OPTIMAL CONTROL FOR STERILIZATION OF CANNED FOODS by

advertisement

OPTIMAL CONTROL FOR STERILIZATION

OF CANNED FOODS

by

Manoj Mangesh Nadkarni

B.Tech., Indian Institute of Technology, Bombay

(1981)

Submitted to the Department of

Chemical Engineering

in Partial Fulfillment of the

Requirements of the Degree of

MASTER OF SCIENCE IN CHEMICAL ENGINEERING

at the

MASSACHUSETTS INSTITUTE OF TECHNOLOGY

September 1983

© Massachusetts. Institute of Technology 1983

Signature of Author:

Deptment

.

of Chemical Engineering

2 August, 1983

Certified by:

. Alan-Hatton, Thesis Supervisor

Accepted by:

Chairman, Departmental Graduate Committee

Archives

MASSACHUSETTS

INSTITUTE

OF TECHNOLOGY

OCT 241983

LIBRARIES

OPTIMAL CONTROL FOR STERILIZATION

OF CANNED FOODS

by

MANOJ MANGESH NADKARNI

Submitted to the Department of Chemical Engineering

on August 2, 1983 in partial fulfillment of the

requirements for the Degree of Master of Science in

Chemical Engineering

ABSTRACT

A mathematical model has been developed for maximizing the

nutrient retention during thermal sterilization of canned

foods. Pontryagin's minimum principle as applied to distributed parameter systems, has been used in the analysis. The

necessary conditions for optimization, derived by variational

methods, lead to bang-bang type of control which requires the

sterilization

and cooling.

to be carried out at maximum

rates

of

heating

A numerical procedure is outlined for the solution of the

resulting two-point boundary-value problem, which consists of

a system of nonlinear, coupled partial differential equations.

The unique behaviour of the costate variables makes it possible to integrate only the state equations in the forward

direction

in the time domain,

and

to

iterate

on

the

final

desired reduction of micro organisms. A single point switching

shows less nutrient degradation than any combination of

multiple switchings.

Optimization with constraints on the retort

temperature

results in a dual point switching where the control is either

at a maximum

or minimum,

or

is

zero.

The

model

has

been

applied to the sterilization of pork puree.

Comparison with

the nutrient retention obtained using other

temperature

policies, shows that bang-bang control with single. point

switching represents the optimal solution.

Thesis Supervisor: Dr. T. Alan Hatton

Title: Assistant Professor of Chemical Engineering

2

ACKNOWLEDGEMENTS

This is a necessary, but not a sufficient expression of

my indebtedness to several individuals. Undoubtedly, the

person to whom I owe the most, is my thesis advisor, Prof. T.

Alan Hatton, whose able guidance and endless efforts will

never be forgotten. His continuous encouragement and the

willingness to spend long hours of discussions have enabled me

to complete this thesis.

Among others, I am grateful to Prof. Robert A. Brown for

useful discussions on numerical methods, both in the class as

well as outside the class. A word of very special thanks goes

to Prof. Robert R. Tenney of the department of electrical

engineering at MIT, for patiently explaining to me many

intricacies of the optimal control theory. His help is greatly

appreciated. The financial support during this research work

was provided by MIT.

There are many friends at MIT and elsewhere, who have

helped me in different ways, perhaps most importantly, by

giving

a moral

support.

I owe it to all of them. Finally,

humble appreciation for what he has done for

dedicate this thesis to my father.

3

me,

I

wish

in a

to

LIST

Number

OF

FIGURES

Title

Page

2.1

Results of Saguy and Karel (1979)

24

4.1

Modified Control for Constraint on the

Retort Temperature

60

5.1

Basis

71

for Obtaining

a Single Point

Switching

5.2

Condition for Optimal Switching

74

5.3

Condition

75

for Switching

for the case of

no Constraint on the Final Concentration

of Micro Organisms

5.4

5.5

Bang-Bang Control: Single Switching

77

Final Concentration of Micro Organisms

79

as a Function

of Switching

Time

5.6

Results for Computer Simulation for BangBang Control

80

5.7

Effect of Variation

Control u

81

5.8

Variation

5.9

Nutrient Degradation at Different

Activation Energies

84

5.10

Optimal Control for Upper Constraint on

the Retort Temperature

86

5.11

Optimal Control with Lower Constraint on

the Retort Temperature

87

5.12

Bang-Bang Control: Two Switching Points

94

5.13

Results for Two Switching Points

95

5.14

Optimal Concentration Using Two Switching

Points

96

in Process

4

in the Limits

of the

Time

83

5

Title

Number

Page

5.15

Optimal Control: Three Switching Points

97

5.16

Optimal Concentration with Three Switching

Points

99

5.17

Variation

99

in Second Switching

Time t 2

( Three Switching Points )

6.1

Maximum Nutrient Retention at Constant

Uniform Temperature

6.2

Results of Teixeira

6.3

Spatial Domain

107

6.4

Optimal Control for Sterilization of Pork

Puree

109

6.5

Temperature Distribution at the CenterPlane

111

6.6

Nutrient Degradation during Cooling

Process

113

6.7

Variation in Maximum Rates of Heating and

Cooling

115

6.8

Nutrient Retention at Different Inlet

Hot-Fill Temperatures

117

6.9

Process Time and Total Sterilization Time

at Different Inlet Hot-Fill Temperatures

118

6.10

Variation

119

104

et al.(1975)

in Limits of the Control

103

u

LIST

OF

Number

TABLES

Title

Page

4.1

Variables and Parameters for System

Equations

44

5.1

System Equations

66

5.2

Initial, Terminal and Boundary Conditions

for System Equations

67

6.1

Process Data

102

6.2

Results for Two Dimensional Model

114

6

CONTENTS

Abstract

2

Acknowledgements

3

List of Figures

4

List of Tables

6

Chapter

Introduction

9

Chapter

Principles of Thermal Processing

14

2.1

Thermobacteriological Considerations

14

2.2

Retention of Nutrient Quality

18

2.3

Approaches to Optimization

21

Optimal Control Theory

25

3.1

The Minimum Principle

26

3.2

Bang-Bang Control

32

3.3

Distributed Minimum Principle

34

3.4

Remarks

38

Mathematical Model for Maximizing

Nutrient Retention

40

4.1

Model Formulation

40

4.2

Optimality Conditions Using the

Variational Approach

47

4.3

Comments on Optimality Conditions

55

4.4

Constraint on the Retort Temperature

57

Chapter

Chapter

7

8

Chapter 5

Numerical and Analytical Solutions

Strategy

64

64

5.1

Computational

5.2

Analytical

Solution

85

5.3

Multiple Switchings: Numerical

Solutions

91

Two Dimensional Models

101

6.1

Preliminaries

101

6.2

Results

108

6.3

Discussion and Conclusion

120

6.4

Suggestions for Future Work

123

Chapter 6

Appendix I Nomenclature

References

125

130

CHAPTER

1

INTRODUCTION

Sterilization of canned foods is one of the major

tions in the food processing

industries.

The

opera-

sterilization

process involves a suitable heat treatment of canned foods

that the can contents are virtually free of any

isms which

could degrade

the

food.

