Document 10901519

advertisement

A THERETICAL

AND EXPERT1'MNT

INVE7STIGATTON 0'P THE "DERFORMANCE

O7 7T,APPED

TTThDERS

by

Bohdan W. Orrnenheim

Undergraduate

M.S.,

Diploma,

Warsaw 7olvtechnic,

Poland,

1970

Stevens Institute of Technology, 1973

A Thesis

Submitted in

Partial Fulfillment of the Requirements

for the

Degree of Naval Architect

at the

MASSACHUSETTS

TNSTITUTE OF TECHNOLOGY

May, 1974

Signature of the Author:

Denjrtment of Ocean Engineering,

1 av, 1P74

M

Certified By:

Thesis Supervisor

Accepted By :

ARCHIVE9

Chaman, Dent.

JUL 16 .974

Comm ttee on Graduate Students

ABSTRACT

Two flapped rudders with .10

and .20

flao

areas of a typical

high speed vessel were examined exnerimentally in a water tunnel,

in

free stream,

and behind a oroneller.

metry are discussed

ration,

thickness,

A lifting

in detail, in

sween angle,

Effects of rudder geo-

particular,

effects of taner

and flan size.

surface nrogram was written and used in

compare and choose the best rudder planform.

order to

Pesults include

free-stream coefficients of lift, drag, moment and flan moment,

for a wide range of angles of attack and flan deflection angles.

Effects of variations

amined.

in

nropeller-rudder axial clearance was ex-

Presented is a discussion of effects caused by viscosity,

gans,and wall interaction.

Comnarison was made with the nerform-

ance of other flapped rudders.

A rudder with 20. flan was selec-

ted as one having the best performance characteristics.

A strong effect of rropeller wake on rudder characteristics

was observed.

TndeDendence

of rudder forces on axial clearance

between propeller and rudder was noticed.

CON TmENTS

1.

Introduction ...............

1

2.

Rudder Shape ...............

3

3.

Design of Test Equipment

17

...

4. Accuracy of Measurements and Data Reduc tion ..............

53.

Range of Parameters measured

32

6.

Results and conclusions ....

33

7.

Comparison of Theoretical an d Exrerimen .a1

Data . ....................... ...........

Acknowledgement ............ ...........

0.

61

Nomenclature ............... ...........

63

10.

References ................. ...........

11.

List of Figures and Tables

12.

Appendix

. ...........

(Lifting Surface Program)

66

1.

INTRODUCTION

Flaps have long been recognized and apolied in aerodynamics

to increase the lifting characteristics of control surfaces.

But prior to 1972, there appeared to be very little systematic

data available on flaped control surfaces, with aspect ratios

suitable for ships.

In

1968-1972,

a project was carried out at MIT,

to provide

the beginning of a systematic series of experiments yielding

flapped rudder data of direct use to the designer (1).

It

was an

experiment which determined the free stream characteristics of a

series of twelve rudders with systematic variations in the amount

Shapes of rudders were tvnical of

of flan area and flao balance.

a high sneed vessel.

to be 1.4.

Asoect ratio was chosen rather arbitratelv

Flap size varied from 20% to 60% of the total project-

ed rudder area, and balance -

(defined as the distance the hinge

line was moved aft of the center of circular radius flan leading

edge as a percentage

of the nominal flap chord)

-

from 0 to 10%.

Among other interesting results of that investigation,

it

was observed that the 201 flan, no balance all-movable rudder,

had the best characteristics.

It was also concluded that balan-

ced flaps produce disadvantageous

flow effects.

This information aroused a speculation that nerhans an allmovable rudder with a smaller than 20Y

flap, of zero balance,

would be more beneficial.

The objective of the nresent work was to obtain the steady

-l-

force coefficients acting on a 10

flap rudder in

free stream, as

well as behind a propeller for different propeller-rudder configurations, namely for single screw-single rudder, double screwsingle rudder,

and double screw-double

speed vessel.

-2-

rudder of a tyrnical high

2.

Rudder Shane

The initial

series

(1),

idea was to nreserve the rudder shane from the

decreasing only the flan area to 105 by moving the

flan hinge axis towards the trailing

edge;

and,

if

needed,

ing the model size to suit the geometrical reouirements

nronortions of the tunnel test

section,

scal-

of mutual

and nroneller and rudder

sizes.

The first

difficulty encountered

that the hinge line of the 10

flan,

during this attemnt,

(which was arbitrarely

strained to be nerpendicular to the root and tin sections),

was

conwould

intersect the rudder tin so far aft that the thickness of the tin

was too small to allow installation of any bearing of renuired

strength.

Several solutions were possible:

sween angle,

section,

to increase the rudder

thus moving the tin section aft relative to the root

so that the ratio of the flan chord to the tin chord

would be much larger at the tin than at the root , or to increase

the basic thickness of the tip section, or finally to increase

the taner ratio

to apply all

(ratio of the tin chord to the root chord);

these changes simultaneously

Here a matter of ontimization

or

In some suitable way.

Of these narameters became of prime

imnortance.

Decision at the thickness change was based on the exnerience

from the original experiments (1).

Those rudders tapered from a

root thickness ratio of 0.? to a tin thickness

-3-

ratio of 0.1 following

typical Practice.

However,

one of the reasons given in (1)

for

the poor maximum lift coefficient of the rudders comnared for

example, to the Whicher-Pehlner data (14)

a uniform thickness ratio of 0.15.

is that the latter has

'or this reason, it was de-

cided to adopt a uniform thickness ratio of O.15 over the whole

rudder span.

as in

Asnect ratio, it was decided, would remain the same

the original rudders,

namely 1.4.

The remaining values to

be determined were the sweep angle of the auarter chord line, and

taner ratio.

Asnect ratio of 1.4 is

too low for lifting line theory anoli-

cation and too high for low asnect ratio theory.

Tn view of the

lack of any analytical solution for ontimization of sween angle

and taner ratio values, a lifting surface Program was written (2).

The listings of this program is included in the Appendix.

This

is a rather general computer program for numerical evaluation of

lift slope, induced drag, rudder efficiency, moment coefficients,

and position of the center of Pressure for any flapped rudder

tra.erzoidalola

form, with a constraint that the hinge line does

not intersect leading or trailing edges,

the root and tin sections.

and is

nernendicular to

Characteristics of rudders without

flaps can also be obtained by snecifying in

the innut,

a dummy

flap area, subject to the above constraint.

Solutions for several nlanforms with systematic variations

in sweep angle and taper ratio were obtained using this nrogram.

Pinal choice of these narameters was based on three values

that appear in the output:

lift slone coefficient, induced

coefficient, and rudder efficiencv.

drag

An additional condition that

had to be satisfied was that the hinge line had to intersect the

tin section far enough forward,

so that at this point the tin

section of assumed thickness would be thick enough to nermit installation of hinge details of sufficient strength.

sweep angle

came out to be 170 aft, comnared to 110 aft used with

The optimum taner ratio came out to be, coinci-

the series (1).

dentally,

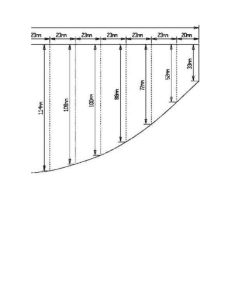

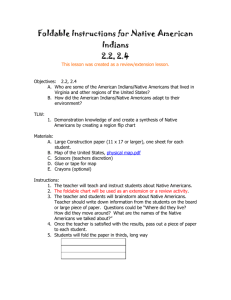

(Figure

The ontimum

namely 0.60..

identical with that of' the original series,

1).

the combination of a taner ratio of' 0.60 and a

Purthermore,

sween angle of 150 of the ouarter chord,

resulted in

the trailing

edge of the rudder being nernendicular to the root and tin chords.

Since

the flan hinge is 'also normal tOLthe root chord,

simplification in

is

described in

This

the geometry of the flan was made nossible.

the following chanter.

