Appendix F Laboratory Safety Procedures

advertisement

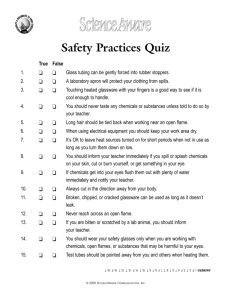

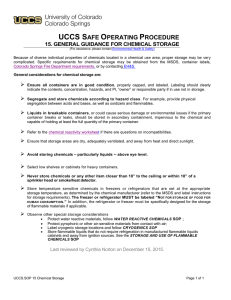

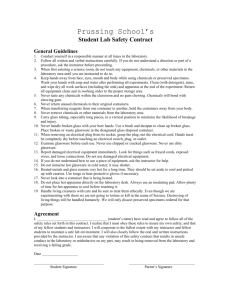

Appendix F Laboratory Safety Procedures This appendix gives general guidance for working safely with chemicals and equipment in laboratories. It is not meant to be a complete safety manual, but using this section in conjunction with other safety references (such as Prudent Practices in the Laboratory) will help maintain a safe laboratory and maintain compliance with the Occupational Safety and Health Administration (OSHA) standard for laboratories. General Laboratory Safety No food or drink in any lab at any time, even if the class is lecture only. Do not use ice from a laboratory ice machine for human consumption. Laboratory microwaves and refrigerators are not to be used for food intended for human consumption. No horseplay is allowed in any lab at any time. Know about the chemicals and hazards in the lab. Know their potential flammability, reactivity, corrosivity and toxicity. Know how to read and interpret labels and Safety Data Sheets (SDSs). Know what to do in different emergency situations (see Appendix I). Avoid working alone in the lab (see section 14 in the main content for the UW-Stout policy on working alone in laboratories). Do not underestimate risks: assume any mixture will be more hazardous than its most hazardous component and that all substances of unknown toxicity are toxic. Minimize all chemical exposures. Few lab chemicals are without hazards, so use precautions when handling all chemicals. Wear personal protective equipment appropriate to the work. Use extreme care when working with needles, blades and glass. Provide adequate ventilation by using fume hoods: this is the best way to prevent exposure to airborne hazards. Protect unattended operations from utility failures and other potential problems that could lead to overheating or other hazardous events. Confine long hair and loose clothing. Wear long pants or a lab coat to protect legs. Wear shoes at all times in the laboratory but do not wear sandals or perforated shoes. Be alert to unsafe conditions and see that they are corrected when detected. Immediately report unsafe conditions to the laboratory supervisor and Chemical Hygiene Officer. Laboratory Housekeeping: Generally speaking, a clean, orderly lab is a safer lab. Good housekeeping can lower the number of lab accidents and reduce the risk and consequences of a fire. It can also increase working space. For a safe and efficient laboratory: Keep passageways to exits clear. 1 Do not block areas around safety showers and eyewashes, fire extinguishers, fire blankets and electrical panels and controls. Do not store chemicals on the floor, where they may be broken or become a trip hazard. Return chemical containers to their proper storage location after use. Do not use floors, stairways or hallways as storage areas for equipment, supplies or chemicals. Clean contaminated equipment and spills immediately. Keep balances, hoods, centrifuges, incubators, refrigerators, ovens and other common-use items clean and neat for the next user. Personal Hygiene in the Laboratory: Good personal hygiene will help minimize exposure to hazardous substances. Even small exposures from some compounds may result in harmful effects. In general, the goal should be to avoid skin contact with all laboratory chemicals and biological materials. In the event of a spill, a careless person can quickly spread contamination throughout a laboratory. To keep yourself and others safe from contamination: Do not eat, drink or apply makeup or lip balm while in the lab. Do not touch things that are used by non-gloved hands (e.g., telephone, door knobs, etc.) if you are wearing gloves that have touched chemicals or biological materials. Gloves can be washed with soap and water if removal is not convenient. Wash hands thoroughly and frequently, especially after lab work and before eating, drinking, applying cosmetics (including lip balm) and leaving the lab. Routinely wash door knobs, telephones, keyboards and work surfaces. Never use mouth suction to fill a pipette. Use a bulb or other pipette filling device. Never allow a laboratory chemical or biological material to touch your skin; use gloves and wear a lab coat. Remove contaminated clothing immediately and do not use the clothing again until it has been properly decontaminated. Do not immerse fingers or hands in liquids; use tongs or a tool. Do not sniff or taste chemicals. Moving Chemicals: Whenever a chemical is moved the risk of a spill increases. Take precautions whenever moving chemicals, whether it is across the lab or across campus. Use secondary containment: No matter how careful you are, containers can drop and bottles can break. Use a tray, bucket or carrier specifically designed for transporting containers whenever you move chemicals from one room or building to another. Use carts and secondary containment for moving large amounts of chemicals. It is a safer practice to take several trips with fewer chemicals than to try to overload a cart and raise the risk of an incident. 