limitations of the ordered-probit model, we used a neural network regression model in

an effort to improve prediction accuracy, goodness-of-fit, and application feasibility.

4.3.2.1 Neural Network Model Mathematical Equations and Algorithm

Neural network is usually referred to the various mathematical models that imitate human brain

functions (Huangjin Tang, Kay Chen Tan and Zhang Yi, 2007). It has wide applications in areas

such as artificial intelligence, information processing, engineering, and finance for pattern

recognition, function approximation, forecasting purposes. In statistical forecasting, unlike

traditional regression model which relies on modeler's ability in guessing the causal-and-effect

function between the inputs and the outputs, neural network method provides a way directly

learn the internal relationship between the variables in a system (Ke-Lin Du & M.N.S Swamy,

2014). This feature is very helpful when the underlying relationship between the inputs and

outputs in a system cannot be very well estimated.

The most widely used neural network model in statistical forecasting is feed-forward networks.

A typical feed-forward network structure consists of a layer of inputs, a single or multiple hidden

layers and an output layer. A typical feed-forward neural network model's mathematical

equations can be described as follows:

1. Input variables and non-linear transform function:

=(S j)

Xj

0

d(l-1)

)

(-

(1w 1=

38

6(S)

es - e-s

es + e-s

=

Where:

1

1

L (1 stands for which layer in the model, L is the largest layer in the model)

0

i

1

j < d(') (i stands for which output in the model, d is the number of outputs)

d(-')(i stands for which input in the model, d is the number of outputs)

x

is the ith output at layer (1 - 1)and the ith input at layer I

x!is the jth output at layer 1

w!- is weight

0(S)is a tansigmoidnonlineartransform function for the input variable

2. Output and error term:

The final output of the model is a linear output. The error term, which is the difference between

the model output and actual value, is often measured by mean squared error. Based on the

equations for the input variables, the error term is essentially a function of w!b . To minimize the

error term, w!b can be determined by:

de(w)

Ve(w):

de(w)

a

(1

awi

de(w)

sl

__S_

aw(1)

Since:

39

x.

, so only

8w

(w) needs to be calculated.

S~l

3. Back propagation:

To find the optimal weight, neural network regression models use a method known as back

propagation. The error terms are run through the network layers in reverse order, then a gradient

descent method is used to determine the optimal weight that minimizes the error term (Ke-Lin

Du & M.N.S Swamy, 2014). Its mathematical equation usually can be described as follows:

80)

=e(w)

as~l

Starting from the last layer:

d(l)

-ae(w)

81 d =1

i

j=1

a

_ x>

e(11)l

=x

i

i

d(1)

_

i

=

8

x1w0f(

x 6' (SO'~)

j=1

4. Algorithm:

A typical back propagation neural network algorithm follows the following steps:

a) Randomly initialize w (1

b) Forward compute all x! in the net

)

c) Back propagate all 6(1

d) Update wf

e) Iteration

f)

Find the optimal wf that gives the lowest e(w)

The neural network mathematical structure also has many derivatives which can use different

non-linear transform functions, error term measurements, layer structures and so on. In this

study, the modelling is based on the back-propagation feed forward model described above.

40

More specifically, the neural network model used in this study has one input layer, one output

layer, and 10 neurons.

4.3.2.2 Model Building in Matlab

To build, run, and test the neural network model, we used Matlab technical computing software.

3,000 purchase orders are first used to build the model. A rolling forecast mechanism is designed

to roll the model over the entire 37,617 purchase orders in order to fully test the accuracy and

robustness of the model. Parameters such as model size, variables to be included, and which part

of the dataset to use to build the model and forecast, can be entered as the script starts to run.

Because the sponsor company would only be able to use data from POs that have been delivered,

we include a gap of 3,000 purchase orders in the initial model to represent the time gap needed to

update the model. The size of this gap is another parameter that can be controlled. The detailed

Matlab script for our model is presented in Appendix II.

