Radial A theoretical analysis Xiao , Hong-Ping Zhao

advertisement

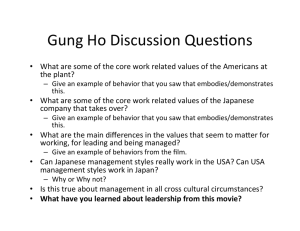

International Journal of Solids and Structures xxx (2015) xxx–xxx Contents lists available at ScienceDirect International Journal of Solids and Structures journal homepage: www.elsevier.com/locate/ijsolstr Radial wrinkles on film–substrate system induced by local prestretch: A theoretical analysis Xiao Huang a, Hong-Ping Zhao a, Wei-Hua Xie a, Wei Hong b, Xi-Qiao Feng a,c,⇑ a Institute of Biomechanics and Medical Engineering, AML, Department of Engineering Mechanics, Tsinghua University, Beijing 100084, China Department of Aerospace Engineering, Iowa State University, Ames, IA 50011, USA c Center for Nano and Micro Mechanics, Tsinghua University, Beijing 100084, China b a r t i c l e i n f o Article history: Received 26 May 2014 Received in revised form 22 November 2014 Available online xxxx Keywords: Radial wrinkle Film–substrate structure Hankel transform Theoretical model a b s t r a c t Local wrinkles are widely observed in film–substrate systems both in nature and in engineering. In this paper, we investigate the surface wrinkling of a film–substrate structure subjected to local prestretch in a circular region. Hankel transform is used to unravel the interface condition between the stiff film and the compliant substrate. The critical prestrain and the corresponding wrinkling number are solved as functions of the radius of the prestretched region and the Young’s modulus ratio between the film and substrate. The theoretical analysis is validated by a semi-implicit numerical method based on the Fourier spectral technique. The postbuckling behavior is also simulated via the numerical method. It is found that during postbuckling, the surface wrinkles may experience a secondary bifurcation and evolve into branching patterns. Ó 2014 Elsevier Ltd. All rights reserved. 1. Introduction The issue of surface wrinkling has attracted much attention in the past decades because of its technological significance in, for instance, stretchable or flexible electronic devices (Kim and Rogers, 2008), film metrology (Stafford et al., 2004), surface topography (Cai et al., 2011), medical engineering (Li et al., 2012), and colloidal crystal assemblies (Efimenko et al., 2005). Besides, surface wrinkling frequently occurs in biological tissues and systems with normal and morbid physiological processes, e.g., scar contraction (Cerda, 2005; Flynn and McCormack, 2008), skin corrugation (Genzer and Groenewold, 2006), mucosal morphogenesis (e.g., esophagus, airway, and stomach) (Li et al., 2011; Moulton and Goriely, 2011), and fruit shrinkage (Yin et al., 2008). For a stiff film lying on a compliant substrate subjected to compressive strain beyond a critical value, the system may buckle into various surface patterns, e.g., stripes, checkerboards, hexagons, herringbones, etc. (Cai et al., 2011; Cao et al., 2012; Chen and Hutchinson, 2004; Cheng et al., 2014; Huang et al., 2005; Li et al., 2010; Song et al., 2008). The wrinkling mode in a specific system depends on its geometric and material parameters, external loads, and boundary conditions. ⇑ Corresponding author at: Institute of Biomechanics and Medical Engineering, AML, Department of Engineering Mechanics, Tsinghua University, Beijing 100084, China. Tel.: +86 10 62772934; fax: +86 10 62781824. E-mail address: fengxq@tsinghua.edu.cn (X.-Q. Feng). In recent years, much effort has been directed toward understanding various wrinkling phenomena in freestanding thin films and film–substrate systems, including surface wrinkling induced by local loads or differential volume growth/shrinkage (Cerda, 2005; Chung et al., 2009; Coman and Bassom, 2007; Coman and Liu, 2013; Flynn and McCormack, 2008; Géminard et al., 2004; Qiao et al., 2013). Take eye wrinkles as an example. Human skin is comprised of a thin epidermis resting on top of a thick and much softer dermis layer (Genzer and Groenewold, 2006) and, therefore, it can be modeled as a stiff film–compliant substrate system. The appearance of eye wrinkles with aging is primarily due to the differential volumetric growth/shrinkage and elastic modulus variations of epidermis and dermis. Among various types of surface patterns, radial wrinkles have recently attracted much attention. Géminard et al. (2004) conducted an experiment in which the center of an elastic disc is sucked into a small ring, generating radial wrinkles around the inner ring when the suction is beyond a critical value. On the basis of experiments, Cerda (2005) established a scaling model to investigate the local wrinkling of skin due to scar contraction, with the influence of underlying supporting dermis neglected. Coman and Bassom (2007) performed numerical simulations and asymptotic analysis to study the radial wrinkling of an annular thin film without substrate in tension. They elucidated the exponential decay of wrinkles by using the Wentzel–Kramer–Brillouin theory (Coman and Haughton, 2006). Wang et al. (2014) studied, both experimentally and theoretically, the local surface wrinkling of a thin film on a compliant substrate subjected to surface torsion. They http://dx.doi.org/10.1016/j.ijsolstr.2014.12.011 0020-7683/Ó 2014 Elsevier Ltd. All rights reserved. Please cite this article in press as: Huang, X., et al. Radial