It

micro

is

organ-

impractical

achieve complete sterility; the cans are commercially

ized so that a desired degree of destruction of

isms is achieved.

tion is that the

One of the major

thermal

problems

processing

nutrients and food quality.

The

and organoleptic properties,

the

to

steril-

micro

organ-

in the steriliza-

causes

destruction

deterioration

and

so

of

of

nutrients

destruction

of

micro

organisms follow similar kinetics, and hence higher kill rates

for micro organisms also

quality.

involve

greater

loss

in

While it is highly undesirable to incur any degrada-

tion of nutrients, it

is

nevertheless

essential

to

ensure

a

factor

sufficient reduction of micro organisms, usually by

of five

nutrient

to

ten

log

cycles,

and

hence

nutrient

loss

is

unavoidable.

Much attention has been paid in recent

years

to

izing the nutrient quality in a sterilization process

to a specified reduction of

micro

9

organisms.

maximsubject

Sterilization

10

continuously

or

can be carried out in a batch retort

In both cases, the

hydrostatic sterilizers.

retort

ture and the process time are the two variables

mine the degree of sterilization.

made

to

design

temperatures,

retention.

a

with

suitable

a

view

to

been

have

the

maximizing

deter-

retort

for

policy

in

tempera-

which

Several studies

control

as

nutrient

Most of these studies are based on optimizing some

either

functional form for the temperature-time relationship,

analytically or experimentally, and are approximate in nature.

However, the recent advances in computer-aided process design,

and the development of modern control theory have provided the

The

potential for a new approach to optimization.

originally

this approach is the "minimum principle" which was

developed for lumped systems by Pontryagin and

for

basis

co-workers

in

the early sixties (Pontryagin et al., 1962). Subsequent developments have extended the concepts to incorporate

distributed

parameter systems.

The

major

advantage

associated

minimum principle is that now

with

state

the

distributed

the

variables

control variables can be spatially distributed in

of dimensions.

The

control

system

then

While the distributed

information and can more

systems than can lumped

model

accurately

models,

it

can

also

the

number

coupled,

and

provide

represent

is

any

involves

nonlinear partial differential equations of first

order.

and

much

second

more

the

physical

more

complex.

11

Compl&te analytical

However,

with

the

are

solutions

finite

of

availability

possible.

not

generally

and

difference

the

Galerkin finite element methods for discretizing

partial

differential equations, numerical solutions can be achieved to

a high degree of accuracy.

food

Application of the distributed minimum principle to

problems

processing

should

optimization of nutrient quality

sophisticated approaches.

better

provide

We

make

a

no

(e.g.

regarding the functional form

those

than

high

priori

assumption

temperature

versus

in

temperature

Also, the distributed nature of the model allows for

a rigorous mathematical formulation of the problem with

simplifying

studies.

short

conditions

Rather it is the necessary

the minimum principle which determine the optimal

profile.

less

on

based

time, ramp, sinusoidal etc.) of the retort temperature

time relationship.

for

procedures

assumptions

than

those

In this thesis, the optimal

canned foods is investigated

using

in

embodied

thermal

the

fewer

earlier

processing

distributed

of

maximum

principle as a starting point.

In what follows, the salient aspects of

food

processing

operations and the associated kinetics are discussed.

In

the

second chapter, the basics of sterilization processes and the

Note that the terms 'minimum principle' and 'maximum

principle' are used synonymously. Actually, they differ only

in sign.

12

reviewed.

for

work

esearch

past

nutrient

optimizing

retention

are

with

the

The third chapter is primarily concerned

tools for optimal control.

time

It deals with the continuous

minimum principle, analyzes some of

the

the

of

limitations

lumped model and establishes the need for a distributed model.

described

also

A generalized distributed parameters model is

here.

In the fourth chapter, the emphasis is on the application

of the minimum principle to the problem of optimizing nutrient

retention.

The

are

optimality

for

conditions

necessary

derived here starting from the basic principles of variational

the

calculus. The discussion on numerical methods for solving

system

above-mentioned

equations,

fifth

the

in

follows

chapter. We have considered here one dimensional slab geometry

for

mathematical

nature

and

of the optimal

computational

control

is

also presented

in this chapter.

chapter, we are mainly

concerned

it

known,

derive analytical solutions for system

In the

the

is

possible

to

These

are

equations.

sixth

and

the

exists

for

puree,

comparison

final

of a

with an application

dimensional model to sterilization of pork

for which significant data

Once

convenience.

a

two

process

purposes.

Most of the previous research has failed to account rigorously

for sterilization during the cooling cycle, necessitating some

new definitions. We elaborate two main aspects

of

our

model

here, namely the minimum principle leading to optimal nutrient

13

retention and the distributed nature of the system giving more

accurate predictions.

Conclusions and

some

suggestions

for

future work follow.

Though the present work is primarily concerned

maximization of the nutrient quality subject

to

the

with

an

integral

constraint on the final concentration of micro organisms,

the

results would very well apply to any process which is governed

by a diffusion-like equation with the surface concentration or

temperature as a control variable.

be to enhance

one kind of reaction

other, where both would

have

The objective

product

similar

and

then

suppress

temperature

kinetics with different activation energies.

would

the

dependent

CHAPTER

2

PRINCIPLES OF THERMAL PROCESSING

It is of prime concern for the food

to be able to design a flexible heat

sterilizing canned foods.

processing

treatment

engineer

schedule

The objective is always

to

that sufficient destruction of contaminating

micro

is achieved with a minimum loss in

quality.

the beginning of the twentieth

nutrient

century,

several

ensure

organisms

Since

researchers

have reported analytical and experimental work in

this

Bigelow et al.

method

(1920)

gave

the

first

general

for

area.

for

calculating thermal process times, and shortly thereafter Ball

(1923) defined

several

parameters

of

interest

in

thermal

processing and developed mathematical formulas which are still

used in the food processing

industry.

Several

others

have

done pioneering work in this area during the last few decades.

There have been numerous textbooks describing the

practice of thermal processing, such as those by

Beverloo (1975), Loncin and Merson (1979),

Charm

theory

and

Leniger

and

(1978)

and

Harris and Karmas (1975).

2.1 TERMOBACTERIOLOGICAL

CONSIDERATIONS

The micro organisms present

14

in

food

are

destroyed

by

15

thermally induced changes in the original

of the proteins

usually assumed

This leads to an

in the cells.

the cells to reproduce.

to

by

a

first

structure

inability

of micro

The destruction

occur

chemical

of

organisms

is

irreversible

order,

reaction often described by the rate equation

(2.1)

dN/dt = - K N exp(-E/RT)

t is the time and the term

where N is the concentration,

K

exp(-E/RT)

is

the

temperature

degradation of organoleptic quality

such

as

vitamin

C

and

The only difference in

kinetics.

values

rate

Chemical reactions occurring in food which lead

constant.

trients

reaction

dependent

of the constants

higher for

nutrients

and

thiamine,

these

micro

for

(1982) and Lund (1975) give a detailed

of activation

energies

for

different

follow

is

cases

K and the activation

than

of

destruction

to

nu-

similar

that

the

energy E are much

organisms.

listing

micro

of

Thompson

the

values

organisms

and

nutrients.

