Hot -Wire Sensing of Micro-Jet Flow

By

Yanxia Sun

B.S., Precision Instruments and Mechnology

Tsinghua University, China, 1999

Submitted to the Department of Mechanical Engineering

in Partial Fulfillment of the Requirement for the Degree of

Master of Science

at the

Massachusetts Institute of Technology

February 2002

©Massachusetts Institute of Technology 2001. All rights reserved.

Signature of A uthor....................................................................................

Department of Mechanical Engineering

June 12,2001

Certified by...............................................

..... ......

Taiqing Qiu

Associate I

essor of Mechanical Engineering

Thesis Supervisor

A ccepted by....................................................A

Ain A. Sonin

Professor of Mechanical Engineering

Chairman, Department Committee on Graduate Students

MASSACHUSETTS INTITUTE

OF TECHNOLOGY

MAR 2 5 2002

LIBRARIES

BARKER

1

Hot -Wire Sensing of Micro-Jet Flow

By

Yanxia Sun

Submitted to the Department of Mechanical Engineering

On January 16, 2001, in partial fulfillment of the

requirements for the Degree of

Master of Science

ABSTRACT

Uniformity of chemical vapor deposition (CVD) depends greatly on gas delivery systems.

A typical CVD machine uses metering tubes with a linear array of micro-orifices to

deliver gas-phase reactants. This work developed a measurement technique to

characterize sub-millimeter scale jet flow produced by a metering tube. It utilizes a hotwire probe as the sensing element, and the probe is scanned across a flow field narrower

than the probe width.

A general heat transfer model was established to describe the probe response to a highly

non-uniform jet flow. Both hot-film and hot-wire probes were tested for jet sensing

experimentally. Hot-film sensors were found to be more robust and easier to handle. The

effect of different sensor operation modes was studied experimentally. Results show that

a probe operated under constant current provides a higher sensitivity of detecting small

variation of jet velocity than that under constant temperature mode. On the other hand,

2

constant-temperature probes are more suitable for detecting flow directions. Scanning

profiles of micro-jet reveal non-uniform flow distribution along a typical metering tube.

Optical imaging of the tube shows that manufacturing defects of the orifices contribute

significantly to the non-uniformity of jet flow. This work lays a solid foundation for

building flow-testing systems in the semiconductor industry.

Thesis supervisor: Taiqing Qiu

Title: Associate Professor of Mechanical Engineering

3

TABLE OF CONTENTS

ABSTRACT ........................................................................................................................

2

TABLE OF CONTENTS .................................................................................................

4

LIST OF FIGURES.......................................................................................................

6

LIST OF TABLES ............................................................................................................

10

CHAPTER 1 INTROD UCTIO N ......................................................................................

11

CHAPTER 2 NUMERICAL SIMULATION OF JET FLOW ......................................

14

2.1 Exit jet velocity ...................................................................................................

15

2.2 Lam inar jet flow ...................................................................................................

2.3 Incom pressible turbulent jet flow ........................................................................

17

21

CHAPTER 3 HOT-WIRE SENSING OF MICOR-JET ...............................................

25

3.1 Introduction .............................................................................................................

3.2 Structure of hot-wire probes...............................................................................

3.3 Heat transfer model............................................................................................

3.4 Results and discussion........................................................................................

3.4.1 Hot-wire sensing in still air ..........................................................................

3.4.2 Hot-wire sensing in uniform flow ....................................................................

3.4.3 Hot-wire sensing profiles for micro-jet flow ...............................................

25

26

28

34

34

37

40

Chapter 4 EXPERIM ETNAL SETUP ..........................................................................

46

4.1 Air supply ................................................................................................................

46

4-2 Hot-wire probes and signal conditioning .............................................................

4.3 Probe scanning system ........................................................................................

47

50

Chapter 5 HOT-WIRE SCANNING OF MICRO-JETS ..............................................

5.1

5.2

5.3

5.4

Effect of sensor types sensing results.................................................................

Sensitivity to axial position.................................................................................

Sensitivity to backpressure.................................................................................

Reliability of hot-wire sensing for m icro-jet flow ..............................................

5.5 Jet direction .............................................................................................................

53

53

55

57

59

61

4

5.6 Sensing profiles at different backpressures........................................................

5.7 Uniformity of micro-jets .....................................................................................

64

70

Chapter 6 CONCLUSION AND FURTHER WORK .................................................

85

RE FE CE N C E S ..................................................................................................................

87

5

LIST OF FIGURES

Figure 1-1. Schematic diagram of CVD deposition......................................................

12

Figure 1-2. Schematic diagram of flow metering tube...............................................

12

Figure 2-1. Schematic diagram of gas flow in a metering tube ..................

14

Figure 2-2. Enlarged view of flow near an orifice ........................................................

15

Figure 2-3. Exit jet velocity........................................................................................

17

Figure 2-4. Jet flow from an orifice ..............................................................................

18

Figure 2-5. Axial velocity profile for laminar flow (z=3mm) .....................................

20

Figure 2-6. Radial velocity profile for laminar flow (z=3mm).....................................

20

Figure 2-7. Axial velocity profile for turbulent flow (z=1.0mm) .................................

23

Figure 2-8. Radial velocity profile for turbulent flow (z=1.0mm)...............................

23

Figure 2-9. Axial velocity profile for turbulent flow (z=2.5mm) .................................

24

Figure 2-10. Radial velocity profile for turbulent flow (z=2.5mm)...............................

24

Figure 3-1. H ot-w ire operation......................................................................................

25

Figure 3-2. Optical images of hot-wire and hot-film probes....................

26

Figure 3-3. Structure of hot-wire and hot-film probes .................................................

27

Figure 3-4. Schematic model of hot-wire and hot-film probes ......................................

29

Figure 3-5. The heat transfer model for wire support ...................................................

32

Figure 3-6. The temperature distribution along the wire (TSI1210-60, CC, 1=100 mA) .35

Figure 3-7. Electrical resistance of hot-film probe in still air ........................................

36

Figure 3-8. Average wire temperature in still air..........................................................

37

Figure 3-9. Effect of convection on wire temperature (I=100mA)...............................

39

6

Figure 3-10. Correlation of probe resistance (I=lOOmA) ............................................

40

Figure 3-11. Horizontal wire in mixed convection and conduction...............................

41

Figure 3-12. Temperature distribution along the wire when HFA sits at the jet's center. 42

Figure 3-13. Probe temperature during scanning (I=lOOmA)......................................

43

Figure 3-14. Effect of jet velocity on scanning profiles...............................................

44

Figure 3-15. Effect of axial position on scanning profiles.............................................

45

Figure 4-1. Schematic diagram of air supply system...................................................

46

Figure 4-2. Calibration of pressure transducer...............................................................

47

Figure 4-3. Schematic diagram of TSI1210 general purpose probe (-T1.5, -20, -60) ...... 48

Figure 4-4. Constant-current circuit ...............................................................................

49

Figure 4-5. Constant-temperature circuit .....................................................................

50

Figure 4-6. Experim ental setup ...................................................................................

51

Figure 5-1. Hot-wire probe sensing of micro-jet flow .................................................

54

Figure 5-2. Hot-film probe sensing of micro-jet flow.......................................................

55

Figure 5-3. Scanning along jet centerline......................................................................

56

Figure 5-4. Hot-film sensing of micro-jet flow near orifice ....................

57

Figure 5-5. Hot-film scanning of orifice #23 ....................................................................

58

Figure 5-6. Hot-film scanning of orifice #24 ....................................................................

59

Figure 5-7. Optical im age of orifice #35........................................................................

60

Figure 5-8. Repeatability of hot-wire scanning.............................................................60

Figure 5-9. Hot-film profiling of jet at relatively low velocity ..................

62

Figure 5-10. Hot-film profiling of jet at relatively high velocity.................63

Figure 5-11. Hot-film profiling of jet at relatively high velocity (CC mode).........64

7

Figure 5-12 . Three working backpressures when four orifices open............................65

Figure 5-13 . Scanning profiles of jet #22 (CC mode).................................................

66

Figure 5-14 Scanning profiles of jet #23 (CC mode)....................................................