2 Extra precautions for vehicles: Chemicals should never be transported in the passenger compartment of a vehicle. The Wisconsin Department of Transportation and Department of Natural Resources regulate the transport of hazardous materials on the road. Depending on the type and quantity of material transported, the driver may be required by law to have a commercial driver’s license, carry proper shipping manifests and use specified packaging. Shipping hazardous materials: Many government agencies regulate the shipment of hazardous materials (including chemicals and biological materials). Anyone who prepares hazardous material packages for shipment via ground transportation (e.g., FedEx or UPS) or air must attend a training class and become certified. Contact the CHO for information on how to find a class. Chemical Storage and Management: Proper chemical storage is as important as proper chemical handling. Chemical inventories must be actively managed. Read chemical labels and SDSs for specific storage instructions. Store chemicals in a safe place. Fume hoods should not be used for long-term storage of chemicals; use a ventilated cabinet to store volatile and odiferous chemicals (there are several in Jarvis Science Wing Addition). Use sturdy shelves (ideally with a lip to prevent chemicals from being knocked off shelves) with ample space for every chemical. Use secondary containment to contain liquid spills. Keep large, heavy items on lower shelves. Do not store chemicals on the floor or above eye level (approximately six feet off the floor). Keep incompatible chemicals separate to prevent chemical reactions. General guidelines include: o Separate acids from bases. o Separate oxidizers and acids from flammables. o Separate highly toxic chemicals and carcinogens from all other chemicals. o Do not keep peroxide-forming chemicals longer than 12 months. Dispose of expired chemicals. Inspect storage areas at least annually. Remove unwanted or expired chemicals and update CISPro. Replace defaced or missing labels. Visually inspect stored chemicals to determine viability and safety. Chemicals showing any of these indications should be evaluated for disposal: o Slightly cloudy liquids o Darkening or change in color o Spotting on solids o Caking of anhydrous materials 3 o Existence of solids in liquids or liquids in solids o Pressure buildup in containers o Evidence of reaction with water o Corrosion or other damage to container Storage and Use of Reactive Chemicals: The hazards of reactive chemicals are specific to each chemical’s properties, so it is important to understand their dangers before working with them. Read the label, SDS and other published information on their safe use. With all reactives, use as small a quantity as possible. Use proper eye protection, possibly including a face shield. Segregate reactive chemicals and store them away from heat and sunlight. Oxidizers. Oxidation reactions are a frequent cause of chemical accidents. Store oxidizers away from flammable and combustible materials, organic material and other reducers. Pyrophoric chemicals. Pyrophorics (e.g., boranes, n-butyl lithium, white phosphorus) ignite spontaneously on contact with air. Avoid a spill by storing breakable glass bottles inside a rubber or plastic bottle carrier. Use and store all pyrophorics in an inert atmosphere (e.g., stored under nitrogen or argon). Always wear a lab coat and proper eye protection when working with pyrophorics. Shock sensitive, self-reactive, explosive and endothermic substances. Atoms of these substances are bonded to each other in an arrangement that has high potential energy. They can then spontaneously release large amounts of energy when struck, vibrated, dropped or agitated. Some can explode with only slight increase of temperature, light vibration, grinding or a chemical initiation. o Some chemicals become increasingly shock sensitive with age. Inspect reactive chemicals regularly and dispose of any that appear degraded. o Lab accidents can occur from the inadvertent formation of explosive or shock sensitive materials such as peroxides from oxygen exposure, perchlorates from perchloric acid procedures performed in fume hoods and azides from azide salt solutions acting on lead in drains. o Silver oxide and ammonia solution can produce a fulminating silver which is very sensitive to movement and energetic in decomposition to its elements. o Nitro organics such as nitromethane, nitrophenol and picric acid form salts with a strong base that are both thermal and shock sensitive, producing quick, energetic decomposition. Storage and Use of Peroxide-Forming Chemicals: Certain chemicals can turn into potentially dangerous, shock sensitive organic peroxides with prolonged storage and/or concentration. One step to reduce the risk is to avoid the prolonged storage of all peroxide-forming chemicals. 