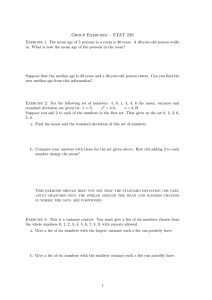

Graduate Lectures and Problems in Quality Control and Engineering Statistics:

advertisement