66

Figure 5-15 Scanning profiles of jet #24 (CC mode)....................................................

67

Figure 5-16 Scanning profiles of jet #25 (CC mode)....................................................

67

Figure 5-17. Scanning profiles of jet #22 (CT mode)...................................................68

Figure 5-18. Scanning profiles of jet #23 (CT mode)...................................................69

Figure 5-19. Scanning profiles of jet #24 (CT mode)...................................................

69

Figure 5-20. Scanning profiles of jet #25 (CT mode)...................................................70

Figure 5-21. Scanning profiles of four orifices ............................................................

71

Figure 5-22. Optical images for four neighboring orifices ..........................................

72

Figure 5-23. Scanning profiles at low backpressure (CC mode) ...................................

73

Figure 5-24. Scanning profiles at medium backpressure (CC mode) ............................

73

Figure 5-25. Scanning profiles at high backpressure (CC mode).................................74

Figure 5-26. Scanning profiles at low backpressure (CT mode)...................................74

Figure 5-27. Scanning profiles at medium backpressure (CT mode) ............................

75

Figure 5-28. Scanning profiles at high backpressure (CT mode) .................................

75

Figure 5-29. Scanning profiles of jet #22......................................................................

76

Figure 5-30. Scanning profiles of jet #23......................................................................

77

Figure 5-31. Scanning profiles of jet #24......................................................................

78

Figure 5-32. Scanning profiles of jet #25......................................................................

79

Figure5-33. Scanning profiles along the metering tube .................................................

81

Figure5-34. Scanning profiles of jets near metering tube inlet ......................................

82

8

Figure5-35. Scanning profiles of jets near the dead end of metering tube....................83

Figure5-36. Optical images of orifice #3 and #35 .......................................................

84

9

LIST OF TABLES

Table 3-1. Dimensions of hot-wire probes...................................................................

28

Table 3-2. Physical properties used in simulations .......................................................

33

Table 4-1. Characteristics of TSI hot-wire probes .......................................................

48

10

CHAPTER 1 INTRODUCTION

Chemical vapor deposition (CVD) of thin films is widely used in the semiconductor

industry to produce integrated circuits, liquid-crystal displayers and solar cells. Figure 11 shows a schematic diagram of a typical CVD deposition process (Dobkin et al., 1995).

Gas-phase reactants are first introduced into an injector head through separate metering

tubes and then directed into a straight channel. As the reactants leave the channel, they

form a sheet of one-dimensional jet, impinging on a heated silicon wafer. As the

chemicals approach the wafer, the gas temperature increases, initiating chemical reactions

and thin-film deposition. The depleted reactants are pumped away from the wafer

through the exhaust channels of the injector.

The uniformity of CVD deposited films depends greatly on the uniformity of flow along

the long and narrow sheet of jet exiting the injector head. As the wafer diameter increases

from 200mm to 300 mm, the requirement for flow uniformity is significantly increased.

Metering tubes play an important role in controlling flow uniformity. A typical metering

tube consists of a lineal array of 30 to 50 sub-millimeter orifices. Figure 1-2 is a

schematic diagram of a metering tube. There exit two fundamental factors affecting flow

uniformity: manufacturing defects and fluid mechanics. The fine orifices on a metering

tube are typically produced through electrical-discharge machining (EDM). During EDM

the fine discharge wire wears and deforms, resulting in variations in orifice diameters and

11

pointing directions. Furthermore, the molten metal may not be removed completely

during EDM, forming solid debris around the orifices.

Injector head

Exhausj

Metering Tubes

sass

I

Gasga

N2

A-

J1L~

11-

"

wafer

Heated Hloor

Figure 1-1. Schematic diagram of CVD deposition

Metering Tube

Inlet

On*fices

Figure 1-2. Schematic diagram of flow metering tube

12

The second factor causing flow non-uniformity is due to two competing physical

processes. As chemicals flow within a metering tube, friction at the wall results in a

gradual decrease of the gas pressure. On the other hand, as the gases exit the tube through

the orifices, the mean velocity of the gases drops along the tube, which in turn leads to an

increase of gas pressure. Numerical simulations show that these two competing processes

produce a non-uniform pressure distribution and thus a non-uniform jet velocity

distribution along the tube (Mokhtari et al., 1997). They found that this intrinsic flow

distribution depends significantly on the orifice diameter and total inflow rate.

The objective of this work is to develop a sensing technique capable of measuring both

the magnitude and direction of sub-millimeter jet flows. It will provide a better

understanding of jet flows from a linear metering tube. It will also be used in the

semiconductor industry for quantitative evaluation of metering tubes.

A hot-wire probe is used in this work as the sensing element. Chapter 2 simulates

velocity distributions of ideal laminar and turbulent jets. Since the characteristic jet width

is much smaller than the sensing length of a typical hot-wire probe, chapter 3 develops a

heat transfer model to describe responses of hot-wire probes in a highly non-uniform jet

flow. It establishes the physical foundation for this unique hot-wire sensing technique.

Chapter 4 describes details of the experimental system, and chapter 5 presents the

experimental data and discusses the results. This work is summarized in chapter 6.

13

CHAPTER 2 NUMERICAL SIMULATION OF JET

FLOW

Figure 2-1 shows a schematic diagram of gas flow in a metering tube. For typical CVD

applications, the flow is laminar, single-phase and non-reacting within the tube. The tube

temperature is about 20 0 C higher than the inlet gas temperature, which is around 22 0C.

The inlet gauge pressure, P, controls the total flow rate through the tube. The objective of

this chapter is to estimate the exit jet velocity and velocity distribution of the jets. The

numerical simulations are conducted under the following assumptions.

1. Both the pressure variation and slight heating along the metering tube are

neglected.

2. The orifice diameter is 0.2 mm, and the orifices are circular and smooth. The

inside diameter of the tube is 5.10 mm and the wall thickness is 0.28 mm.

V1

P1

V2

P2

Vj

Pj

Figure 2-1. Schematic diagram of gas flow in a metering tube

14

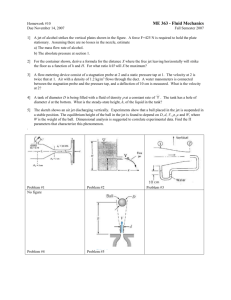

2.1 Exit jet velocity

This section estimates the exit velocity of jets. Applying the Bernolli's equation along a

streamline (figure 2-2), the exit jet velocity, Ve, is related to the inlet gas pressure, P, as

P + IpV

2

12

2

pVe2 + APO + AP + AP2+

(2.1)

A,

(2)

d

L

P,V 1

(1)

Figure 2-2. Enlarged view of flow near an orifice

where V1 is the inlet gas velocity. The pressure change along the tube, AP, is

APO = I pKOVe 2

2

(2.2)

where the pressure coefficient, Ko can be positive or negative (Mokhtari, et al., 19997).

The pressure loss near the orifice entrance, AP, is

AP = I pKIVe 2(2.3)

2

15

where the loss coefficient due to sudden contraction is K1=0.42 (White, 1994). Since the

wall thickness of the metering tube, L, is larger than the orifice diameter, d, pressure loss

due to friction at the orifice wall, AP 2 , is

AP

I

2

L

2

d

1

(2.4)

2

2

At a typical Reynolds number of Re=1000, the friction coefficient, f, is 0.064. The

pressure loss at the orifice exit, AP3, is

AP = 1PK

2

3

(2.5)

V,2

The value of K3 =1 for sudden expansion is used here. Since the exit jet velocity, Ve, is

much larger than the inlet gas velocity VI, jet velocity can be found from equation 2.1 as

V

Ve

--

I

2

p(1+ K + K +K+K

(2.6)

pK

Figure 2-3 presents jet velocity as a function of the inlet pressure at different value of

total pressure loss coefficient, K.