Since the nlanform of the 1%

from the original rudders,

flan rudder had been changed

and one of the objective

nroject was to comnare this rudder with the 20l

model had to be built,

rudder without a flan,

by filling

flap

of the nresent

rudder,

another

namely one with a 201 flan, and the same

planform as the 10"' flan rudder.

the above,

significant

Tt was also intended to test one

and such a rudder could be ma.d.e of one of

the gap between the skeg and the flap with

a filler.

Span length was determined

tions of mutual proportions,

as well as of the tunnel test

from geometrical considera-

between the rudder and the nroneller,

section blockage limitations.

Tvi-

cal values of the clearance between the ship hull and the nropeller circumference is 0.3 of the propeller diamter D.

Rudder

tip is usually 0.25D above the lowest point of the proneller circumference.

With the nroneller of the diameter 7.4p"

for these tests,

selected

the rudder span came out to be 7.P75".

The sectional shape of the 66 series (5)

(Pigure 1).

was selected for the

original tests, because its maximum thickness is well aft of the

leading edge,

which was desirable

for large flan rudders.

Since

no large flap rudders are included in the current nroject, this

constraint no longer applies.

selected for the current

The 63 series shape was therefore

series,

because

it should have

stall angle and higher maximum lift than the 66 series.

a larger

The 632~

A015 sections have, however, been slightly altered in order to

develop a plain two-dimensional

This permits

leading edge,

prismatic flan,

and flan gap.

the flap section to consist only of a circular arc

and straight lines emanating from the tangency noints

of the leading edge to the sharp trailing

edge,

with a selected

edge thickness of 0.020".

The flap gap was chosen to be very small, namely 0.010", in

order to minimize the flow through it, inasmuch as such cross flow

decreases the pressure jumn across the hydrofoil, thus reducinp

7.031-73

+-0.

200% FLAP HINGE

10% FLAP HINGE

-.

__

____

MAC

4.219

Fig. 1

Planform of the 10% and 20% Flap Rudders

-7-

562

Comparison of Current Rudder with

Table 1:

rogram (1)

Rudders Tested in the Oriinil

Original

Rudders

Current

udders

Modified 63 2 A015

Section shape

6627020

66E10

0.60

Taper ratio

1.40

1.4110

Root thickness ratio

0.1507

0.21)

Tip thickness ratio

0. 1562

0.10

Geom.

aspect ratio

inches

Root chord,

inches

Tip chord,

20% Flap chord,

inches

10% 'Flap chord

degrees

MAC, inches

Area, So.

4.219

5.955

10

7. P75

Span, inches

Sweep angle,

8.925

inches

Tip shape

Location of stock axis

in 5M2AC aft of leading

edge

Flap size and flap

balance, 0 of MAC

1.125

0.562

15

11

5. 711'21

71.4

144.3

sauared off

sauared off

variable

37.0

0 flap

"

10%

20%

-

0 bal.

- 0

-

0

0 flan

"?

20"

"?

30%

30%

0 bal.

0

0

"'

"?

-

-

30

0

w40%it

-

0

140%

140%

50%

"?

-

"~

"t

78

?

1)

-

-8-

"?

I

.3:; T

the lift

force.

The minimum size of the gap is limited by a roughness of the

skeg trailing

edge,

and the flap leading edge,

due to a machining

Details

process, as well as due to biochemical effects of water.

and comparisons of the overall rudder and flap configuration and

the geometry of the oresent oroject rudders, and of the original

series, is included in

ject are presented in

Rudder shanes of the nresent nro-

Table 1.

Figure 1.

Modification of the Rudder to Suit Convenient Manufacture

The NCA 63 2 A015 section had to be slightly modified to oermit

an important simplification.

This section has a straight line

section shape from 75% of the chord aft of the leading edge to

the trailing edge.

In

order to further simolify fabrication

of the 20% flap it was desirable to have this straight line section extend from 70% of the chord to the trailing edge in order

to encompass both the flap as well as the mating surface on the

rudder.

Since the flan chord is constant from root to tip, it

was decided to make the flan strictly two-dimensional for the ultimate ease of fabrication.

In fulfilling this requirement, the

root and tip sections differ slightly both from each other and

from the NACA 63 2 A015 section.

A program outlined in the followirgparagraphs was written

to modify the 63 2 A015 section to oroduce the tio section and

the root section needed to meet the above reouirement.

The out-

put of this program was tabulated data in a form convenient to

the model from 6061-T6

the machinest-model maker who machined

in narticular,

aluminum alloy using a milling machine.

230 soan-

wise cuts were specified along straight lines connecting points

The final machine

of constant percentchord at root and tio.

marks were small and were removed by polishing the surfaces by

hand.

The resultant accuracv of the rudder surfaces

satisfactory.

Roughness does not exceed 0.002"

ance of the offsets

is

very

and the toler-

is smaller than 0.0057".

Modification of the tip foil section by numerical methods

(the referred sketches

was accomplished in the following steos:

are shown

(a)

an

'Figure 2).

The 63 2 A015 foil sections has a finite

edge thickness eaual to 0.032

trailing

(see Sketch 1).

(Prime

denotes values non-dimensionalized by chord length).

(b)

From this section a wedge was removed centered around

the plane of symmetry of the section leaving a sharo

trailing edge:

=

1

Y't=

(c)

(see Sketch 2)

' 0.032 - x'

0 < x' < 1

(1)

0

non-dimensional offsets of 612A019 section

Straight lines that form the trailing

edge of the last

250 of chord were extended beyond the trailing

edge

sufficiently that over the longer chord thus created

the last 30% of the chord would be linear (see Sketch 3).

(d)

A new wedge was added to remove the negative thickness

from the previous sten and the abscissa was rescaled

to go from 1 to 1000.

-10-

This

foil

has a shar

trailing

(e)

I and 5).

(see Sketches

edge

edge

Then a wedge was added to bring the trailing

thickness on model scale to 0.020"

(±0.010"):

(see

Sketch 6).

Y=

Y

As shown in Sketch 7,

flap region.

+

xt

(2)

root and tip sections differ in the

The root section was therefore next modified to

be identical to the tip section between 70% of tin chord and the

edge for this model with a 0.60 taner ratio.

trailing

"hese stens

are as follows:

(f)

edge thickness was removed by

The 6? 2 A015 foil trailing

subtracting a wedre then brought to 0.020"

(see Sketch P).

by adding a wedge:

=

(g)

thickness

Y-.032

- x' + 0'010 .x'3cr

c

Sct()

<x'<

edge wedge with that of the

Compare the root trailing

tip at the 700 of the tip chord from the leading edge

to evaluate a ratio, N=a/b

(see Sketch 9),

by which all

coordinates on the root section could be multiolied to

edge angles of root and tip identi-

make the trailing

cal on model scale.

(h)

the root foil with a sharp trailing edge

Re-evaluate

then multiply all ordinates by the ratio N:

Y=

4

-

3

x,

0.010".

0 < xt

cr

(cont.

-11-

overleaf)

<

(h)

2

4

I

II

100%

0%

100% 112%

100%

L.

I

I

0%

75%

~I~iI~5

0%

TIP CHORD

I00

7

ROOT CHORD".

t7~

+20%

FIG. 2

b

of c,

MIODIFICATIONS TO NACA 63 A015 SECTION

2

-12-

y

=

(i)

N

-

5

0

<

(5)

< 1

x'

4

The last step is to bring the trailing edge thickness

at the root to 0.020".

V

Y'/cr

5

=

+

0.010

(6)

0 < x' < 1

X

Cr

Table 2 shows the comparison between the unmodified NACA

63 2 A015 coordinates and the corresnonding coordinates for the

tip and root sections on the MIT flanned rudder model,

in

modified

accordance with the nreceding stens.