4 The Class A chemicals shown in Table F-1 can form polyperoxide chains or cyclic oligoperoxides that are difficult to detect and eliminate. They can come out of solution and form crystals or a gel in the bottom of the container and are extremely unstable and can violently decompose with the smallest disturbance or even spontaneously. o Do not store these chemicals longer than suggested. Good practice requires they be discarded within three months of receipt. o If a container of Class A peroxidizable is past its expiration date, or if the presence of peroxides is suspected or proven, do not attempt to open the container. The act of unscrewing a cap or dropping a bottle can be enough to trigger an explosion. The Class B chemicals listed in Table F-1 as hazardous due to peroxide initiation of autopolymerization can undergo explosive polymerization initiated by dissolved oxygen. Do not store these chemicals longer than suggested, unless tests show that they contain less than 80 parts per million (ppm) of peroxides. o Class B chemicals are often sold with autoxidation inhibitors. If the inhibitor is removed, particular care must be taken in their long-term storage because of the enhanced probability of peroxide formation. Purging the container headspace with nitrogen is recommended. o If a container of Class B peroxidizable is past its expiration date, open it with caution. o Mark the container with the opening date and inspect it every six months. Test for peroxides annually, or discard one year after opening. The Class C chemicals listed in Table F-1 as peroxide hazard on concentration can form hydroperoxides and ketone peroxides. They are soluble and can be detected with peroxide test strips or a KI-starch test. o In most cases, commercial samples of Class C materials are provided with polymerization inhibitors that require the presence of oxygen to function and therefore are not to be stored under inert atmosphere. Inhibitor-free Class C compounds (i.e., the compound has been synthesized in the laboratory or the inhibitor has been removed from the commercial product) should be kept in the smallest quantities possible and under inert atmosphere. Unused inhibitor-free material should be disposed of immediately. o If a container of Class C peroxidizable is past its expiration date, open it with caution. o Mark the container with the opening date and inspect it every six months. Discard one year after opening. o It is common to distill these peroxidizable solvents before use and this concentrates the dissolved peroxides and subjects them to heat and mechanical shock. To safely distill peroxidizable solvents: Eliminate the peroxides with a chemical reducing agent or pass the solvent through activated alumina. 5 Add mineral oil to the distillation pot. This has the combined effect of cushioning any bumping, maintaining dilution and serving as a viscous reaction moderator in case the peroxides begin to decompose. Carefully monitor the distillation process to ensure that it does not dry out completely and overheat. Testing peroxide-forming chemicals. With some exceptions, these procedures will work only with Class B peroxidizables. o Peroxide test strips, which turn to an indicative color in the presence of peroxides, are available commercially. Note that these strips must be air dried until the solvent evaporates and exposed to moisture for proper indication and quantification. Follow the manufacturer’s instructions closely. o Add 1 to 3 mL of the liquid to be tested to an equal volume of acetic acid, add a few drops of 5% aqueous potassium iodide solution, and shake. The appearance of a yellow to brown color indicates the presence of peroxides. Alternatively, addition of 1 mL of a freshly prepared 10% solution of potassium iodide to 10 mL of an organic liquid in a 25-mL glass cylinder produces a yellow color if peroxides are present. o Add 0.5 mL of the liquid to be tested to a mixture of 1 mL of 10% aqueous potassium iodide solution and 0.5 mL of dilute hydrochloric acid to which has been added a few drops of starch solution just before the test. The appearance of a blue or blue-black color within one minute indicates the presence of peroxides. Table F-1: Peroxide-Forming Chemicals Class A: High risk peroxide forming materials. Oxidation products are easily formed that are sensitive and energetic. Discard within three months of receipt. The usual peroxide test will only work for isopropyl ether. Butadiene (106-99-0) Isopropyl ether (108-20-3) Sodium amide (7782-92-5) Divinyl ether (109-93-3) Potassium amide Vinylidene chloride (17242-52-3) (75-35-4) Divinyl acetylene (821-08-9) Potassium metal Chloroprene (126-99-8) (7440-09-7) Class B: Common solvents that can accumulate peroxide products that are a risk on heating and concentration. Mark container with opening date and inspect every six months; test for peroxides yearly or discard after 1 year. Acetal (105-57-7) 2-Butanol (78-92-2) Cellusolves (e.g., 2Ethoxyethanol, 110-80-5) Cumene (isopropylbenzene) (98-82-8) Cyclohexene (110-83-8) Decalin (91-17-8) Cyclopentene (142-29-0) Dicyclopentadiene (77-73-6) Diglyme (111-96-6) Diethyl ether (ethyl ether) (60-29-7) 1,4-Dioxane (123-91-1) Dimethoxyethane (monoglyme) (110-71-4) Tetrahydronaphthalene (119-64-2) Diacetylene (460-12-8) Furan (110-00-9) Isopropanol (67-63-0) Methylcyclohexane (108-87-2) Methyl isobutyl ketone (108-10-1) Tetrahydrofuran (109-99-9) Cyclooctene (931-87-3) Methyl acetylene (74-99-7) 6 Methylcyclopentane (96-37-7) 2-Phenylethanol (60-12-8) Isoamyl alcohol (123-51-3) Cyclohexanol (108-93-0) 2-Cyclohexen-1-ol (822-67-3) 2-Hexanol (626-93-7) 2-Pentanol (6032-29-7) 4-Heptanol (589-55-9) 4-Methyl-2-pentanol (108-11-2) 4-Penten-1-ol (821-09-0) 1-Phenylethanol (98-85-1) Class C: Liquids and liquefied compressed gases that can be initiated by oxygen to polymerize. Mark container with opening date and inspect every six months, discard after 1 year. The usual peroxide test may not show peroxides, but there are indicators of polymerization: look for an increase in viscosity of liquids or residue after evaporation of a sample of gases. Both of these may indicate a polymer. Acrolein (107-02-8) Chlorotrifluoroethylene Styrene (100-42-5) (79-38-9) Acrylonitrile (107-13-1) Ethyl acrylate (140-88-5) Tetrafluoroethylene (116-14-3) Acrylic acid (79-10-7) Ethyl vinyl ether (109-92-2) Vinyl acetate (108-05-4) Vinyl acetylene (689-97-4) Chloroprene (126-99-8) Methyl methacrylate (80-62-6) Vinyl chloride (75-01-4) 2-Vinyl pyridine (100-69-6) 4-Vinyl pyridine (100-43-6) Storage of and Use of Flammables and Combustibles: Use labels and SDSs to identify flammable and combustible chemicals. Improperly stored and used flammable and combustible chemicals can provide the fuel that can lead to a catastrophic laboratory fire. Minimize the amount of flammables and combustibles. Buy only what will be used in the immediate future. Excess flammable solvents risk a fire, a dangerous spill and health risks. Store flammables in an approved flammable storage cabinet. Store flammables, combustibles and other fuels away from strong oxidizers. Limit flammable liquids stored outside of flammable cabinets to less than 10 gallons per room. Limit the storage of flammable liquids on benchtops to those only in immediate use. Handle flammables in areas free from ignition sources. Exercise caution when using flammables in confined spaces with hot plates and other electrical equipment that is not intrinsically safe; a hot plate thermostat cycling on can be an ignition source if flammable vapors have built up in a small space. Always bond metal containers to metal receivers when transferring large volumes of flammable liquids or gases. If static electricity is a problem (especially in the winter), use nonconductive materials (floor mats, etc.) and grounding straps on instruments and machines, especially when transferring flammable chemicals between metal containers. Never heat flammable chemicals with an open flame. Use a water bath, oil bath, heating mantle, hot air bath, etc. Use a fume hood when there is a chance of dangerous vapors. 7 If flammables need to be refrigerated, keep them in an explosion-proof or flammable refrigerator, not a standard refrigerator. Storage and Use of Compressed Gas Cylinders: Compressed gas cylinders in the lab present both chemical and physical hazards: if handled incorrectly, they can be extremely dangerous. A broken cylinder valve can cause a cylinder to act like a rocket, and exposure to some gases leaking from a cylinder can be lethal. Only use regulators approved for the type of gas in the cylinder. Do not use adapters to interchange regulators and never use improvised adapters. Always wear safety glasses or goggles when working with compressed gases. Never refill cylinders. Before using, check all connections under pressure for leaks. Swab connections with a soap solution and look for bubbles. Turn off both the main valve and regulator when not using the cylinder. Do not leave regulators and valves on cylinders except when they are in frequent use. When not in use, remove regulators and valves and screw on the safety cap. Use spark-proof tools on cylinders that contain flammable gases. Do not force valve stems, which can easily snap off. Clearly mark empty cylinders as “empty.” Do not store empty and full containers together: move empty containers to a designated storage area. All cylinders (empty and full, in use and in storage) must be chained, strapped or otherwise securely attached to a wall or other sturdy surface to prevent the cylinder from falling and potentially becoming a missile. If attached to a wall, the attachment points should be driven into studs or other structural members. To safely move cylinders: o Wear safety glasses, leather gloves and appropriate footwear. o Ensure that valves are fully closed and the safety cap is secured in place. o Only use carts or hand trucks designed for moving cylinders. o Do not allow cylinders to drop or strike each other violently. o Never lift cylinders by the cap. o A best practice for moving cylinders between floors is to secure the cylinders on a cart and put them on an elevator by themselves. An elevator is a confined space that would be difficult to escape from if there was an accidental release. 