A Comparison of Short-Circuited Streaming

Potentials in Westerly Granite From Changes in

the Rock's Volume, Shape, Saturation, and

Fracture Under Unconfined Uniaxial

Compression

by

Elizabeth Annah Jensen

Submitted to the Department of Earth, Atmosphere, and Planetary

Science

in partial fulfillment of the requirements for the degree of

MASSACHUSETTS INSTI U E

Master of Science in Geosy stems

at the

TECHNOLOG1999

MASSACHUSETTS INSTITUTE OF TECHNOLOG x

May 1999

LW49-w

@ Massachusetts Institute of Technology 1999. All rights reserved.

Author

a)

-

a

......

....

..

...............

.

.

....

...

.

.

..........

Department of Earth, Atmosphere, and Planetary Science

April 23, 1999

trtified by

I

Frank Dale Morgan

Professor

Thesis Supervisor

rtified by...................................................

Chris J. Marone

Professor

Thesis Supervisor

A ccepted by ......................................................

Ronald G. Prinn

Department Head

A Comparison of Short-Circuited Streaming Potentials in

Westerly Granite From Changes in the Rock's Volume,

Shape, Saturation, and Fracture Under Unconfined

Uniaxial Compression

by

Elizabeth Annah Jensen

Submitted to the Department of Earth, Atmosphere, and Planetary Science

on April 23, 1999, in partial fulfillment of the

requirements for the degree of

Master of Science in Geosystems

Abstract

An experiment was designed to gain some insight into the phenomena of electrical

charge in the uniaxially stressed environment of a sample of Westerly granite. Varying properties of size, shape, saturation, and stress rate of the Westerly granite, a

tentative set of physical relationships were measured. For instance, there is a strong

suggestion that the amount of acoustic energy released when the sample fractures is

proportionately related to the amount of charge that moves into or out of the sample,

the net charge, over the period of the experiment. Increasing the concentration of

the saturating solution increased the amount of charge that moved into or out of the

sample. With all the samples that were dry, more charge move in than out over the

period of the experiment. The few samples that were alike in every way before and

after they fractured had a difference in charge and acoustic energy by a magnitude

of their measured net charge and acoustic energy.

Thesis Supervisor: Frank Dale Morgan

Title: Professor

Thesis Supervisor: Chris J. Marone

Title: Professor

Acknowledgments

I would like to thank:

Deborah Jensen, Edward Jensen, and Patricia Chapela for their unparalleled emotional, financial, and editing support;

Zhenya Zhu for his careful and patient instruction in the experimental setup procedure;

Dale Morgan for strategic guidance and research support;

Chris Marone for allowing me to use (and occasionally break) all the equipment I

needed in his lab;

Steve Karner and Karen Mair for their assistance in helping me to avoid damage

to the biax and in processing load data;

Karyn Green, Toby Kessler, and Robert Fleming for technical support and tracking down obscure references;

Kate Lehetola and Mary Krasovec for helping me keep a sane mind in a sound

body;

Youshun Sun for all the support and guidance a former Geosystems student could

give;

Philip Reppert for filling in the gaps of my knowledge while I was writing my

thesis;

and most especially, Rebecca Saltzer, for giving me both good advice and information about where to find good advice on the Geosystems program elements.

Biographical Note

Education

Massachusetts Institute of Technology 1998-1999 SM Geosystems

Texas A&M University 1993-1998 BS Geophysics

Texas A&M University Honors

F. Vilas, E. A. Jensen, and L. A. McFadden. Extracting Spectral Information about

253 Mathilde Using the NEAR Photometry. Icarus, 129(2):440+, 1997.

F. Vilas, E. A. Jensen, D. L. Domingue, L. A. McFadden, and C. R. Coombs. An

Unusual Photometric Signature Detected on Lunar Complex Crater Rims at the South

Pole. In Lunar and PlanetaryScience XXIX, Lunar and Planetary Institute, Houston

(CD-ROM).

E. A. Jensen.

Satellite Observations of Oceanic Shelf-Slope Exchange.

Graduate Research Fellows Thesis, Texas A&M University, 1997.

University

Contents

1 Introduction

2

6

1.1

Background Description of Sample Material

1.2

Characteristics of Westerly Granite in Electrolytic Solutions ....

1.3

Compression of Core Samples ...................

. .............

6

.

...

Methods and Materials

8

10

17

2.1

Sample Selection and Preparation . ..............

2.2

Collection of Data ..............

.

. . . . .

.

........

..

17

20

3 Results

22

4

29

5

Discussion

4.1

Qualitative Differentiation ...................

4.2

Other Electrical Sources . ..................

4.3

The Piezoelectric Problem ...................

.....

......

.....

Conclusions

5.1

Future Investigations ...................

32

32

33

35

........

36

A Calculation of the Resistance of Saturated Westerly Granite

37

B Sample Preparation

39

C Streaming Potentials

41

D Experiment Data

43

Chapter 1

Introduction

Before the Ms (surface wave magnitude) 7.1 Loma Prieta, CA earthquake in 1989,

Fraser-Smith, Bernardi, McGill, Ladd, Helliwell, and Villard (1990) [6] recorded several anomalous magnetic (EM) signals. Peaks were detected on September 16-17,

followed by a rise in background noise on October 6 and an EM spike on October 17

approximately 3 hours before the quake. The regional stress prior to the earthquake

changed by less than 1 pbar[18].

Park, Johnston, Madden, Morgan, and Morri-

son (1993) review the history of looking for a possible link between generation of

anomalous EM signals and a subsequent earthquake. The study of how electricity

is generated and transfered in a rock is required. The objective of this research is

to study the generation of electrical charge in Westerly granite before and during

uniaxial fracture.

1.1

Background Description of Sample Material

Granite rocks are igneous in origin, comprising of interconnected crystals of quartz,

feldspar, mica and other minerals of various concentrations. Because granite is formed

in the crust, the uplifting and release of pressure compounded with exposure to the

atmosphere causes the rock to crack, with cracks even developing between the crystals

themselves (Figure 1-1). The core samples used in this study were Westerly granite,

which comes from Westerly, Rhode Island. It is composed of 27.5% quartz, 35.4%

Figure 1-1: Wong, Fredrich, and Gwanmesia (1989) show a view of what the crack

surface areas look like. This is also typical in that the cracks often occur on grain

boundaries.

microcline, 31.4% plagioclase (with 17% anorthite), and 4.9% biotite [1]. The distribution of minerals in Westerly granite is virtually homogenous, which makes it a

popular specimen for rock mechanics experiments.

There is also extensive information about the microstructure of Westerly granite.

The cracks between the grains occupy about 0.9% of the space. Labeled as a low

porosity rock, Westerly granite also does not have much connectivity between the

cracks, thus making it a low permeability rock as well [1].

Wong, Fredrich, and

Gwanmesia (1989) [21] found that Westerly granite has crack apertures that vary

from 0.7 to 0.002 micrometers in width. The crack surface area per volume (Sv)

was measured to be approximately 7.98 mm 2 /mm 3 . The distribution of cracks in

this range corresponded to a fractal dimension of 2.84 with the smallest apertures

occurring with the greatest frequency. The mean crack aperture is 0.015 micrometers.

1.2

Characteristics of Westerly Granite in Electrolytic Solutions

When Westerly granite is saturated, the connected pore space is filled with fluid.