However,

it is usual practice

in

the

food

engineering

literature to denote the temperature dependence of

the

reac-

tion rate constant by

K = Kref exp [ b(T-Tref)

so that an equivalent

organisms

expression

and nutrients

(2.2)

]

is

for the destruction

of

micro

16

(2.3)

dN/dt = - Kref N exp [b(T-Tref)]

Furthermore,

microbiologists

and

define two more parameters, D and z.

to reduce the reactant

concentration

given temperature, while z

is

the

food

technologists

D is the

time

by a factor

increase

required

of 10,

in

at

temperature

necessary for reducing the value of D by a factor of 10.

the definition of the reaction rate constant

K,

a

one

From

obtains

D=2.303/K, so that the kinetic expression becomes

dN/dt = - (2 .303/Dref).N exp [(T-Tref)/(z/2303)]

Here the time and the Dre f values

are

usually

minutes,

the

z

and the temperature

and

celsius (or Fahrenheit). The

reference

(2.4)

expressed

values

in

temperature

in

degrees

Tref

is

normally taken as 121.1 degree C ( 250 F).

Points along the center of a cylindrical

the slowest heating region.

The mechanism for

can

heat

is assumed to be primarily conduction, though some

currents may be set up

in

Leniger

(1975)

and

Beverloo

qualitatively.

the

case

have

of

constitute

transfer

convective

semi-liquid

discussed

this

foods.

aspect

The coldest spot may occur below the geometric

center of the can if

during processing.

there

is

The process

no

agitation

design

of

containers

calculations

may

be

based on the temperature history at these points. Many a time,

however, it is desirable to achieve a certain level of average

17

concentration over the entire can rather than

tion at a few critical points. Some other

the

factors

concentrawhich

can

affect the degree of sterilization are: the size and the shape

of the cans, movement of cans in

the

sterilizer,

empty space in the sealed can and perhaps the

volume

of

composition

of

the vapour/gas mixture in this space.

Hayakawa (1978) gives a summary of how the empirical

analytical formulas have been developed in the past.

Olson (1957)

have

developed

tables

for

the

and

Ball and

variation

in

process values with respect to heat transfer coefficients

and

the difference between the temperature of the center point and

the surface of the

containers.

Stumbo

(1953)

developed

mathematical model which based the process time on the

a

proba-

bility of survival of micro organisms in the whole

container,

and not just the center of the can.

Smith

Tung (1982) have reviewed various

compared their accuracy.

Most recently,

formula

methods

Most of the currently used

and

energy

have

sterili-

zation methods seem to have a high factor of safety and

there is considerable scope for saving

and

hence

and

improving

a

lethality

the organoleptic quality.

Lenz and Lund

(1977

a,b)

have

developed

Fourier number method for estimating sterility

center of the can.

Lund et al.

value

This is an extension of the work

at

the

done

by

(1972), which introduces the concept of adiabatic

equilibration temperature.

The mass

average

temperature

of

18

the food contents is higher than

during the heating period.

the

centerline

Containers are

temperature

heated

until

the

average temperature inside the can is sufficient to induce the

desired kill rates. Then they are held adiabatically until the

centerpoint

temperature

rises

distribution is achieved.

and

a

uniform

temperature

This concept was first

applied

by

Lund for quick blanching operations.

2.2 RETENTION OF NUTRIENT QUALITY

In recent

kinetics

years,

of nutrient

research

degradation

nutrient quality of thermally

has

been

directed

to

the

and to the prediction

of

the

Harris

and

processed

foods.

Karmas (1975) and Lund (1977) have discussed

heat processing on nutrients.

the

effects

of

It may be ocassionally possible

to improve the taste of the canned food by heat treatment, but

that is rarely an objective.

In most cases,

the

nutritional

and the organoleptic quality of the food reduces as

of thermal processing.

The kinetics of

nutrient

are similar to those of the destruction

of

a

result

degradation

micro

organisms,

two parameters of interest being the rate of nutrient destruction Kr, at a reference

temperature

Tr,

for

a

first

reaction, and the Arrhenius activation energy Ea .

parameters are equivalent to the Dr-value

perature

Tr, and the

z

value,

discussed

at

in

These

reference

the

order

two

tem-

preceding

19

section.

It has been observed by Joslyn and Heid

(1963)

that

at

higher temperatures, the destruction rate of bacteria accelerates more rapidly than the degradation rate of nutrients, thus

favoring

high

temperature

short

time

Ammerman (1957) studied the effects

of

(HTST)

heat

processes.

treatment

different processing temperatures and equal microbial

ity values, on selected food constituents,

by

thermal

calculations

Stearothermophilus.

organisms

are

Stumbo

used

C.

(1973)

energy-values for these micro

lethal-

analyzing

effect on colours, flavours and nutrients such as

The two main kinds of micro

as

vitamin

a

organisms

the

as

This

means

that

for

a

and

B.

activation

50-80

given

C.

in

kcal/mole

which are significantly higher than those of nutrients

20 kcal/mole).

the

basis

Botulinum

gives

with

(about

increase

in

processing temperatures, the rate of micro

organism

destruc-

tion will increase more rapidly

rate

nutrient

than

the

degradation. This observation forms the basis

of

for

optimizing

rate

constants

processes to yield maximum nutrient retention.

The activation energies and the reaction

for different nutrients depend on factors such as

medium, the composition of the food medium and

reduction potential.

There are

several

e.g. texture, colour and the flavour of

pH

its

quality

of

the

oxidation

attributes,

food,

which

exhibit

similar degradation due to thermal processing.

Their

activa-

20

tion energies vary in the range 10 to 25

kcal/mole

1971). The activation energy for thiamine,

has been studied extensively, is

not

a

(Timbers,

nutrient

strongly

which

dependent

on

food medium or composition, and hence the mechanism of thermal

degradation of thiamine appears to be the same

for

different

media.

the

reference

at

the

reference

and

the

pH.

However, the reaction rate constant at

temperature (or equivalently the

temperature)

is a function

D

of the

value

medium

For

example, the thiamine destruction at pH 6.6 is about 12

faster than at pH 3.2 .

Other

nutrients

include vitamin C and chlorophyll.

frequently

times

studied

Their activation

energies

vary between 10 and 25 kcal/mole.

Mulley et al. (1975 a,b,c) have

for thiamine destruction in various

studied

food

reaction

products

observed that, in natural foods thiamine is more

rates

and

heat

have

resis-

tant than thiamine in buffered and aqueous solutions, although

a first order reaction mechanism seems to hold for both acidic

(pH less than

4.5)

and

non-acidic

Ohlsson (1980 a) and Castillo et

al.

foods.

(1980)

More

recently,

have

developed

quantitative expressions for retention of nutrients.

Thompson (1982) discusses some of the pitfalls

the

simplified

approach

of

first

order,

non-cyclic reaction for predicting nutrient

other

nutrients

using

irreversible,

degradation.- The

degradation rate for a particular nutrient may be

of the concentration of

of

and

a

hence

function

it

may

21

concentrations

change in a complex manner as various reactant

However, in the absence

change during thermal processing.

and

any detailed

more

to

complex reactions, an approximation

al.

of

reaction

is

kinetics

Hill

by

given

for

appli-

predicting nutrient quality. A general treatise on the

cability

be

(1971)

models

mathematical

are among others who have developed

may

order

first

(1977) and Jen et

Downes and Hayakawa

justified.

for

modeling

mathematical

accurate

of

and

Grieger-Block (1980).