8 Storage and Use of Cryogenic Liquids: Cryogenic liquids are hazardous because of the physical and chemical characteristics of their super-cooled state. They can cause explosions, fires, asphyxiation, tissue destruction or embrittlement of structural materials. Avoid skin and eye contact by always wearing chemical splash goggles and a face shield and appropriate cold-resistant gloves. Keep cryogenic liquids away from all sources of ignition. Store in a well-ventilated area to avoid buildup of flammable gases or displacement of breathing air. Store in double-walled, insulated containers (e.g., Dewar flasks). Handle all containers carefully. Tap Dewar flasks thoroughly to prevent the release of a large number of tiny glass slivers in the event the flask shatters. Pre-cool receiving vessels to avoid thermal shock and splashing. Select work materials wisely. Cryogenic liquids alter the physical characteristics of some materials; accidents have been reported where Pyrex tubes have failed and caused injury. Use tongs to place and remove items in cryogenic liquids. Rubber and plastic may become very brittle; handle these items carefully when removing them. Use extreme care in transporting. Use a cart for large cryogenic containers. When moving between floors, secure carts and containers and put them on the elevator by themselves. An elevator is a confined space that would be difficult to escape from if there was an accidental release. Safe Use of Centrifuges: Centrifuges present the possibility of two serious hazards: mechanical failure and aerosols. The most common hazard associated with centrifuges is broken tubes; given the high speeds and the necessity to maintain balance it is important to properly load the unit, operate it only at speeds recommended by the manufacturer, wait until it has completely stopped before removing all samples and properly cleaning the unit. Always wear safety glasses (at a minimum) when working with centrifuges to protect the eyes in the event of an accident. When loading the rotor, examine the tubes for signs of stress and discard any tubes that are damaged. Inspect the inside of each tube cavity or bucket. Remove any glass or other debris from the rubber cushion. Ensure that the centrifuge has adequate shielding to guard against accidental flyaways. Use a centrifuge only if it has an interlock that deactivates the rotor when the lid is opened. Do not overfill a centrifuge tube to the point where the rim, cap or cotton plug becomes wet. 9 Always keep the lid closed during operation and shutdown. Do not open the lid until the rotor is completely stopped. Do not brake the head rotation by hand. Do not use aluminum foil to cap a centrifuge tube: it can rupture or detach. When balancing the rotors, consider the tubes, buckets, adapters, inserts and any added solution. Stop the rotor and discontinue operation if you notice anything abnormal such as noise or vibration. Rotor heads, buckets, adapters, tubes and plastic inserts must match. Some low-speed and small portable centrifuges may not have aerosol-tight chambers that can allow aerosols to escape. In these cases use a safety bucket to prevent escape of aerosols. High-speed centrifuges present additional aerosol hazards due to the higher stress and force applied to their rotors and tubes. o Filter the air exhausted from the vacuum lines. o Keep a record of rotor usage to reduce the hazard of metal fatigue. o Frequently inspect, clean and dry rotors to prevent corrosion or other damage. Proper inspection, care and cleaning of centrifuge rotors are important. o Clean any spills immediately. o Review the manufacturer’s safety instructions. o Visually inspect the rotor for mechanical or chemical damage prior to each use. Look at the underside of the rotor, the web area and the outer rim. Ensure the top and bottom pieces of the rotor are tightly connected. o Certain chemicals (e.g., phenol) attack plastic rotors and some nucleic acid extraction kits can damage the rotor. Look for discoloration, peeling or other deterioration of the rotor finish. o Mechanical damage such as cracks, scratches or gouges can often be seen or detected as an increase in noise or vibration during a spin. Do not ignore excessive vibration that does not resolve after rebalancing and checking the fit of the rotor cover. Do not use the rotor if any damage or change is evident. Safe Use of Glassware: Broken glass is one of the most common causes of laboratory injuries. To reduce the chance that something will happen, use common sense when working with glassware. Always wear safety glasses when conducting operations that have a high risk of breaking glass (e.g., operating centrifuges or vacuums). 