When the fluid is an aqueous electrolytic solution, some of the ions adsorb to the

grain surfaces around the cracks and some of the ions on the surfaces of the cracks

dissolve into the solution. Because most of the molecules that make up granite consist

of SiO 2 1

Revil and Glover (1997) [19] argue that there are five chemical species that occur

on the surface of Si0 2 mineral lattices (where > refers to the mineral lattice): >SiOH,

> SiO-, > SiOH-, and >SiONa (in the presence of high pH values).

The adsorbtion of the ions make a net negative electrical charge on the grain

surfaces around the cracks. Different solutions react to the static electrical charge in

different ways.

Figure 1-2 of Morgan, Williams, and Madden (1989) [14] illustrates the adaptation

of the current view of how ionic charge distribution on the surface of the cracks with

respect to SiO2 surfaces depending on the nature of the aqueous soltion with respect

to the composition of the rock. The negative electrical charge on the surface of the

rock is neutralized by positive ions in the electrolytic saturating solution. Because

the ions have diameters, only a limited number can reach the charged surface. As

a result, it takes more than one layer in most cases for the negative potential to

be neutralized. The negative charge is at first linearly reduced by several layers of

positive ions, then it decays exponentially with distance from the Inner Helmholtz

1

It is observed that the solution used to saturate Westerly granite changes in composition after

saturation. The solution conductivity measurements were made before and after the Westerly was

saturated with tap water were different; the conductivity decreased from 200 pS to 8 pS. Other ions

are probably involved in the development of the double layer [15]:

1. quartz is essentially pure SiO2

2. microcline KA1Si 3 08

3. plagioclase (17% CaA12 Si 2 08, 83% is NaAISi 3 0s)

4. biotite K 2 (Mg,Fe)3 A1Si 3Olo(OH,O,F)2

$

S

7

O(STANCE

•

7<

Figure 1-2: "S" corresponds to the slipping plane. The fixed layer where the electrical

potential decreases linearly is inside the slipping plane. The diffuse layer where the

electrical potential decreases exponentially is outside the slipping plane. Morgan,

Williams, and Madden (1989).

Layer. The plane where this behavior changes corresponds to the Outer Helmholtz

Layer. Within a short distance outside of the Outer Helmholtz Layer, ions can move.

This is labeled the slipping plane. The region outside of the slipping plane where

potential electrical energy is still decaying is labeled the diffuse layer. The region

inside the slipping plane is labeled the fixed layer. The zeta potential is defined as

the electrical potential that exists at the slipping plane.

This situation becomes a little more complex as the smallest crack apertures of

.002 micrometers occur more frequently. The diffuse layer in some solutions is greater

than half this value. In this situation, the double layer will overlap in a manner

described by Hunter [8]. The repulsion between the double layers on either side of

the crack creates an osmotic pressure. In a confining pressure situation, this adds to

the pore pressure of the system.

Movement of ions outside of the slipping plane has been studied for several decades.

When a pressure is applied, a physical current displaces ions in the diffuse layer. This

is called a streaming or convective electrical current. The physical flow of ions which

had kept the surface charge neutral begins to concentrate in some areas and dilute in

others. This causes a current of ions, labeled the conduction current, to be induced

in the opposite direction.

When a steady state is achieved, ions physically flow

in both directions. An electrical potential field forms that is labeled the streaming

potential. This is quantitatively described by the Helmholtz-Shmoluchowski equation

(derivation from streaming current in a capillary shown in (Appendix D):

A(P)

A(V)

c

aov

P=physical pressure

V=voltage in the streaming potential

( =zeta potential

E =dielectic constant

a =conductivity of the electrolytic solution

v =viscosity of the liquid

1.3

Compression of Core Samples

As the rock sample is compressed uniaxially, those cracks that are easiest to close are

closed. As the compression continues to increase past 50% of the fracture strength

of the rock, new cracks open and old cracks dilate to wider apertures [1] (Figure

1-3). The dilating effect tends to follow a particular orientation that develops into

a fracture in the rock [12] (Figure 1-4). Scholz [20] (Figure 1-5) explained that the

fracture mode for unconfined samples is an elongated fracture in the direction of

compression extending through the sample. Jaegar [10] (Figure 1-6) showed that

the stronger platens above and below the sample affect how the uniaxial pressure is

distributed in the sample. This distribution tends to follow two cones with their bases

on the platens, and their tips touching in the middle of the sample. It is not surprising

that the acoustic activity in Lockner's samples was first localized in the middle of the

sample. Furthermore, the rupturing highlighted the side of the pressure cone as the

sample approached failure. This is probably due to the high pressure gradient on

the side of the cones in unconfined samples. The inside of the cone has the pressure

load, while the outside experiences only atmospheric pressure. The samples in this

r

i

II

Cracks in the sample

are closing

Axial

>

Cracks in

the sample

are dialating

Tra nsverse

'

1

i

,I

,

Percent of fracture

IXII^IIII

w

100O

50

stress

Figure 1-3: Brace and Orange (1968) measured the changes in resistivity of Westerly

granite under uniaxial compression. The results they found was an increase in resistivity followed by a decrease in resistivity. This was due to the closing and widening

of cracks in the process of stressing the rock.

experiment exhibited behavior that was either conical or a combination of conical and

elongated.

__:___ _;. ~Yi~i~_i

....................................................................

Perpendicular

to the plane

of fracture

.

\ ''" i

L

I

L

..........

""

24

~r

•

4

i

i

Looking at

plane of

fracture

face on

b

d

Figure 1-4: Lockner, Byerlee, Kuksenko, Ponomarev, and Sidorin (1991) measured

acoustic emissions from uniaxially compressed Westerly granite sequentially over time.

At first the acoustic waves are distributed through out the sample. Then they begin

to concentrate on the plane of the developing fracture.

12

il

Figure 1-5: Scholtz (1990) illustrates three modes of fracturing seen in rocks. Arrows

indicate the direction of stress. (a) tensile fracturing. (b) triaxial fracturing. (c)

uniaxial fracturing.

Figure 1-6: Jaegar and Cook (1969) illustrate how pressure is distributed in a rock

under uniaxial compression. A saddle point occurs in the middle where pressure

increases toward the platens and decreases on all other sides.

Chapter 2

Methods and Materials

2.1

Sample Selection and Preparation

All samples except one were cored from the same block of Westerly granite to ensure

uniformity of chemical makeup and crystal distribution in the samples. Core samples

were obtained from the Westerly granite by using a drill press, then slicing the column

to various lengths using saws. Then the core samples were polished on the ends with

a diamond drill while squeezing on the sides of the sample with a conical base to

ensure that the ends were also parallel. The samples varied in size and ranged from

1870 mm 3 to 37800 mm 3 .

The samples were subsequently wrapped with an insulated wire, size #18 19/30,

attached to the lengthwise surface of the core by conductive glue, DuPont conductor

composition 4929N, submitted to different atmospheric pressures and humidities, and

soaked in different solutions before being submitted to uniaxial stress. The acoustic

transducer marked the time range for recording the electrical signals produced during

fracture of the core samples.

Figure 2-1 shows how the wires were placed onto the samples using 2 different

methods. The experimental setup is drawn out in Figure 2-2 in terms of what the

electrical circuit of the experiment consists of.

Sample

2~

'p

Mlethod I

This was the first method used for

wrapping the wires around the

sample. Conductive glue was

brushed around the wires.

