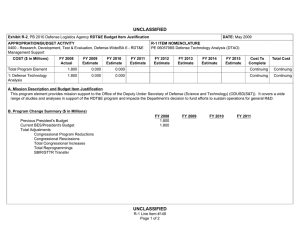

UNCLASSIFIED

advertisement