10 Inspect all glassware for chips and cracks before use. Do not use glassware that has any defects. Never use laboratory glassware to serve food or drinks. Use care in handling to avoid damaging it. Leave at least 10% air space in containers with positive closures. When possible, substitute plastic or metal connectors for glass connectors. Thoroughly clean and decontaminate glassware after each use. When inserting glass tubing into rubber stoppers, corks or tubing: o Use adequate hand protection (e.g., gloves or a hand towel). o Lubricate the tubing using glycine or similar material. o Hold hands close together to minimize movement if the glass breaks. o Rotate the tube back and forth while gently pushing it into the stopper. Never attempt to push tubing directly through a stopper. Use thick-walled, round-bottomed glassware for vacuum operations. Flat-bottomed glassware is not as strong. Carefully handle vacuum-jacketed glassware to prevent implosions. Dewar flasks, vacuum desiccators and other evacuated equipment should be taped or shielded. Use only glassware designed for use with vacuums. Large glass containers are highly susceptible to thermal shock: heat or cool them slowly. Use Pyrex or heat-treated glass for heating operations. Do not pick up broken glass with bare or unprotected hands: use a brush and dustpan. Remove glass in sinks by using tongs for large pieces and cotton held by tongs for small pieces and slivers. Dispose of uncontaminated broken glass in designated cardboard boxes. Glass contaminated with a biological material must be disposed of in a sharps container. Electrical Safety: Many laboratory fires start with the careless handling of electrical equipment. Un-safe practices and worn or defective equipment can also cause electrical shocks. Before use, check all electrical apparatus for worn or defective insulation and loose or broken connections. Power cords should be checked closely and replaced if defective. Connect all ground wires to clean metal (avoid painted surfaces). Use three-prong grounded plugs wherever possible. Never remove the ground plug or use an adapter to make a three-prong plug fit a two-prong receptacle. Keep electrical wires away from hot surfaces. Do not allow water and other potentially destructive liquids to leak on electrical wires, switches and outlets. Never touch a switch, outlet or other electrical power source with wet hands. 11 Avoid the use of extension cords for other than temporary situations. The only exception is surge protectors. The cord must be grounded. Do not use homemade or makeshift wiring; call an electrician for all wiring. Safe Use of Electrophoresis Equipment: Electrophoresis equipment can be a major electrical hazard; it uses both high voltage and conductive fluid, which can present a potentially lethal combination. A standard electrophoresis operating at 100 volts can deliver a lethal shock, and even a slight leak in the device tank can result in serious shock. Follow the equipment operating instructions. Use physical barriers to prevent inadvertent contact with the apparatus. Use electrical interlocks. Do not disable safety devices. Use warning signs to alert others of the potential electrical hazard. Frequently check the physical integrity of the electrophoresis equipment. Turn the power off before connecting the electrical leads, opening the lid or reaching into the chamber. Use only insulated lead connectors and connect one lead at a time using one hand only. Ensure that hands are dry when connecting the leads. Keep the apparatus away from water and water sources. Safe Use of Heating Systems: Next to glass failure, the most common source of laboratory injury is the improper manipulation of heating apparatus, particularly gas burners. Common hazards associated with lab heating devices include open flame/fire hazards, electrical hazards and hot surfaces. When temperatures of 100°C (212°F) or less are required, it is safer to use a steam-heated device than an electrically-heated device because steam-heated devices do not present a shock or spark hazard and they can be left unattended with the assurance that their temperature will never exceed 100°C. Before using any electrical heating device, ensure that the heating unit has an automatic shutoff to protect against overheating and that all connecting components are in good working condition. Heated chemicals can cause more damage more quickly than would the same chemical at a lower temperature. Always wear chemical splash goggles and appropriate gloves when heating chemicals. Heating baths should be equipped with timers so they turn on and off at appropriate times. Use a chemical fume hood when heating flammable or combustible solvents. Arrange the equipment so that escaping vapors do not contact heated or sparking surfaces. 