16

I

10C

I

I

I

I

I

I

I

I

I

I

90

K=3

8C

K=4

-'O

70

I

I

)

60

0

50

7a)

40

x

uJ 30

20

10

I I I I I I I I I I I I I I

C

1

2

3

4

5

6 7 8 9 10 11 12 13

Inlet pressure, P (kPa)

14 15

Figure 2-3. Exit jet velocity

2.2 Laminar jet flow

Figure 2-4 illustrates the essential features of a jet issued from an orifice into still air. The

velocity profile is assumed to be uniform at the orifice exit here. There exists a region

called the potential core of the jet (0 : z < Z, ). Within the potential core, the jet velocity

is not affected. Outside this region, significant fluid mixing exists, resulting a monotonic

decrease of the jet velocity.

17

The potential region is generally within 5-7 orifice diameters. Beyond the potential core

(Z>Zc), the effects of viscous shear are active across the whole width of the jet, and the

jet flow becomes self-similar.

A

Jet Edge

Z=Z2

Z=Zc

-

-.

-

-=-

-

-

-

-

I-

-

-

Potential core

.

r

Z=L

Figure 2-4. Jet flow from an orifice

Jet flow can be characterized by the Reynolds number based on the exit velocity, Ve,

and the orifice diameter, d,

Re =

dV

e

V)

(2.7)

At a small Reynolds number, e.g., Re<30, the jet flow is laminar. Far away from the

orifice, the axial velocity, Vz and radial velocity Vr, have been reported in the

literature (Schlichting, 1979; Turns, 2000),

18

V

(2.8)

[1+9 ]2

8Vc q (1-_72)

(2.9)

Re (1+)r2)2

where Vc is the axial velocity at the jet center,

3

d

Re-Ve

32

z

Vc =

the similarity parameter,

(2.10)

ij,

is

- 6 Re 16

z

(2.11)

and z and r are the axial and radial positions measured from the orifice, respectively.

The radial position at which the axial velocity is half of the center velocity is

ro. =-

1.49

xz

Re

(2.12)

the jet width at half center velocity is

dO.5=

2.98

--- X z

Re

(2.13)

It increases with the axial position and decreases with the increase of the Reynolds

number.

Figures 2-5 and 2-6 present simulated velocity profiles at z=3mm at different exit jet

velocities. The results show that the radial jet velocity is significantly smaller than the

axial velocity.

19

5

4 .5

Ve=5m/s

4

E 3 .5

3

2

0

75

2

76

Ve=3m/s

1 .5

0 .5

-.

A

-500 -400 -300

100 200

0

-200 -100

Radial position, r (um)

300

400

500

Figure 2-5. Axial velocity profile for laminar flow (z=3mm)

0.04

Ve=5m/s

0.035

CD

E

0.03

0.025

Ve=3m/s

-.

0

-

0.02

4'

~

%

%

I

4'

j

I

I

I

/

I

II

,~

/

1

0.01

I

I

j

j

'

1

I

0.005

II

I

I

I

II

I~

~I

0

-4 00

I

-300

-200

/

-100

0

100

200

Radial position, r (um)

I

300

I

400

Figure 2-6. Radial velocity profile for laminar flow (z=3mm)

20

2.3 Incompressible turbulentjet flow

At relatively high Reynolds number, jet becomes turbulent. Turbulence greatly enhances

fluid mixing, which in turn increases internal friction of fluid. This effect can be modeled

by replacing the kinetics viscosity v in laminar flow case by eddy viscosity

C

(Schlichting, 1979),

e=0.0143Re v

(2.14)

Far away from the orifice and assuming that the jet momentum is conserved, the

similarity solution of jet velocity are given by Schlichting (1979),

V"

-

=

8Vc 17(l1-17 2

[3 Re (1+172)2

V= 6.6dVe

z

(2.15)

(2.16)

(2.17)

where the similarity parameter, 11, is

7/ = 7.59 r(2.18)

z

Figures 2-7 to 2-10 present velocity profiles at locations z=lmm and z=2.5mm. The

radial velocity is found to be less than 2% of the axial velocity.

The location at which the axial velocity is half of the center velocity is

21

70 .5 =0.64

or

ro

= 0.08 4 z.

(2.19)

The full width of the jet at half center velocity is

dO5 = 0.17z

(2.20)

The jet width is independent of the Reynolds number. The center jet velocity decreases

with z. It drops to half of the exit jet velocity at location zO,

z05 =13.2d

(2.21)

For the orifice used in this work, d=0.2mm, z0 sis 2.6mm. The width of the jet at this

location is about 0.5mm. The results suggest that sensing of the jet flow should be

conducted within a few millimeters of the orifice, and the jet velocity is highly nonuniform within a radial range of 0.5mm.

22

90

-

80

--- Vexit=40m/s

Vexit=60m/s

-

-

_

Vexit=80m/s

--

70

E

N

-

-

60

50

0

40

I /

I

-

-

30

20

' '

'

'

1

U

-400

-300

-200

0

-100

100

200

Radial position, r (lam)

300

400

Figure 2-7. Axial velocity profile for turbulent flow (z=1.Omm)

I2

-. Vexit=40m/s

Vexit=60m/s

-- Vexit=80m/s

1.8CO)

E

-

1.6

1.4

0

0i

1

II

/

Xi 0.8-

I

/

/Ii

,

I

\

-\

0.4

0.

I. 'I

-200

-150

-100

-50

0

50

100

Radial position, r (gm)

150

200

Figure 2-8. Radial velocity profile for turbulent flow (z=1.Omm)

23

4-

Vexit=40m/s

Vexit=60m/s

Vexit=80m/s

-

-

40

- -

-35

E

-

-

N 30

I It

.25

0

0

/

0 20

\

I%

~15

-

-.-

10

5

200 400

- 000 -800 -600 -400 -200 0

Radial position, r (Gm)

600

800 1000

Figure 2-9. Axial velocity profile for turbulent flow (z=2.5mm)

0.9

- Vexit=40m/s

- - - Vexit=60m/s

Vexit=80m/s

0.8

_

E 0.1

-

44

C.)

0

(D

0.4

40

Pe

0.

Cz

-

Im

44/

/

0.2

''

0.1

U'

-200

-150

-100

-50

50

0

Radial position, r (um)

100

150

200

Figure 2-10. Radial velocity profile for turbulent flow (z=2.5mm)

24

CHAPTER 3 HOT-WIRE SENSING OF MICOR-JET

3.1 Introduction

A hot-wire probe is a thermal transducer based on the convective heat transfer from a

heated wire to fluid flow. Consequently any change in the flow, which affects heat

transfer from the heated element, can be detected with hot-wire probe system.

Figure3-1 shows a schematic diagram of hot-wire operation. An electric current is passed

through a fine wire, heating the wire to about 2000 C. As the flow velocity varies, heat

transfer from the wire varies. This in turn causes a variation in the heat balance of the

wire and wire temperature. The wire is made from a material possessing a relative large

temperature coefficient of resistance, e.g., tungsten and platinum. The wire temperature is

monitored by measuring the wire resistance. A hot-wire probe can be operated either at

constant temperature or constant current mode.

Flow velocity U, Temperature Tf

Hot Wire/Film Sensor

Average probe

resistance, R

Average

temperature, T

Current: Im

Voltage: Vw

Figure 3-1. Hot-wire operation

25

Conventional applications of hot-wire anemometry require that the flow velocity along

the wire is uniform. In this work the jet flow is confined in a sub-millimeter width.

Existing models for hot-wire operation are not valid. The objective of this chapter is to

develop a general heat transfer model to describe hot-wire responses to highly nonuniform flow.

3.2 Structure of hot-wire probes

Two types of probes are used in this work. Figure 3-2 shows the optical images of the

hot-wire probe and hot-film probe. The hot-wire probe uses a fine tungsten wire as the

sensing element. The sensing element for the hot-film probe is a quartz rod coated with a

thin layer of platinum. The ends of the rod are coated with gold and welded to the

supporting structure. The hot-film probe has a much thicker sensing element than the hotwire probe.

Figure 3-2. Optical images of hot-wire and hot-film probes

26

Figure 3-3 presents dimensional parameters used in this work to characterize hot-wire

and hot-film probes. Table 3-1 lists dimensions of the probes used in this work.