Propeller

The proneller used in the current steps is a tvnical modern

high-speed ship five bladed propeller model no. 4427.

meter is

7.48"

and the nitch P.03".

Its dia-

Design value of J is

0.8.

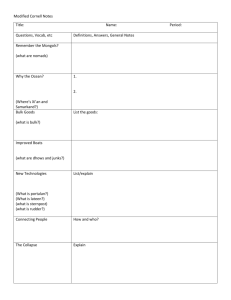

The onen water characteristics of this propeller, as measured

in

the MIT tunnel,

the same data in

are shown in

PigIure

3.

Tabulated values of

the region of the design J appear in

-12-

Table 3.

Table 2:

NACA

Comnarison of Coordinates

63 2 A015 Basic Thickness Form MIT Modified Section Shape

x

(per cent c)

Y

(ner cent c)

Y

T

V

Root

0

0.5

00

1.203

1.139

0

1.122

0.75

1.25

2.5

1.448

1.8P14 4

2.570

1.330

1.707

2.596

1.298

1.663

2.514

5.0

3.618P.833

7.5

4.3 2

3.715

10

4.997

14.511

5.171

15

5.942

6.1714

6.619

6.910

25

7.091

7.307

30

7.117

35

40

45

7.3814

7.496

7.1435

7.215

7.704

7.812

7.733

7.4-7

7.4'20

7.533

7

7.271

50

55

60

6.858

6.397

5.R20

6.915

6. 450

5.93

65

5.173

70

4.468

7.104

6.602

6.004

.339

4.616

3.813

20

75

.59

4.993

5.056

6.652

5.02h

3.731

3. 884

80

2.991

3.15

3.080

85

2.252

2.4214

2.346

90

1.512

1. 694

1.612

95

0.772

0.964

0.978

100

0.032

0.234

0.1-44

-1 4-

40

0

0.9

0.8

0.7

0.6

o0

I-a

0

0.5

0.4

0.3

0.20.\0.0.-0.1

-

0.0

Fig. 3

0.2

0.8

0.6

0.4

ADVANCE COEFFICIENT J

4

1.0

- Open-water characteristics of NSRDC Propeller 4427 as measured

in the MIT Tunnel.

1.2

Table 3:

15th August 1973

Onen Water Characteristics of Proneller h427

as Measured in ITTW'_ater Tunnel

MODEL 41127

5-BLAD)E

J-COR

KT

KQ

E

0.550

0.560

0.570

0.580

0.590

0.600

0.610

0.620

0.630

0.640

0.650

0.660

0.670

0.680

0.690

0.700

0.710

0.283

0.278

0.273

0.269

0.261

0.259

0.254

0.219

0.245

0.240

0.235

0.231

0.226

0.221

0.217

0.212

0.208

0.0471

0.0465

0.0458

0.0451

0.0444

0.0)430

0.0431

0.0425

0.0418

0.0412

0.0105

0.0399

0.0393

0.0387

0.0380

0.0374

0.0368

0.526

0.534

0.542

0.550

0.557

0.565

0.572

0.579

0.586

0.593

0.600

0.607

0.613

0.620

0.626

0.632

0.637

0.937795

0.08984

0.843023

0.799716

0.798886

0.72036P

0.680112

0.649679

0.617242

0.586592

0.557591

0.530162

o.504180

0.)479574

0.456224

0.434057

0.41204

0.720

0.203

0.0362

0.6)43

0.392965

0.730

0.740

0.750

7.760

0.770

0.780

0.790

0.800

0.810

0.820

0.830

0.8,40

0.850

0.860

0.870

0.880

0.890

0.900

0.910

0.920

0.930

0.940

0.950

0.960

0.970

0.980

0.990

1.000

0.199

0.194

0.190

0.185

0.101

0.177

0.172

0.168

0.163

0.159

0.154

0.150

0.145

0.141

0.136

0.132

0.127

0.122

0.118

0.113

0.100

0.103

0.090

0.094

n.o0o

0.0)4

0.079

0.074

0.0356

0.03'50

0.0344

0.0330

0.0322

0.0326

0.0320

0.0314

0.030p

0.0301

0.0295

0.0280

0.0283

0.0276

0.0270

0.0262

0.0256

0.0249

0.0242

0.0235

0.0228

0.0221

0.0214

0.020P

0.010A

0.0191

0.0183

0.0175

0.6)40

0.6Y4

O.650

0.664

0.660

0.673

0.677

0.61

0.60r1

0.688

0.691

0.6)Q

0.606

0.6(9

0.700

0.702

0.703

0.703

0.704

0.703

0.702

0.700

0.690

0.69)4

0..

0.6P)4

0.67P

0.660

0.37901

0.3557412

0.)9432

0.321915

0.2061415

0.291073

0.276659

0.262862

0.2)406)46

0.23675

0.22 418

0.213144

0.201925

0.191136

0.190750

0.170746

0.161102

0.151796

0.142012

0.131130

0.125730

0.117626

0.10079h

0.102201

0.004 P70

0.007790

~0.08002)

0.07 4203

-16-

KT/J**2

3.

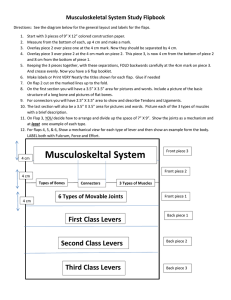

Design of Test Equioment

The experiments were run

water tunnel,

in the 20"x20" test section of the

in the MIT Marine Hydrodynamics Laboratory.

This

facilitypermits tests with water velocities up to 30 ft/sec

(figure 4).

Rudder forces were measured on the six comoonent

force dvnamometer.

steel worm gear,

hole,

in

The base of it consists of a heavy stainless

set on a tapered plug that rotates in

a plexiglass test section window.

a matching

The rudder shaft

passes through a flexible seal, and is securely clamoed. to the

floating structure of the dynamometer (Figure 5).

ing is achieved by a tapered key.

connected to the dynamometer

strain gage load cells.

der, high strength

The floating structure is then

base,

by a set of Lebow Model 3345

The load cells are attached through slen-

steel,

flextures,

as possible to pin-ended support.

movable for calibration,

Angular clamp-

in order to orovide as close

These load cells are easily re-

and can be reolaced by elements of diff-

erent caracity, depending on the requirements of the test.

The

load cells are electrically connected to Lebow Model 6r digital

strain indicators.

The propeller shaft extends into the test section following

the section center axis.

In

order to model the ship bottom,

in

an appropriate scale to the propeller, and rudder sizes, and to

house the mechanism supporting the rudder model, a horizontal

splitter plate had been introduced.

It was an aluminum rigid

flat plate displaced 2.5 inches from the test section ceiling.

-17-

Flf~

Ns

-.--------

---

Fig. 4

M.I.T. Water Tunnel.

-16-

FIG.5

MODEL IN THE TUNNEL TEST SECTION

-19-

Fig.20a

Rudder Model

in the Tunnel Test Section

Propeller-Rudder interaction

Fig.20b

(Photograph taken with a strobe-light)

-20-

This plate was rigidly secured to the unner window by an aluminum

streamlined foil,

area left

which occupied about 2/? of the cross-sectional

above the plate.

Inside this foil

connecting the model to the shaft,

was the mechanism

as well as the hinge moment

sensor.

The splitter plate extended across the whole width of

the test

section,

and was in

addition,

sealed to the test

section

side walls by means of rubber strips,

so that the flow entering

the test

above and below the plate.

section was split

comnletely

The leading and trailing

edges of the plate extended

upstream and downstream from the rudder stock axis.

were faired in

the plate.

order to minimize

As it

Both edges

the leading edge senaration on

later turned out,

and. caused significant trouble.

15 inches

the fpiring was not sufficient

Discussion of this is

presented

in the Section 7.

It

was honed that the solitter

thinner boundary layer,

olate would develon a much

than that 6n the test

section walls,

due

to being less extended upstream.