wrinkles on film–substrate system induced by local prestretch: A theoretical analysis. Int. J. Solids Struct. (2015), http://dx.doi.org/10.1016/j.ijsolstr.2014.12.011 2 X. Huang et al. / International Journal of Solids and Structures xxx (2015) xxx–xxx found that each spiral wrinkle has the shape of an Archimedean spiral curve. Besides, an elastic sheet floating on a fluid may buckle due to the capillary force at the solid–liquid contact line, referred to as elastocapillary buckling (Huang et al., 2007; Liu and Feng, 2012; King et al., 2012; Toga et al., 2013; Vella et al., 2010). Radial wrinkles often occur in biological tissues and engineering structures. However, the critical condition for the occurrence of radial wrinkles and their morphological evolution of film– substrate systems remains unclear. In this paper, therefore, we will investigate, through theoretical analysis and numerical simulations, the local radial wrinkling of a thin stiff film lying on an infinite compliant substrate engendered by a prestretch in a circular region. The layout of this paper is as follows. In Section 2, we develop a theoretical model to analyze the critical radial buckling behavior of a film–substrate structure. Hankel transform technique is introduced to account for the effect of elastic interaction between the film and the substrate. In Section 3, a semi-implicit numerical algorithm is utilized to calculate the morphological evolution and validate the theoretical model. The results are given in Section 4, where two important features of the normalized radius of the prestretched area and the film/substrate modulus ratio are discussed. Besides, a curve-fitting analysis is made to simplify the theoretical results and a postbuckling simulation is further conducted when the prestretch is beyond the critical value. Finally, Section 5 gives the conclusions drawn from this study. e0 ð1 þ v f Þ r0 2 efrr ¼ 2 r frr ¼ Ef e0 r 0 2 ; 2 r r ; efhh ¼ r fhh ¼ e0 ð1 þ v f Þ r0 2 2 Ef e0 r 0 2 ; 2 r r ; efrh ¼ 0; r frh ¼ 0: ð2Þ ð3Þ When the prestrain exceeds a critical value, the film would buckle into an actinomorphic morphology. Here it is assumed that the wrinkling wavelength is much larger than the amplitude, so that the von Kármán nonlinear elastic plate theory can be applied to describe the deformation of the film (Landau and Lifshitz, 1959). Let wf denote its deflection in the z direction, ufr and ufh the in-plane displacements in the r and h directions, respectively. Then the total fr þ ubr , ufh ¼ u fh þ ubh , and displacements can be decomposed as ufr ¼ u f þ wb , where ubr , ubh , and wb represent the additional diswf ¼ w placement due to buckling in the r, h, and z directions, respectively. In the polar coordinate system (r; h), the strains efab in the film can be expressed as efrr ¼ 2 @ufr 1 @wf þ ; @r 2 @r 2 1 @ufh ufr 1 @wf þ þ 2 ; r @h r 2r @h 1 1 @ufr @ufh ufh 1 @wf @wf : ¼ þ þ 2 r @h r @r @h @r r efhh ¼ efrh ð4Þ 2. Theoretical analysis Using Hooke’s law and Eq. (4), the membrane forces in the film can be obtained as 2.1. Model h i f h ð1 v f Þef þ v f ef dab ; Nab ¼ E ab cc ð5Þ Consider a stiff thin film of thickness h, perfectly bonded to a compliant semi-infinite elastic substrate. In a circular area of radius r 0 , the film has a homogeneous prestretch with equal-biaxial strain e0 . This model can mimic such film–substrate systems as skin with local strain induced by different reasons, e.g., differential growth in scar. Refer to a cylindrical coordinate system (r; h; z), as shown in Fig. 1, where the origin O is located at the center of the prestretched region, and the r and h axes are along and normal to the radial direction, respectively. Both the film and the substrate are assumed to be linear elastic and isotropic, with Young’s moduli Ef and Es , and Poisson’s ratios v f and v s , respectively. When the prestrain e0 reaches a critical value, the region outside the prestretched area may wrinkle into a radial or spoke-like morphology because the maximal compressive stress is along the circumferential direction. The unbuckled state of the system under the given prestrain e0 is axisymmetric and taken as the reference configuration. The corresponding displacements in the film outside the prestretched area (r P r0 ) are fr ¼ u e0 ð1 þ v f Þr20 2r fr , u ; fh ¼ w f ¼ 0; u ð1Þ fh , u f denote the radial, circumferential, and out-ofwhere and w plane displacements, respectively. The corresponding strains and stresses can be written as z r0 Prestrain ε 0 O θ Stiff film r where Ef ¼ Ef =ð1 v 2f Þ is the plane-strain elastic modulus of the film and dab is the Kronecker delta. Einstein summation convention is adopted for repeated Greek indices, which take the values of 1 (or r) and 2 (or h). 2.2. Three-dimensional solution of film–substrate interaction at the radial wrinkling state The interaction between the thin film and the substrate plays a significant role in the wrinkling of the system. In this study, the effect of shear stresses at their interface will be taken into account. However, this problem is mathematically complicated, involving three-dimensional and non-axisymmetric wrinkling deformations of the film and the substrate. In what follows, we introduce the Hankel transform to solve this problem. Let T r and T h denote the shear stresses and T z denote the normal stress at the film–substrate interface. Then the equilibrium equations of the film are expressed as @Nrr 1 @Nrh 1 þ þ ðNrr N hh Þ; r @h r @r @Nrh 1 @Nhh 2 Th ¼ þ þ Nrh ; r @h r @r 3 h E @wf 1 @wf @ 2 wf f 4 f Tz ¼ r w þ Tr þ Th þ Nrr 12 @r @r 2 ! r @h ! 