Also, in choosing the input variables, we narrowed down number of input variables from the

nine variables used in the ordered probit model to five variables, which are Merchandise Type,

Pre-ticked, Pre-packed, Division, and Time between Cargo Receipt and LP Month. The reason is

that in building our neural network model, we found that adding the Department, Time between

PO creation and LP month, and Place of Delivery variables didn't help to improve the

performance of the model, and adding them into the model will simply complicate the

application of the model, since it will ask users to provide more inputs than necessary.

We use this script and the first 3,000 purchase orders in the dataset to build, train, and validate a

neural network model. Figures 13, 14 and 15 show the resulting model construction.

41

Best Validation Performance is 106.2722 at epoch 7

10

-

10,

0

h

Train

Validation

Test

Best

3

So

10

_

102

10

10 0

_k

0

4

2

6

8

12

10

13 Epochs

Figure 13 - Model Training and Validation

Error Histogram with 20 Bins

700

Training

Validation

Test

Zero Error

600

500

0

500-

400

300

200

100

C

9

Errors = Targets - Outputs

Figure 14 - Error Distribution Histogram

42

Validation: R=0.9243

Training: R=0.96247

t

250

d

a

+

o

250

Data

Fit

Y= T

-200

CP

Data

Fit

---- Y = T

200

150

150

100

D

0

100

50

50

0.

o05

100

0

+

0

250

C4

200

150

All: R=0.95947

250

0'

200

LM 150

150

100

100

0

50

100

Test: R=0.965

Data

Fit

Y =T

-

50

Target

/

0

0

200

Target

50

0

200

250

0

Data

-- -Fit

Fit

0'

0

0

o -5o

-50

0

100

Target

200

0

100

200

Target

Figure 15 - Regress Predicted Value on Actual (In-sample test)

As shown in figure 13, after training and validating, the model found the minimized MSE, which

is the mean squared error between the actual value and predicted value, is at 106. Figure 14

shows and compares the error term distributions, which is the difference between the predicted

value and actual value, during model training period, validating and train periods. The allocation

of the sample data for training, validating and testing is 70%, 15% and 15% respectively. In

figure 15, the predicted value, which is the output of the model, is regressed on the actual value,

which is the target of the model. The dashed line represents the ideal situation where the output

value is exactly equal to the target value and the R squared value is 1, while the solid line

represents the actual fitness. Overall this model has very good fitness as indicated by the high R

43

squared value. Next the model is used to predict the dwell time for 100 out-of-sample purchase

orders. Figures 16 and 17 show the result:

: R=0.99273

o

200

-

Data

Fit

--

'0

Cl!

150

'D

100

50

0

0

0

50

100

150

200

Target

Figure 16 - Regress Predicted Value on Actual (Out-of-Sample Prediction for 100 POs)

I

I

I

I

I

I

I

I

I - -

-

I

I

I

I

I

-

I

I

I

- -

-

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

60

SI

1

10

20

30

4

I

0

0

8

100

Figure 17 - Predicted Result VS Actual Dwell Time (Out-of-Sample Prediction for 100 POs)

In this out-of-sample prediction, the model achieves fitness of 99% with a constant bias of 4.2

days. In the following section, more tests are performed to evaluate this model's accuracy and

robustness.

44

4.4 Tests and Results

In this section, both the ordered-probit model and the neural network model are tested and

evaluated in terms of their predictive abilities, fitness, and feasibility in application.

4.4.1 Ordered-Probit Model

Due to the multicollinearity problem caused by the use of binary variables, testing for model by

choosing different sample size becomes difficult. The chosen binary variables that work over the

first 10,000 samples may have multicollinearity problems when the model is built from the next

10,000 samples, and the binary variables that cause this problem will have to be deleted from the

model, which will make the test results become incomparable. Therefore, we kept 36,617

purchase orders as our sample size, and run the model to predict the dwell time for the remaining

1,000 purchase orders in the dataset. Below is the result:

Table 2 - Ordered Probit Model - Test Result for 1,000 POs

Actual

Predicted correctly

Accuracy

Category 1

111

25

22.52%

Category 2

Category 3

467

422

128

290

27.41%

68.72%

Total

1000

443

44.30%

S

J

The prediction accuracy for this test is 44.3%, which indicates that the out-of-sample prediction

power of the ordered probit model is not accurate enough for the company to make business

decisions. One approach often used to improve the forecasting performance is to reduce the

number of categories to be predicted. however, in our study, when we used logit model to predict

one category, the forecast accuracy was even worse with the accuracy lower than 10%.