In

order t'o realistically

model a single rudder-double

screw

and single-rudder single-screw configurations, a rudder model

would have to be displaced off the vertical centernlane of the

test section.

This was accomplished by attaching the rudder model

rigidly to several different circular coverplates, which had

mounting holes in their different chords, in steps of 0.5 inches,

ranging from 0 to 2" from the plate center.

The coverplates were

in turn rigidly attached to a turntable, which was formed of a

wide and rigid collar at the lower end of the shaft

-21-

(Figure 5).

The bottom side of the covernlate was held flush with the

bottom side of the splitter plate.

plates was equal to l/P".

The gap between these two

A stainless 1.5" diameter shaft was

rigidly connected to the coverplate by means of a special bracket,

which was at the same time a housing for the flap moment sensor

and flan ball bearing.

rudder model,

All these mechanical narts, excent the

were completelv sheltered from the flow by the foil

connecting the solitter nlate and the unner wall of the tunnel

test section.

This arrangement also had an advantage of comnletef

ly removing the gap between the rudder model and the unner wall

of the test section.

As it

was observed in

(1),

such a gan has

very disadvantageous effects on rudder lifting characteristics.

Rotation of the turntable together with the coverplate would

change the angle of attack,

but at the same time would change the

clearance between the rudder and the nroneller in

lateral directions (see Figure 6).

both axial and

Tt was an easy task to keep

the axial clearance constantby simnlv moving the propeller shaft

by distance x,

since the nroeller shaft can be moved back and

forth by simply cranking a gear outside of the tunnel.

The lateral displacement (changing as 11 -

cosaI, Pigure 6),

it was hoped, could be neglected inasmuch as this distance is

small for the angles of attack of interest.

The flap was hinged to the skeg at two points: at the tip

and at the root.

The tip hinge was made of a shaft oermanently

pressed into the flap at the zero balance point, and was free to

rotate with a light sliding fit

-22-

in a stainlesshousing,

extending

from the skeg.

This housing had the outer contour faired to

match the rudder contour.

The unner hinge consisted of a shaft

permanently pressed into the flap root section, and housed in a

ball bearing, which in turn, was housed in the bracket connecting

The flan hinge moment sensor

the coverplate to the turntable.

was attached to the flap shaft.

it consisted of a tiller connec-

ted to the flan shaft, by a split collar, and clamning screw,

thus permitting adjustments of the flan angle.

The tiller was

instrumented with four strain gauges for measurements of flan

moment.

The gauges formed a full four arm bridge,

thus

giving a temnerature compensated output of significant amlification.

The outnut was read on a seventh digital Tebow strain

indicater.

The tiller

with the gauges was waternroofed,

ted completely submerged,

and onera-

thus eliminating the need for passing

the flap shaft through the dynamometer base nlate.

An electrical cable was lead through a drilled hollow in the

rudder stock shaft,

sealed and connected to the strain gauge in-

dicator.

Since two rudders were to be tested, each with a different

flap,

the housing bracket mentioned. above,

had a double housing

for two positions of the flap bearing, and flan tiller.

When one

flap was used, the hole in the covernlate for the other bearing

was sealed,in.order to eliminate any flow across the coverplate.

Both rudders had the same relative nosition with resnect to

the coverplate, and with the rudder stock axis.

able to locate the stock at the nosition where it

-23-_

It would be desiris

most likely

6

U

T JNNEL

SIDE

W

'ALL

XI

SPLITTE

PLATE

I

= sina

Fig.

6

y=I-cos a

R

(PROPORTIONS EXAGGERATED)

* = 0.133

a=30*

R |a=

Scheme of the mechanism changing rudder angles of attack

to be installed in

pondent

oractice.

on the rudder stock,

to zero torque

between 100 and 150.

This nosition is

According to (1),

roughlv corresat an angle of attack

this corresnonds to rough-

ly 30% of the MAC aft of the leadinr edge, at the MAC for the 201

flao rudder at a rudder angle of 12.50 , and a flan angle relative

to the rudder of 12.50 .Unfortunately,

because of structural

reasons it was not possible to locate the stock at this point.

In

the current series,

the stock was 37% of the MAC aft of the

leading edge at the TAC

-25-

4.

Accuracy of Measurements and Data Reduction

Much effort has been snent in order to assure the best accu-

racy of measurments and to eliminate most of the side effects.

Rudder stock diameter was increased from 1.0" - what the former

force dynamometer structure permiteed to 1.5" for better stiffness

of the model support and to compensate for the longer shaft needed

due to the introduction of the splitter plate.

redesign of the sealing and clamping systems.

the angles of attack more accurately,

This reauired a

In order to measure

the old system of a mechani-

cal counter connected to the dynamometer warm gear was abandoned

due to its lack of rigidity and a new ontical system was designed

and installed.

It consists of a circular scale mounted rigidly

on the room wall completely independent of the dynamometer rotation.

An optical telescone with a cross hair was mounted on ton

of the dynamometer and fixed to it.

As the dynamometer rotates

with the model, the current scale reading of angle of attack can

be seen in the telescone ocular.

approximately 0.010.

The accuracy of this system is

A special device had been made for measuring

and setting the flan deflection angle in place

test section.

in the tunnel

It consisted of a base attached to the rudder skeg

during the set up, with a circular rail in it.

The upper plate

rotated on the base rigidly, with the flap rotation following the

rail shane.

Rotation of the unner plate relative to the base was

read out optically through a magnifying glass, on a scaled vernier.

As the flap reached its nosition it was clamped by the flan tiller

-26-

clamp.

The accuracy of this device

0.50 or better.

is

Tunnel flow sneed was measured by means of pressure taps in

the contraction section connected to a Meriam !Iodel 33K A3R5 manometer with an indicating fluid with a specific gravity of 1.75.

The typical column height at 20 ft/s

is

1408

mm.

Readings were

The velocities are corrected for

taken with accuracy of 1 mm.

both tunnel and gauge temperatures

effects.

The calibration of

pressure tans was obtained by comparison with a Pitot tube transColumn heigcht of fluid was corrected

verse of the test section.

to the zero velocity meniscus.

In the present case, with a new solitter plate and its supo-

ort body installed and also the presence of the prooeller drive

shaft, a new calibration was required.

A factor was determined

which related. the original calibration to the new test section

configuration.

In particular, the calibration factor, which is

2.183,

numerically

by the actual manometer reading

is rultiplied

and the resultant number is reduced to velocity by the nrevious

calibration procedure.

When this is done, the average water

velocity at the rudder station is

obtained.

The distribution of the ratio of velocity at the given noint

in

section at the rudder position to the average velocity

the test

at this section has been measured using a Pitot tube.

represents

a man of this ratio

dary layer

.

in

P'igure 7

the region away from the boun-

The results indicate that the velocity profile away

from the boundary layer is

quite uniform.

The average ratio of velocity in the current test section to

-27-

the velocity in the original tunnel section is 1.0q9.

ber stays constant

is

for auite a range of velocities (15 -

Typical value of velocity in

sec).

This num25 ft/

the test section during tests

about 20 ft/sec.

Boundary layer thickness on the snlitter plate has been

measured at two cross sections: at the nroneller and at the rudder

positions

(see Figure

9).

This thickness is smaller than at the

tunnel wall due to the shorter length of the solitter

not as small as it

the plate.

but

would be expected from the Reynold.s number on

The explanation of this relatively thick boundary

layer is given in Section 7.

tunnel wall boundary layer.

The plate itself is away from the

On Figure

P there are two olots of

boundary layer thickness at the mentioned nositlons.

represent

plate,

The numbers

again the ratio of velocity at a given point to the

velocity in the test section away from the boundary layer.

The

abcissa represents the distance away from the splitter plate in

inches.

The individual load cells as well as the assembled unit and

the flap sensor were calibrated by hanging weights.