2 f 2 f f 1@ w 1 @w 1 @ w 1 @wf þ 2Nrh þ þ Nhh 2 ; r @r@h r 2 @h r @h2 r @r Tr ¼ ð6Þ where h Compliant substrate ! @ 4 wf 2 @ 3 wf 1 @ 2 wf @ 4 wf r w ¼ 4 þ 2 2 r @r 3 r @r @r 2 @r 2 @h2 ! ! 1 @wf @ 3 wf 1 @ 2 wf @ 4 wf þ þ 3 2 4 þ r r4 @r @r@h2 @h2 @h4 4 f ð7Þ Fig. 1. A stiff film resting on a compliant substrate. The film has a uniform biaxial prestretch in the circular area. Please cite this article in press as: Huang, X., et al. Radial wrinkles on film–substrate system induced by local prestretch: A theoretical analysis. Int. J. Solids Struct. (2015), http://dx.doi.org/10.1016/j.ijsolstr.2014.12.011 3 X. Huang et al. / International Journal of Solids and Structures xxx (2015) xxx–xxx is the bi-harmonic operator in the polar coordinate system. The equilibrium equations and the constitutive relations of the substrate read @ rrr 1 @ rrh @ rrz 1 þ þ þ ðrrr rhh Þ ¼ 0; r @h r @r @z @ rrh 1 @ rhh @ rhz 2 þ þ þ rrh ¼ 0; r @h r @r @z @ rrz 1 @ rhz @ rzz 1 þ þ þ rrz ¼ 0; @r @z r @h r 0 ð8Þ @u 1 @uh ur þ ks S; rrr ¼ 2Gs r þ ks S; rhh ¼ 2Gs þ r @h @r r @w 1 @ur @uh uh ; rzz ¼ 2Gs þ ks S; rrh ¼ Gs þ @z r @h @r r @w @ur @uh 1 @w ; rhz ¼ Gs ; rrz ¼ Gs þ þ @r r @h @z @z ð9Þ f ðz; rÞrJ n ðnrÞdr; 0 1 ð14Þ ~f hni ðz; nÞnJ ðnrÞdn; n ~ hnþ1i @2u p ~ hnþ1i n2 u p @z2 ! ðks þ Gs Þn~Sshni ¼ 0; ! ~ hn1i @2u q 2 hn1i ~ þ ðks þ Gs Þn~Sshni ¼ 0; n u q @z2 ! hni ~ hni @2w @ ~Ss s 2 hni ~ w n ¼ 0; þ ðks þ Gs Þ s 2 @z @z ð15Þ @w ~ hni s ~Shni ¼ n u ~ phnþ1i u ~ hn1i ; þ s q 2 @z respectively. By applying the Hankel transform to the constitutive relation in Eq. (9), in conjunction with Eq. (15), we can derive the displacements and stresses in the Hankel space as ks þ Gs zðC 3 enz þ C 4 enz Þ; 2Gs ks þ Gs ~nþ1 ¼ C 5 enz þ C 6 enz þ zðC 3 enz C 4 enz Þ; u p 2Gs ks þ 3Gs ks þ 3Gs ~hn1i u ¼ 2C 1 þ C 5 C 3 enz 2C 2 C 6 þ C 4 enz q Gs n Gs n ks þ Gs zðC 3 enz C 4 enz Þ; 2Gs ks þ Gs enz T~ hnþ1i ¼ G nðC C Þ þ C s 1 5 3 p 2 ks þ Gs þ Gs nðC 2 þ C 6 Þ C 4 enz 2 ~ ns ¼ C 1 enz þ C 2 enz w uh ¼ uhs ðz; rÞ sinðnhÞ; w ¼ ws ðz; rÞ cosðnhÞ; S ¼ Ss ðz; rÞ cosðnhÞ; ð10Þ rrz ¼ rrzs ðz; rÞ cosðnhÞ; rhz ¼ rhzs ðz; rÞ sinðnhÞ; rzz ¼ rzzs ðz; rÞ cosðnhÞ: Substituting Eq. (10) into Eqs. (8) and (9) leads to urs þ 2nuhs @Ss þ ðks þ Gs Þ Gs r2n urs ¼ 0; r2 @r uhs þ 2nurs nSs ðks þ Gs Þ ¼ 0; Gs r2n uhs r2 r @Ss ¼ 0; Gs r2n ws þ ðks þ Gs Þ @z @urs urs nuhs @ws Ss ¼ þ þ þ ; @r r r @z 2 2 ð11Þ þ ðks þ Gs ÞnzðC 3 enz þ C 4 enz Þ; 3ks þ 7Gs nz T~ hn1i ¼ G nð3C þ C Þ C s 1 5 3 e q 2 3ks þ 7Gs þ Gs nð3C 2 C 6 Þ þ C 4 enz 2 ðks þ Gs ÞnzðC 3 enz þ C 4 enz Þ; 2 @ where the operator r2n ¼ @r@ 2 þ 1r @r@ nr2 þ @z 2. For simplicity, introduce the following intermediate variables uq ¼ urs uhs ; T q ¼ rrzs rhzs : ð1 þ 2nÞup @Ss nSs þ ðk ¼ 0; Gs r2n up þ G Þ s s r2 @r r ð13aÞ ð2n 1Þuq @Ss nSs þ ðk ¼ 0; Gs r2n uq þ þ G Þ þ s s r2 @r r ð13bÞ @Ss ¼ 0; @z @ðup þ uq Þ up þ uq nðup uq Þ @ws Ss ¼ þ þ þ : 2@r 2r 2r @z hni ~ zzs r ¼ ð2Gs nC 1 Gs C 3 Þenz ð2Gs nC 2 þ Gs C 4 Þenz ðks þ Gs ÞnzðC 3 enz C 4 enz Þ: ð16Þ ð12Þ Substitution of Eq. (12) into (11) yields Gs r2n ws þ ðks þ Gs Þ Gs Gs ur ¼ urs ðz; rÞ cosðnhÞ; T p ¼ rrzs þ rhzs ; 1 respectively, where Jn ðnrÞ is the nth Bessel function. From the (n + 1)th and (n–1)th-order Hankel transform of Eqs. (13a) and (13b), and the nth-order Hankel transform of Eqs. (13c) and (13d), one obtains Gs where ur , uh , and w are the displacements of the substrate in the r, h, and z directions, respectively, rij (i; j ¼ r; h; z) are the stresses, Gs is the shear modulus, ks ¼ 2Gs v s =ð1 2v s Þ is the first Lamé’s constant, r h and S ¼ @u þ urr þ 1r @u þ @w is the volumetric strain. @r @h @z When the film buckles into n radial wrinkles along the r axis, the displacements and stresses in the underlying substrate can be expressed as up ¼ urs þ uhs ; ~f hni ðz; nÞ ¼ Z f ðz; rÞ ¼ Z ð13cÞ The coefficients C i (i ¼ 1–6) need to be determined from the top and bottom boundary conditions of the substrate. It is known from Eq. (16) that when the substrate is incompressible (i.e., v s ¼ 0:5), the constants C 3 ¼ C 4 ¼ 0. This indicates the decoupling between the in-plane and out-of-plane components at the interface, in accord with the solution in the Cartesian coordinate system (Mei et al., 2011). At the perfectly bonded interface, the film and the substrate have continuous displacements in all directions. Assume that the film has a perturbation of displacements in the following form: ubr ¼ urm f ðrÞ cosðnhÞ; ð13dÞ We use the Hankel transform to solve the above differential equations in the cylindrical coordinate system. The nth-order Hankel transform and its inversion are defined as (Sneddon et al., 1972) ubh ¼ uhm f ðrÞ sinðnhÞ; ð17Þ b w ¼ wm gðrÞ cosðnhÞ; where urm , uhm , and wm are small amplitudes of the corresponding displacements. The functions f ðrÞ and gðrÞ define the profile of the Please cite this article in press as: Huang, X., et al. Radial wrinkles on film–substrate system induced by local prestretch: A theoretical analysis. Int. J. Solids Struct. (2015), http://dx.doi.org/10.1016/j.ijsolstr.2014.12.011 4 X. Huang et al. / International Journal of Solids