IMPROVING THE MANAGEMENT OF SYSTEM DEVELOPMENT SYSTEMS

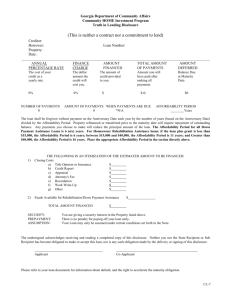

advertisement