A computer

program was written to provide the final data in the tabular form.

Force coefficient curves were plotted by hand.

The individual

load cell readings were first corrected for zero drift by linearly

interpolating

the zero reading before and after

the test.

The cell readings were then converted to forces in accordance

with the instrument calibration.

These forces were then conver-

ted from instrument axis to stream axes to yield lift, drag and

-28

moment forces.

attack.

Three corrections were aplied to rudder angle of

The first correction accounts for the torsional flexi-

bility of the dynamometer and rudder shaft, and it was assumed

to be a linear function of the measured torque, the constant

having been determined by calibration.

reaches

This correction typically

a maximum of 0.6 degrees.

The second correction accounts for the tunnel wall interference.

Since the test section is not square any more due to

the splitter plate, a special correction had to be made according

to (6) for the span and chord of the rudder and the height and

width of the test section.

It became,

Aa

=

0.9618 cT

ACT

=

0.01674 cL i

(deg.)

Typical values of Aa at the highest lift was 1.30 and this amount

was added algebraically to the measured value.

Typical corres-

nonding value of AcD was 0.032 and again this was added to the

measured drag coefficient.

The third correction was applied after initially

unsuccess-

ful trials to obtain an antisymmetric lift curve when there was

no flap deflection.

It is a correction obtained from the experi-

ments with undeflected flap in

measurements

uniform flow,

and consisting of an aoronriate

aoplied to all

shift

in

the abcissa

on the plots of force coefficients versus angle of attack.

-2 C)....

F--MAXMM

WU)TH OF FAMRED-j

Su. ORT

SPITRPLATE

-

O Pn

QJ4

9V96

40or$ .

LO

.. O

LOO

pi .9.0

o

.n.K.A

/*9

PRO

eel.00

I L..C.

CONTOUR

AKE SURVEY ABOUT PROPELLER AXIS

AT RUDDER STATION

LOOKING DOWNSTREAM

FIG.7

WAKE SURVEY

0.0

0.0

.

0.2

0.4

0.6

0.2

U

U00

0.4

0.6

0.8

1.0

0.8

1.0

1.2

1.4

1.6

1.8

z (irnches)

BOUNDARY LAYER AT

PROPELLER POSITION (UPSTREAM)

U

0.0

0.0

0.2

0.4

0.6

0.8

0.2

0.4

0.6

0.8

1.0

1.0

1.2

1.4

1.6

1.8

z (inches)

BOUNDARY LAYER AT

RUDDER POSITION (DOWNSTREAM)

Fig. 8

Boundary Layers at two locations under splitter plate

-31-

5.

Range of Variables

To sum un the above, the following range of Darameters was

made available for testing in the nresent nroject set uo:

(1)

Two rudders were tested, with 10% flan and with 2flY

flap.

(2)

Plan deflection angles varied between 0 and 3 5

on one tack.

(3)

Rudder angles of attack varied between -100 and +?0o.

(1)

Reynolds number was kent constant and was approximately

equal to 0.9 * 106 based on the MAC length.

(5)

Axial clearance between the nroneller hub and the

leading edge of the rudder at the wAC was varied

continuously between x = 0.T) and x = I.0D where

T)

is

the proneller diameter.

(6)

Proneller revolutions were kept constant at

h50 'M

at the design J equal to 0.P.

(7)

The transverse oosition of the rudder could be adjusted

so that the rudder would be disolaced off the centerline,

by v=0, v=0.q"=0.067D,

y=1.5"=

v=.="=0.134D,

0.201D and v=2"=0.268D, where D is the oroneller diameter.

Unfortunately, the variations described in (7)

were never tested due to the budget and time limitations.

Results and Conclusions

6.

Results of the nerformance tests are shown in Figures 9 - 18

Figures 9 - 12 show the performance of 200

flow for all

angle,

flap rudder in

uniform

combinations of angle of attack and flano deflection

whereas Vigures 16,

19 show the comnarison of nerfor-

17,

mance between uniform flow condition and three different axial

positions behind the proneller location for 20fl% flap rudder.

The latter are,

Figures 13,

however, only for zero flan angle condition.

14 and 15 show the nerformance curves in free stream

for 10q flap rudder for all combinations of angle of attack and

flap deflections, as well as for behind the proneller condition

for two flan angles: n0

cient cL,

drag coefficient

moment coefficient

flo

and 35 0 .

cgo.

cD,

Data shown include lift coeffi-

rudder moment coefficient

The moment data in

ferred to a phantom stock axis located 491

ing edge at the MAC.

tially

cq,

and

Figure 11 are re-

of MAC aft of the lead-

At this noint rudder moment becomes essen-

independent of the flap deflection in the non-stalled range

of angles af attack,

and all

data collapses to a single curve.

The same data reduced to 19% of the MAC aft of the leading edge

of the MAC would result in

a family of curves with shapes simi-

lar to those of Figure 15.

A summary of principal characteristics of the rudders tested

in

this project,

and comparison to,

the 20%

original series (1) is given in Table 4.

flap rudder of the

Comparison of 20% Flap Rudders of the Present Project and of the

Original Series

(1).

Table 4 shows that the current 205 flap rudder does achieve

somewhat better maximum lift than the original rudder in (1).

The lift curve slooe of the current test rudder seems to be independent of the flap deflections for small deflection angles,

and is

slightly higher than that of the original rudder in

region,

while for larger flao

deflection,

this

the onnosite becomes

true.

Drag coefficient of the current rudder is lower at the maximum lift, as well as at the zero angle of attack at all flap deflections.

Stall occurs on the current rudder at similar angles

of attack for small flap deflections as on the original rudder,

but it occurs approximately 2 tions.

SO earlier for larger flan deflec-

Moment and flap moments are similar on both rudders.

The experiments confirmed the right choice of the sween angle

and taper ratio of the rudder, which was expected from the lifting

surface calculations.

the tests,

When the tunnel oressure was lowered during

thusih4-%v cavitation,

it

was observed that the

cavitation inception on the leading edge of the rudder was uniform over the entire span.

On the other hand, -the stall occur-

ance was earlier than expected on the current rudders, which, it

is suspected, could be exolained by non-optimum choice of the

basic thickness form of the current rudders.

Comparison of 20% and 105 FlaD Rudders of the Current Project

In view of a hopebased on the project (1),

-3 1-_

that the 10%

flap

0

0

0

0

0

0

0

00

0

0

0

0

-0

1

CL

60

aCL/9a CL

@ CL

max

max

a=0

max

@ CD

max

@ CD @

a=0

=

CL

max

L/D @

CL

CMF

21.0

20.5

20.0

20.5

21.2

19.6

-0.007

-0.008

-0.007

-0.007

-0.011

-0.017

3.37

0.190

19.6

-0.017

30

6.45

5.11

4.32

3.74

4.90

4.40

3.56

3.49

3.90

3.82

3.63

3.52

3.40

3.26

3.14

2

-0.110

-0.128

-0.150

-0.174

-0.192

-0.208

-0.222

-0.238

-0.105

-0.150

-0.180

-0.227

-0.260

-0.290

-0.310

-0,345

no

no

data

data

avail,

avail.

