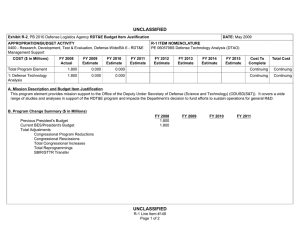

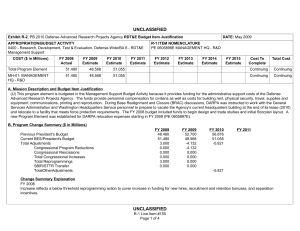

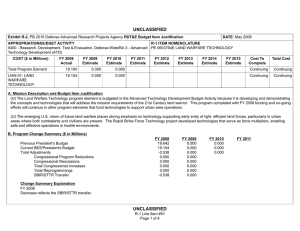

Defense Logistics Agency May 2009 Fiscal Year (FY) 2010 Budget Estimates

advertisement