L

ds

dl

d2

Ls

(a)Hot-wire probe

L

-- - --

d2

Ls

I

(b) Hot-film probe

Figure 3-3. Structure of hot-wire and hot-film probes

27

Table 3-1. Dimensions of hot-wire probes

Probe Type

Hot-Wire

Hot-Film

Hot-Film

Model

1210-T1.5

1210-20

1210-60

Sensing Diameter d,

3.8um

50.8um

152.4um

Sensing length, Ls

1.27mm

1.02mm

2.03mm

Total Length, L

1.52mm

1.65mm

3.05mm

Diameter of Wire Support, di

40um

-

Diameter of Supporting Rod, d2

100um

200um

200um

50

30

30

--

3.3 Heat transfer model

Operation of a hot-wire probe involves Joule heating in the sensing element, convective

heat loss from the probe to surrounding fluid, and conductive heat loss form the sensing

element to sensor supports. Compared to convection, radiation heat loss by the wire is

negligible.

The energy equation for a hot-wire probe is

pA(x)C,

aT

a

at

ax

7 =-

(A(x)K(x)

aT

ax

) + P(x)h(x)(To - T(x)) + I 2 p, (x)

(3.1)

28

where p, C, and K are the density, heat capacity and thermal conductivity of the wire

respectively, A is the cross sectional area, P is the wire perimeter, To is the ambient

temperature, I is the current, and p, is the electrical resistance per unit length. Equation

3.1 is a general equation applicable to both hot-wire and hot-film probes. A hot-film

probe has a uniform cross sectional area (Figure 3-4). On the other hand, a hot-wire probe

has a much smaller diameter in the sensing zone (region 2 in Fig. 3-4). The electrical

resistance in regions 1 and 3 is much smaller than that in region 2.

I-I

Region1

x=-0.5L

Region3

Region2

x=-0.5Ls

x=0.5Ls

x=O

x=0.5L

(a) Hot-film sensor

Region1

II

x=-0.5L

Region3

Region2

II

-

x=-O.5Ls

x=O

I

I

x=0.5Ls

I

x=0.5L

(b) Hot-wire sensor

Figure 3-4. Schematic model of hot-wire and hot-film probes

29

The convective heat transfer coefficient, h, can be calculated from the Nusselt number,

Nu,

h(x) = Nu(x)Ka

d,(x)

(3.2)

where Ka is the thermal conductivity of air, and d, is the wire diameter.

For natural convection, the Nusselt number is correlated to the Rayleigh number

(Incropera and Dewitt, 1996),

NuN = (0.6+0.321Ra 1 / 6 ) 2

Ra =

g(T -T0 )d, 3 #

ay

(3.3)

(3.4)

where a is the thermal diffusivity of air, and 8 = 1 is the expansion coefficient.

For forced convection, the Nusselt number is correlated to the Reynolds number

(Incropera and Dewitt, 1996),

NuF = 0.3+0.48

Re

Re,

Vd_

L

(3.5)

(3.6)

where V is the velocity component normal to the wire. Contribution to convective heat

transfer by flow component parallel to the wire is neglected here.

30

For mixed convection, the effective Nusselt number is

3

3

Nue = (NuF + NuN ) 1/3

(3.7)

From equation 3.1, the thermal time constant of the sensing element is

Ir =

pC A

(3.8)

Ph

As steady state, equation 3.1 becomes

d

-(A(x)K(x)

dx

dT

) + P(x)h(x)(To -T(x))

dx

+I

2

p(x) = 0

(3.9)

The boundary conditions for the sensing wire are

dT

dx

(3.10)

x=0, -=0

x

=

L

-,2T = T,

2

- KA-

dT

=Q

dx

(3.11)

The supporting rods for the sensing wire are modeled as infinitely long fins of uniform

cross sectional area (Figure 3-5). The rods conduct heat away from the sensing wire.

Since the rods are outside micro-jet flow, they lose heat mainly through natural

convection,

Qb =7w1d2

2

(3.12)

NUKaK(Tb TO)

where d2 is the rod diameter, Kr is the thermal conductivity of the rods. The Nusselt

number is assumed to be 0.6 here.

Combining equations 3.11 and 3.12 yields the boundary condition at x =

L

2

31

L

x=+ -KA

dT

2

dx

1

7Td

2

-

NuKK,(T -T,,)

(3.13)

Heat flux from

the wire: Qb

Base tem perature,

Tb

Wire su pPort

Ln

0%

d2

V

Figure 3-5. The heat transfer model for wire support

The electrical resistivity of sensing wire is

_po(I+ao(T - To))

A

(3.14)

where po is the electrical resistivity at 00 C, and ao is the temperature coefficient of

resistivity. The total sensor resistance is

L/2

R = fpw(x)dx =

-L/2

L/2

jdx

-L/2

(3.15)

A

32

where the electrical resistance outside the sensing region is neglected.

The steady-state energy equation is solved numerically using the finite different method.

The sensing wire is divided into 100 small elements. Table 3-2 lists properties used in the

simulations. The fluid properties are evaluated at a film temperature of 110 0C.

Table 3-2. Physical properties used in simulations

] Thermal conductivity of air, Ka

0.034W/m-K

Thermal diffusivity of air, a

.83* 10- m2/s

Viscosity of air, v

2.64*10 rm2/s

Thermal conductivity of tungsten, K

159W/m-K

Thermal conductivity of quartz, K

7.6W/m-K

Heat capacity of tungsten, pCp

2.6*106 J/m 3-K

Heat capacity of tungsten, pCp

2.3*10 6 J/n 3 -K

Thermal conductivity of support, Kr

16W/m-K

The total heating power is

QiI= I2R

(3.16)

Heat loss by convection is

LQ2

=cn

Jh(x)P(x)(T - To)dx

(3.17)

-L/2

33

Heat loss by conduction to wire supports is

Qcond = 2 Qb

(3.18)

The numerical solutions are found to satisfy the energy balance within 0.01%,

Qin

- Qcond -

conv

<; 0.01%

(3.19)

Qin

3.4 Results and discussion

3.4.1 Hot-wire sensing in still air

Experiments were conducted to validate the heat transfer model for hot-wire probes. A

TSI1210-60 hot-film probe was heated by a constant current in still air. Figure3-6 shows

the simulated temperature distribution along the probe at a constant current of lOOmA.

Heat is generated mainly within the 2mm long sensing region at the center. Conductive

heat loss through the wire supports is significant, leading to a highly non-uniform

temperature distribution. The total electrical resistance of the probe can be calculated

through equation 3.15. Figure3-7 compares the predicted probe resistance with

experimental results. Model prediction agrees with the experimental results.

Figure3-7 compares the average probe temperature. The probe temperature is deduced

from measured probe resistance,

34

-

R-R

T=

ROa

(3.20)

0

where RO is the probe resistance at 00 C. The predicted average sensing temperature is the

average wire temperature in the sensing zone,

-

L /2

T =- L

T(x)dx

(3.21)

L/2

The results show that the center wire temperature can be 40 0 C higher than the average

wire temperature at lOOmA.

250

200

150

0Z

L.

a 100

E

50

-

.......

0

0

0.5

1

1.5

Wire Temperature

Averaged Temperature

2

2.5

3

Position along the wire y(mm)

Figure 3-6. The temperature distribution along the wire (TSJ1210-60, CC, 1=100 mA)

35

6.2-

.

Experimental data

Curve fits

cc

57------

Simulation data

--

0

C

S5.2/

4.7

TS11210-60

4.2-

0

20

40

60

80

100

Input current,l (mA)

Figure 3-7. Electrical resistance of hot-film probe in still air

36

m

Experimental data

Curve fits

250---------

Simulation results

200-

00150

E

.

100-

Cz

50 -

5.0-

.

0

TS11210-60

I

I

20

40

.