Wires

S00-

lmll

)

Method 2

This was the second method

that was used to wrap the wires

amund the sample. Conductive

glue was rubbed on to the

sample around the wires.

Wres

Figure 2-1: Methods used for wrapping wires around the samples

Current

to wund

Impedance>> 1 mega-ohm

Figure 2-2: Experimental setup using GageScope as an Ammeter

2.2

Collection of Data

The electrical signals resulting from fracture of the samples were recorded with a

GageScope, an IBM PC-software based oscilloscope. The current passed through the

wire wrapped around each sample with a 1 mega-ohm impedance, which has to be less

than the impedance of saturated Westerly granite (Appendix A) [2] for the Gagescope

to work as an ammeter. The signal was recorded in terms of volts with a sample rate

of 200 kilohertz. The system accepted an external trigger source from an acoustic

transducer which measures pressure waves in terms of electrical volts. 5 milliseconds of

time requires 30 kilobytes of memory. This sort of precision is necessary to get enough

points into the electrical waves produced by the sample at the amplitudes before and

after fracture. Maintaining this precision for the duration of the experiment would

require 24.3 megabytes of memeory for 8.5 minutes. At least 4 files were produced

for each run. The acoustic transducer signal was processed through an amplifier to

increase the voltage of the signal to positive or negative 5 volts. The voltage was

recorded with the oscilloscope both before and after the trigger signal of positive 5

volts, so 512 points were recorded for each sample both before and after the signal

making a total of 1024 points.

The core samples were fractured using a biaxial system produced by Downhold

Piston

Plastic Film

Top Probe

Middle Probe

Bottom Probe

...

.

Sample

..

.....................

Plastic Film

Acoustic Transducer

PlasticPlastic FilmFIm

Figure 2-3: This is the experimental setup used in fracturing the samples of Westerly

granite. The plastic film was used to isolate the sample from the ground. Each of

the probes have 1 MQ impedance.

Systems, Inc. following plans drawn up by E. Sholtz in 1993.

The loadcell and

LVDT recordings of displacement over time were recorded by Superscope II Macintosh

program with the sampling rate at 1 hertz. The samples were lined up with a manual

laser placed in the loadcell to ensure radial symmetry of the samples before they were

fractured . Plastic film was placed above steel blocks on the sample and below the

sample itself. The uniaxial system grounded the probes that connected the wires on

the sample to the computer. The acoustic transducer produced electrical disturbances

from pressure waves interacting with its bladder. The plastic film acted as an electrical

insultator for the sample by preventing the electrical energy from passing straight to

the ground rather than through the 1 mega-ohm probe (Figure 2-3).

Chapter 3

Results

An integration to calculate the number coulombs which had moved through the acoustic transducer and the probes in any particular direction was used 1. The' Acoustic

versus Net Charge (Figure 3-1) shows a rough increasing relationship between the

acoustic total charge in coulombs and the net charge of coulombs flowing through the

Westerly granite. This plot uses all the experimental data that has been collected by

Morgan and Zhu (1998) and Jensen (this report). The increasing relationship is also

in samples that had a net influx of positive electrical charge. An influx of positive

electrical charge is negative, and these samples were not plotted in Figure 3-1.

When plotting the Net Acoustic energy versus the Volume of all the different

samples (Figure 3-2). There are three ranges of acoustic energy that appear. The

topmost range, Region 1, exists above 8X10 -

1

Coulombs.

Region 2 ranges from

1The data collected from the probes and the acoustic energy were received in terms of volts. To

find the current at each point in time, the values were divided by the 1 mega-ohm resistance. For

some, a smoothing function was applied. This took the form of a running average of 10 points. For

these, the values were buffered on the ends by 10 points. In order to compare how much the values

changed in the integration to total up the the moving charge, an average was taken of the beginning

of each spectra. The average used the first 200 points for the Poland Spring data and the first 100

for the data collected by Morgan and Zhu (1998). This average was then used to set the zero level.

The caculation of how much charge had moved added the electrical current multiplied by the change

in time to the previous calculation of electrical current by change in time. Then the value from this

calculation for each probe were summed together. This was the net flow of charge in the sample.

If it was negative, in the case of all the dry samples, then this meant that more positive electrical

charge had flowed into the sample. If it was positive, more positive electrical charge had flowed out

of the sample. The value for the Relative Acoustic Energy was calculated as the root-mean-square

of the acoustic signal.

10-'

108

"

U

E

-"

oa 0 10'

1 0 -14

1 0 -' 3

0-

2

1 0-"

10- 0

Acoustic Relative Energy

Figure 3-1: Net charge shows an increase with respect to the acoustic relative energy

1.4E-10 -r

1.2E-10

IE-10

U

8E-11

6E-11

1A

4E-1 1

2E-11

I

2

0.OOE+00

2.00E+04

4.00E+04

6.00E+04

8.00E+04

1.00E+05

U

1.20E+05

1.40E+05

1.60E+05

Yolume (mm^3)

Figure 3-2: The acoustic relative energy is unrelated to volume. With respect to

Figure 3-1, the net charge is unrelated to volume.

5X10 - 12 and 2X10 - 11 Coulombs. Region 3 lies below. This strongly suggests that

there is no relationship between the volume of the sample and the relative acoustic

energy that the sample produces when it fractures. This in turn argues that there is

no relationship between volume and the net electrical charge flux.

In Region 1, there are only three points. Two are 25mm diameter by 50.8mm

length dry samples which were broken at a loading rate of 100 um/sec. The third is

a 25mm diameter by 50.8mm length sample that was saturated in 200 uS tap water

and broken at a loading rate of 100 um/sec. The most remarkable point to make

in Table 3.1 is that the saturated sample produced as much as a magnitude more

coulombs of net charge than the dry samples.

To get an idea as to how much variation there is in samples that are identical

experiments, three sets of data were compared. The samples used in the data set

include:

Table 3.1: The three highest acoustic

Acoustic Relative Energy Charge (coulombs)

1.28E-10

-2.05E-09

1.04E-10

-1.38E-09

1.04E-10

1.13E-08

relative energy samples

sample style

dry

dry

wet

1. The dry samples from Table 3.1

2. Two 25mm diameter by 50.8mm length Region 2 samples that were saturated

with 200pS tap water and broken at a 100 pm/sec loading rate

3. Two 25mm diameter by 76.2mm length Region 3 samples that were saturated

with 225pS Poland Springs water and broken at a 1 pm/sec loading rate

It is important to note that the experiment was identical for these samples except

in the way that they fractured. The Fracture Variation plot (Figure 3-3) demonstrates

that a relationship may exist between the Acoustic energy produced during rupture

and the fracture type. Six samples were compared. Four Poland Springs saturated

samples broken at 1 um/sec and two tap water samples broken at 100 um/sec were

plotted against each other depending on which fracture type they followed (Figure

3-4). There are two main fracture types with some variations. The first fracture type

is a fault extending from upper portion of one side of the sample to the lower portion

of the other side. The second fracture type is a combination of the first type but

with the development of a second fault on the other side that propagates through the

sample at least part way. An example of other fracture types is pictured as well, but

other fracture types did not occur in the samples used in the plot. For the samples

which were broken at the 1 pm/sec loading rate, a strong relationship is suggested

between the acoustic energy and the way the sample fracture. At the 100pm/sec

loading rate, this trend does not appear to be present.

