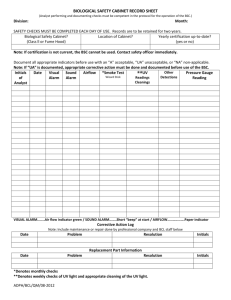

Safety Precautions SmartCabinet™ User Manual

advertisement