and Structures xxx (2015) xxx–xxx wrinkled morphology along the r axis and will be obtained approximately by considering the results from numerical simulations, as described below. Now we solve the interaction between the film and the substrate induced by perturbation. For a semi-infinite substrate, the boundary conditions read 8 8 > < ur jz¼0 ¼ urm f ðrÞ cosðnhÞ; > < ur jz¼1 ¼ 0; uh jz¼0 ¼ uhm f ðrÞ sinðnhÞ; uh jz¼1 ¼ 0; > > : : wjz¼0 ¼ wm gðrÞ cosðnhÞ; wjz¼1 ¼ 0: ð18Þ Then the unknown constants are obtained as C 1 ¼ wm Z 1 gðsÞsJ n ðnsÞds; Z nð1 2v s Þurm 1 f ðsÞs½J nþ1 ðnsÞ J n1 ðnsÞds C3 ¼ 3 4v s 0 Z 1 nð1 2v s Þuhm þ f ðsÞs½J nþ1 ðnsÞ þ J n1 ðnsÞds 3 4v s Z0 1 2nð1 2v s Þwm gðsÞsJ n ðnsÞds; þ 3 4v s Z 1 0 C 5 ¼ ðurm þ uhm Þ f ðsÞsJ nþ1 ðnsÞds; 0 ð19Þ 0 C 2 ¼ C 4 ¼ C 6 ¼ 0: Combining Eqs. (18), (19) and the inversion of the Hankel transform of Eq. (16), we can finally obtain the shear stresses and the normal stress at the interface as 0 1 0 1 T r = cosðnhÞ urm B C B C @ T h = sinðnhÞ A ¼ K@ uhm A; T z = cosðnhÞ ð20Þ wm 2.3. Linear perturbation analysis On the basis of the above solution, we now perform a linear perturbation analysis of critical buckling. Let n denote the number of wrinkles along the circumferential direction. The corresponding perturbation of displacements is expressed by Eq. (17). Castigliano’s first theorem is employed to determine the critical condition for the onset of buckling. At the wrinkled state, the elastic strain energy in the film outside the circular area contains two parts, namely, the membrane energy U m and the bending energy U b , which correspond to the in-plane and out-of-plane deformations, respectively. They are calculated by Z 1 Z 2p n h io Ef h 2 2 Um ¼ ðefrr þ efhh Þ þ2ð1 v f Þ ðefrh Þ efrr efhh dhdr; ð22Þ 2 2ð1 v f Þ r0 0 8 !2 Z 1 Z 2p < 2 f 3 Ef h @ w 1 @wf 1 @ 2 wf þ þ 24ð1 v 2f Þ r0 0 : @r 2 r @r r 2 @h2 2 !2 ! !39 1 @wf 1 @ 2 wf @ 2 wf 1 @wf 1 @ 2 wf 5= þ2ð1 v f Þ4 2 þ dhdr: ð23Þ ; r @h r @r@h r @r r 2 @h2 @r 2 Ub ¼ Using Castigliano’s first theorem, in conjunction with Eq. (20), we can obtain the equilibrium equations of the film in the three directions as Z 1 Z 2p @ðU b þ U m Þ þ ðK 11 urm þ K 12 uhm þ K 13 wm Þf ðrÞcos2 ðnhÞdhdr ¼ 0; @urm r0 0 Z 1 Z 2p @ðU b þ U m Þ 2 þ ðK 21 urm þ K 22 uhm þ K 23 wm Þf ðrÞsin ðnhÞdhdr ¼ 0; @uhm r0 0 Z 1 Z 2p @ðU b þ U m Þ þ ðK 31 urm þ K 32 uhm þ K 33 wm ÞgðrÞcos2 ðnhÞdhdr ¼ 0: @wm 0 r0 ð24Þ where K is a 3 3 stiffness matrix. Its components are given by K 11 ¼ K 12 ¼ K 13 8ð3 þ v s þ 4v 2Þ s 8ð3 þ v s þ 4v 2s Þ K 22 ¼ K 23 ¼ K 31 ¼ 8ð3 þ v s þ 4v 2Þ s 8ð3 þ v s þ 4v 2Þ s 1 Z 1 Z 1 Z Es ð1 2v s Þ 2ð3 þ v s þ 4v 2s Þ Z f ðsÞsn2 J n1 ðnrÞ ð7 8v s ÞJ n1 ðnsÞ þ J nþ1 ðnsÞ J nþ1 ðnrÞ J n1 ðnsÞ þ ð7 8v s ÞJ nþ1 ðnsÞ dsdn; 1 gðsÞsn2 J n ðnsÞ J nþ1 ðnrÞ J n1 ðnrÞ dsdn; 1 f ðsÞsn2 J n1 ðnrÞ ð7 8v s ÞJ n1 ðnsÞ J nþ1 ðnsÞ þ J nþ1 ðnrÞ J n1 ðnsÞ ð7 8v s ÞJ nþ1 ðnsÞ dsdn; 1 f ðsÞsn2 J n1 ðnrÞ ð7 8v s ÞJ n1 ðnsÞ J nþ1 ðnsÞ J nþ1 ðnrÞ J n1 ðnsÞ þ ð7 8v s ÞJ nþ1 ðnsÞ dsdn; 0 1 Z 0 1 0 Z 1 gðsÞsn2 J n ðnsÞ J nþ1 ðnrÞ þ J n1 ðnrÞ dsdn; 1 f ðsÞsn2 J n ðnrÞ J nþ1 ðnsÞ J n1 ðnsÞ dsdn; 0 1 0 Z 1 0 0 Es ð1 2v s Þ 2ð3 þ v s þ 4v 2s Þ f ðsÞsn2 J n1 ðnrÞ ð7 8v s ÞJ n1 ðnsÞ þ J nþ1 ðnsÞ þ J nþ1 ðnrÞ J n1 ðnsÞ ð7 8v s ÞJ nþ1 ðnsÞ dsdn; 0 0 Z 1 0 0 Z Es Z 0 Z Z Es 1 0 Z Es Es ð1 2v s Þ ¼ 2ð3 þ v s þ 4v 2s Þ K 21 ¼ Z ð21Þ 0 Z 1 Es ð1 2v s Þ f ðsÞsn2 J n ðnrÞ J nþ1 ðnsÞ þ J n1 ðnsÞ dsdn; 2 2ð3 þ v s þ 4v s Þ 0 0 Z 1Z 1 2Es ðv s 1Þ ¼ gðsÞsn2 J n ðnrÞJ n ðnsÞdsdn: 3 þ v s þ 4v 2s 0 0 K 32 ¼ K 33 Z Es 1 Thus, once the functions f ðrÞ and gðrÞ are determined, the stiffness matrix K in Eq. (20) and the stresses at the film–substrate interface can be solved. In the critical buckling analysis, the amplitudes of wrinkles are infinitesimal. In this case, the equilibrium equations (24) become the following linear eigenvalue problem Please cite this article in press as: Huang, X., et al. Radial wrinkles on film–substrate system induced by local prestretch: A theoretical analysis. Int. J. Solids Struct. (2015), http://dx.doi.org/10.1016/j.ijsolstr.2014.12.011 5 X. Huang et al. / International Journal of Solids and Structures xxx (2015) xxx–xxx r0 / h = 20 r0 / h = 30 ufa ðx1 ; x2 Þ ¼ r0 / h = 50 wf ðx1 ; x2 Þ ¼ r0 / h = 60 r0 / h = 70 Ef / Es = 2000 Ef / Es = 4000 ð27Þ qffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffi 2 2 over a quantity stands for its Fouwhere k ¼ k1 þk2 , and the cap rier transform. F Nab wf;ab þ T a wf;a represents the Fourier transform of the nonlinear terms in the parentheses. To solve the nonlinear ^_ f into algebraic equation, we introduce a pseudo viscoelastic part lw the second equation of Eq. (27): 1 ^_ f ¼ k4 w ^ f þ F Nab wf;ab þ T a wf;a ; T^ z þ lw 12 wf / h ð28Þ f . The nonlinear part in the right-hand side of Eq. where l ¼ Gs =E (28) cannot be transformed explicitly, and we use the fast Fourier transform technique to calculate it. For the considered problem, the interfacial tractions in the Fourier space are given by 0.2 (b) Fig. 2. Critical wrinkling patterns under different geometric and material parameters. (a) Size effect of the normalized radius r 0 =h of the prestretched region, where we take Ef =Es ¼ 1000. For r 0 =h = 20, 30, 50, 60, and 70, the mode numbers are ncrit = 6, 8, 12, 14, and 16, respectively. (b) Effect of the elastic modulus ratio between the film and