0.97

1.00

1.04

1.11

1.17

1.35

20.0

22.0

20.0

16.0

16.2

18.0

0

0.11

0.23

0.34

0.41

0.53

0.015

0.018

0.025

0.036

0.049

0.082

0.163

0.342

0.300

0.220

0.258

0.364

5.95

2.92

3.47

5.04

4.53

3.71

35

3.05

1.40

18.0

0.58

0,105

0.416

0

5

10% flap 10

15

20

rudder

25

30

35

1,

0

original 5

10

20% flap 15

20

25

rudder

30

lin (1) .35

2.75

2.75

2.75

2.75

2.86

2.95

2.98

3.06

2.07

2.74

2.82

3.01

3.04

3.06

3.08

3.24

0.80

0.92

0.95

1.01

1.07

1.10

1.16

1.20

0.78

0.88

0.98

1.09

1.19

1.27

1.32

1.40

17.0

19.0

18.0

19.0

17.0

17.0

18.0

18.0

20.0

20.0

20.0

20.0

20.0

20.0

20.0

20.0

0

0.07

0.15

0.22

0.24

0.25

0.26

0.33

0

0.05

0.12

0.19

0.27

0.35

0.43

0.47

0.124

0.015

0.180

0.017

0.220

0.022

0.270

0.025

0.218

0.031

0.250

0.039

0.326

0.045

0,34 4

0,052

0.20

0.021

0.23

0.023

0.27

0.028

0.31

0.039

0.35

0.050

0.39

0.075

0.42

0.085

0.110 10.47

*

CM

0.260

0.200

0.251

0.255

0.255

0.195

2.86

2.86

2.86

2.86

2.86

2.96

Principal Hydrodynamic

CM

@

ac

@*

ap

CMFmax

30

30

30

30

30

30

max

0

20% flap 5

10

15

rudder

20

30

Table 4:

*

max

max

31

31

31

31

31

31

31

31

30

30

30

30

30

30

30

30

max

0.002

0.005

0.007

0.010

0.012

0.014

0.016

0,017

Characteristics of Rudders

The moment coefficients are reffered to a phantom stock axis located at:

49% of the MAC for 20% flap rudder, aft of the LE at the MAC

24.8% Of the MAC for 10% flap rudder, aft of the LE at the MAC

18.0% of the MAC for the original 20% flap rudder, aft of the LE at the MAC

30

30

30

30

30

30

30

30

rudder might exhibit a more desirable performance than similar

rudders with larger flaps, the results of the present oroject

Table 4 shows that the maximum

seem to be somewhat dissapointing.

lift

is lower on the 10% flap rudder.

Stall occurs at lower

angles of attack on this rudder than on either the ?00 flan or

the original rudders.

Only the drag coefficient is more advantageous on the 105

flap rudder.

is

Plan moment coefficient data for the 10,

not available,

flan rudder

because the flan moment sensor waternroofing

lost its water tightness during the experiments.

Comna.rison of Rudder Performance in 1ree Stream and Behind Propeller

A dramatic increase in lift characteristics was exhibited

on the rudders when tested in the propeller wake. (Tables 5, 6).

Due to a helical shape of the wake and the fact that the rudders

were immersed mostly in the upper half of the proneller wake,

the rudder forces show assvmetry on two tacks, even when there

is no flap deflection.

The 201

flan rudder (Table 5) has a 20%

increase of the lift curve slop due to propeller wake.

lift increases 35% and 32

on two tacks resnectively.

angles occur at 50 and 9O later.

Drag coefficient

Maximum

Stall

at the maxi-

mum lift unfortunately increases as well, but only on one tack

this increase is

very dramatic,

namely 400 %.

On the other tack,

this increase is 40%.

A very interesting result concerns the drap coefficient when

the rudder has zero angle of attack,

-36-

and its

flan is

in the neutral

0

00

0

0

0

Table 5:

0

X

o prop

20% flapT 0.5 D

rudder 0.75 DJ

LL1.0 D.

0

0

0

0

L/ ;a

2.86

3.23

3.23

3.23

0

Q

Q

20?

I

0

0

Flap Rudder behind Propeller

C

CL

max

-a

+

-0.97 0.97

-1.5 1.43

-1.5

1.43

-1.5 1,43

-

CD

Lmax

+a

-20

-25

-25

-25

20

29

29

29

a=0n

0.015

0.004

0.004

0,004

CD

max

@ CL

MalX

aa

0.163 0.163

0.264 0.642

0.264 0.642

0,264 0,642

Table f:

Flap

behind Propell r

10%

10?/ Flan Rudder

Rudder behind Pro eller

Table 7:

Maximum Lift-Drag Ratio

I

tA

-4

1

position.

The drag coefficient then decreases from 0.020 when

in the free stream to 0.00h when behind the proneller.

This can

be explained by the interaction between the propeller hub vortex

and the rudder tip vortex.

In behind the propeller conditions,

rudders "feel" an angle of attack due to the proneller helical

wake, even when the geometrical angle

free stream direction is zero.

of attack relative to the

The rudder tip vortex thus in-

duced cancels partially with the nroneller hub vortex,

and there-

fore the induced drag on the rudder decreases.

The relative nosition of the rudder tin and the proneller

axis can change significantly the rudder drag.

of this geometrical relationship may be worth

The ontimization

some further in-

vestigation.

Another interesting result of the propeller-rudder

configu-

ration is that the steady forces on the rudder are comoletely indenendent of axial clearance downstream of the nroneller in the

range of locations tested 0.5D to 1.0D (D = proneller diameter).

In earlier work at MIT, Professor F.M. Lewis has shown that very

small changes in

axial clearance between the propeller and rudder

could result in a very large reduction in the blade frequency

vibration force on the rudder.

10%

flap rudder exhibits similar behaviour behind the pro-

peller (Table 6).

This rudder was tested at only one location

behind the propeller, namely at 0.75 of the propeller diamter,

since, as it was shown for the 20% flan rudder, the changes in

axial clearance

do not affect the rudder performance.

-2

0.-..

An effect

of one additional parameter was observed,

namely

of the flap deflection.

Increase of lift slooe of this rudder is 20% with undeflected flap and 17% with the 350 flap deflection angle.

Maximum lift is increased by 32% and 495% respectively, on

two tacks with undeflected flap and 38O on the ooerational tack

with flap deflected 350.

Stall occurs 50 later, and 110 later resnectively, with undeflected flap and 40 later on the operational tack with the

flap deflection.

Drag increase on the 10%

flan rudder is

also

significant, 300f and 4005 with undeflected flan on the two tacks

resoectively,

operational

and ?00" with flan deflection angle

of 350 on the

tack.

MaJor Conclusions

The following conclusions

anoly to the 7eynolds number of

the experiments which were about 0.96 * 10*

but there is

no evidence that they do not

(based on the MAC),

?poly to larger Rev-

nolds numbers.

1.

In

view of the above observations,

the 105 flap seems

to be less advantageous than the 20% flan rudder because of its

worse lifting characteristics.

2.

The 20%

flan rudder developed for the present tests is

better overall than the corresponding 20%

inal series (1).

flap rudder of the orig-

It has a higher lift, lower drag, similar mo-

ment and more uniform spanwise loading than the original rudder.

-39-

Since the 20% flan rudder in (1)

was selected as the best

rudder of the whole series described in

(1),

it

can be concluded

that the 20% flap rudder of the oresent project is

all

rudders considered in

both orojects and is

superior to

therefore recomm-

ended for nractical apolications.,

3.

Tt was observed, both in the nroject (1) and in the

current observations, that the ratio of flap deflection to rudder

deflection

angle to produce minimum drag increases with lift.

This indicates that in practical installations, it may be desirable to develor a linkage that incorporates

ween the flan angle and the rudder angle.

L.

a variable ratio bet(See Table 7).

Disadvantages of the all movable rudders with movable

flaps are their increased hinge moments, mechanical complexity

and nossible maintenance difficulties.

5.

Figures 9, 13 and 16 show a remarkable linearity of the

lift coefficient, completely unaffected by the flap action in

the nnstalled region.

*40

-

00

0 3s

z

-"

IL

a

00

-30_

ANL

Fig.9

20% Flap Rudder

-

-0

-to

FA

IL

ERE

in Uniform Flow

-o-03

0

0

0

0

1.2

L

LL

(U

ANGLE OF ATTACK -- DEGfEES

Fig.10

20% Flap Rudder in Uniform Flow

0

0

49

W

(A.