2.3 APPROACHES TO OPTIMIZATION

There has been growing concern over the nutritional value

of canned foods and this has led to active research programmes

Broadly speaking, optimiza-

for optimizing thermal processes.

tion refers to a

alternatives, that process which

some

preset

quantities,

Various approaches have

selecting

for

procedure

will

subject

been

certain heat treatments of

used

canned

or the design

minimize

maximize

or

certain

constraints.

to

for

this

foods,

one

of equipment.

For

purpose.

may

optimize the temperature-time profile, or the size

of containers,

various

, among

wish

shape

and

Teixeira

to

et

(1975) have considered different geometries for containers

al.

to

yield better heat penetration and thereby to optimize thiamine

retention.

Flat container geometries or cylindrical cans with

22

However, in

very high height to diameter ratios are favoured.

practice

the shape and the size of containers

is determined

by

other considerations such as cost of manufacturing and attractiveness of the product.

rotation

providing

Processing equipment is designed for

and agitation of cans during the sterilization process.

There

this

area.

designs

patented

are several variations and

Hydrostatic sterilizers, which can process

ture policy developed in

more

used

now

retort

The optimal

subsequent

the

continuously

cans

are

in a pressurized high temperature space,

frequently (Fairbrother, 1982).

in

temperawill

chapters,

be

applicable to both batch-type processes as well as to continuous sterilizers.

Teixeira

et

al.

have

(1969)

shown

on

dependent

retention of nutrients is also

energy or the z value of nutrients.

that

maximum

the

activation

the

For a low z

(high

value

E) nutrient, a process with low temperature and high

time

preferred while for those having high z values, shorter

and higher process temperatures are

Ball (1971), Teixeira

et al. (1975) and

and

Thijssen

(1980) have considered variable retort temperatures to

ize the nutrient retention.

However,

study the influence of other factors as

and

simplifications

inference.

made,

if

any,

one

should

well

before

times

Hayakawa

desirable.

as

is

and

Kochen

maxim-

carefully

assumptions

drawing

For example, Teixeira and co-workers have

any

neglec-

23

ted the sterilization as well as the micro

tion during the cooling

detail in chapter 6.

cycle.

This

organism

will

be

destruc-

discussed

in

Loncin and Merson (1979) briefly discuss

the use of the Euler-Lagrange

equation

in optimizing

nutrient

quality.

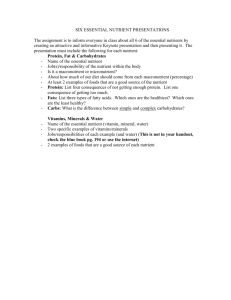

Saguy and Karel (1979)

principle as applied to

have

lumped

used

Pontryagin's

models,

for

minimum

maximizing

the

nutrient retention during sterilization of canned foods.

is possibly the only published application of optimal

theory to food processing operations.

optimal temperature profiles

Figure

obtained

using

2.1

This

control

shows

this

the

technique

principle. These temperature policies are shown to improve the

thiamine retention by more than two percent as

compared

with

other schemes. Their results are encouraging, although some of

their assumptions may not

be

strictly

correct.

They

have

averaged the micro organism and nutrient

concentrations

over

the entire can, and have then used first

order

the averaged quantities.

to be the fact that

kinetics

The reason for this averaging

Pontryagin's

applied only to the lumped models.

minimum

principle

This is a

for

seems

can

severe

be

limita-

tion of the model as presented by Saguy and Karel.

There appears to be some scope for the formulation of the

optimization problem more rigorously by

the spatially distributed

nature

of

taking

the

into

system,

account

and

applying the minimum principle. This is the prime task of

then

the

24

thesis research that follows in the subsequent chapters.

t.

a

6-

4

0

WJ

g

A

a

I.-

0

0.2

0.4

TIME,

0.6

0.8

1.0

ldimensionless)

Optimal retort temperature (B0). mass average temperature

(Bin, and central point temperature (B,) during the sterilization

process (A 12 can).

a

I

44

4

w

IC

TIME,

procn

(dimensionloss)

Optimal retort wnperature profiles for the sterilization

of peapurse in #303 can and pork puree in A2K~ can.

Fig. 2.1 Results of Saguy and Karel (1979)

3

CHAPTER

OPTIMAL CONTROL THEORY

Pontryagin's

Minimum

Principle

is

one

of

the

major

contributions to the development of optimal control theory. It

has found a variety of applications in many different types of

control

in

especially

problems,

electrical

wish

engineering. In this chapter, we

to

and

review

aerospace

the

basic

statement of the minimum principle in one of its commonly used

represent

forms, using the state space approach throughout to

the system. In

what

follows,

we

a

consider

deterministic

system with a known relationship between the system states and

the input control.

The aim is to find the

which drives the state X(t) to

a

desired

functions

continous and continously differentiable to first

noted).

The existence

It

objective.

important to assume that all scalar and vector

(unless otherwise

control

particular

is

are

derivatives

of a solution

to

the

control problem must also be assumed in deriving the necessary

conditions.

The latter part of

the

chapter

important aspects related to our subsequent

bang-bang control and the

distributed

pr incipl e.

25

introduces

research,

minimum

(or

two

namely

maximum)

26

3.1 THE MINIMUM PRINCIPLE

The minimum principle for lumped models is

Lumped models are

this section.

discussed

the

by

characterized

in

fact

that the state variables are functions of time alone, and that

the system dynamics can be described by ordinary

equations.

To begin, assume

that

the

interest is completely represented by a

differential

linear

of

process

physical

nonlinear

or

system of coupled or uncoupled differential equations

of

the

form,

(3.1)

X = f (X,u,t)

where the m-dimensional control

vector

u(t)

determines

the

n-dimensional state vector X(t). A fixed time interval [to,tf]

for the process;

is considered

concepts to the

case

of

it will be easy to

variable

terminal

extend

time.

the

General

statements of the initial and final conditions are given by

Q [(to),to]

(3.2)

= 0

and

(3-3)

R [X(tf),tf] = O

respectively.

Obviously, the dimensions of Q and

less than or equal to n.

R

will

be

The following analysis considers the

case where initial conditions are specified by equation (3.2).

27

The objective of the optimal control problem is to search

for a control policy u(t) which will minimize a cost function,

J.

The exact form

judgement.

of

the

cost

function

The optimality conditions, namely

is

a

matter

the

of

conditions

which will lead to a minimization of J, will

depend

strongly

on the nature

to

able

of J.

Hence it

is

important

be

quantify the cost or the performance index correctly.

Most of

the time, the cost function consists of two terms, namely

cost associated

with the terminal

state, and

cost over the entire time domain.

the

to

the

accumulated

In mathematical terms,

the

cost function J can be written as

J = C [X(tf),tf] +

g[X(t),u(t),t] dt

(3.4)

to

Costate variables P(t), which are similar to the Lagrange

multipliers for the case of static optimization, are

to the system

equations

and incorporated

into the

adjoined

cost

func-

tion such that

J = C rI(tf),tf] +

5 {g[X(t),u(t),t] +

to

p T (t).rf(X(t),u,t)-X(t)]

dt

(3.5)

A scalar function Hamiltonian is defined as

H[X(t),u(t),P(t),t] = g[X(t),u(t),t] + PT(t).fEX(t)u(t)t]

(3.6)

28

Incorporating the Hamiltonian

into

the

cost

function,

one

obtains

J = C[X(tf),tf] +

.