substrate, where we take r 0 =h ¼ 50. For Ef =Es = 200, 500, 1000, 2000, and 4000, the mode numbers are ncrit = 20, 16, 12, 10, and 8, respectively. M½urm ; uhm ; wm T ¼ 0; ð26Þ ^ f ðk1 ; k2 Þ expðikb xb Þdx1 dx2 ; w ^ ab ; T^ a ¼ ikb N 1 4 f ^ þ F Nab wf;ab þ T a wf;a ; T^ z ¼ k w 12 Ef / Es = 1000 -0.3 Z 0.2 (a) Ef / Es = 500 ^fa ðk1 ; k2 Þ expðikb xb Þdx1 dx2 ; u where the Greek subscripts take the values 1 and 2, kb are the coordinates in the Fourier space, and i is the imaginary unit. In the following analysis, we will normalize all stresses with the plane-strain f , and lengths with the film thickness h. modulus of the film E The normalized equilibrium equations in the Fourier space are written as wf / h -0.4 Ef / Es = 200 Z ð25Þ where M ¼ ðMij Þ16i;j63 is a 3 3 coefficient matrix. Once the material and geometric parameters of the film–substrate system are given, the matrix M has only two unknowns, namely, the prestrain e0 and the wrinkling number n. The film will buckle when the determinant of matrix M vanishes. From this condition, the critical value of prestrain e0 at buckling can be obtained as a function of wrinkling number n. Among all possible wrinkling patterns, the system will prefer to the mode, with a wrinkle number designated as ncrit , which corresponds to the minimal value of critical prestrain, deemed as ecrit . When the prestretched strain reaches ecrit , the thin film will buckle into ncrit radial wrinkles. ^ f1 þ D12 u ^ f2 þ D13 w ^ f; T^ 1 ¼ D11 u ^ f1 þ D22 u ^ f2 þ D23 w ^ f; T^ 2 ¼ D21 u f f ^ þ D32 u ^ þ D33 w ^f; T^ z ¼ D31 u 1 ð29Þ 2 where D ¼ ðDij Þ16i;j63 is the substrate stiffness in the Fourier space, which is expressed as (Huang et al., 2005) 21 Gs 6 k D¼ 4 3 4v s 2 2 ½4k ð1 v s Þ k2 k1 k2 k 2ik1 ð1 2v s Þ k1 k2 k 2 1 ½4k ð1 k v s Þ k21 2ik2 ð1 2v s Þ 2ik1 ð1 2v s Þ 3 7 2ik2 ð1 2v s Þ 5: 4kð1 v s Þ ð30Þ Combining Eqs. (26)–(30), we obtain the normalized iterative equation: 1 n h 1 2 2 2 ^ n þ F T a wn;a þ Nab wn;ab ðk1 þ k2 Þ dt lw 12 o ^ n1 D32 u ^ n2 dt ; D31 u ð31Þ ^ nþ1 ¼ w l þ D33 þ 3. Numerical scheme To validate the theoretical analysis derived in Section 2, we adopt the Fourier spectral method (Huang et al., 2005) to simulate the local radial wrinkling in a film–substrate system. In the following discussion and simulations, we use the Cartesian coordinate system ðx1 ; x2 ; zÞ. Through the Fourier transform, the linear parts of partial differential equations will become a system of algebraic equations in the Fourier space, while the nonlinear terms need to be calculated in the real space. We will apply the semi-implicit numerical scheme developed by Gottlieb et al. (1977) to solve the resulting equations. First, the displacements of the film are transformed into the Fourier space as: ^ na and w ^ n denote where dt is the iterative increment in each step, u the in-plane and out-of-plane displacements of the film at the iteration step n, respectively. The iteration will be stopped when the total energy converges to a constant. We simulate the local wrinkling patterns in a square region in the ðx1 ; x2 Þ plane with periodic boundary conditions. The calculation model is sufficiently large such that the periodic boundary conditions do not interfere with the results. The square region is meshed into 512 512 elements with identical sizes. A random deflection field is prescribed with a magnitude smaller than 0.001. Specify the prestrain e0 > 0 in a central circular region with a given radius. The final wrinkling pattern will be obtained when the iteration procedure is finished. Please cite this article in press as: Huang, X., et al. Radial wrinkles on film–substrate system induced by local prestretch: A theoretical analysis. Int. J. Solids Struct. (2015), http://dx.doi.org/10.1016/j.ijsolstr.2014.12.011 X. Huang et al. / International Journal of Solids and Structures xxx (2015) xxx–xxx 4. Results and discussions " 4 2 # r r ; f ðrÞ ¼ exp g r0 r0 " # 5 2 r r gðrÞ ¼ ; exp g r0 r0 ð32Þ where g is an attenuation coefficient. Our simulations show that g varies with the normalized radius r 0 =h, and we take g ¼ 0:26ðr0 =hÞ0:33 to fit the numerical results under different values of r 0 =h. Then we further quantify the effect of prestrain on the wrinkling mode. For a specified value of the prestretched region radius r0 =h and the film/substrate modulus ratio Ef =Es , the prestrain e0 is solved from Eq. (25) as a function of the wrinkling mode number n. 0.10 0.06 14 11 8 20 30 40 50 60 70 60 70 Normalized radius r0 / h (b) 0.10 Theoretical result Numerical solution 0.08 0.06 0.04 0.02 0.00 10 20 30 40 50 Normalized radius r0 / h Fig. 4. Comparison between the theoretical and numerical solutions for (a) the mode number ncrit and (b) the critical strain ecrit as functions of the normalized radius r0 =h of the prestretched region, where we take Ef =Es ¼ 1000. (a) 34 Theoretical result Numerical solution 30 26 22 18 14 10 6 0 1000 2000 3000 Modulus ratio Ef / Es 4000 (b) 0.30 Theoretical result Numerical solution 0.25 0.20 0.15 0.10 0.00 30 3 ncrit 6 50 60 9 12 15 Mode number n 0 1000 2000 3000 4000 Modulus ratio Ef / Es 40 0.04 0.02 Theoretical result Numerical solution 0.05 r0 / h = 20 ε crit Prestrain ε 0 0.08 17 5 10 Critical strain ε crit First, we use the numerical scheme in Section 3 to predict the critical radial wrinkling patterns. In