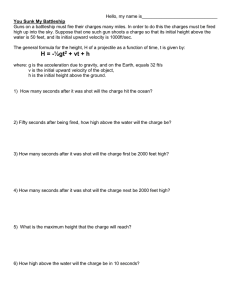

Lined-Cavity Shaped Charges and Their Use in Rock and Earth Materials

advertisement