H[X(t),u(t),P(t),t] - Pr(t).X I dt

(3.7)

*t

A necessary condition for optimality is

that

the

first

variation in J must be zero for independent variations in

the

state vector X and the control

the

vector

u.

canonical equations for the state and

(Pontryagin

the

This

yields

costate

variables

et al., 1962)

X = JH/aP = f(X,u,t)

(3.8)

P = - a H/a

(3.9)

and an additional optimality condition,

aH /

(3.10)

u = 0

The state variables X(t) are free to end on any

manifold (i.e. can have any values at the

terminal

terminal

time).

A

transversality condition of the form

P(tf) = DC /

x(tf)

is obtained for the

(3.11)

costate

variables.

Thus,

the

terminal

condition on the costate variables is determined by the nature

of C, the cost for having

a particular

end point

state.

The

control system equations constitute a two point boundary value

29

problem.

This is an important

characteristic

of

the

minimum

principle, where the costate variables always evolve backwards

in time.

When the terminal time is not fixed, there

is

tional equation corresponding to the variation in tf

H[X(tf),u(tf),P(tf),tf] +

C/atf + (R

/tf).L

an

addi-

which is

= 0

(3.12)

where the end point constraint on the state variables, described by an r dimensional

vector

R

[equation

(3.3)]

is

also

adjoined to the cost function by an r-fold Lagrange multiplier

L. Note that r is less than or equal to n.

The transversality

conditions are then given by

P(tf) =

C/@X(tf) + (R

Thus there are

r

T /;X(tf)).

L

additional

(3.13)

equations

given

by

(3.3)

to

account for the r dimensional unknown vector L.

In

cases

where

the

control

variable

vector

is

constrained, the necessary condition given by equation

(3.10)

can hold only if the domain

u

completely in

the

interior

of

of

the

optimal

the

control

constraints.

speaking, it is no longer possible to take independent

tions in u and the optimality condition

(3.10)

must

is

Strictly

variabe

re-

placed by the more general form,

H[X*(t),u*(t),P*(t),t] < [X(t),u(t),P*(t),t1

(3.14)

30

where the superscript * denotes optimal states.

In

essence,

the necessary condition for optimality is the global minimization of the Hamiltonian H within the constrained domain for u.

The variational

approach

has

generally

been

deriving optimality conditions [Berkowitz(1961),

used

in

Denn(1969)],

although it may not always be possible to apply the techniques

of variational calculus, for example, in the case

or state variable

inequality

constraints.

proof of the minimum principle is that

Falb (1966). It gives a

new

A

given

interpretation

of

more

control

by

to

rigorous

Athans

the

and

costate

variables P; namely, the costate equation for P describes

motion of a normal of a hyperplane

trajectory.

along

optimal

The optimal trajectory represents

in cost with change in the state space X

cluded as a state variable.

optimality, any

portion

which considers temporal

According

of

optimal trajectory itself.

time)

the

the

the

where

to

optimal

state

variation

time

the

the

is

in-

principle

of

trajectory

is

an

This forms the basis for the proof

variations

and spatial perturbations

in u

that the motion of the hyperplane

in

.

tf

In

described

(free

effect,

by

the

terminal

it

shows

costate

equations does indeed lead to necessary conditions for minimizing the Hamiltonian. The proof of the minimum principle

also

yields one of the key properties for the state and the costate

variables, namely,

31

< X(t),

P(t) > = XT(t).P(t)

(3.15)

= constant

variables

i.e. the inner product of the state and the costate

is invariant with time.

It is not necessary to

minimum

the

formal

to

use

it.

able

to be

principle

know

variational

Ray

and

(1969)

Gould

cases.

approach is adequate in most

The

the

of

proof

appli-

(1981) have discussed some of the chemical engineering

cations of the minimum principle for lumped models (i.e. where

the

system

can

by

represented

be

differential

ordinary

equations). Szepe and Levenspiel (1968) derived an

solution

for the optimal

in the case

temperature

catalyst

of

Among

kinetics.

irreversible

deactivation via first order,

analytical

columns

separation processes, the application to distillation

operations by Jones (1974).

Other uses

tower

cooling

to

has been considered by Robinson (1970) and

include

optimization

of polymerization temperature and initial initiator concentration for batchwise

Jeng, 1978), two

radical

step

catalytic

(Chen

polymerization

chain

in

reactions

bed reactors

in

the

presence

of

deactivating

of

using the

applied

minimum

principle.

Pontryagin's

minimum

Murase

in

et

principle

fed

batch

al.

in

fixed

immobilized

enzyme catalyst (Patwardhan and Sadana, 1982). Yamane

(1977) maximized the metabolite yield

beds

packed

(Chang and Reilly, 1976), and the optimal operation

and

et

al.

culture

(1970)

optimizing

have

the

32

in

temperature profile for ammonia synthesis

a

multitubular

reactor heat exchanger system.

3.2 BANG-BANG CONTROL

A very interesting case arises when

the

Hamiltonian

given

linear in the control vector u. The necessary condition

by equation (3.10) does not

respect to u since

extremize

the

Hamiltonian

H/;u is now independent of u.

It

is

with

can

vector

immediately seen that if the domain for the control

be

u

to

can

be

driven

negative infinity by choosing infinitely large

or

infinitely

is infinitely large, then the Hamiltonian

However,

small values of u.

most

in

physical

situations,

there will be some bound on u, for example,

Umin < u <

(3.16)

max

The condition for optimality

is

given

by

equation

(3.14),

which in this case will be

u = umax for

H / u<

O

and

u = umin for

H /

u > 0

(3-17)

Thus the Hamiltonian is minimized

boundaries of the domain of u. The

by

operating

at

the

occur

at

the

switchings

33

singular points where

H/au=O. When the term

not just at certain finite points but in a

for a

problem

certain

state-space

interval,

is said to have a singular

arc, the contribution

aH/au

continuous

the

arc.

is

solution

Along

not

be

further

the

the

singular

is zero

extremized

choice of u. An additional equation is required to

manner

to

of the u term to the Hamiltonian

and the Hamiltonian can

zero,

by

any

solve

for

u, which is obtained by considering

d/dt ( H/,u

) = 0

If the above equation

(3.18)

is

insufficient,

time derivatives of (H/au)

successively

higher

can be set to zero to solve for

u

in terms of the state and costate variables.

Bellman

et al. (1956), Johnson

(1965)

have discussed bang-bang control and

the

and

Sage

singular

arising in optimal control. One of the early

(1968)

solutions

applications

of

the variational approach for deriving necessary conditions for

a singular control was given

by

Desoer

(1959).

Canon (1964) have presented a solution in

switchings for the problem

of

minimum

space vehicles, where the control

is

terms

fuel

Athans

of

used bang-bang control for

and

deriving

applied

for

Gibilaro

optimal

multiple

consumption

whenever a given amount of consumed fuel would result

most efficient motion. Farhadpour

and

'firing',

in

(1981)

inlet

in

the

have

reactant

concentrations in the case of an unsteady state operation of a

34

continously stirred tank reactor.

