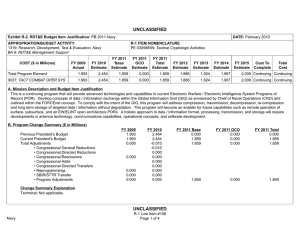

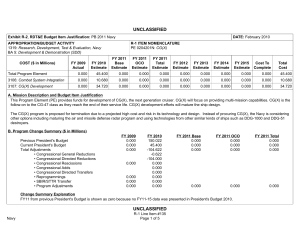

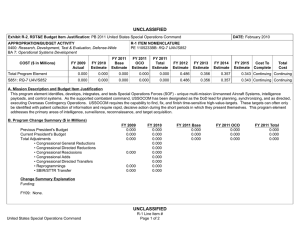

UNCLASSIFIED

advertisement