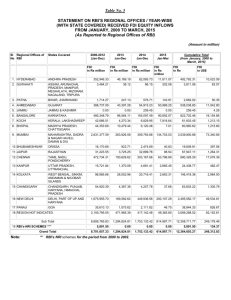

Making FDI Work for Sustainable Development

advertisement