Most of the examples of bang bang control, including

those which are mentioned above, are for lumped systems.

problems are, however, distributed in nature

of the minimum principle to distributed

and

all

Many

application

parameter

models

is

discussed in the next section.

3.3 DISTRIBUTED MINIMUM PRINCIPLE

The emphasis in this section will be on

the

development

of the minimum principle for systems which are distributed

nature.

Distributed

systems

are

characterized

by

partial

differential equations in the spatial coordinate vector y

time t.

and

Butkovskii and Lerner (1960) were among the first

consider the

minimum

principle

as

applied

to

in

to

distributed

parameter systems.

Consider a distributed system described by

DX(y,t) / t = f

y,t,u(y,t),aX/y,

...

, kx/yk,

..

]

(319)

The initial conditions on the state variables are specified at

t=t o, and the boundary conditions on the distributed variables

are specified in terms of X(t,y), ;X/ay, etc. at the

ies of the spatial

domain.

The objective

boundar-

is to find an optimal

control u(y,t) which will extremize the cost function

35

J = .C [X(ytf),

k

.X(y,tf)/y

tf] dy +

5g[X(y,t),

kX/-ay',

y, u(y,t), tdy

t

As before,

(3.20)

i

the first term in the cost

associated with the terminal

represents

dt

the accumulated

spatial domain.

The

state,

cost

Hamiltonian

function

while

over

H

the

the

is

is

the

cost

second

term

entire

defined

time

as

and

before,

namely,

H[ X(y,t), aX/y

k(y,t), y, t, u(y,t), P(y,t)]

g[X(y,t), kX/y_ (y,t), u(y,t), y,t] +

P(y,t).f[X(y,t),

X/;y (yt),

(y,t), y, t]

(3.21)

The system equations

are adjoined

via spatially distributed costate

cost

function

Hamiltonian.

can

then

be

to

variables

expressed

The process time is assumed

though extension to a free

the

terminal

in

and

the

terms

of

the

be

is

first variation in J, namely 5J, is found by

function

P(y,t)

to

time

dent variations in the state, costate and

cost

fixed,

al-

possible.

The

taking

control

indepen-

variables,

and one then obtains the following necessary conditions:

aX/ t = H/P = f

(3.22)

36

_P/,t)

= -

H/ax - (-1 )k k/ yk

H/

(3.23)

x/[_1

and

H[X*(yt),

(DaX

v,y, t, _ (y,t)]

H[X*(y,t), (X/y*

Equation (3.24)

is

, y, t, u(y,t)]

the

general

form

(3.24)

for

the

global

minimization of the Hamiltonian. If the control vector u is

function of time

alone,

i.e.

u(y,t)=u(t),

then

the

a

above

condition reduces to

SH[X*(y,t), ( kX/ayk)*, y, t, u*(t)] dy

H[X*(yt), ( akX/y ),

y, t, u(t)]dy

(3.25)

Similarly, for u(y,t)=u(y), this reduces to

f H )kk),y,t, u (y)] dt

5

H[X_(yt),

(;k/ap*,

y, t, u(y)]

Note also that when u is unconstrained,

equal to zero for optimality,

(3.26)

t

H/au can be

either at each point

in the case

of equation (3.24), or over the entire spatial domain

time domain in the cases of

conditions

(3.25)

set

and

or

the

(3.26)

respectively. (Ray and Szekely, 1973)

The distributed components of the state

or its spatial derivatives

are

generally

variable

specified

vector

on

the

37

boundaries of y, and the initial state,X(y,to ) is

transversality

The

be completely known.

to

assumed

conditions

on

the

applied

to

the

costate variables evolve from the variations

state vector x. The end point conditions (t=tf) are given as:

P(y,tf) = C(y,tf)

The transversality

/ X(y,tf)

(3.27)

conditions on

the

y

of

boundaries

are

derived for the distributed costate variables as

ak-{

H /k

kx/yk]

=

}1 /

Equation (3.28) holds for

all

O

(3.28)

values

conditions for optimality, namely (3.22)

associated transversality conditions

t.

of

to

(3.27)

derived using the variational approach.

The

necessary

The

and

the

(3.28)

are

(3.24)

and

steps

detailed

involved in using this approach can be best illustrated for

particular problem at hand. This is shown in the next

a

chapter

for the problem of maximizing the nutrient retention of canned

foods during sterilization processes.

There have been a few

applications

of

the

distributed

maximum principle to chemical engineering processes.

Hahn

et

al. (1971) have computed an optimal start up policy for a plug

flow reactor wherein a first order, reversible and

reaction takes place. The distributed

maximum

exothermic

principle

was

also applied to the problem of catalyst deactivation by Ogunye

and Ray (1971) and by Gruyaert and Crowe (1974).

38

Nishida et al. (1976) have compared linear and

lumped models and distributed models, with

their

to problems in reaction engineering. They

have

nonlinear

application

considered

catalytic series reaction in a tubular, nonisothermal

where

the

control

catalyst

variable.

activity

This

is

appears

the

to

radially

the

only

a

reactor

distributed

example

of

bang-bang control as applied to a distributed system.

3.4 REMARKS

The

necessary

conditions

principle, namely equations

derived

(3.8)

to

using

(3.10)

the

or

maximum

(3.12)

to

(3.14) for lumped systems and equations (3.22) to

(3.24)

distributed systems,

optimality.

correspond

Actually, the first variation

in

only

J

to

local

yields

only

the

extremum of the cost function. By taking the second

local

variation

.2J, it can be shown that this extremum does correspond

local minimum. However, note that the global

for

to

minimization

a

of

the Hamiltonian does not imply global minimization of the cost

function over all values of u (Athans and

Falb,

1966).

Thus

more than one solution may be possible for the given system of

state and costate equations and the associated

transversality

conditions.

Some other observations are also in order. The

ian H is always minimized

as long

as

the

optimal

Hamiltonu

is

a

39

continous function. This may not occur, for

example,

switching points in bang bang control, since at

the contribution

is zero

of u to the Hamiltonian

these

at

the

points

irrespective

of the choice of u. Thus the Hamiltonian can not be extremized

at the singular points, which

frequently referred to as

is

bang-bang

why

suboptimal

control.

should be noted that the only difference between

and the minimum

principle

is

that

equation (3.14) or (3.24) must be

the

control

is

Further,

it

the

Hamiltonian

globally

maximized

maximum

in

the

rather

than minimized; other necessary conditions remain unchanged.

CHAPTER

4

MATHEMATICAL MODEL FOR MAXIMIZING NUTRIENT RETENTION

The main task in this chapter is to develop a

cal model for optimal control of

the

mathematiprocess.

sterilization

The system equations are cast in dimensionless form, and based

on the variational approach, a detailed proof is presented for

shown

the derivation of the optimality conditions. It is

how

policy.

the problem formulation leads to a bang-bang

control

The control must be modified when inequality

constraints

are

incorporated into state variables, such as a constraint on the

retort temperature. The resulting

policies

control

less optimal in such cases than those obtained with

will

be

fewer

or

no constraints.

