IEOR 165 Discussion 3 February 20, 2015

advertisement

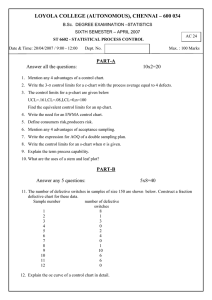

IEOR 165 Discussion 3 February 20, 2015 Question 1. Suppose that when a process is in control each item will be defective with probability .04. Suppose that your three sigma (z1−α/2 = 3) control chart calls for taking daily samples of size 500. What is the probability that, if the probability of defective item should suddenly shift to .08, your control chart would detect this shift on the next sample? Question 2. The following data present the number of defective bearing and seal assemblies in samples of size 100. Does it appear that the process was in control throughout? If not, determine revised control limits if possible. 1 Solution 1. X is the number of defective items in a subgroup of n items F = X/n is the fraction of the subgroup that is defective X ∼ Binom(n, p) However if n is large we can approximate X by N (np, np(1 − p)) F ∼ N (E[X/n], V ar(X/n)) ∼ N (p, p(1 − p)/n)) p = 0.04 n = 500 r r p(1 − p) 0.04(0.96) = 0.04 − 3 = 0.014 LCL = p − 3 n 500 r r p(1 − p) 0.04(0.96) U CL = p + 3 = 0.04 + 3 = 0.066 n 500 Then for X, LCL = 500(0.014) = 6.85, U CL = 500(0.066) = 33.15. If p0 = 0.08, X ∼ Binom(500, 0.08) since n is large X ∼ N (500(0.08), 500(0.08)(0.92)). P (detect|p0 = 0.08) ≈ P (X ≥ 34) = 1 − P (X ≤ 33) = 0.86 Solution 2. k = 20 n = 100 p is unknown Estimate of p is given by 89 X1 + X2 + ... + Xn = = 0.0445 kn 20 · 100 r r F̄ (1 − F̄ ) 0.0445(0.9555) LCL = F̄ − 3 = 0.04 − 3 = −0.017 → 0 n 100 r r 0.0445(0.96) F̄ (1 − F̄ ) U CL = F̄ + 3 = 0.04 + 3 = 0.106 n 100 Then for X, LCL = 0 and U CL = 10.6. Thus no more than 10 defectives in a sample. All samples satisfy this condition. The process was in control throughout. No need to revise the control limits. F̄ = 2