In Region 2, there are two samples which are identical in every way except in the

conductivity of the solutions that they were saturated in. Shown in the Conductivity

versus Net Charge plot (figure 3-5), the 450 and 820 pS samples are 25mm diameter

by 50.8mm length, broken at the same 100 pm/sec loading rate, and produced similar

1

10

I

S100 um/sec

10-* [

*

fracture 1-1urn/sec

*

fracture 2-1um/sec

100 um/sec

U.

1o10

10-11

i

10

-

i

10-1

1 014

1

0-12

I

1 0-11

1 0-1

Acoustic Relative Energy

Figure 3-3: Fracture versus Stress Rate (Positive Charge)

Fracture Type 1

Fracture Type 2

Other types of

fractures

Figure 3-4: These are the most common ways that the Westerly granite samples

fractured.

2.00e-9

1.00e-9

2j -1.OOe-9

E

a-

SO.OOe+O

Wires Method 1

using electrodes

-1.0e-9

'

I 02

103

Solution Conductivity (uS)

Figure 3-5: Solution Conductivity versus Charge and Electrode Placement

amount of Net Charge. They indicate a general increasing trend in the Net Charge

produced and the conductivity of the saturating solution.

More variation may be in seen in how the electrical energy is drawn off of the

sample. The conductivity samples varied somewhat in this respect. The 450 and 820

pS saturated samples had electrodes placed as seen in Figure 3-6(a). The Conductivity versus Net Charge plot also shows the 590 AS saturated sample. The electrodes

on this sample were place with 1 vertical as used in the 450 and 820 AS saturated

samples and with 2 electrodes placed around the length of the sample which is somewhat similar to Method 1 (Figure 3-6b). Although the 590 /S saturated sample lines

up with the 450 and 820 AS saturated samples, it appears that the electrodes in this

formation did not collect as much electrical charge. The 570 S saturated sample had

electrodes placed on it almost identical to the wires in Method 1. The electrodes in

(b)

(a)

C

>E3

EI1

El

E(

/ El

Morgan and Zhu (1998) placed

electrodes on the Westerly

granite samples in this way

Morgan and Zhu (1998) placed

electrodes on the Westerly

granite sample in this way

for the sample saturated in the

590 microsiemens solution.

for the samples saturated in

450 and 820 microsiemens

solutions.

Figure 3-6: Variations in electrode placement

this formation detected even less charge (Figure 3-5). Method 2 for placing the wires

onto the samples was meant to take advantage of the geometry of having a conducting loop wrapping around the sample, as well as cover much more of the sample with

conducting wires to collect any local charges. The raw data plot from sample 101

(following the appendicies) shows that the current was moving in opposite directions

through wires that were next to each other on the sample.

Chapter 4

Discussion

The phenomenon of piezoelectricity in a quartz crystal is the release of electrical energy when the crystal is compressed. There is 25.7% quartz in a Westerly granite; this

is a source of some electricity. Quartz is a very hard mineral, 7 on the hardness scale.

For this reason, many cracks in the Westerly granite develop between the quartz

grains and the plagioclase grains and along the cleavage planes of the plagioclase. As

the granite is loaded, these cracks are among those closed. As the faulting begins, it

will tend to go around the quartz crystals; however, when a faulting plane propogates,

enough inertia is built up that it will pass through the crystals and break them. The

dangling bonds on the new cracks become a new electrical field for adsorbing ions.

Electricity that is produced by breaking quartz minerals or through piezoelectricity [16][17] has two ways of passing through the rock to the wires surrounding it:

through the grains themselves, and through any sort of fluid in the cracks. With

the impedance of dry Westerly being greater than 1 mega-ohm (Appendix A), the

preferred vector for the propogation of electrical energy is through any fluid in the

cracks. Since the percentage of quartz in Westerly granite is constant, a voltage increase in the maximum amplitude of the amperes may be initially detected between

a dry granite and a granite that is saturated with a conductive solution. However, as

the conductance of the solution increases, the finite energy source of the electricity

prevents it from contributing more than a constant value to the voltage readings.

Morgan and Zhu (1998) broke four samples that were 25mm diameter by 50.8mm

i/

I

Figure 4-1: Matijevic (1974) illustrates the effect of increasing the concentration of

the aqueous solution on the zeta potential. cl and c2 are solutions with increasing

molarities. x is the distance from the surface wall.

in length. Electrodes were glued onto the sample in the manner shown in Figure

3-6. When the results are plotted against the conductivity of the saturating solution,

there is an increasing trend that becomes visible (Figure 3-5).

One aspect of the behavior of the system described by the Helmholtz-Shmoluchowski

equation argues that the greater the molarity of a solution, the less the amperage of

the streaming current should be.

This is because the greater conductivity of the

solution decreases the amount of charge in the diffuse layer by concentrating it in

the fixed layer which decreases the zeta potential [8] (Figure 4-1). The streaming

current depends on the zeta potential through a logarithmic relationship. The other

variables which effect the streaming potential, geometry, conductivity of the solution,

and viscosity, are relatively constant in comparison to the zeta potential.

If the piezoelectric effect were at work, the electrical relationship should be a flat

line; if the streaming current effect were taking place, the line should be decreasing.

Because this is not the behavior observed in Figure 3-5, neither of these phenomena

are producing the increasing electricity with concentration.

4.1

Qualitative Differentiation

Three types of fractures were observed (Figure 3-4). The first type is a fracture

extending through the sample to the other side. The second type was characterized

by curved structures that did not always pass through the center of the sample. The

third type consisted of the loading surface of the sample breaking through as if two

type one fractures on either side met up at the top of the sample. There appears to

be different acoustic energy generated with the different fracture types (Figure 3-3).

4.2

Other Electrical Sources

Another electrical potential field exists at the contact points between the wires and

the metal in the conductive glue. This probably does produce some electricity. The

purpose of the glass experiment was to determine what the magnitude of this would

be. An amorphous glass sample cored from a block of Corning glass was broken

using the setup described for the Poland Springs saturated sample. The glass sample

of dimensions (19mm by 54mm) was loaded to a significantly higher pressure than

the sample of Westerly granite of the same dimensions was because it took twice as

long for the sample to rupture. When it broke, it produced a popping sound about

four times before shattering. Table 4.1 shows that some electrical energy was detected

after the sample ruptured. The postive results was surprising. Because of the positive

detection of electrical energy, samples of the same magnitude of electrical energy are

suspect.

Morgan and Zhu's (1998) data for the conductivity experiments confirms the concept that the measured electrical signal is not due to the wires alone because electrodes

were place on the sample instead of glued wires. The signal that he measured could

not have been produced by the electrical potential field between the glue and the

wires because neither were present.

Much of Morgan and Zhu's (1998) data which measured the effects of loading rates

and piezoelectric trends used wires rather than electrodes placed on the sample in the

manner shown in the description of sample zhu. In order to be able to use Morgan

and Zhu's (1998) data in this thesis for comparing amplitudes and frequencies, it was

necessary to use the same placement of wires on the sample. Some minor variations

were used as shown in Figure 2-1. The geometry is similar to zhu's, yet more surface

area of the sample is covered with glue and electrical wires. This was the best way

to measure how the electrical signal varied between volumes of the sample that were

wrapped by the wires. Rather than a wire measuring a circle in the volume, the

volume itself was measured.

