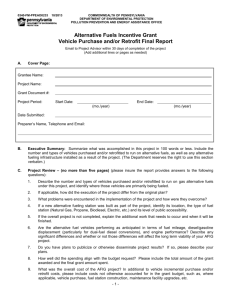

Future Light-Duty Vehicles:

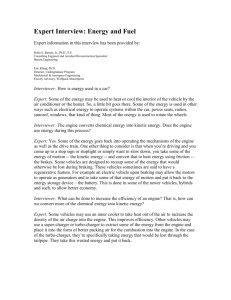

advertisement