Document 10834735

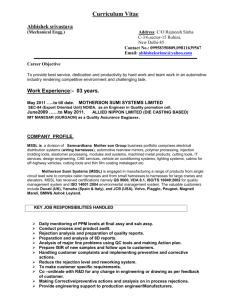

advertisement