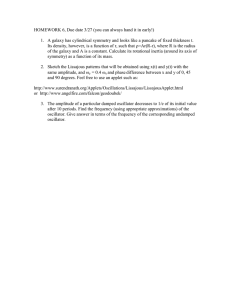

Force Multiplier in a Microelectromechanical

advertisement