I

60

80

100

Current input, I (mA)

Figure 3-8. Average wire temperature in still air

3.4.2 Hot-wire sensing in uniform flow

Figure3-9 compares the predicted average probe temperature with that deduced from

measured probe resistance in a uniform flow. The flow velocity was determined using a

pitot tube. The TSI1210-60 probe was operated at a constant current of lOOmA. By

neglecting conductive heat loss by probe supports, Joule heating of the sensing wire is

balanced by convective heat loss,

37

I 2 R = rds LS h(T -TO)

(3.22)

The convective heat transfer coefficient can be expressed as

h = C + DS

(3.23)

where C and D are probe constant (Bruun, 1995). The probe resistance is related to the

probe resistance is related to the probe temperature,

R = R (1+ aT)

Ra

(3.24)

= R0 (1+ aTO)

(3.25)

where Ra is the probe resistance at the ambient temperature, To. Combing the above

equations lead to

R

R~

R- R

+ DV)

7rsLs(C+DJ= A + B-

_7dL(C

ROaO 12

at constant sensing current.

(3.26)

A and B are constants. Figure3-10 presents the ratio, R/(R-Ra), as a function of flow

velocity. Above 5m/s, the experimental data follow a straight line, which agrees with the

theory prediction. The results suggest that the experimental data are valid. At low

velocities, conductive heat loss to the probe supports becomes more and more important.

As a result, the experimental data fall below the straight line.

38

Sensor Temperature in Air Flow (1=100 mA)

100

-

Simulation results

Experimental results

90

C)

80

40~

9

E

U)

70

.9

'4

60

U)

L.D

U)

50

-4

401L

5

10

15

20

25

30

35

40

Flow exit velocity (rn's)

45

50

55

60

Figure 3-9. Effect of convection on wire temperature (I=lOOmA)

39

.

7.5-

experimental data

Linear curve fit result:

7.0-

R

=3.62 + 0.64V

No

R-Ra

6.56.0C55

CF

5.5-

5.04.5-*

TS11210-60

4.01

2

3

4

Vi_ (

5

6

mis)

Figure 3-10. Correlation of probe resistance (I=lOOmA)

3.4.3 Hot-wire sensing profiles for micro-jet flow

By combined the heat transfer model of hot-wire probes with jet velocity fields presented

in chapter 2, local wire temperature can be determined. Figure3-11 presents a schematic

distribution of the wire temperature. The typical width of micro-jets is smaller than the

length of a sensing wire. A micro-jet produces intense cooling in a small region of the

wrie.

40

micro-Jet flow

Large-scale uniform flow

Temperature profile(micro-jet)

Temperature profile

(large scale unifrom flow)

Wire elemen\

Tm Tp

d.

4T

1

0

U2

Prong

x

I

I

dx

L

Figure 3-11. Horizontal wire in mixed convection and conduction

Figure 3-12 shows the predicted temperature distribution profile along a TSI 1210-60

probe when the probe is at the center of a jet. The probe is operated at a constant current

of 100mA and is located at an axial position of z=lmm.

41

When the probe is placed across the center of the jet, convective cooling by the jet is the

strongest, resulting in the lowest average wire temperature. If the probe is located near

the edge of the jet, the sensing wire is only slightly cooled, leading to a higher average

wire temperature. Figure 3-13 simulates the average probe temperature as the probe scans

across the jet.

15C

14C

13C

12C

j-

11C

10C

9C

0

8C

c*

7C

E

%

6C

5C

4C

3C

.5

0

2

2.5

1

1.5

0.5

Position along the wire, y (mm)

3

3.5

Figure 3-12. Temperature distribution along the wire when HFA sits at the jet's center

42

24(

Ve:=40m/s, z=1 mm,

TS11210-60

22C

20C

U>

3 18C

U)

E 16C

14C

)

cD

12C

10

.5 -0.4 -0.3 -0.2 -0.1

0

0.1

0.2

0.3

0.4

0.5

Radial position, r (mm)

Figure 3-13. Probe temperature during scanning (I=lOOmA)

When the exit jet velocity increases, whatever the jet is laminar or turbulent, the cooling

effect becomes stronger and the average probe temperature decreases (Figure 3-14).

According to the simulation results in chapter 2, when the axis position increases, the jet

expands, and the centerline jet velocity decreases. Figure3-15 shows that average probe

wire temperature decreases with the axial position and the scanning.

43

ST11210-60 HFA, axis position z=1mm

24C

-

-

Vexit= 4 m/s

Vexit=6 )m/s

Vexit=8 m/s

Cz

20C

/4.f

C

CD

1-

12C

a

.44f

CO

> 1 4C

'4e

1 2C

.000

10C

-C.5

-0.4

-0.3

-0.2

-0.1

0

0.1

0.2

0.3

0.4

0.5

Radial scanning position, x (mm)

Figure 3-14. Effect of jet velocity on scanning profiles

44

t

240

-

22C

--- Z3=1.0mm

Z2=1.5mm

Z3=2.Omm -

/ -TI

20C

-F-.

I

18C

I.

-V

16C

14

I

-1-

>14C

.\

I.

120

100

1

-0.8

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

0.8

1

Radial position, x (mm)

Figure 3-15. Effect of axial position on scanning profiles

45

Chapter 4 EXPERIMETNAL SETUP

An experimental system was established to characterize micro-jet flow with hot-wire

probes. It consists of supply of regulated compress air, hot-wire probe and signal

conditioning circuits, probe scanning system and data acquisition system.

4.1 Air supply

Figure 4-1 shows a schematic diagram of the air supply system. A dry diaphragm air

compressor is used to avoid oil contamination of the metering tube. A large gas filter is

used to remove particles larger than 1 pim. The gas flow rate is monitored by a rotary

flow meter. A pressure transducer monitors the transient line pressure. A digital pressure

gauge with ± 1% accuracy in serial is used to calibrate the pressure transducer. The

pressure transducer has a linear response,

(4.1)

P=25.OV(V)-26.2 (kPa)

Filter/Reservoir Flow Meter

Metering Tube

IT

Compressor

Pressure

Transducer

12 VDC Power Supply

- Presure

Gauge

MicroJetrFgaw

Signal to

Computer Pv

Figure 4-1. Schematic diagram of air supply system

46

Experimental data

Linear Fit

P=25.OVp(v)-26.2 (kPa)

0

100-

80-

7

60-

40-

~20-

0

I

1.0

I

*

I

*

I

*

I

"

I

"

I

1.5

2.0

2.5

3.0

3.5

4.0

Voltage output of pressure transducer, Vp (v)

"

I

*

4.5

5.0

Figure 4-2. Calibration of pressure transducer

4-2 Hot-wire probes and signal conditioning

Commercially available TSI hot-wire probes are used for micro-jet sensing. Figure 4-3

illustrates typical dimensions of the probes. Table 4-1 lists electrical characteristics of the

probes. The probes were operated at a nominal temperature of 2000C in this work.

47

12.7mm Hot Film

9.5mm Hot Wire

38mm

-i

1-

I

-0

t==

T

t-4.6mm

3.2mm

Figure 4-3. Schematic diagram of TSI1210 general purpose probe (-T1.5, -20, -60)

Table 4-1. Characteristics of TSI hot-wire probes

Probe type

Hot-Wire

Hot-Film

Hot-Film

Model

1210-T1.5

1210-20

1210-60

Serial number

225479

#27

996002

Working Temperature

2000 C

200 0 C

2000 C

Total probe resistance at 00 C, Ro

5.90Q

5.94 2

4.21 2

Total probe resistance at 200 0C

6.7492

6.4292

4.692

Lead resistance

0.19Q

0.652

0.202

Working current

34mA

65mA

lOOmA

Temperature coefficient

0.0042 / 0 C

0.0024 / 0 C

0.0024 / 0 C

The probes can be operated either under the constant-current mode or constanttemperature mode. Figure 4-4 shows the circuit used for the constant-current mode.

48

"V1

Reference resistor

R1

Current

source:1

Hot wire/film

sensor, R

Vw

Figure 4-4. Constant-current circuit

For constant-temperature operations, a commercially available control module from TSI

is used. It contains a Wheatstone bridge circuit with the sensor as one arm of the bridge.

A differential feedback amplifier senses the bridge unbalance and adds current to hold the

sensor temperature constant. Before the probe is placed in operation, the control resistor

is set to a value so that the bridge will be balanced at the working temperature of the

probe. An increase in fluid velocity cools the sensor and unbalances the bridge. This

causes the feedback amplifier to increase the sensor heating current and to bring the

bridge back into balance. Since the feedback loop responses rapidly, the sensor

temperature remains constant. The voltage drop across the probe is related to the fluid

velocity. Figure 4-5 shows a typical constant-temperature circuit.