I I

I-

O.2

I

49% Cf MAC AFT CMAC LEADING EDGE

STOCK AXIS

-----

---

-

--

--

--

-

_

--

-

-

-

-

-

@0

a0

u

0

30

o.ao

I-'

as

--

- ------- - --Q2 - --

-30

-20

-- -- ----

-to

0

--

------

10

AIG E

Fig.11

20% Flap Rudder in Uniform Flow

-

--

--

-

W

W

T

.C|

-

z

--

.

0

--

---

-

-

0

30'

G

0 FLAP

C:

U

z

woso

a 10

.0!FLA

205

-30

-20

-0

0

ANGLE OF ATTACK

Fig.12

20%

Flap Rudder

10

DESREES

in Uniform Flow

20

30

0

A

'.5

-

owIle

F

1u

n

-0

-4

-

..-

-

....

-.

--

-

-

--

Z7*

U--

Fig.13

-loo0

ANa.A-

OFATIAK

D~4

10%Flap Rudder In.Uniform Stream and Behind a Propeller

S

VM

vatm11.

.04

.

1--

0123

gvce

FIg.14

10% Flap Rudder In Uniform Flow and Behind a Propeller

x

U

a

w-

.2 - - - - - -

-J--

-

-40

Ftg.15

~

-M

and Behind a. Propeller

10% Flap Rudder in Uniform Flow

9

0

V

PRO10

4x

I-o 5 ..

0.z

uIAp

-3I2

O203

x

-'

ANL O TAK

~ -DECE

..-..

10 ...

-30

- 0

-00103

ANGLE OF ATTACK

Fig.16

20% Flap Rudder Behind a Propeller

DLCM4LES

-

v

-

-

-

------

*X-0.75

aIX-I.

uK

4

-30

---

-

-zoOA

A

AN'.GLE OF ATTACK~

FIg.17 '20%

Flap Rudder Behind a Propeller

~

E

EEE

- - --

-

----

3

Q3

-I

STOCK AXIS

=

49% OF MAC AFT OF MAC LEADING EDGE

02

oL

*

-0.3-

-30

-20

-go

0

0

ANGLL OF AT lACK ~EGREES

Fig.18

20% Flap Rudder Behind a Propeller

20

30

7.

Comparison of Theoretical and Exnerimental

Table

Data

P shows some of the major hydrodynamic performance re-

sults of the 20% flap rudder obtained by the lifting

surface pro-

gram calculations and the exneriments described in the nrevious

chapters.

The center of pressure position is given as a percen-

tage of the MAC measured from the flap hinge line.

Moment co-

efficient curve slone is referenced also to the flan hinge and is

expressed per unit angle of attadcin radians.

Lift curve slopes are given per unit angle of attack in

radians too.

(Table

8)

The values in

the last

will be described later

in

row of the Table overleaf

this chanter.

The table shows that there is quite a strong discrepancv between the theoretical and experimental predictions.

The authors

of (2) believe that the theoretical results are correct to within 1% of the linear solutions and may, therefore, serve as a basis

for comparison with the experiment.

The values of the lift

curve slop

L

on the rudder with

no angle of attack were expected to differ significantly from the

theory, since all the lift was generated by the flap alone, operating in a fully separated, turbutent region, where the net velocity dueto the Von Karman effects

is

considerably smaller.

This

fact is not accounted for in the theory.

On the other hand, the experimental lift slone coefficient,

3CL/aa

,

which is 9% lower than the corresoondant theoretical

value, suggests that a strong side effect must have been taking

S

0

0

0

20% flap

3CL/ca

aCL/as

CL @

a=00

6 =ii

CL @

CD @

a=1008=10o a=10 6=

gCM/aa

XCP/MAC @

CD @

rudder

6=00

a=0 0

theory

3.134

1.771

0.547

0.856

0.0476

-1.893

-60.4 %

0.0085

2.86

1.17

0.48

0.73

0.049

-1.609

-61.6 %

0.0150

0.057

-1.725

-58.7

%

0.0152

experiment

6=00

6=00

6=00 a=j

experiment

iew plate

2.947

-

0.514

-

U,

Table 8:

Comparison between the Experimental and Theoretical results

place during the tests.

It was suspected that the boundary layer on the snlitter

plate (see Figure 8) might be the cause of this decrease in the

rudder load at the neighborhood of the root section.

later confirmed,

As it was

the unexpectedly large boundary layer was caused

by the splitter plate leading edge separation due to a too small

radius of curvature of the leading edge.

In

order to obtain a

auantitative information of how much this phenomena had been

changing the rudder characteristics,

the solitter plate shape

has been changed and one additional test of the 20% flan rudder

was performed.

The forward

3" of the solitter plate was curved unward to

provide a smooth, faired entry to the flow, and the.sunnort of

the splitter plate located between the plate and the unper tunnel

wall was extended aft, up to the solitter plate trailiner edge.

Since this new geometry of the test section forces more flow to

go under the plate, a new wake survey was required.

that the velocity increases now by 15.58

the previous splitter plate shape,

It

determined

more as compared with

or by 15.57% as compared with

the original tunnel test section.

New boundary layer thickness measurements

thickness decreased from 1.4" to 0.35".

showed that the

The latter value is in

a close agreement with the theoretical prediction, which for the

considered Feynolds number on the plate is

results of the test section of the 20

equal to O.34".The

flan rudder in

flow condition is oresented in the last row of

-53-

Tmable

this new

P.

The agreement between the theoretical and exDerimental results is now much better.

with

The lift curve slope on the rudder

undeflected flap differs by 6% from the theory,

according to (8)

which

is within the reasonable limits. It was expected

that the theoretical and new experimental values of the drag coefficient differ now more.

It can be explained by the fact,

that more of the rudder sur-

face is now exposed to the high velocity field, because the wall

boundary layer is thinner, thus causing more of the rudder area

to be subjected to the viscous stresses.

Also the induced drag,

which is proportional to the sauare of the lift coefficients, is

now larger, since the lift is larger.

Having a workable and well checked lifting surface Program,

it was considered worthwhile to confirm the above analysis theoretically,

in other words, to obtain theoretical results of the

rudder characteristics for the condition of non-uniform distribution of spanwise inflow velocity.

The original version of the lifting surface program has an

assumption built into it, that the incoming velocities at all

spanwise positions are the same, non-dimensionalized to unity.

In order to account for the non-uniformity, the velocities

from Tigure 8 were specified at the soanwise stations.

Also, to

increase the sensitivity of the solution to the flow field near

the root section, where the wall boundary layer was sunnosed to

affect the loading, a slightly different vortex and control point

grid was introduced in place of that given in Figure 3 of (2)

In particular,,four uper control noints stations were displaced toward the root section into the region of the boundary

layer.

This change required some changes in the vortex line

distribution in order to obtain a converging solution.

The result of this new lifting surface program calculation

confirmed fully the experimental result,

namely,

that the re-

duction in the boundary layer thickness from 1.4" to 0.35" for

the 7.875" rudder span resulted in 3% increase of the lift curve

slope.

(Figure 19).

Unfortunately, the formulation of the spanwise mode functions

in (2) is such, that all the modes produce a final value of the

circulation at the root section.

This was correct for a uniform

velocity field soecified at the control ooints on the wing.

In

order to obtain a solution for a non-uniform spanwise distribution of the velocity, which is the case if a tunnel wall boundary

layer is Present, another definition of the soanwise modes is

needed, namely, that the mode harmonics have a period twice that

of the existing modes over the same span and are symmetric with

respect to the root section.

Since this modification had not

been introduced to the program, the resultant lift slope coefficient curves in Figure19 do not go the zero at the root section,

where the actual velocity is zero due to the boundary layer, but

rather to the same finite value.

Nevertheless, the author believes that the above numerical

estimation of the overall lift slooe coefficient decrease

-55-

due to

00000000

0

0

0

0

U'

a'

S ,

0.1

root sect Ion

FI G.19

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

tip section

SPAIll SF Di STRIMITio0

OF LIFT SLOPE COEFFICIENT (THEORY)

0

9

the presence of the boundary layer on the tunnel wall is reasonable, since the same result (3%) was confirmed by the experiment.