all simulations, the Poisson’s ratios of the stiff film and the compliant substrate are set as v f ¼ 0:3 and v s ¼ 0:4, respectively, and the size of the computational region is 560h 560h. Fig. 2 gives some representative wrinkling patterns, presented by the normalized displacement field wf =h of the film. The effect of the normalized size of the prestretched region r 0 =h is shown in Fig. 2(a), where the film/substrate modulus ratio is fixed as Ef =Es ¼ 1000. For r0 =h = 20, 30, 50, 60, and 70, the corresponding mode numbers are ncrit = 6, 8, 12, 14, and 16, respectively. It is seen that the number of wrinkles is approximately proportional to the normalized radius r 0 =h of the prestretched zone. The effect of Ef =Es is illustrated in Fig. 2(b) under a fixed value of r0 =h ¼ 50. For a few representative values of Ef =Es = 200, 500, 1000, 2000, and 4000, the corresponding mode numbers are ncrit = 20, 16, 12, 10, and 8, respectively. For a specified value of r 0 =h, the smaller the modulus ratio Ef =Es between the film and the substrate, the larger the wrinkling number. Moreover, when Ef =Es is small, it has a great influence on the mode number, while its effect weakens as Ef =Es increases. A distinct size effect can be seen from Fig. 2. With the normalized radial coordinate r=h increases from r0 =h, the profile of the wrinkling morphology rises rapidly to an extremum and then gradually attenuates. The functions f ðrÞ and gðrÞ in Eq. (17), which represent the displacement variations in the radial direction, should exhibit the same changing tendency. Besides, they should also be easy to perform the Hankel transform and its inverse transform. Considering these conditions, we take Critical mode number ncrit 4.1. Critical radial wrinkling Critical mode number ncrit (a) Critical strain ε crit 6 18 70 21 Fig. 3. Relation between the prestrain e0 and the wrinkling number n. In each curve, the lowest point corresponds to the critical strain ecrit and the mode number ncrit for the corresponding value of r0 =h. Fig. 5. Comparison between the theoretical and numerical solutions for (a) the mode number ncrit and (b) the critical strain ecrit as functions of the elastic modulus ratio Ef =Es , where we take r 0 =h ¼ 50. For several different values of r 0 =h and the fixed value of Ef =Es ¼ 1000, Fig. 3 plots the e0 versus n curves. In each curve, the minimal value of e0 is determined as the critical strain ecrit , Please cite this article in press as: Huang, X., et al. Radial wrinkles on film–substrate system induced by local prestretch: A theoretical analysis. Int. J. Solids Struct. (2015), http://dx.doi.org/10.1016/j.ijsolstr.2014.12.011 7 X. Huang et al. / International Journal of Solids and Structures xxx (2015) xxx–xxx which would minimize the total potential energy of the system. The corresponding mode number is acquired as ncrit . The variations of the wrinkling mode number ncrit and the critical prestrain ecrit with respect to the prestretched region radius r 0 =h are illustrated in Fig. 4(a) and (b), respectively, where we take Ef =Es ¼ 1000. Both Figs. 3 and 4 show that with the increase in r 0 =h, the critical strain ecrit decreases whereas the mode number ncrit increases. In Fig. 4(a), the stair-step trend arises from the integer constraint on the mode number. Also observed is a good agreement between the numerical results and the theoretical analysis for the mode number. It is seen from Fig. 4(b) that the numerical solutions of the critical strain ecrit are slightly higher than the theoretical predictions. This might be due to the simplification of theoretical models and the limit of the numerical algorithm in the critical radial buckling. The effects of the film/substrate modulus ratio Ef =Es on the critical strain ecrit and the critical wrinkling mode number ncrit are shown in Fig. 5, where the normalized radius of the prestretched region is fixed as r 0 =h ¼ 50. It is found that both the critical strain ecrit and the mode number ncrit reduce with the increase in the modulus ratio Ef =Es . The variations of both ecrit and ncrit with increasing Ef =Es is dramatic when Ef =Es < 1000, but they will become relatively gentle for Ef =Es > 2000. This result can be understood as follows. When the substrate is very compliant in comparison with the thin film, the elastic strain energy in the substrate will be small and the buckling behavior of the system is dominated by the strain energy of the thin film. To facilitate the application of the above model, we further give approximate expressions of the critical strain ecrit and the mode number ncrit . The considered system has the following main independent parameters: the prestretched region radius r0 , the film f ¼ Ef =ð1 v 2 Þ thickness h, and the plane-strain elastic moduli E f 2 and Es ¼ Es =ð1 v s Þ. Inspired by some previous studies on film/ substrate systems (Li et al., 2012), we assume the following fitting solutions: Critical mode number ncrit (a) 50 r0 / h=20 r0 / h=50 Eq. (33) 40 r0 / h=40 r0 / h=70 30 10 0 5 10 15 ( r0 / h ) ( Ef / Es ) 20 −0.29 (b) 0.30 0.25 Critical strain ε crit ε 0 = 0.01 (b) ε 0 = 0.011 wf / h wf / h 0.2 0.2 -0.4 -0.4 (c) ε 0 = 0.02 (d) ε 0 = 0.05 wf / h wf / h 1.0 2.0 -4.0 -2.0 Fig. 7. Postbuckling evolution of radial wrinkles. (a) Axisymmetric deformation before radial buckling, (b) formation