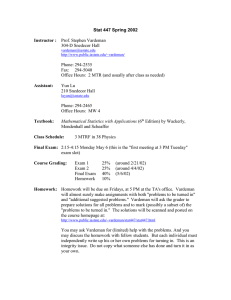

Process Capability Measures and Their Estimation (Section 5.2 of Vardeman and Jobe) 1

advertisement

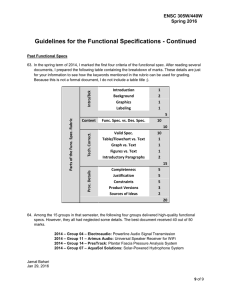

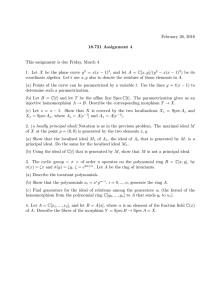

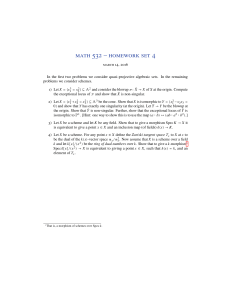

Process Capability Measures and Their Estimation (Section 5.2 of Vardeman and Jobe) 1 “Capability” Measures • Where a process is stable and normal, what it will do can be described by two numbers, µ and σ • Where in addition, there are engineering specifications, L and U, (i.e. I want L<x<U in order to have product functionality) there is sometimes pressure to invent further onenumber summaries 2 “Process Capability” • Most of a normal distribution is within 3 standard deviations of its mean • So 6σ is a reasonable measure of (normal) process capability 3 Process Capability Ratio ( C p ) • With (two-sided) specifications, it is perhaps sensible to compare their spread to 6σ and to create a measure of “process potential” to meet them, C = U − L p 6σ – C p = 1 means that (with perfect aim!) most of process output will meet spec.s – C p < 1 means that (even with perfect aim) a substantial part of process output will be out of spec. – C p > 1 means there is some room for mis-aim 4 C pk • This is a measure, not of process potential, but of current performance (it involves µ ) U − µ µ − L C pk = min , 3σ 3σ L • This is “the number of 3σ 's that µ is to the good side of the nearest spec.” C pk = 1 C pk = −1 U U 5 How to Evaluate These? • Clearly it must be done on the basis of process data … point (single number) estimates are: – 6s for process capability – Cˆ p U −L = 6s U − x x − L ˆ – C pk = min , 3s 3s • We had better keep in mind that x and s vary 6 Simulated Example • Suppose L=0, U=10, µ = 7 and σ = 1 so that 6σ = 6, C p = 1.67 and C pk = 1.00 • (200) samples of size n=30 produce estimates: 7 “Confidence Limits” Take Account of This Variation • Limits on 6σ are (display (5.5)) n −1 n −1 6s and/or 6s 2 2 χ upper χ lower (the χ quantiles come from Table A.7 or a statistical package) 2 • Corresponding limits on C p are U −L χ U −L χ and/or 6s n −1 6s n −1 2 lower 2 upper 8 More Confidence Limits • An approximate lower confidence limit on C pk is (display (5.10)) Cˆ pk − z 2 ˆ C pk 1 + 9n 2n − 2 (actually, an upper limit can also be had by replacing the minus sign with a plus above) – e.g. use z=1.645 to be approximately 95% sure that the real C pk is above the limit 9 Example 5.5 • Angles of n=50 holes drilled by EDM had x = 44.117 and s = .983 • Spec.s were 45 ± 2 so – 6s=5.898 4 ˆ – Cp = = .678 5.898 – Cˆ pk = .38 but how good are these values? • Find confidence limits 10 Example 5.5 continued • Minitab was used to find χ quantiles for ν = n − 1 = 49 d.f. and then 90% limits for 6σ are (from display (5.5)) 2 50 − 1 50 − 1 6(.983) and 6(.983) , i.e. 66.34 33.93 5.07 and 7.09 • Corresponding limits for C p are 4 4 and , i.e. .56 and .79 7.09 5.07 11 Example 5.5 continued • A 95% lower confidence bound for C pk is 2 .38) ( 1 .38 − 1.645 + = .28 9(50) 2(50) − 2 • Notice that even a sample size of n=50 leaves a fair amount of uncertainty in the estimation of capability figures 12 Workshop Exercise • For L=0, U=10, n=30, find 6 s, Cˆ p and Cˆ pk for one of the simulated ( x , s ) pairs below (that Vardeman generated in the making of the figures on slide 7) 7.30687 7.05134 7.10610 6.78466 6.94911 7.20956 7.02438 6.58039 7.15414 6.89519 1.09556 0.98880 1.01570 0.97536 1.04932 1.07948 1.00874 1.02006 0.99741 1.03046 13 Workshop Exercise • For your ( x , s ) pair from the previous slide, plug into limits 30 − 1 30 − 1 6s and 6s 42.557 17.708 to get a 90% confidence interval for 6σ • Find corresponding limits for C p • For your ( x , s ) pair, find a 95% lower confidence limit for C pk 14