4.1 MODEL FORMULATION

During the sterilization process,

heat

transfer

the can occurs primarily by conduction. This holds

or semi-solid foods for which the convection

for

currents

inside

solid

inside

the can are insignificant. Many of the liquid canned foods, on

the other hand, have pH less than 4.5, so

requirements for

these

foods

are

not

thermal processing the convective heat

40

that

severe.

transfer

sterilization

Also,during

coefficients

41

at the surface of a can are very high, thus

assume that the temperature at

the

can

enabling

surface

one

equals

to

the

retort temperature.

Heat conduction inside the can is governed by

the

equa-

tion,

, T(y',t')/

t = V2 T(y',t')

(4.1)

with appropriate boundary conditions on the time

and

spatial

domains. Thus,

T = T i at

t = 0

(4.2)

and, at the planes of symmetry

in the spatial domain, we have

'V T = 0

where

(4.3)

is the unit outward normal vector.

At the external boundaries of the spatial domain,

T = TR (t')

(4.4)

The retort temperature TR(t), which is the variable to be

controlled, affects the

system

behaviour

boundary condition (4.4). Denn et al.

only

(1966)

solutions to problems where the control may

through

have

operate

the boundaries. Here, however, we find it more

apply the minimum principle by transferring the

the

discussed

only

at

convenient

to

control

from

42

the boundaries to the system equations. For

this

a

purpose,

new variable T2 (y',t') is defined as follows:

T2(Y',t') = T(y',t') - TR(t')

(4.5)

The heat conduction equation is now modified to read

~T2(Y',t')/

t' = V 2 T 2 (y',t') - dTR/dt'

(4.6)

with the initial condition

2

= Ti -

TR(t'=O)

(4.7)

at t'=O

At the planes of symmetry, we have

_.VT

= 0

2

and at the boundaries

(4.8)

of y',

T2 = 0

(4.9)

This formulation transfers the problem inhomogeneity from

the boundary conditions to the differential

itself,

equation

and this can have some advantages in the eigenfunction

sion solution of the problem.

expan-

It is interesting to note

now the rate of change of retort temperature u',

or

should be considered as the control variable rather

that

dTR/dt',

than

the

concentrations

are

retort temperature itself.

The nutrient and the micro

governed by the equations,

organism

43

3C N

/

t' = - Ko,N.CN exp(-EN/RT)

(4.10)

= - KO,M.CM exp(-EM/RT)

(4.11)

and

CCM /

t

respectively. The initial conditions on the nutrient and micro

organism concentrations are:

(4.12)

CN = CNo at t'=O

and

(4.13)

CM = CMo at t'=O

respectively.

Table 4.1 describes

which appear

in

the

the

variables

formulation

of

and

system

the

parameters

equations.

In

dimensionless form, the system equations can be represented as

dX1

/ dt = u

X2 / at =

DX3 /

(4.14)

2X2 - u

(4-15)

t = - a 1.X 3 exp[-E/(X1 +X 2+1)]

X 4 / at = - a 2 .X4 exp[The initial

and

boundary

(4.16)

E/(XI

1+X 2 +I)]

conditions

(4.17)

on

the

variables are given as follows. At t=O, we have

dimensionless

44

TABLE 4.1: VARIABLES AND PARAMETERS FOR SYSTEM EQUATIONS.

Variables/Parameters.

Dimensional

Time

t'

Characteristic

Length

L

Space

y'

Temperature

T(y',t')

Retort Temperature

TR(t')

Initial Temperature

Ti

1

y =

Initial Nutrient

Concentration

CNo

Micro organisms

Concentration

C ('

Initial Micro org.

Concentration

CMo

Activation Energy

Nutrients, Micro org.

Ea

EN EM

X1=(TR

-

Ti)/ T i

0

t')

X 2 = (T - TR)/ T i

X 3 = CN/ CNo

1

t')

X 4 = CM/ CMo

1

E = Ea/RTi

= E /(X 1 +X 2 +l)

Exponential Term

Reaction Rate

Constants

'/ L

X1+X2

T - TR

C ('

L2

t =t'/

Temperature Difference

Nutrient Concentration

Dimensionless

K

a = KoL2/

Contd.

45

TABLE 4.1 (Continued)

Variables/Parameters

Rate of Change of

Retort Temperature

Dimensional

u'= dTR/dt'

Thermal Conductivity

oC

Ratio of Activation

Energies

F

Dimensionless

u = dXl/dt

= E /E

M N

46

X1

X2 =

X

3

(4.18a)

= X10

-

(4.18b)

X1 0

= 1

(4.18c)

= 1

(4.18d)

and

X

If the initial retort temperature

hotfill temperature of

the

is the

cans,

then

same

X10

as

will

the

inlet

be

zero.

Boundary conditions are required only for X2. At the planes of

symmetry,

Q.VX 2

(4.19)

= 0

and at the external

boundaries

of yI,

(4.20)

X2 =

The system is autonomous, i.e.

not

explicitly

dependent

on

time t. In shorthand notation, it can be represented as

ax/ at = f[x,

,

(4.21)

v 2 X2 ]

The objective is to maximize the nutrient retention

the entire can during sterilization.

minimizing the cost function J, where

This

is

equivalent

over

to

47

J = 9

(-

(4.22)

X3 ) dy dt

or

J =

5

t=o y

2 +1)]

fa 1 .x 3 exp[-E/(X+X

processes,

sterilization

In most

final

on the average

it

is

essential

micro

of

concentration

to

Then

level.

organism

achieve a specified reduction in micro

the constraint

(4.23)

dy dt

organisms can be described as

5x

(/V).

4

dy < C 1

(4.24)

Typical

where V is the dimensionless volume of the container.

values of C 1 may be in the range from 10- 5 to 10-10

.

4.2 OPTIMALITY CONDITIONS USING THE VARIATIONAL APPROACH

optimi-

The general form of the necessary conditions for

zing a

distributed

chapter. The aim in

system

this

was

presented

section

specific necessary conditions

for

will

in

to

be

maximization

the

previous

the

develop

of

nutrient

using

retention by considering the dynamics of the system and

the principles of variational calculus. One

dimensional

geometry is considered first to keep the mathematics

However, a logical extension to two and three

slab

simpler.

dimensions

can

be conveniently made. The spatial variable y has domain [0,1].