49

Bridge voltage

R2

R1

D.C Diferential

Amplifier

|

Sensor

Control resistance,

Rc

Flow

Figure 4-5. Constant-temperature circuit

4.3 Probe scanning system

Figure 4-6 shows a schematic diagram of the probe scanning system. A hot-wire probe is

mounted on a three-dimensional transnational stage. The probe position in the y and z

directions is adjusted manually with micrometers. During measurements, the stage is

driven along the x direction at a constant speed by a DC motor. An encoder provides the

stage position with ±1 gm accuracy.

50

Gas inlet

M et ering

Tube

Orifice

0

Jet

X

3-D linear moving station

Gas metering

Figure 4-6. Experimental setup

A typical experiment involves (1) determination of probe position, (2) probe alignment,

(3) alignment of the scanning stage, and (4) probe scanning. A dummy probe is used to

determine the probe position. It has the same structure and size as the working probes

except there is no wire attached between wire supports. As the probe is moved slowly

along the z direction approaching the metering tube, the electrical resistance between

them is monitored. When the probe contacts the tube, the resistance drops sharply and the

probe position in the z direction is set to z=O. The probe is then moved into a jet and

adjusted along the y direction until it is centered. To align the scanning stage parallel to

the tube, the distance between the probe and metering tube is determined at the two travel

51

extremes of the stage along the x direction using the above electrical resistance method.

Over a travel range of 25mm, the stage is aligned parallel to the metering tube within

20um. During measurements, the probe is driven at a constant speed of 60um/s when the

probe is near or within a jet and at about 200um/s when the probe is traveling between

jets.

52

Chapter 5 HOT-WIRE SCANNING OF MICRO-JETS

This chapter investigates effects of different operation modes and different probes on

micro-jet sensing sensitivity, orifice-to-orifice flow uniformity, and relationship between

jet flow and orifice defects.

5.1 Effect of sensor types sensing results

Hot-film probes have a much larger diameter and thermal time constant than hot-wire

probes. Figure 5-1 and 5-2 present typical results from a TSI 1210-T1.5 hot-wire probe

and TSI1210-20 hot-film probe under the constant-current condition. The results show

that the two probes provide similar sensitivity and signal-to-noise ratio. Since hot-wire

probes are significantly shorter than hot-film probes, they are difficult to align to the

center of orifices. They are also very fragile. Hot-film probes are used in this work.

53

0.36

Hot-wire sensor TSI1210-T1.5, CC mode

0.35

0.34

CD)

0

0.33

0.32

.C

40

CO)

Cl)

0

0.31

0.3

0.29

0

0.28

0.27

0

200

400

600

800

1000

1200

1400

1600

1800

2000

Scanning position, x (gm)

Figure 5-1. Hot-wire probe sensing of micro-jet flow

54

0.46-

Hot-film sensor, TS11210-20, CC mode

U)

0

>

0.45

.0

0- 0.44

CD

CO,

CD,

0

o 0.430

0.42-

0.41

0

200

400

'

600

'

800

'

1000

1200

1400

Scanning position, x (pim)

Figure 5-2. Hot-film probe sensing of micro-jet flow

5.2 Sensitivity to axial position

The cooling effect to a hot-wire probe is the strongest when probe is at the centerline of

the jet. Figure 5-3 shows the average probe temperature versus probe axial position at a

constant-current of 100mA. The nominal wire temperature in still air at this current is

200C. As the probe moves away from an orifice, the flow velocity decreases. The

overall convective cooling of the probe decreases, leading to an increase of the averaged

probe temperature. Also, as fluid particles move away from the orifice, turbulent eddies

develop bigger and bigger, resulting a larger fluctuation of the wire temperature. The

probe temperature decreases with the increase of the exit jet velocity. The probe sensing

55

noise decreases with the jet velocity, suggesting that hot-film sensing technology has

good sensitivity for micro-jet flow when the probe is close to the orifice.

16C

k

TSI1210-60, I=100mA

15C

P1=0.8KPa

0

V

14C

..............................................................

.............

.....

..................................

13C

E 12C

Ci)

11C

.....................................................................

..............

..........

P3=3 6KPa

-

10C

...........................................

.........................

..................................................................

-

P4=1 4.3KPa

90

80

70

1.5

2

2.5

3

Axis position, z (mm)

3.5

Figure 5-3. Scanning along jet centerline

When a probe is very close to the orifice, the probe response is not sensitive to the probe

position (figure 5-4), indicating that the probe is within the potential core of the jet.

56

0.47 r-

TSI1210-20, CC mode

0.46

Z=0.5mm

0.45-

0.440)

.0

0

0.42-

0.41

0

'

200

400

600

800

1000

1200

1400

Scanning position, x (gm)

Figure 5-4. Hot-film sensing of micro-jet flow near orifice

5.3 Sensitivity to backpressure

Figures 5-5 and 5-6 show the scanning profiles at different pressures for two neighboring

offices, #23 and #24. The orifices are indexed from the tube inlet. At the nominal gauge

pressure of 7.5kPa, the exit jet velocity is estimated between 50m/s and 70m/s. Although

the drop of the backpressure is only 0.7%, the hot-wire probe can clearly distinguish this

slight variation.

The variation of the exit jet velocity is related to the backpressure as

57

AV = 0.5 AP

(5.1)

P,

Using the nominal pressure of P, =7.5kPa and nominal velocity of V" =70m/s, the hotfilm sensing system can detect jet velocity changes as small as 0.3m/s.

0. 44

'

I

Orifice #23, z=O.5mm

TSI 1210-20,CC mode

CI)

4.

43

7E- 0. 42

41

0

a) 0.

0 40

2

P2=7.5 kPa

39

0

38

----

o.

P i=7.55Kpa

n

-0.2

-0.1

0

0.1

0.2

0.3

Scanning position, x (mm)

Figure 5-5. Hot-film scanning of orifice #23

58

0.44

0.43

0,

0

0.42

Orifice #24, 2=0.5mm

T111210-20, CC mode

0.41

0.40

P2=7.5

0

C,,

0)

L..

kPa

0.39

0.38

0

0.37

0.36

-C .2

r P 1=7.55 K p a

0.1

0

-0.1

Scanning position, x (mm)

0.2

0.3

Figure 5-6. Hot-film scanning of orifice #24

5.4 Reliability of hot-wire sensing for micro-jet flow

Figure 5-7 shows an optical image of a typical orifice, #35. From the image, small

irregular defects can be observed in the left part of the orifice. Multiple scans of the jet

show identical profiles (Figure 5-8). The scanning profiles overlap perfectly in the

smooth parts (i.e., x=800-1200gm). In the left side of the jet, i.e., x=500-800 gm, the

profiles are slightly not identical and include irregular features, indicating the impact of

orifice defects on the jet flow. The results show that hot-wire sensing is reliable.

59

Figure 5-7. Optical image of orifice #35

0.47

Orifice 35, z=0.5mm,

TS11210-20, CC mode

0.46

Test 1

Test 2

0.45

C,,

E 0.44

0.43

2 0.42

0.41

0.40

0

1

200

400

1

1

600

800

1000

1200

Scanning position, x ([tm)

1

1400

1600

Figure 5-8. Repeatability of hot-wire scanning

60

5.5 Jet direction

When the sensing probe is scanned perpendicular to the jet, the ideal scanning profiles

should be symmetric. The asymmetric profiles indicate that the orifice is non-circular and

contains defects. Furthermore, the direction of jet flow can be deduced by tracing the

center point of the symmetric scanning profiles at different axial positions.

Assuming aht the jet center points are 01 (x1, z1) and 02 (x2, z2), the angle between the

jet and the z axis, 6, is

x1)

6 = tan- 1 (x2

( z2 - zl)

(5.2)

Figure 5-9 presents scanning profiles for a typical orifice under the constant-temperature

mode. The axial position of the probe is 1 mm, 1.5mm and 2mm, respectively, and the

backpressure is about 1kPa. At a relatively high jet velocity, the scanning profiles

become asymmetric (figure5-10), and the jet center cannot be determined accurately.