4.3

The Piezoelectric Problem

Ogawa, Oike, and Miura (1985)[17] and Nitsan (1977)[16] similarly measured electricity produced from fracturing rocks. Although neither author discusses how their

experimental samples were prepared, they measure little to no electrical activity in

samples which lack piezoelectrical minerals. Enomoto and Hashimoto (1990) [5] used

samples of different minerals for their fracturing tests. The electrical signals that

Enomoto and Hashimoto measured depended on the moisture content of the rocks

they were fracturing. They detected electrical energy in fracturing saturated rocks

that lack piezoelectric minerals.

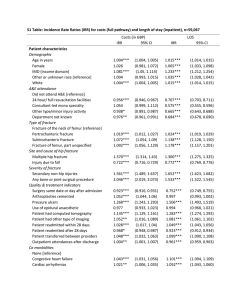

Table 4.1:

Experimental

Data

sample

volume mm 3

4.83E+04

91

6.12E+04

101

6.12E+04

102

1.50E+05

110

1.50E+05

120

6.12E+04

140

9.97E+04

450

9.97E+04

570

9.97E+04

590

9.97E+04

820

1.50E+05

zhu

splayed wires 1.50E+05

9.97E+04

RD

9.97E+04

RG

9.97E+04

RI

9.97E+04

RJ

9.97E+04

RK

9.97E+04

RL

9.97E+04

RM

Acoustic Energy

sum of abs

fracture

sample style

1.13017E-12

6.91819E-12

2.01123E-13

8.63303E-14

1.229E-12

1.78488E-13

7.26319E-12

8.51587E-12

5.44736E-12

6.2775E-12

1.7149E-12

6.02616E-12

1.27559E-10

1.03589E-10

8.96146E-11

1.03589E-10

6.05045E-13

6.02523E-13

6.50963E-12

2.8953E-11

2.0946E-09

3.4867E-11

1.4322E-11

1.6761E-10

2.1E-11

1.5311E-10

7.7034E-11

2.1256E-10

1.1445E-09

1.4451E-11

6.5764E-10

2.0495E-09

1.3841E-09

9.3363E-09

1.1272E-08

2.8541E-09

2.9075E-09

2.3481E-09

1

2

1

1

2x

Poland

Poland

Poland

Poland

Poland

glass

450 uS

570 uS

590 uS

820 uS

dry

1

1

1 or 2

1

2

1

dry

dry

200

200

200

200

200

uS

uS

uS

uS

uS

Spring

Spring

Spring

Spring

Spring

load rate (pm/sec)

1

1

1

1

1

1

100

100

100

100

100

1

100

100

100

100

1

100

100

Chapter 5

Conclusions

Both the piezoelectric effect and the streaming potential effects for the production of

the energy fail to explain why the energy increases with molarity of the saturating

solution in Morgan and Zhu's (1998) conductivity experiment. This leaves taking a

closer look at the whole system and what assumptions have been made. The most

significant assumption is that the layer inside the slipping plane is fixed. This is true

in a steady state, but in the system of a rock under stress, this possibly fails. As

cracks get smaller the repulsion between double layers increases. A lot of charge is

accumulated in a small area. When the crack closes, much of this charge is pushed

out into the adjoining cracks, and the charges unbalance the charge distribution in

the adjoining decreasing crack widths. The movement of this energy is closer to the

charge stored in the surface potential on the grain surfaces.

The acoustic energy is proportional to how much charge moves through the rock

in any particular direction for the duration of the measurement.

In general, the

more acoustic energy the sample breaks with, the greater the amount of net charge

has passeed through. This includes such effects as piezoelectricity. There is some

deviation, however.

The samples that were broken at a 100pm/sec loading rate

were far more dependent on this relationship than samples that were broken at a 1

pm/sec loading rate. For the 1 pm/sec loading rate samples, there was a significant

variation in the way that the samples fractured whenever they were being loaded.

The fracture variation contributed to the increasing net charge with acoustic energy

relationship. Whenever this was taken into account, the samples depended much less

on the acoustic energy in the amount of net charge moving through them.

The movement of electrical energy through the rock appears to be a localized effect

but with a net magnitude and direction for the whole of the sample. The raw data

from sample 101 shows this. Even though the middle and bottom probes literally had

wires right next to each other on the sample, they each had current passing in opposite

directions through the wire. Although it may only be coincidental, it is interesting

to note that all of the dry samples produced negative net electrical charges.

5.1

Future Investigations

Placing multiple small electrodes around the sample in a similar run could provide a

resolved view of just how localized the direction of charge movement is in the sample.

There is even the possibility that observations may be made of how the charge is

flowing with respect to how the rock is fracturing in this type of experiment. However,

the method of data collection would need to be altered.

Continuously taking data through the 1 mega-ohm probes may provide some interesting data on how the system of the saturated sample behaves in a temporal way.

Maintaining this precision for the duration of the experiment would take up 24.3

megabytes for 8.5 minutes. At least 4 files are produced for each run. There is no

reason to assume that there are no significant electrical signals being produced with

longer wavelengths.

Experiments with increasing the conductivity of the saturating solution should

be performed. At greater magnitudes of conductivity, a problem may arise with the

resistance of the rock decreasing into the the range of one mega-ohm. If this is the

case, a new experimental setup would need to be considered.

The behavior of saturated rocks that lack piezoelectric minerals should be explored. The experiments performed by Ogawa, et al(1985)[17], Nitsan (1977)[16],

and Enomoto and Hashimoto (1990) [5] argue that this is an important direction for

more research.

Appendix A

Calculation of the Resistance of

Saturated Westerly Granite

The porosity of Westerly granite is approximately 0.009.

The conductivity of the Poland Springs water was measured to be 225 pS. Morgan

and Zhu's greatest solution conductivity was 820 pS. Using Archie's Law, the resistance of the rock before the experiment was a magnitude greater than the impedance

on the probe. It is improtant to note that the porosity and the level of saturation are

altered at the time of fracture when measurements are made [1].

I

V

where

I = Amperes

V = volts

The resistance of the soltion is

Rsolution =

where

R= Q

If the solution had a shape, a similar volume's resistance could be measured as

R=p

1

A

where

p = Qmeters

1 = meters

A = meters 2

According to Archie's Law

Prock = Psolution

- 2

where

0 = porosity

So the resistance of the rock is calculated as

A

Rrock = Rsolution A-2

1

so

Rrock =

0.009-2

The resistance of a rock saturated in 820pS NaC1, Rrock = 1.2X107

magnitude greater than the impedance of the Gagescope probes.

, is about a

Appendix B

Sample Preparation

The insulated wire wrap size #18 19/30 contains 19 fine wires that were split roughly

in half and wrapped around sample zhu and glued with the conductive glue. The

sample was baked in a vacuum for 30 minutes. One hour later in 22% humidity and

23.5 degrees Celsius, it was loaded and broken in the lab at a piston displacement

rate of 100 microns/sec.

The splayed wire sample had 16 wires around the top, 18 around the middle, and

12 around the bottom. With generous amounts of glue, this sample sat in room

humidity (greater than 22%) for several weeks before being broken in the lab at a

rate of 1 micron/sec.

Samples 91, 101, 102, 110, and 120 were placed in a vacuum for two days. After

this period of time, the samples were placed in 204 microsiemens solution of Poland

Springs water for two days to saturate and moved to the lab while immersed in the

solution. The wires for the samples were placed while still immersed in the solution.

