Document 10869625

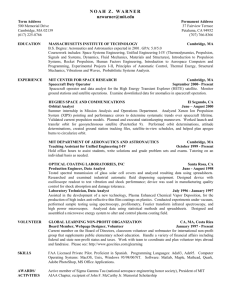

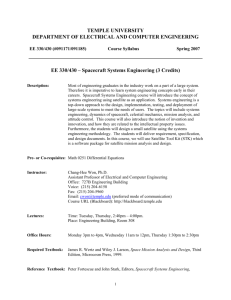

advertisement