48

The Hamiltonian

H =

+

as

(4.25)

T f

where P(t) is

represents

and

H is defined

the

distributed

costate

variable

the right hand side of the system

is the

integrand

of

the

cost

vector,

equation

function

f

(4.21)

defined

by

equation (4.23). Hence the Hamiltonian can be written as

H = alX 3 exp[-E/(X 1+X 2+1)]

+ P 1 u + P 2(

D 2X 2 /

P 3 (-alX3 exp[-E/(X1+X 2+1)]) + P4 (-a2 X 4 exp[-

y2

_ u ) +

8E/(X1+X 2+1 )])

(4.26)

The state equations (4.14) to (4.17) are adjoined to

cost function via

the

costate

variable

vector

P

and

the

the

constraint on the final concentration of micro organisms via a

Lagrange multiplier

. The modified cost function can then be

written as

J

= [ SX4 dy - C1]t=tf +

+ P1 (u - dX1 /dt)

i

aX 3 exp[-E/(X1+X2+1)1

+ P2 ( a2X 2 / ay2 _ u -

+ P3 (-a 1 X3 exp[-E/(X 1+X2 +1)] + P4 (-a2 X4 exp[-.BE/(Xl+X 2+1)] -

2/

t)

X3 / )t)

X4 / at)

I dy dt

(4.27)

49

which can be expressed in terms of the Hamiltonian as

J = U [

S'

4

dy - C 1] t=tf +

f

§§[H- PT(

X/ a2t)] dy dt

(4.28)

In the following analysis, the process time tf is assumed

to be a predetermined factor having a fixed value, so that

no

variations in tf are considered. Then one can obtain the first

variation

in J by varying X, Xyys u and P. Thus

I

S

t

X 4 dy

I

I[[

t=tf +

o

_ ( sp)T(

$2X2/;y2

has only one

non

H/ aX+

(_p)T DH/ aP

O

T

+ ( Su) H/Du + ( i y)

Here Xy

X)T

H/Xyy

-

PTD( X)/ at

X/ at)] dy dt

zero

component,

(4.29)

namely

X2,yy

Note that

pT ( $x)/Dt =

[PT(

tX)/

- ( X)T DP/ t

(4.30)

Also, consider the terms

)[( X2) ( H/aX2 ,yy)/?y]/

[ ( DH/

2,yy)/y] + (

ay = [

2)

( SX2 )/ ay].

2

(9H/ X2,yy)/&Y

The first term on the right hand side of equation

be expressed by using another variational relation

(4.-31)

(4.31)

can

50

[ 11(

X2)/ ay]

I Z3(

D ( L20H/ 2)

-')X2,yy) / ..)Y

; ( Sx2)/ sy] /ay

.H/

( 'SX2, yy)

Combining equations (4.31) and

X2, yy

and

(4.32)

2, yy

(4.32)

rearranging,

one

obtains

(

X2,yy)

(

X2 ) 2 ( ?H/ aX2,yy

DH/ aX2,yy

'a ()H/

;IX2,

y)

.

a( Cx2)/ y] / s +

a[ ( Sx2) . ( aH/ ax2,yy) /y]

/) ;Iy

/ ay

(4-33)

The expressions given by equations (4.14) and (4.17)

incorporated into the variation

SJ

of

are

(4.29)

equation

to

obtain

tF

SJ=

> SX

4

dy'

t=tf

+

(

D

+ (u)

H/ u +

[(

H/

)Tp/ at -

aPT( S]/

+ ( PT

H/ a P

$

2,y)

( (x2)a2( H/ x:I

2, yy V a 2

+ (

aH/

)

D(

SX2 ) / a;Y]/'"

+

1. ) ;)(2a / DX2,

yy)/ ar/

t

(

pT(

DXI at)

I

aI

dydt

(4-34)

For the first variation in J to be zero, the coefficients

of the independent variations,

( P) , ( X) and

u must be

zero, which leads to the following necessary conditions:

D X/ aIt =

H/

P = f

(4-35)

51

aP/at

y2

- 2( H/I

a6)/

/

-

(436)

(4.37)

H/ au = O

and

The second

term on the right hand

namely 2(

H/

side

equation

_Xyy)/ay2 is non zero only

X 2. Also, strictly speaking, equation

only if the variations in u

constrained

of

domain

are

for

(4.37)

allowed

to

the

will

be

since u is a

for u. Secondly,

variable

valid

be

within

the

function

of

(3.25)

will

apply. i.e. since the control variable u does not change

over

of

time alone, a necessary condition

the

type

(4.36),

the spatial domain of y, the Hamiltonian H need

be

minimized

only over the entire domain of y at any time t, rather than at

each point in y. This means that equation (4.37)

will

modify

to

{

S Hdy}/u'(-H/=

(4.38)

u) dy = 0

o

S

or more generally,

H[X*(y,t),

( 2

y2)* ,y,

(t)] dy<

t,

S[I(yt),,( ;X2/Qy2)

,

y, t,u(t)]dy

Next, note that the Hamiltonian as defined by equation

(4.39)

(4.26)

is linear in the control variable u, so that

BH /

u = ( P1 - P2 )

(4.40)

52

The equation (4.38) cannot yield an optimal value of

aH/au is independent of

policy

is required.

u,

and

hence

The constraint

on

a

u

bang-bang

the

rate

since

control

of

rise

of

retort temperature, u, will be of the type

(4.41)

Umin < u < Umax

where umax corresponds to the maximum rate of heating and Umin

corresponds

to the minimum

rate of heating

(maximum

rate

of

cooling). The desired control policy will then be of the form

u = umax if

SD

/H u dy =

and u = Umin if

H /u

S(P1-P2) dy < 0

dy =

§P1-P2)

dy > 0 (4.42)

Switching(s) in the control will occur at point(s)

term I

where

I =2(P1-P 2 ) dy] is equal to zero. For the existence

the

of

a singular arc, the term I must remain zero continously over a

certain time period. This will be

discussed

in

some

detail

later.

It is readily demonstrated that the Hamiltonian

minimized

only

over

the

entire

(4.39)] and not at each individual

spatial

domain

need

[equation

point in the domain

Consider for example, a spatial discretization of

be

the

of

y.

system

equations (4.14) through (4.17). At each time interval a given

partial differential equation is converted into

a

coupled

the

ordinary

differential

equations.

If

number

of

minimum

53

principle developed in the preceding

chapter

is

applied

this new, lumped model, an equivalent optimal control

found. The Hamiltonian at each time interval will be

of contributions from

each

ordinary

differential

Thus the condition for the global minimization of

to

can

the

be

sum

equation.

Hamiltonian

will indeed yield equation (4.39) as the number of discretizations goes to infinity.

The transversality conditions are obtained by setting the

remaining terms in equation (4.34) for

SJ to zero.

Thus

one

obtains

[

4

dX

dYt

f

f

t

[

(x)

I'

X)dy]

-

e4

+

b

Cc~H/

(

H/

X 2,). (

2x

)dt]

X2 )/ y

dt

= o

(4.43)

C

Terms inside each of the square brackets must be

zero,

which

leads to

P1 (tf) =

(4-44a)

P 2 (tf) = 0

(4.44b)

and

P 3 (tf) = 0

(4.44c)

Also, P4 (tf) = V

(4.45)

54

Since X is specified at t=O, ( X)

Note that

'y= O at

X2 /

is uniformly zero

y = O and X 2 = 0 at y =

1

at

t=O.

so

that

the transversality conditions on P2 become

X2,yy

DH/

a (

H/

= P2

= 0

at y = 1

a2, yyP = y

/

(4.46)

= 0 at y = 0

2

(4 47)

Note also that the first necessary condition, equation (4.35),

gives back the system state equations. The governing equations

for each of the costate variables are:

aP1

/

t = -

(1-P 3 ).a1 X 3 exp[-E/(X1 +X 2+1)]. E/(X1+X 2+1) 2 +

p4.a2 .X 4 exp[-BE/(X 1+X

aP2 / at

=-

2

1 )].

BE/(X

1 +X2 +1

)2

(4.48)

(1-P3 ).a 1 .X 3 . exp[-E/(X1 +X 2+ )]. E/(X 1+X 2+1) 2 +