As the stress was being applied to the sample, the conductive glue was being applied to

the wires as well. Compression of all samples was applied at the rate of 1 micron/sec.

Each sample was removed from solution only when the time came for stress to be

applied.

Sample 140 consisted of cored glass from a block of Corning amorphous glass. The

sample had always been in 22% humidity. Wires were placed on the sample, and the

sample was placed under stress as the glue was being applied.

Table B.1: Experimental methods used for preparing samples

Wire Method Prep Procedure

sample

3

2

91

3

2

101

3

2

102

3

2

110

3

2

120

3

2

140

Electrodes 1 1

450

1

Electrodes 4

570

1

Electrodes 2

590

1

1

Electrodes

820

1

1

zhu

2

splayed wires 2

1

1

RD

1

1

RG

1

1

RI

1

1

RJ

1

1

RK

1

1

RL

1

1

RM

Appendix C

Streaming Potentials

I,

=

---

7rr2 p

The pressure p that causes movement of ions on the slipping plane causes an

electrical or streaming current I,. I, then induces a conductive current Ic in the

opposite direction.

Figure C-1 illustrates the geometry of a capillary with radius, r, and length, 1.

Fluid, of viscosity v, in the capillary moves under an induced pressure, p. Adsorbtion

of ions on the surface of the capillary produces a double layer with a slipping plane

conductivity of ao and a zeta potential C. The conductivity with respect to the

distance r towards the slipping plane is described by a,.

7r r2 Vuo

le =

1

The balance of electrical charge between the currents causes the streaming potential V.

I, + Ic = 0

V

_

pHunter [8].

See Hunter [8].

r

T

I

Capillary Surface

Figure C-1: Diagram of capillary geometry with P as the direction of a pressure

gradient

Appendix D

Experiment Data

Integration Sample RM

Fracture 1

r

le-9

D/L=25/50.8 mm

Top Probe

Oe+O

Middle Probe

-e

-le-9

Bottom Probe

III

-0.1

-2e-9 '

-U. 2

0.1

0.0

0.2

Time (sec)

Integration

Sample "zhu"

Fracture 1

D/L=25/76.2 mm

2e-12 I

Top Probe

Oe+O

-2e-12

Middle Probe

-4e-12

-6e-12

Bottom Probe

-8e-12 '

-u.003

I

I

I

I

-0.002 -0.001 -0.000 0.001

Time (sec)

I

0.002

0.003

Integration Sample 101

Fracture 2

D/L =19/57 mm

le-9

-

Top Probe

0

1e-9

E

o le-9

0

8e-10 0

6e-10

Middle Probe

4e-10

0 2e-10

Oe+O

S-2e-10

'

'

'

'

Bottom Probe

'

-u.003-0.002-0.001-0.000 0.001 0.002 0.003

Time (sec)

Integration

-

E

Sample 102

Fracture 1

D/L=19/57 mm

2e-11

Top Probe

0

o le-ll

0

& Oe+

Probe

-Middle

c

0 -le-ll

-2e-1 1

-u.003-0.002-0.001-0.000 0.001 0.002 0.003

S)

Bottom Probe

Time (sec)

Integraition

Sample 110

Fracture 1

D/L=25/76.2 mm

- le-ll

E

Top Probe

0

0

0

Oe+O

Middle Probe

c-

Bottom Probe

1

11

-u.003-0.002-0.001-0.000 0.001 0.002 0.003

Time (sec)

Integratiion

Sample 120

Fracture 21(

D/L=25i/76.2 mm

a 8e-11

E

Top Probe

0

S 6e-11

0

0

4e-11

I

Middle Probe

I

a 2e-11

Oe+O

Bottom Probe

-2e-11

-U.

003-0.002-0.001-0.000 0.001 0.002 0.0 03

Time (sec)

Integr ation

.

E

0

-s

0

a

Sample 140

Fracture ?

D/L=19/54 mm

le-ll

Top Probe

Oe+O

0

Middle Probe

."-1e-11

Bottom Probe

z

-u.003- 0.002-0.001-0.000 0.001 0.002 0.003

Time (sec)

Integration

-

E

Sample 450

Fracture ?

D/L=251/50.8 mm

2e-11

O0e+O

Electrode 1

0

0 -2e-11

&-4e-1 1

Electrode 2

. -6e-11

Electrode 3

S-8e-11

z

-le-10

-u.I 002

-0.001

-0.000

0.001

Time (sec)

0.0 02

Integration

Sample 570

Fracture ?

D/L=25/50.8 mm

-0 le-ll

E

. Oe+O

Electrode 1

o

o -le-11

-2e-1 1

cc-3e-1 1

Electrode 2

S-4e-11

" -5e-11

-6e-11

-u.002

-

-0.001

-0.000

0.001

Electrode 3

0.002

Time (sec)

Integration

Sample 590

Fracture ?

D/L=25/50.8 mm

-0 2e-10

E

0

Electrode 1

o

o

a le-10

Electrode 2

Oe+O

Electrode 3

-le-10

-u.002

Integration

.

E

-0.001

-0.000

0.001

Time (sec)

Sample 820

Fracture ?

0.002

DIL=25/50.8 mm

5e-10

0

- 4e-10

0

Electrode 1

o 3e-10

o 2e-10

I

Electrode 2

I

I-

.c

le-10

m Oe+O

4~

Electrode 3

4I~

-u.002

-0.001

-0.000

Time (sec)

0.001

0.0 02

Integra tion

Sample RD

Fracture ?

D/L=25/ 50.8 mm

Sle-9

E

Top Probe

0

o Oe+O

Middle Probe

-le-9

-2e-9

0

Bottom Probe

Z

-U.2

-u.2

Integration

-0.1

0.0

Time (sec)

Sample RG

0.1

Fracture ?

0. 2

D/L=25/50.8 mm

"5e-10

E

Top Probe

0

0

2o Oe+O

a)

Middle Probe

-5e-10

.

Bottom Probe

z

-le-9

-u.2

Integr ation

0

E

-0.1

0.0

Time (sec)

Sample RI

0.1

0.2

D/L=25/50.8 mm

Fracture ?

6e-9

Top Probe

5e-9

0 4e-9

3e-9

Middle Probe

2e-9

le-9

W

Bottom Probe

Oe+0O

_'

9_

-U .2

I

-0.1

I

0.0

Time (sec)

I

0.1

0.2

Integr ation

6e-9

.

E

. 5e-9

Sample RJ

I

D/L=25/50.8 mm

Fracture ?

I

I

Top Probe

o 4e-9

0 3e-9

0

&- 2e-9

(

Middle Probe

le-9

j Oe+O

z l~ 9

-u2

Bottom Probe

I

I

-0.1

I

0.0

0.1

0.2

Time (sec)

Integration

Sle-9

E

Sample RK

I

Fracture 1

D/L=25150.8 mm

I

0

Top Probe

o

2 Oe+O

Middle Probe

0)

-le-9

.~

Bottom Probe

z

I

-U.2

I

0.0

-0.1

0.1

0. .2

Time (sec)

Integr -ation Sample RL

.0

Fracture 2

D/L=25/50.8 mm

4e-9

E

0

S 3e-9

Top Probe

0

0

2e-9

I

Middle Probe

I

Oe+O

z

Bottom Probe

_tI,-

-U.2

-0.1

0.0

Time (sec)

0.1

0.2

Sample 101

Fracture 2

D/L=19/57 mm

0

0

O

I0

0

-9

-u.003 -0.002 -0.001 -0.000 0.001

0.002

0.003

-u.003 -0.002 -0.001 -0.000

0.001

0.002

0.()03

-u.003 -0.002 -0.001 -0.000 0.001

0.002

0.0 03

0.002

0.0 03

o

O

00

0

o.