of radial wrinkles after critical buckling, (c) extension of wrinkles in the radial direction, and (d) secondary bifurcation rendering branching wrinkles. ncrit ¼ A r E f b1 0 ; s h E r a2 E f b2 0 ; s h E ecrit ¼ B ð33Þ where A, B, b1 , a2 , and b2 are constants as yet to be determined. To demonstrate that the solutions in Eq. (33) work in a wide range of geometric and material parameters, we vary the geometric paramf =E s eter r0 =h in the range from 20 to 70, and the modulus ratio E from 92 to 3692. By fitting the data from theoretical analysis, we obtain the constants as A ¼ 1:77, b1 ¼ 0:29 by linear regression fitting and B ¼ 12:15, a2 ¼ 0:48, b2 ¼ 0:60 by binary linear regression fitting. Fig. 6(a) and (b) give the mode number ncrit and the critical strain ecrit respectively, where the scatters present the solution obtained by the method in Section 2 and the solid line stands for Eq. (33). Thus once the normalized radius and the elastic modulus ratio are specified, one can easily predict the occurrence of radial wrinkling and the corresponding wrinkle number by using Eq. (33). 4.2. Postbuckling evolution 20 0 (a) 0.20 r0 / h=20 r0 / h=50 Eq. (33) r0 / h=40 r0 / h=70 0.15 0.10 0.05 0.00 0.000 0.004 0.008 ( r0 / h ) −0.48 0.012 (E f / Es ) 0.016 0.020 −0.60 Fig. 6. (a) The mode number ncrit and (b) the critical strain ecrit . The scatters present the theoretical solution, and the solid lines are given by Eq. (33). Finally, the postbuckling behavior of the film–substrate system with local prestretch is also discussed on the basis of our numerical simulations. A few surface wrinkling patterns of the film–substrate system with increasing prestrain are presented in Fig. 7, where the size of the computational cell is 2736h 2736h, and the geometric and material parameters are r0 =h ¼ 304 and Ef =Es ¼ 3571. For this system, the critical prestrain is ecrit ¼ 0:011. Fig. 7(a) shows the axisymmetric deformation when the prestrain is lower than the critical value ecrit . With the increase in the prestrain, the circumferential compressive stress around the prestretched region develops and the surface buckles into a nonaxisymmetric actinomorphic morphology, as shown in Fig. 7(b). Then, the amplitude of the radial wrinkles becomes deeper with further increase in the prestrain, which extends the wrinkled region meanwhile (Fig. 7(c)). At this stage, the mode number and the style of the wrinkled pattern remain unchanged. If the prestrain is large enough (e.g. e0 ¼ 0:05) and the film is much stiffer than the substrate (e.g. Ef =Es ¼ 3571), a secondary bifurcation will appear, triggering branching wrinkles (Fig. 7(d)). It shows that the circumferential wrinkles split away from the circular region, which was also observed in the experiment of a floating annulus (Piñeirua et al., 2013). Please cite this article in press as: Huang, X., et al. Radial wrinkles on film–substrate system induced by local prestretch: A theoretical analysis. Int. J. Solids Struct. (2015), http://dx.doi.org/10.1016/j.ijsolstr.2014.12.011 8 X. Huang et al. / International Journal of Solids and Structures xxx (2015) xxx–xxx 5. Conclusions A theoretical model has been proposed to investigate the radial wrinkling of a stiff thin film lying on a compliant substrate triggered by local prestretch within a circular region. Our analysis demonstrates that the radius of the prestretched region and the film–substrate modulus ratio play significant roles in the wrinkling process. Both the critical strain and the critical wrinkling mode number decrease with the increase of film–substrate modulus ratio, while increasing the radius of the prestretched region lowers the critical strain and raises the wrinkle number. Approximate expressions are provided for the critical strain and the wrinkling number in terms of the geometric and mechanical parameters of the system. During postbuckling, the surface wrinkles may experience a secondary bifurcation and evolve into branching patterns. This study is not only helpful for understanding the formation of radial wrinkles in nature, e.g., wrinkles around a circular scar, but also holds a clue for potential applications in the fabrication of surface morphologies with novel functions. Finally, the limitations of the presented study are emphasized as follows. Firstly we have assumed a uniform biaxial prestretch in a circular region, which leads to only radial wrinkles. If the prestretched region is not of circular shape or subjected to other prestretching states (e.g., uniaxial tension or compression, an biaxial compression), the wrinkles would be different. In general, such wrinkling phenomena can be solved through finite element simulations. Secondly, the solution given in Eq. (33) is independent of the characteristic sizes of the system but depends on only the f =E s . When the film thickness dimensional parameters r 0 =h and E shrinks to nanometers, surface/interface effects may have a considerable influence. In this case, the theory of surface elasticity (Gurtin and Murdoch, 1975) can be used to derive a size-dependent solution. Acknowledgments Supports from the National Natural Science Foundation of China (Grant Nos. 11432008 and 11372162), the 973 Program of MOST (2012CB934001), and Tsinghua University (20121087991) are acknowledged. References Cai, S., Breid, D., Crosby, A.J., Suo, Z., Hutchinson, J.W., 2011. Periodic patterns and energy states of buckled films on compliant substrates. J. Mech. Phys. Solids 59, 1094–1114. Cao, Y.P., Jia, F., Zhao, Y., Feng, X.Q., Yu, S.W., 2012. Buckling and post-buckling of a stiff film resting on an elastic graded substrate. Int. J. Solids Struct. 