12 Use non-asbestos thermal-resistant gloves to handle heated materials and equipment. Place oil baths in plastic or metal trays to contain spills, and do not leave them unattended. Minimize the use of open flames. Safe Use of Pressurized Systems: Processes requiring high pressures present a physical hazard (explosion) should the equipment fail. High pressure operations should only be conducted in specificallydesigned equipment and only by trained operators. Do not conduct a reaction in, or apply heat to, a closed system apparatus unless the equipment is designed and tested to withstand pressure (such systems may be stamped with safe operating pressures). Pressure systems should also have an appropriate relief valve, be fully shielded and should not be operated in an occupied space until safe operation has been assured. Always wear safety glasses (at a minimum) when working with pressurized systems to protect the eyes in the event of an accident. Minimize risk and exposure by planning. Identify and assess all hazards and consequences before beginning work. Consider how failures could occur. Do not assume that the apparatus will have an “inherent safety factor.” Use remote manipulations whenever possible. Conduct the procedure in areas that are not occupied by other people. Minimize pressure, volume and temperature. The stored energy available for release is proportional to the total volume and pressure. Use material with a predictably safe failure mode, preferably ductile failure. Do not use a brittle material unless it is properly shielded or barricaded. Demonstrate structural integrity by a proof test. Ensure that the components of the pressurized system will maintain structural integrity at the maximum allowable working pressure. Operate within the original design parameters. Do not exceed maximum allowable working pressure. Do not change working fluids or service environments without re-considering all hazards and consequences. Provide backup protection. Suitable pressure relief valves should be installed to ensure that the pressure level will stay within safe limits if the equipment malfunctions or is improperly operated. Use quality hardware. Use tie-downs to secure hoses, tubing and piping: a line under pressure that fails can whip unless it is restrained. Do not leave a pressure system unattended. Safe Use of Vacuum Systems: Vacuum systems have similar hazards as high pressure systems, except that the danger is from implosion rather than explosion. Dangers include flying glass, spill/spray of toxic chemicals and fire. 13 Always wear safety glasses (at a minimum) when working with vacuum systems to protect the eyes in the event of an accident. Ensure that pumps have belt guards in place during operation. Ensure that service cords and switches are free from defects. Always use a trap on vacuum lines to prevent liquids from being drawn into the pump, house vacuum line or water drain. Replace and properly dispose of vacuum pump oil that is contaminated with condensate. It should be disposed of as a non-halogenated hazardous waste. Place a pan under pumps to catch oil drips. Do not operate pumps near containers of flammable chemicals or in an enclosed, unventilated cabinet. Glassware in vacuum operations presents a particularly dangerous hazard if it breaks. o Only heavy-walled round-bottomed glassware should be used. The only exception is glassware specifically designed for vacuum operations (e.g., Erlenmeyer filtration flask). o Wrap exposed glass with tape to prevent flying glass if an implosion occurs. o Carefully inspect vacuum glassware before and after each use. Discard any glass that is chipped, scratched, broken or otherwise stressed. Glass desiccators may develop a slight vacuum due to cooling of contents. When possible, use molded plastic desiccators with high tensile strength. For glass desiccators, use a perforated metal desiccator guard. Vacuum pumps often have a cold trap to prevent volatile compounds from getting into hot pump oil and vaporizing into the atmosphere, and to prevent moisture contamination in a vacuum line. o Locate the cold trap between the system and vacuum pump. o Ensure the cold trap is big enough and cold enough to condense vapors in the system. o Check frequently for blockages in the cold trap. o Use isopropanol/dry ice or ethanol/dry ice instead of acetone/dry ice to create a cold trap. Isopropanol and ethanol are cheaper, less toxic and less prone to foam. o Do not use dry ice or liquefied gas refrigerant bath as a closed system, as these can create uncontrolled and dangerously high pressures. Safe Distillation of Organic Solvents: Potential hazards from distillations arise from pressure buildup, flammable materials and the use of heat to vaporize chemicals. Care must be taken during construction 14 of the system to ensure effective separation and to avoid leaks that can lead to fires or contamination. Take precautions with distillations and reactions, especially when they run overnight. Prevent overheating by ensuring that all hoses and connections are securely tightened. Use boiling chips or stir bars to prevent bumping during distillations, refluxing and similar procedures. Be aware when distilling chemicals that certain types may auto-oxidize and accumulate peroxides, which can explode when heated and concentrated during a distillation. Use only round-bottomed flasks for vacuum distillations. Erlenmeyer flasks are more likely to implode. Vacuum distillations or evaporations should always be shielded in case of implosion. Do not leave a distillation unattended if possible. Post a phone number on the door of the lab if you must leave. Safe Use of Autoclaves: Autoclaves are used to sterilize materials by high heat and pressure. Burns can result from physical contact with the autoclave