.l

b

-f

-u.003 -0.002 -0.00 L-0.0 00 0001

ime (sec

Sample 102

Fracture 1

D/L=19/54 mm

- 0.07

0

> 0.06

.0 0.05

0

CL 0.04

o 0.03

0.02

-u.003 -0.002 -0.001 -0.000 0.001

0.002

0.003

0.002

0.003

S0.02

S0.01

0

& 0.00

.-0.01

2 -0.02

-u.003 -0.002 -0.001 -0.000 0.001

(A

m 0.00

I

I

0

0

Q-0.01

E

o

0

M .0.02

---

-u.003 -0.002 -0.001 -0.000

0.3

0.2

0.1

0.0

-0.1

-0.2

-0.3

0.001

00

-. 02-00

-U. 003 -0.002 -0.00

L-r0.00 c.0

Time(sec)

01

0.002

0.0 03

0.02

000

0.002

0.003

Sample 110

Fracture 1

D/L=25/76.2mm

0.04

.0

0 0.03

0.02

I0.01

-u.003 -0.002 -0.001 -0.000 0.001

0.002

0.003

0.002

0.003

0.002

0.003

0.002

0.003

0.03

0.02

S-0.01

0.00

'a-.01

2 -0.02

-u.003 -0.002 -0.001 -0.000 0.001

0.01

S0.0

0

, -0.01

-u.003 -0.002 -0.001 -0.000 0.001

o

0.2

S0.1

Fn 0.0 -

n -0.1

0

S-0.2

-u.003 -0.002 -0.00L-n ngn

I me (secT

001

Sample 120

-0.14

o 0.12

0.10

.0 0.08

0

0.06

I

Fracture 2X

I

D/L=25/76.2 mm

I

I

I

0.001

0.002

0.003

-u.003 -0.002 -0.001 -0.000 0.001

0.002

0.003

0.002

0.003

C.0.04

o 0.02

0.00

-U.

0

.0

0

mm0

L

003 -0.002 -0.001 -0.000

0.3

0.2 I

0.1

0.0

0

e0

0.4

0.3

N

0.2

0.1

0o

0

0.0

-u.003 -0.002 -0.001 -0.000 0.001

11

e

0 -

0

-2'

I

I

I

-u.003 -0.002 -0.00Ln

cn

Iime (secl

I

0.002

0.001

0.003

Fracture ?

Sample 140

D/L=19/54 mm

0.022

0.021

0.020

0.019

0.018

0.017

0.016

1

0.015

-u.003 -0.002 -0.001 -0.000

0.001

0.002

0.003

0.001

0.002

0.003

0.001

0.002

0.003

0.03

Q)

O

0

F

n ni I

-U.0 03 -0.002 -0.001 -0.000

I

I

-1I

S0.02

S0.01

.

0

-

0.00

I -0.01

E -0.02

0

w-0.03

0

S-0.0404

-u.003 -0.002 -0.001 -0.000

o

I

0.4

_

S0.2

u) 0.0

0 -0.2

o

o -0.4

-u.003 -0.002 -0.00 rr

m

n

N

N

on

Tme (secT

l

0.002

0.003

0.001

Sample 450

Fracture ?

D/L=25/50.8 mm

0.1

0

I

II

I

I

O

0>

a)

0.0

O

LU

-0.1

-U. 002

0

-0.001

-0.000

0.001

0.002

-0.001

-0.000

0.001

0.0 02

0.2

0.1

0

C)

O

0.0

-U. 002

0.1

0.0

a)

--

iMY

-U. 002

-0.001

-0.1

-0.2

6

4

\r

-0.000

0.001

0.0 02

.0

.0

I

I

2

0

-2

00

001

-.

0

-4

-6

U.' 002

-0.001

-0.000

Time (sec)

0.001

0.002

Sample 570

Fracture ?

0.1

D/L=25/50.8 mm

O

0.0 F

0

0

-0.1

-0.2

I0

Ll

0

'

-u.002

0.0

-0.001

-0.000

0.001

0.002

-0.001

-0.000

0.001

0.0 02

-0.001

-0.000

0.001

0.0 02

0.001

0.002

L

-0.1 F

0

0

0)

-0.2 I

-N L

-u.002

III

0.2

0

0

0.1

L

n

-u.002

6

4

o)

2

0

0

-2

0

-4 L

-6

-u.002

-0.001

T-0.000

Time (sec)

Sample 590

Fracture ?

D/L=25/50.8 mm

0.6

0

a

0

0.4

0.2

0.0

Li -0.2

-0.4

002

-0.001

-0.000

0.001

0.002

-u.4

-u.002

-0.001

-0.000

0.001

0.002

-0.001

-0.000

0.001

0.002

0.001

0.002

-U.

0.6

0

0.4

0.2

w

.10

c11

0.0

-0.2

fk A

0

I--

0

0.6

U

0

0.4

0.2

0

0.0

!--

o

0

-0.2

- -

-0.4

-0.002

cl

LLI

6

4

2

o

-2

-4

-6

-u.002

-0.001

Ti-0.0oe

Time (sec)

Sample 820

Fracture ?

D/L=25/50.8 mm

I

I

I

I

I

I

-u.002

-0.001

-0.000

0.001

-1

-u.002

-0.001

-0.000

0.001

0.002

-u.002

-0.001

-0.000

0.001

0.002

6

4

2

0

-2

-4

-6

-U.

002

0.002

|

I

I

I

I

I

I

-0.001

T-0.000

Time (sec)

0.001

0.002

Sample RD

Fracture ?

D/L=25/50.8 mm

0.4

0

0.2

0.0

0

.

-0.2

0

-0.4

0

-0.6

I-

-0.8 .2

.

-U

l

0

._

-0.1

0.1

0.2

0.0

0.1

0.2

0.0 I0.1

0.1

0.

0.0

0.1

0. 2

.

.

0.1

0.2

0.0

0.2

I

0.0

I-

-0.2

a

0

-0.4

"0

-0.6

.mr

-0.8

-U .2

-0.1

0

o0

.o

0

1.

0

0

I

-0.1

.2

0

0

6

4

2

II

-I

0

-2

.i

u

-4 p.

-6

-u .2

010.

-0.1

0.0

Time (sec)

Sample RG

Fracture ?

D/L=25/50.8 mm

1

-1

0

-1

I

-2

-U.2

-0.1

0.0

0.1

0.2

-0.1

0.0

0.1

0.2

0.3

0.2

0.1

0.0

-0.1

-0.2

-0.3

-U.2

I

.2

-0.1

I

_4

-.

.

0.0

I

0.1

0. 2

I

2

-u.2

-0.1

0.0

Time (sec)

0.1

0.2

Sample RI

Fracture ?

D/L=25/50.8 mm

2

0

1

()

O

0

o

0

-1

-2

-u.2

-0.1

0.0

0.1

0.2

-2 '

-u.2

-0.1

0.0

0.1

0.2

-2

-0.2

-0.1

0.0

0.1

0.2

.