Similar results for hot-film probe working in the constant-current mode are found (figure

5-11).

61

2.5 TS11210-20

2.4

Z-2.0nmr

Z=1. 5mm

P=_1kPa

2.3

'2.2

62.1

7E- 2

1.9

a..

1.8

1.7

1.6 ,

0

200

400

600

800

1000

1200

1400

Scanning position, x (pm)

Figure 5-9. Hot-film profiling of jet at relatively low velocity

62

3.2

TSI1210-20

a

Z=0.5mm Z=0.5mm

Z=1 .0mm

Z=1.Omm

CT mode

P=7.5kPa

A

1.5m

0)

(U

~0 2.4

Z=2.0m

-0

0

2

1.8

200

400

600

800

1000

Probe scanning position x (jim)

Figure 5-10. Hot-film profiling of jet at relatively high velocity

63

0.44

I

P = I .5I

I

TSI 1210-20, CC mode, P=7.5kPa

0.43

0.42

0.4

Z=2.Omm

> 0.41

)

1

0.

:= 0.40

0

Z=1.5mm

2 0.39

0.

0.38

Z=1.0mm

0.37,

0

200

400

600

Scanning position, x (pin)

Figure 5-11. Hot-film profiling of jet at relatively high velocity (CC mode)

5.6 Sensing profiles at different backpressures

This section investigates the effect of backpressure on hot-wire scanning profiles. Figure

5-12 shows the pressure variation during typical hot-wire scanning. The three inlet

pressures used in testing are P1=0.70kPa, P2=2.05kP and P3=7.30kPa. The pressures are

stable. Only four orifices were open in this experiment, and the rest were blocked.

64

P3=7.30tpa

7.5

0O

5.0

CD

CL

a)

P2=2.05]Ya

2.5

P1=0.70- a

0

-300

-200

-100

0

100

200

300

400

Scanning position, r (pm)

Figure 5-12. Three working backpressures when four orifices open

Figures 5-13 to 5-16 show the scanning profiles of jets #22-25 using a TSI 1210-20 probe

under constant-current mode.

65

0.44

Orifice #22, z=0.5mm, l=54.3mA

0.43

0.42

0

,> 0.41

CD

cz 0.40

...

...

...

...

.-...

...

..

..

...

...

...

...

...

...

...

...

...

...

... ......

0

c,

-0

0

0.39

P2

P3

0.37

0.36'

-300

-200

-100

100

0

Scanning position, x (jim)

300

200

Figure 5-13. Scanning profiles of jet #22 (CC mode)

0.44

Orifi e #23, Z=0.5mm

1=54.3rr A

0.43

0,

0.42

0)

0.41

0.40

0

Pi

0.39

P2

0.38

0.37

0.36

P3

-300

-200

200

100

0

-100

Scanning position, x (jim)

300

Figure 5-14. Scanning profiles of jet #23 (CC mode)

66

0.44

Orfice #24, -=0.5mm, I=54.3mA

0.43

0.42

0.41

V,

\J

0.40

>

0

0

1

P

0.39

__P_2

0.38

0.37

I

0.36

-300

__

-200

_

_

_

_P3

100

0

-100

Scanning position, x (prm)

200

300

Figure 5-15. Scanning profiles of jet #24 (CC mode)

0.45

0.44

-

_Orifice

#25, Z=0.5mm, I=54.3mA

0.43

0.42

(D

CU

0

.0

0.41

0.40

0.39

0.38

0.37

0.36

-300

P3

-200

100

0

-100

Scanning position, x (rm)

200

300

Figure 5-16. Scanning profiles of jet #25 (CC mode)

67

The scanning profiles are symmetric and smooth. When the inlet pressure increases, CC

mode curves are symmetric and smooth. When the pressure as well as jet exit velocity

increases, the average wire temperature decreases. Since the scanning plane is only 2.5orifice diameter away from the orifices, the probe is within the potential core of the jets.

In this region, the jet velocity increases with the backpressure. The jet width, however, is

not strongly affected by the pressure.

Figures 5-17 to 5-20 show scanning profiles under the constant-temperature mode. The

results are similar to those under the constant-current mode.

3.2

P3

3

I-,

0

Orifice #22: CT mode

z=0.5mm

2.8

2.6

0)

Ca

2.4

0

P1

CD

n02.2

0

a.

'

2

/

1.8

1.6

600

-400

-200

0

200

400

600

800

Scanning position, x (gm)

Figure 5-17. Scanning profiles of jet #22 (CT mode)

68

3.2

P3

3-

Orifice #23, CT mode,

z=0.5mm

2.-

5'

Ca -2.84-P

--

8P1

a~2.2-

24

0.

1.8

-600

-400

-200

0

200

400

600

800

Scanning position, x (p m)

Figure 5-18. Scanning profiles of jet #23 (CT mode)

3.2

P 3

3

Orifice #24, CT mode,

z=0.5mnm

2.8

2.6

P 1

z

2.4

-

2.2

-2

1.8

1.6

-600

-400

200

0

-200

Scanning position, x (pim)

400

600

800

Figure 5-19. Scanning profiles of jet #24 (CT mode)

69

3.2

P3

3

P2

I-,

0)

Orifice #25, CT mode,

z0.5mm

2.8

7E)

2.6

P1

CO

2.4

.0

..

..

..

.. ...

..

...

..

..

..

..

..

..

...

..

..

..

..

..

...

2.2

..

..

..

....

..

..

...

..

..

..

..

..

...

..

..

..

..

..

..

..

.

2

1.8

1 .6

-400

-200

0

200

400

600

800

Scanning position, x (pm)

Figure 5-20. Scanning profiles of jet #25 (CT mode)

5.7 Uniformity of micro-jets

Figure 5-21 presents hot-wire scanning profiles when only four orifices, #22 - #25, are

open. The sensing probe, TSI1210-20, was operated under constant-current mode. The

axial position of the probe is 0.46mm, and the inlet pressure is 7.3kPa. The spacing

between jets #22, #23, #24 and #25 are found to be 5.1mm, 4.7mm and 4.5mm,

respectively. Jet #25 has the highest velocity.

70

0.44

0.44

3

022

0.43

0.43

0.42

0.42

0.41

0.41

0.4

0.4

0.39

0.39

0.38

0.38

037

0.37

.

0.4

0.5

0.6

0.7

0.8

20

0-

1

1.1

1.2

0.36

5. 7

nA--

0.44

0.43-

0.43

0.42

-240-4

0.42

0.41

-

0.41

0.4

-

0.39

0.38

6.2

6.1

6

5.9

5.8

Scanning position, x (mm)

044

0

0.9

_23

.

025

0.4

0.39

0.38

-

0.37

0.361

10.4

0.37

10.5

10.6

10.7

10.8

10.9

11

-

0.36

15

15.1

15.2

15.3

15.4

15.5

Scanning position, x (mm)

Figure 5-21. Scanning profiles of four orifices

Figure 5-22 shows optical images of the solid debris can be seen on the inner edges of

orifices #23 and #25. Orifice #25 is also not circular.

71

15.6

Orifice#22

Orifice#24

Orifice#23

Orifice#25

Figure 5-22. Optical images for four neighboring orifices

Figures 5-23 to 5-30 compare the sensing profiles of the four jets under different

operation modes, and at different exit velocities. The axial position of the probe is

0.5mm. The results show that the jet velocity increases consistently form jet #22 to jet

#25. Scanning profiles are smooth and symmetric at inlet pressures less than 2kPa. At the

inlet pressure of 7kPa, irregular features are present near the center of the scanning

profiles. The constant-current mode provides better velocity resolution than the constanttemperature mode.

72

7.36

CD

/

7.27 k......

-..........

Cn

U)

ft

P1=0.7OkPa

/.

I/I

7.18

0

1*...

)

22

I...

)23

7.09

7.00

..

........

4

015

2

-

-300

-200

-100

0

100

200

300

Radial position, r (gm)

Figure 5-23. Scanning profiles at low backpressure (CC mode)

7.36

P2=2.05kPa

1-0

U)

7.18

-0

0

I...