itself, with the hot pressurized steam that it generates and with hot items as they are removed from the autoclave. Explosive breakage of glass vessels due to temperature stresses can produce mechanical injury and cuts during opening and unloading. Additionally, because of the extreme conditions created inside steam autoclaves they can easily malfunction if not carefully maintained. Load the autoclave properly. Be sure to clean the drain strainer before loading. Do not load plastic materials that are not compatible with the autoclave. Individual glassware pieces should be within a heat-resistant plastic tray on a shelf or rack; never place them directly on the autoclave bottom or floor. Be sure the autoclave is OFF and the steam pressure is down before opening the door. Open the door slowly, keeping head, face and hands away from the opening. Wait at least 30 seconds after opening the door before reaching or looking into the autoclave. Before removing autoclaved items, wait five minutes for loads containing only dry glassware and 10 minutes for liquid loads. When removing items wear heat-resistant, long-sleeved gloves and safety glasses or goggles treated with anti-fog solution. Remove solutions from the autoclave slowly and gently; some solutions can boil over when moved or when exposed to room temperature. Let glassware cool for at least 15 minutes before touching it with ungloved hands. Be alert for autoclaved liquid bottles still bubbling. Let liquid loads stand in an out-of-the-way location for a full hour before touching them with ungloved hands. Clean up any spills immediately. The following form shall be used as part of the laboratory safety introduction for all students enrolled in a UW-Stout instructional laboratory covered by the Laboratory Standard. Laboratory instructors shall ensure all 15 students enrolled in their class sign this form. Laboratory instructors shall retain signed forms with class records. 16 STANDARD OPERATING PROCEDURES FOR STUDENTS 1. No eating or drinking is permitted in any laboratory at any time. 2. Eye protection must be worn when required by the lab instructor. 3. Wear sensible clothing. Loose fitting clothing and open sandals or open footwear shall not be worn. 4. Long hair must be confined. 5. No unauthorized experimentation is allowed. Do not change written laboratory procedures without permission of the instructor. 6. Students may not work in the laboratory without an instructor present. (Exceptions may be made depending on the course.) 7. Students are not allowed to work in instructional laboratories outside of regularly scheduled hours without written permission from instructor. 8. Students should know locations of all available safety equipment. This includes eye wash stations, safety showers, fire extinguishers, fire blanket and first aid supplies. 9. Pipetting by mouth is not allowed. Never place anything in the mouth except as directed by instructor while in the laboratory. Smell chemicals only by wafting a small amount of vapor toward the nose with the hand. 10. Personal protective equipment in addition to eye protection should be used at the direction of the laboratory instructor. This equipment includes gloves when working with certain corrosives and organic solvents and laboratory aprons. 11. Keep lab bench clear of book bags and outer clothing. These should be placed in provided areas. Students are responsible for maintaining a safe and clean work area. 12. Chemical fume hoods should be used for all operations that have the potential to release fumes, gases or volatile solvent vapors in excess of recommended exposure levels. Follow written laboratory procedures and the laboratory instructor's directions. Notify the instructor if you think the fume hood is not functioning properly. 13. Read lab procedures before entering the laboratory. Do not proceed with an experiment if you do not understand the procedure. All chemical names and identities should be carefully double-checked prior to any use. Check labeling before using a chemical so that potential hazards are known. 14. Report all injuries, no matter how minor, to the laboratory instructor. The instructor will give guidance on any appropriate treatment which may be needed or call 911 if necessary. 15. Proper disposal of laboratory waste is essential. Do not dispose of any chemical down sewer/sink without approval from the instructor. Use appropriate waste containers when provided. 16. Clean up spills promptly. If you should break a mercury thermometer, notify the instructor so that the mercury is promptly recovered. If you have questions on spill clean-up, ask your instructor. 17 17. Only students registered for the class are allowed into the laboratory. 18. Students should clean work area and wash hands thoroughly with soap and water before leaving the laboratory. I have read and I understand the above standard operating procedures. I understand that it is my responsibility to follow the above procedures and I agree to follow these procedures. Date: Signature: ___________________________________________________ 18 19