45

4.4.2 Neural Network Model

Unlike the ordered-probit model, using binary variables in a neural network model does not

cause any problems in running and testing the model. Therefore, the neural network model can

be tested over any portion of the given dataset. There are two ways to do this:

1) Build a single model to predict the entire dataset

Under this method, the first 3,000 purchase orders are selected to build the model. This model is

used to predict the remaining purchase orders.

2) Build initial model then update it on a rolling basis to predict the rest of the dataset

Under this method, the first 3,000 purchase orders are selected to build the model. This model is

then updated using the rolling window method to predict the rest of the dataset. For example, if it

is set to predict 500 purchase orders per run, it will use the first 3,000 POs to build the model and

predict the dwell time for the POs from 6,001 to 6,500 (including the timing gap size of 3,000

POs). For the next run, POs from 1 to 500 will be excluded from the model and POs from 3,001

to 3,500 will now be included in the model used to predict dwell time for POs from 6,501 to

7,000.

In either case, it is important to know how far this model can predict into the future while

maintaining an acceptable accuracy level and what sample size results in the most accurate

predictions. In other words, how frequent the model should be run in application to achieve the

highest accuracy.

The following table summarizes the test results under the two approaches:

46

Table 3 - Test Results without updating the model (model size=3,000, gap=3,000)

How far into the future

100 POs

500 POs

1000 POs

5000 POs

10000 POs

30000 POs

Fitness

99.27%

98.23%

98.30%

97%

96.50%

92%

Coefficient

1

1.1

1.1

1.1

0.98

0.89

Bias (days)

4.2

4.9

5.9

2.9

1.8

0.69

Table 4 - Test Results with updating the model (model size=3,000, gap=3,000)

Number of POs updated per run

100 POs

500 POs

1000 POs

1500 POs

3000 POs

Fitness

86%

86%

85.80%

83.70%

82%

Coefficient

0.92

0.87

0.88

0.93

0.82

Bias (days)

1.5

1.5

1.4

1.5

1.4

As indicated in Table 3, when tested under approach one the model achieves at least 92% fitness.

The coefficient

,

which measures the slope of the linear relation between the actual value and

predicted value, with one as the perfect forecast performance, averages at one and the bias is

between one and six days. When tested under approach two, the model achieves at least 82%

fitness, the coefficients vary between 0.82 and 0.92, and bias is 1.5 days.

Based on these results, two observations can be generalized:

1) Prediction accuracy will drop as the time horizon is extended

2) The rolling approach results in less fitness accuracy but is less biased

In the initial tests, the model size is fixed at 3,000 POs. The next step was to test the sensitivity

of the model performance relative to the model size. Figure 21 indicates that increasing the

47

model size generally improves performance. Additionally, once the model size crosses a

threshold the performance becomes less sensitive to changes in model size.

Fitness Coefficient

0.34

0.59

500

Model Size

700

0.94

Bias

3

1.1

2.5

1000

0.98

1

5.9

2000

3000

4000

0.97

0.98

1

1.1

-10

5.9

0.986

5000

6000

7000

0.97

0.95

0.97

1

0.97

0.93

0.99

2.21

3.5

2.5

10000

0.965

0.92

2

1.6

02

04

02

0

0

r

4400

M

60-tj

8000I

Figure 18 - Performance Sensitivity Relative to Change of Model Size (Number

1 X IL

IP

)X)

of prediction=1,000 POs)

4.5 Potential Application of Model (Proof of Concept)

Because the neural network model showed a clear advantage in prediction accuracy, we will not

explore the potential use of the ordered-probit model.

The predictions from the neural network model only solve part of the actual problem. How to

segment the POs based on the predicted dwell time and how to apply different supply chain

speed to improve on-time performance are the next steps to be taken for this model to be useful.