7.09

22

7.00

024

025

6.91

-500 -400

-300 -200 -100

100

0

Radial position, r (im)

200

300

400

500

Figure 5-24. Scanning profiles at medium backpressure (CC mode)

73

7.09

P3=7.3OkPa

7.00

4)

0

6.91

4)

4)

023

0

4)

6.82

4)

025A

0024

6.73

-500 -400

-300 -200

0

100 200

-100

Radial position, r (Elm)

300

500

400

Figure 5-25. Scanning profiles at high backpressure (CC mode)

025

2.7

024

2.6

P1=0.7kPa

ai)

2.5

00

22.3

-1--

2.2

2.1

2

1.9

1.8

1 .7

-800

-600

-400

-200

0

200

400

600

800

Radial position r (urn)

Figure 5-26. Scanning profiles at low backpressure (CT mode)

74

3.0

02C

025

2.8

P2=2.05kPa

*-a

~0 2.4

023

22

2.2

2.0

1.8

1.6

- 600

-400

-200

0

200

400

600

800

Radial position r (urn)

Figure 5-27. Scanning profiles at medium backpressure (CT mode)

3.2

3

P3=7.3OkPa

24

02

2.8

0

023

2.6

0

I

2.4

02

j

_____________U

2.2

2

al.

1.8

-600

-400

-200

0

200

400

600

800

Radial position r (urn)

Figure 5-28. Scanning profiles at high backpressure (CT mode)

75

Figures 5-29 to 5-32 present scanning profiles of jets #22 to #25 when all the 49 orifices

in the center region were open. The TSI1210-20 probe was operated under the constantcurrent mode and at an axial position of 1mm. The results show a continuous increase of

the jet velocity for jets #22 and #24. The jet velocity drops slightly for jet #25 compared

to jet #24.

Qifice #2, z=1.OM CC mode

V1.

C1

*~8

~0

01

?D7.6

P1=05kPa

7.4

P2=6.CkPa

79

-300

-200

-100

0

Scaning position, x (pm)

100

200

300

Figure 5-29. Scanning profiles of jet #22

76

8.6

Orifice #23, z=1.Omm

8.4

8.2

C.)

8

0

C,,

7.8

7.6

P1=0.5kPa

7.4

P2=Z.OkPa

72

-300

-200

-100

0

Scanning position, x (pm)

100

200

300

Figure 5-30. Scanning profiles of jet #23

77

Oifice #24, z=1.Orm

CO

E

0

4-1

UD

8

L..

C)

.0

0I...

0L

C)

7.8

a

7.6

P1=O5kPa

7.4

P2=6,UPa

72

I.

-300

-200

-100

0

100

200

300

Soaning position, x (pnj

Figure 5-3 1. Scanning profiles of jet #24

78

a6

Qifie#25 z-1.Omi

8.4

C,,

a)

T78

0

L-

CD

P1:=.5kPa

7.4

F2-6.0kPa

72

-300

-200

-100

0

100

200

300

Smanrirg posifion, x (pm

Figure 5-32. Scanning profiles of jet #25

79

Figure5-33 shows scanning profiles of every eight orifices along the metering tube. The

center positions of the jets are arbitrarily shifted to make the results more distinguishable.

The jet velocity has a relatively uniform distribution in the center region. At both ends of

the tube, jet velocity is highly non-uniform (figure5-34 and figure 5-35). Optical images

show significant defects at the inner surface of orifice #3 (figure5-36). The axial position

of the TSI1210-20 probe is 0.5mm± 0.1mm along the entire tube. As this sensing

position, the scanning profiles are not sensitive to a small change of the axial position.

The inlet pressure is 1.0kPa.

80

0. 0.sl

I

-

-

0.47

0.46

0.45

D0.44

Cr

0

-0.43

0

0-

0.42

-03

c#43

0.41

0.4

-500

-

0

9

0#

500

To measure the velocity fields

for every 8 orifices along the

tube.

0#35

1000

-

1500

2000

2500

Scaming position. x* (pm)

Figure5-33. Scanning profiles along the metering tube

81

0.49

I

I

P=1.OkPa, z=0.5mm

0.48

Orifice35 scanned for comrparison.

0.47

0.46

0

0.45

0.44

-16

0.43

0.42

I0#

0.41

0.4

-500

0

500

1000

1500

2000

2500

Scanning position, x* (pm)

Figure5-34. Scanning profiles of jets near metering tube inlet

82

0.47

03 is scanned for comparison

0.46

0.451

a)

0

.0

0-

0.441

0.43F

I...

0.421

CV47

CM46

0.411

=

=3

P=1 .0kPa, z=O.5rrr

0.41

-5CxJ

0

500

1000

1500

2000

Scanning position, x*(pm)

Figure5-35. Scanning profiles of jets near the dead end of metering tube

83

Figure5-36. Optical images of orifice #3 and #35

84

Chapter 6 CONCLUSION AND FURTHER WORK

This work investigated applications of hot-wire probes for flow characterization of

micro-jets, both theoretically and experimentally. A general heat transfer model was

developed to describe the probe response to highly non-uniform jet flows. The

experimental study established general features of hot-wire scanning of micro-jets.

First, the sensitivity of hot-film probes are similar to hot-wire probes. Since hot-film

probes are more reliable and easier to align, they are recommended. Second, both the

constant-temperature and constant-current models can be used to detect jet direction and

velocity. The constant-current mode provides a slightly better resolution for resolving jet

velocity, while the constant-temperature mode provides a slightly better delectability of

the jet center. Third, within five-orifice diameters, the scanning profiles of a jet are not

sensitive to the axial position of the probe. The profiles are smooth and symmetric at

relatively low backpressures, e.g., 2kPa. At relatively high pressures, e.g., 7kPa, irregular

features develop in the profiles. Fourth, the output signal from a hot-wire probe becomes

increasing noisy as it moves away form an orifice. Fifth, large jet-to-jet velocity

variations are found to be caused by orifice defects. In conclusion, this work

demonstrated that a combination of hot-wire scanning and optical imaging techniques can

be sued for rapid identification of manufacturing defects and qualification of gas delivery

system of CVD machines.

85

In further studies, two or more wires can be integrated into one probe together. And then

the jet flow can be scanned by wires from different directions simultaneously. Moreover,

different work modes (CC/CT) can be applied to different wires for best sensing results.

It will greatly reduce the sensing time and collect more information about the jet velocity

filed together.

In addition to wires integrations, a high-resolution imitating system can also be integrated

along with the sensor and capture the orifice sidewall defects simultaneously. The

relationship between the distortion of the sensing curve and the orifice shape defects can

be studied in details in the future.

86

REFECENCES

Borgos, J.A, "A review of electrical testing of hot-wire and hot-film anemometers," TSI Quart., VI,

No.3, 3-9, 1980.

Bruun, H.H., Hot-wire Anemometry: Principles and Signal Analysis, Oxford University press,

Oxford, 1995.

Dobkin D.M. Mokhtari S., Schmidt M., Anil P. and Robinson L., "Mechanisms of Deposition of

SiO2 from TEOS and related organosilicon compounds and Ozone," J. Electrochem. Soc., Vol. 142,

No. 7, 2332-2339, 1995

Fingerson L.M. and Freymuch, P., "Thermal anemometers', in Fluid Mechanics Measurements," (ed.

R.J. Goldstein), pp. 99-154, Hemisphere, Washington, 1983.

Freymuch P. and Fingerson L.M., "Electronic testing of frequency response for thermal

anemometers", TSI Quart., 3, No.4,5-12, 1977a.

Freymuch, P. "A comparative study of the signal-to-noise for hot0film and hot-wire anemometers," J.

Phys. E.: Sci. Instru., 10, 705-710, 1978

Freymuth, P. "Frequency response and electronic testing for constant temperature hot-wire

anemometers," J. Phys. E.Sci. Instruments, 10, 705-710, 1977b.

Incropera F.P. and DeWitt D.P., Fundamentals of Heat and Mass Transfer, fourth edition, John

Wiley &Sons, Inc., 1996