49, 1656– 1664. Cerda, E., 2005. Mechanics of scars. J. Biomech. 38, 1598–1603. Chen, X., Hutchinson, J.W., 2004. Herringbone buckling patterns of compressed thin films on compliant substrates. J. Appl. Mech.-Trans. ASME 71, 597–603. Cheng, H., Zhang, Y., Huang, K., Rogers, J., Huang, Y., 2014. Buckling of a stiff thin film on a pre-strained bi-layer substrate. Int. J. Solids Struct. 51, 3113–3118. Chung, J.Y., Nolte, A.J., Stafford, C.M., 2009. Diffusion-controlled, self-organized growth of symmetric wrinkling patterns. Adv. Mater. 21, 1358–1362. Coman, C.D., Haughton, D.M., 2006. Localized wrinkling instabilities in radially stretched annular thin films. Acta Mech. 185, 179–200. Coman, C.D., Bassom, A.P., 2007. On the wrinkling of a pre-stressed annular thin film in tension. J. Mech. Phys. Solids 55, 1601–1617. Coman, C.D., Liu, X., 2013. Buckling-resistant thin annular plates in tension. Math. Mech. Solids. http://dx.doi.org/10.1177/1081286513493108. Efimenko, K., Rackaitis, M., Manias, E., Vaziri, A., Mahadevan, L., Genzer, J., 2005. Nested self-similar wrinkling patterns in skins. Nat. Mater. 4, 293–297. Flynn, C., McCormack, B.A., 2008. A simplified model of scar contraction. J. Biomech. 41, 1582–1589. Géminard, J.C., Bernal, R., Melo, F., 2004. Wrinkle formations in axi-symmetrically stretched membranes. Eur. Phys. J. E 15, 117–126. Genzer, J., Groenewold, J., 2006. Soft matter with hard skin: from skin wrinkles to templating and material characterization. Soft Matter 2, 310–323. Gottlieb, D., Orszag, S.A., MA, C.H.I., 1977. Numerical Analysis of Spectral Methods. SIAM. Gurtin, M.E., Murdoch, A.I., 1975. A continuum theory of elastic material surfaces. Arch. Ration. Mech. Anal. 57, 291–323. Huang, J., Juszkiewicz, M., De Jeu, W.H., Cerda, E., Emrick, T., Menon, N., Russell, T.P., 2007. Capillary wrinkling of floating thin polymer films. Science 317, 650–653. Huang, Z., Hong, W., Suo, Z., 2005. Nonlinear analyses of wrinkles in a film bonded to a compliant substrate. J. Mech. Phys. Solids 53, 2101–2118. Kim, D.H., Rogers, J.A., 2008. Stretchable electronics: materials strategies and devices. Adv. Mater. 20, 4887–4892. King, H., Schroll, R.D., Davidovitch, B., Menon, N., 2012. Elastic sheet on a liquid drop reveals wrinkling and crumpling as distinct symmetry-breaking instabilities. Proc. Natl. Acad. Sci. U.S.A. 109, 9716–9720. Landau, L., Lifshitz, E., 1959. Theory of Elasticity. Pergamon, London. Li, B., Cao, Y.P., Feng, X.Q., Gao, H., 2011. Surface wrinkling of mucosa induced by volumetric growth: theory, simulation and experiment. J. Mech. Phys. Solids 59, 758–774. Li, B., Cao, Y.P., Feng, X.Q., Gao, H., 2012. Mechanics of morphological instabilities and surface wrinkling in soft materials: a review. Soft Matter 8, 5728–5745. Li, B., Huang, S.Q., Feng, X.Q., 2010. Buckling and postbuckling of a compressed thin film bonded on a soft elastic layer: a three-dimensional analysis. Arch. Appl. Mech. 80, 175–188. Liu, J.L., Feng, X.Q., 2012. On elastocapillarity: a review. Acta Mech. Sin. 28, 928–940. Mei, H., Landis, C.M., Huang, R., 2011. Concomitant wrinkling and buckledelamination of elastic thin films on compliant substrates. Mech. Mater. 43, 627–642. Moulton, D., Goriely, A., 2011. Circumferential buckling instability of a growing cylindrical tube. J. Mech. Phys. Solids 59, 525–537. Piñeirua, M., Tanaka, N., Roman, B., Bico, J., 2013. Capillary buckling of a floating annulus. Soft Matter 9, 10985–10992. Qiao, L., He, L.H., Ni, Y., 2013. Local-buckling-induced elastic interaction between inclusions in a free-standing film. Int. J. Solids Struct. 50, 3742–3747. Sneddon, I.N., Mathematician, P., Britain, G., 1972. The Use of Integral Transforms. McGraw-Hill, New York. Song, J., Jiang, H., Liu, Z., Khang, D., Huang, Y., Rogers, J., Lu, C., Koh, C., 2008. Buckling of a stiff thin film on a compliant substrate in large deformation. Int. J. Solids Struct. 45, 3107–3121. Stafford, C.M., Harrison, C., Beers, K.L., Karim, A., Amis, E.J., Vanlandingham, M.R., Kim, H.C., Volksen, W., Miller, R.D., Simonyi, E.E., 2004. A buckling-based metrology for measuring the elastic moduli of polymeric thin films. Nat. Mater. 3, 545–550. Toga, K.B., Huang, J., Cunningham, K., Russell, T.P., Menon, N., 2013. A drop on a floating sheet: boundary conditions, topography and formation of wrinkles. Soft Matter 9, 8289–8296. Vella, D., Adda-Bedia, M., Cerda, E., 2010. Capillary wrinkling of elastic membranes. Soft Matter 6, 5778–5782. Wang, J.W., Cao, Y.P., Feng, X.Q., 2014. Archimedean spiral wrinkles on a film– substrate system induced by torsion. Appl. Phys. Lett. 104, 031910. Yin, J., Cao, Z., Li, C., Sheinman, I., Chen, X., 2008. Stress-driven buckling patterns in spheroidal core/shell structures. Proc. Natl. Acad. Sci. U.S.A. 105, 19132– 19135. Please cite this article in press as: Huang, X., et al. Radial wrinkles on film–substrate system induced by local prestretch: A theoretical analysis. Int. J. Solids Struct. (2015), http://dx.doi.org/10.1016/j.ijsolstr.2014.12.011