Document 10915488

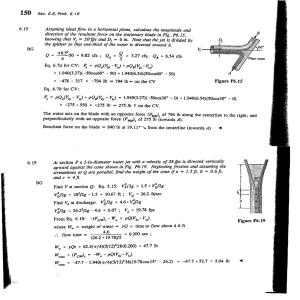

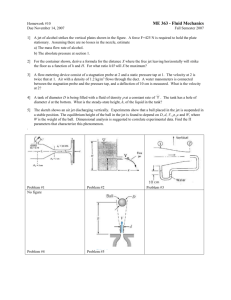

advertisement