Since the real rudders operate in the shin hull boundary

layer and wake,

in

the author believes that the results presented

Figures 9 to 18 do represent the realistic rudder performance

characteristics in spite of the fact, that the experiments were

performed on the rudders, which had been unintentionally subjected

to a large boundary layer on the splitter

plate.

It remains to be explained why there is still about a

difference between the theoretical and the new experimental value

of the lift curve slopes.

The lifting surface program (2),

is

based on the linear inviscid theory, which assumes, that for an

uncambered airfoil all the lift is generated by the angle of attack

alone, and that the thickness effects do not contribute to the

lift.

But it is known from a two-dimensional analysis that, in

fact, a viscous fluid does affect the lift by introducing some

secondary effects.

When the wing operates in a viscous fluid,

and is subjected to some angle of attack, the so-called displacement thickness of the boundary layer on the wing is affected by

the potential pressure field around the body, and the streamlines

a.re displaced into the outer regions.

As the displacement thick-

ness is bigger on the suction side, especially near the trailing

edge, due to a lower pressure on this side, an uncumbered wing

becomes effectively cumbered with a negative cumber.

generated by this negative cumber subtracts

The lift

from the lift genera-

ted by the angle of attack. Schlichting in (9) states, that this

phenomena may decrease the overall lift curve slope by large

amounts depending on the Reynolds number, aspect ratio and the

wing thickness.

Another factor contributing to the discrepancy between the

theory and experiment is the three-dimensional effect, namely,

behaviour of the flow near the tip section.

It was shown in (7) that a change of the tin cross-sectional

shape from a square tin to a rounded tip may change the lift by

as much as 3.5% and this effect is not accounted for in the lifting surface theory.

Tests of airfoil models in a closed test section of wind or

water tunnels, where the models are placed at the tunnel walls,

are inevitably encumbered with an error caused by the wall boundary layer effects.

It seems appropriate, therefore, to conclude

this discussion with a short review of some of the major works

done in this field.

In

1944, Preston (10) calculated analitically the loading

on a two-dimensional model spanning a closed wind tunnel.

He

assumed that the loading would be decreased at each end of the

model, in proportion to the square root of the local velocity

through the tunnel wall boundary layer.

in

that work was,

that this change in

Another assumption made

loading will produce

induced effects over the whole model.

From computations of the vortex strength in

terms of the

experimentally obtained tunnel wall boundary layer thickness,

-58-

an

estimate of the induced angle of attack loading over the wing

was made by a consideration of the tunnel width and model chord.

A typical result

of that theory was that for a two-dimensional

wing of the span chord ratio of 2 and the ratio of the boundary

layer thickness to the span equal to 0.05, the decrease in the

lift curve slope varied from 10% at the model ends to 2' at the

midspan.

The resulting decrease in

the overall lift

was

3.5%.

An experimental approach is presented in (11).

Two-dimensional loading tests

NACA

65-012 airfoil

in

were made of a two foot chord

the 2.5 by 6 foot test

section of the

wind tunnel.

This test indicated that only a very small loss (less than

1%)

in

the average

load may be expected.

It was also shown that large changes in the tunnel wall

boundary layer thickness produce small changes in the overall

load.

(10)

The author of (11) concluded that the theory of Reference

strongly over-estimates the effect of the tunnel wall boun-

dary layer.

The same remark, but without any explanation, apnears

in

(12),

Reference

page 383.

The third approach is presented by K'6rner (13).

It is a

lifting surface program for evaluation of an airplane wing performance in the presence of fuselage.

The theory takes into con-

sideration many effects of the fuselage-wing interactions, including the wing twist, relative position of the wing and the fuselage,

and some details of the wing fuselage

-59-

jointing.

It also presents an analysis of the fuselage boundary layer

thickness effect on wing loading.

That approach is essentially

identical with that shown earlier.in this chapter by the author

of the present work, namely, that the control points on the wing

sense the changes of the oncoming velocity field, and the solution for the circulation distribution is a function of the nonuniform velocity field.

The spanwise harmonics are defined in

such a way, that the lift goes to zero at the wing root section.

The author of the present work feels that the lifting surface

theory, when properly formulated, is the best tool in approaching

the analysis of effects on loading caused by non-uniform velocity

stream due to thick boundary layers.

If the boundary layer thick-

ness on the tunnel wall is smaller than 3 -

5% of the wing span,

its effects become negligible, according to (11) and (12),

and a

lifting surface program is not able to detect any difference in

the velocity distribution.

In this case, the nummerical result

obtained for a velocity field which is uniform at all the spanwise stations will have a very satisfactory accuracy.

In view of the discrepancy of opinions expressed by the

authors of (2),

(5),

(8),

(10) and (13),

concerning the quanti-

tative effects of the viscous flow around airfoils, it seems

that this field

is

far from being solved and still

significant amount of research.

-60-

requires a

Acknowledgement

The author participated in this project as a Research Assistant.

Other participents who contributed a significant amount

of effort and time to this project were ProfessorsJ.E. Kerwin

and P. Mandel, Research Engineer D.S Lewis and Technicians

W. Connoly and G. Graham.

In particular, Professor Kerwin is the author of the following parts of this work:

1.

Conceptual Formulation and Description of the Lifting Surface

Program (2).

2.

Data Reduction Program.

3.

Formulation

4

.

5.

of. Modification Method of the Rudder Sections.

Subroutine HSVEL in (2).

Data Concerning the Propeller used for the Tests.

Decision concerning the basic thickness form of the rudders

was conceived by Professors Kerwin and Mandel, based on the Performance

of the rudders described in

(1).

Professor Mandel prepared the first

draft of (3).

Mr.

Lewis

and Mr. Conolly orepared by hand the plots of rudder coefficients

curves and the Figures

testing of the rudders.

7 and

8 and performed some of the actual

Models of rudders were made with very

satisfactory precision by Mr. Kovar.

All other mechanical narts were made by Mr. Conolly, Mr.

Graham and the ME Machine Shop at MIT sunervised by Mr.

R.

Johnson.

I wish to express my gratitude to all these persons for their

-61-

friendly cooperation.

In particular, I would like to thank Professor Kerwin and

Mr. Lewis for their help, time and effort spent in a very friendly manner on many stimulating discussions.

The project was supported by ONR contract Number,

N00014-67-A-0204-0067.

9.

Nomenclature

A

=

total rudder area (flap plus skeg)

a

=

half width of tip chord @ 20% of tip chord forward

of trailing edge (see Figure 3, Sketch 1)

b

=

half width of root chord 9 same longitudinal position

c

=

length of mean aerodynamic chord

CD

=

drag coefficient = D/P/2 AU_2

=

lift

=

rudder moment coefficient = M/ 0 /2 AcU 2

=

flap moment coefficient = MF/0/2 AcU, 2

ct

=

tip chord

cr

=

root chord

D

=

propeller diameter

D

=

total drag of rudder

flap

=

movable after portion of rudder

CM

2

/3(ct

+cr- CTUR)

CT+CR

coefficient = L/P/2 AU_2

flap area =

rudder area between flap hinge location and trailing

edge of rudder

flap gap

=

distance between trailing edge of skeg and leading

edge of flap measured in the rudder plane of symmetry

with zero flap deflection

GHR

=

General Hydrodynamics Research (program)

L

=

total

M =

MAC

=

MF=

rudder

=

lift

of rudder

total moment acting on rudder about the shaft axis

shown in Figure 8

mean aerodynamic chord

moment acting on flap about flap hinge line

flap plus skeg

-63-

Nomenclature

(cont.)

of rudder

skeg

=

forward portion

taper ratio

=

ct/cr

U

=