Development of New Tools for the Production... Plasmid DNA Biopharmaceuticals ARCHIVES by

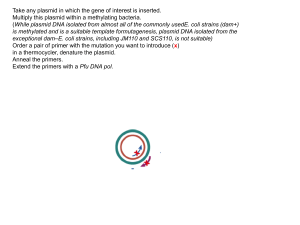

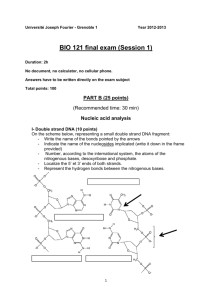

advertisement