0

L,

-o

."I

O

oa

E

E

0

6

4

l

2

0

-2

C.

-4

-6

-u.2

-0.1

0.0

Time (sec)

0.1

0.2

Sample RJ

Fracture ?

D/L=25/50.8 mm

I

I

I

-0.1

0.0

0.1

0.2

-u.2

-0.1

0.0

0.1

0.2

-2 -u.2

-0.1

0.0

0.1

0.2

23

-u.2

2

1

0-1

-

2

1

0

-1

-2

-3

-4 2

-U .2

-0

I

-0.1

I

0.0

Time (sec)

I

0.1

0.2

Sample RK

Fracture 1

D/L=25/50.8 mm

S0.01

0

o 0.00

a.

0

I-0.01

-u .2

-0.1

0.0

0.1

0.2

-0.1

0.0

0.1

0. 2

0.0

0.1

0. 2

- 0.02

.0 0.01

0

L.

Ia 0.00

S-0.01

-u .2

7 0.04

> 0.03

e 0.02

2 0.01

I

0.00

-0.01

-0.02

m -0.03

-U

.2

-0.1

o 0.0

-.

-

....- n --

C -0.1

-0.2

0

o -0.3

-t

j.2

-0.1

0.0

Time (sec)

0.1

0.2

Sample RL

-u.23

-u.2

_1 __I

-u.

-u .2

Fracture 2

D/L=25/50.8 mm

-0.1

0.0

0.1

0.0

0.1

0.2

0.0

0.1

0.2

0.1

0.2

1

-1 _'rl

-u.2

-0.1

6

4

2

0

-2

-4

-6

-U .2

1

-0.1

I

Ti 0.0

Time (sec)

0

0.1

0.2

Fracture 1

Sample RM

D/L=25/50.8 mm

S0.00

S-0.01

0

-0.02 II-0

-0.03

'

-u.2

-0.1

0.0

0.1

0.2

-0.1

0.0

0.1

0.2

-0.1

0.0

0.1

0.2

.

.I

.

0.1

0.2

0.01

o

.0 0.00

0

I-

aS-0.01

m

S-0.02-u.2

o

0.01

.0

0

. 0.00

E

0o

m -0.01

-U .2

0

0.8

•I

_ 0.6

S0.4

Cl

0.2

-

0.0

= -0.2

0

.2-.

-0.4

-0 .2

SII

-0.1

0.0

Time (sec)

Sample "zhu"

Fracture 1

D/L=25/76.2 mm

- 0.03

> 0.02

e 0.01

0 0.00

"-0.01

o -0.02

-0.03

-u.0 03 -0.002 -0.001 -0.000 0.001

0.002

0.003

o 0.04

0.02

•

-

-

:

1'* --: ' -- -- =

=" ' "--

':

:---

:

----

-

' -

- = '

'

=

L

-

o 0.00

-0.02

S-0.04

I

2 -0.06

-u. 003 -0.002 -0.001 -0.000

0.001

0.002

0.003

-u.003 -0.002 -0.001 -0.000 0.001

0.002

0.003

0.002

0.003

o 0.00

a -0 . 0 1

0

L

-0.02

E

o -0.03

0

M -0.04

o

2

-

I

I

I

I

I

1

r

.-

M

0

o

00

0

-2

-3

I

-4

-u.003 -0.002 -0.001 -0.000

0.001

Time (sec)

Bibliography

[1] W. F. Brace and A. S. Orange.

Electrical resistivity changes in saturated

rocks during fracture and frictional sliding. Journal of Geophysical Research,

73(4):1433-1445, 1968.

[2] W. F. Brace, J. B. Walsh, and W. T. Frangos. Permeability of granite under

high pressure. Journal of Geophysical Research, 73(6):2225-2236, March 1968.

[3] G. O. Cress, B. T. Brady, and G. A. Rowell. Sources of electromagnetic radiation

from fracture of rock samples in the laboratory. Geophysics Research Letters,

14:331, 1987.

[4] J. T. Dickinson, M. K. Park, E. E. Donaldson, and L. C. Jensen. Fracto-emission

accompanying adhesive failure.

Journal of Vacuume Sciece and Technology,

20(3):436-439, 1982.

[5] Y. Enomoto and H. Hashimoto. Emission of charged particles from indentation

fracture of rocks. Nature, 346:641-643, August 1990.

[6] A. C. Fraser-Smith, A. Bernardi, P. R. McGill, M. E. Ladd, R. A. Helliwell,

and Jr. O. G. Villard. Low-frequency magnetic field measurements near the

epicenter of the ms 7.1 loma prieta earthquake. Geophysical Research Letters,

17(9):1465-1468, August 1990.

[7] Gage Applied Sciences Inc., Montreal, Quebec, Canada. Gagescope Technical

Reference and User's Guide, seventh edition, 1996.

[8] Robert J. Hunter. Zeta Potentialin Colloid Science. Academic Press, San Diego,

California, 1981c1988.

[9] T. Ishido and H. Mizutani. Relationship between fracture strength of rocks and

zeta-potential. Techtonophysics, 67:13-23, 1990.

[10] J. C. Jaegar and N. G. W. Cook. Fundamentals of Rock Mechanics. Chapman

and Hall, New York, New York, third edition, 1969c1979.

[11] Ayao Kitahara and Akira Watanabe. Electrical Phenomena at Interfaces, volume 15 of Surfactant Science Series. Marcel Dekker, Inc., New York, New York,

1984c.

[12] D. A. Lockner, J. D. Byerlee, V. Kuksenko, A. Ponomarev, and A[] Sidorin.

Quasi-static fault growth and shear fracture energy in granite. Nature, 350:3942, March 1991.

[13] Egon Matijevic. Surface and Colloid Science, volume 7 of Electrokinetic Phenomena. John Wiley & Sons, New York, New York, 1974c.

[14] F. D. Morgan, E. R. Williams, and T. R. Madden. Streaming potential properties of westerly granite with applications.

Journal of Geophysical Research,

94:12449-12461, September 1988.

[15] William D. Nesse. Introduction to Optical Mineralogy. Oxford University Press,

New York, New York, second edition, 1986c1991.

[16] U. Nitsan. Electromagnetic emission accompanying fracture of quartz-bearing

rocks. Geophysical Research Letters, 4(8):333-336, August 1977.

[17] T. Ogawa, K. Oike, and T. Miura.

Electromagnetic radiations from rocks.

Journal of Geophysical Research, 90:6245-6249, June 1985.

[18] S. K. Park, M. J. S. Johnston, T. R. Madden, F. D. Morgan, and H. F. Morrison. Electromagnetic precursors to earthquakes in the ulf band; a review of

observations and mechanisms. Reviews of Geophysics, 31(2):117-132, 1993.

[19] A. Revil and P. W. J. Glover. Theory of ionic-surface electrical conduction in

porous media. Geophysical Review B Journal,55(3):1757-1773, January 1997.

[20] Christopher H. Scholz. The Mechanics of Earthquakes and Faulting. Cambridge

University Press, Cambridge, Massachusetts, 1990c.

[21] T. Wong, J. T. Fredrich, and G. D. Gwanmesia.

tics and

Crack aperture statis-

pore space fractal geometry of westerly granite and rutland

quartzite: Implications for an elastic contact model of rock compressibility.

Journal of Geophysical Research, 94:10267-10278, August 1989.