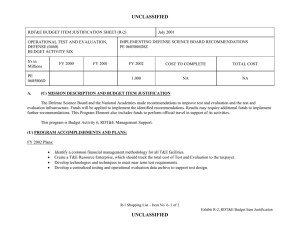

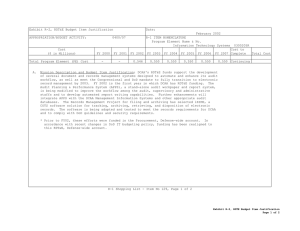

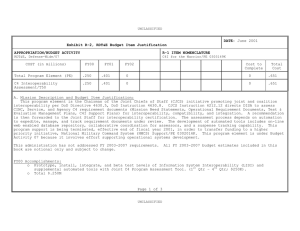

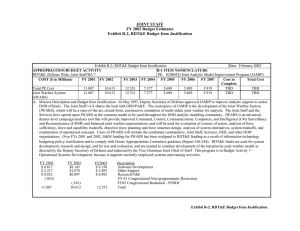

DEFENSE LOGISTICS AGENCY RESEARCH, DEVELOPMENT, TEST AND EVALUATION FEBRUARY 2003

advertisement