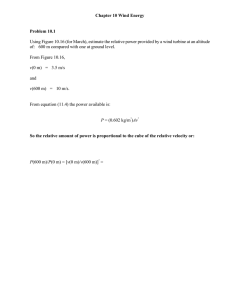

LEo

advertisement