A Syllabus For CSTM 493, ENGR 493, GCOM 493 Technology Internship

advertisement

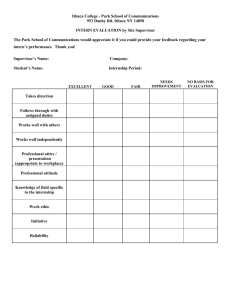

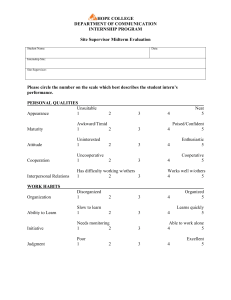

A Syllabus For CSTM 493, ENGR 493, GCOM 493 Technology Internship Department of Engineering Technology College of Business and Technology Western Illinois University Macomb, Illinois Revised January, 2009 This Syllabus can be found at: www.wiu.edu/engrtech/internship If You Remember Nothing Else… Remember These Five Things! 1. Your first week’s report must contain the company description, organizational chart, weekly activity log with questions answered, work hours, fmap and written directions to find your place of employment . 2. If you are doing a 9 semester hour internship, you must work nine (40 hour) weeks. If you are doing a 12 semester hour internship, you must work twelve (40 hour) weeks. 3. You must do a technical report for week 9 (or 12, as the case may be). Your “Final Report” is done in addition to that technical report. 4. If this internship is your final requirement before graduation, you have one year to complete it. 5. You must include a weekly activity log, including two answered questions, with each week’s report, and all technical reports must be signed by your supervisor. This syllabus contains all the documents that you will need for the course. It is suggested that you make a copy of your syllabus and place the original in a safe place. When you begin using the forms, you are to use the original documents. Topic Page I. Introduction................................................................ 1 II. Objectives ................................................................... 1 III. Qualifications To Apply For An Internship ............. 1 IV. Requirements ............................................................. 2 A. Training Schedules ....................................... 2 B. Weekly Reports ............................................. 2 C. Final Report .................................................. 4 V. Faculty Visitation ....................................................... 5 VI. Evaluation................................................................... 5 VII. Additional Course Work ........................................... 6 VIII. University Housing Contracts ................................... 6 IX. Registration For Your Next Semester....................... 6 X. Payment of Fees.......................................................... 6 XI. Dropping The Internship........................................... 7 XII. Communication .......................................................... 7 XIII. Exceptions................................................................... 7 TABLE OF CONTENTS – Continued Forms and Examples A. Minimum Competency for Enrolling in ENGR 493 Technology Internship ...................................................8 B. Application For Internship.......................................... .9 C. Cover Letter/Resume ..............................................10-12 D. Preliminary Internship Information........................... 13 E. Internship Training Schedule...................................... 14 F. Report #1 Items 1. Company Description ......................................... 15 2. Organization Chart (Example)........................... 16 3. Weekly Activity Log............................................ 17 4. Map/Directions .................................................... 18 5. Intern’s Working Hours Schedule ..................... 19 G. Weekly Activity Log (Example) .............................20-21 H. Format for Weekly Reports......................................... 22 I. Confirmation & Itinerary of Internship Visit .......23-24 J. Supervisor’s Evaluation..........................................25-26 K. Format/Questions for Final Report ............................ 27 L. Technical Report Examples....................................28-31 M. Bibliography of Suggested Text .................................. 32 I. Introduction The technology internship provides qualified students with a supervised program in production practices, management techniques, research applications, and other activities found in manufacturing, in construction, or in graphic communication. This syllabus contains the guidelines for the course and is intended to clarify the student’s requirements. Each student must thoroughly know the contents of this syllabus. II. Objectives A technology internship is a unique educational experience and offers specific goals relative to student achievement as follows: 1. 2. 3. 4. 5. Provides the intern with relevant education about manufacturing, construction, or graphic communication. Acquaints the intern with the physical, technical, academic, and environmental requirements of his or her chosen career. Develops the intern’s technical writing skills. Develops the intern’s ability to search for and find employment in industry. Demonstrates the importance of responsibility and personal interactions in the work place. III. Qualifications To Apply For An Internship Each student must: 1. Be a major in the Department of Engineering Technology. 2. Have completed a minimum of 60 s.h. of credit. 3. Have a cumulative GPA of 2.00 and major GPA of 2.50. 4. Have completed minimum competency as detailed on page 8. 5. Complete ENGR 493 application Form #1 (see page 9). 6. Follow the 493 Internship Semester Hour Credit Ratio of 9 (40 hr. wks.) = 9 sem. Hrs. of credit, or 12 (40 hr. wks.) = 12 sem. Hrs. credit. 7. Find a sponsoring industry anywhere in the State of Illinois or within a 250-mile radius of Macomb. Internships outside of these limits must be pre-approved. 8. Be willing to interview with the sponsoring industry at his or her expense. 9. Follow the policies of the employer. 10. Pay University fees and tuition for the number of hours of the internship. 11. Accept being graded on a satisfactory-unsatisfactory basis. 1 12. 13. Have prior approval of the internship coordinator before enrolling in ENGR 493 internship. Have completed and passed a test covering the contents of this syllabus. See Section XIII for any exceptions to items 1 through 13. IV. Requirements A. Training Schedule Each intern is expected to formulate, in cooperation with the participating firm and program coordinator, a training schedule (see page 14). This Training Schedule is the most important document of the internship. The Training Schedule must be accurately completed in its entirety by the intern and then signed by the company supervisor. This Training Schedule gives a summary of the responsibilities of the intern and should be completed before the intern starts working. THIS TRAINING SCHEDULE MUST BE MAILED TO THE UNIVERSITY COORDINATOR NO LATER THAN THE END OF THE FIRST WEEK OF WORK. Along with the Training Schedule, you must submit an Intern’s Working Hours Schedule (see Form #3, pg. 19). B. Weekly Reports Each intern is required to submit a weekly typed report. Professional business standards require a neatly typed paper on one side of 8 ½” by 11” letterhead paper from your company. FIRST WEEK The first weekly report is to be a description of the company. The description should include such information as: products produced, type of customers, and methods of manufacturing, construction, or graphic communication. If the company has a general booklet covering this information, submit that booklet or a copy of it in place of writing the description (see page 15 for format). The first weekly report must also include an organizational chart of your internship site. For small companies, it is expected that you will show the entire organizational chart. For larger corporations, your chart should indicate only those areas where you are scheduled to work (see example on page 16). Be sure to note where your job or position is on the chart. Additionally, the first week you are to fill out a “Weekly Activity Log”. Proper format is included on page 17. An example is shown on pages 20 and 21. 2 Also with your first report, mail a map and written directions on how to find your place of employment for the upcoming coordinator’s visit (see page 18). Here are a few pointers for drawing maps: 1. 2. 3. 4. 5. 6. Assume the coordinator will be coming from Macomb unless otherwise instructed. Maps are always drawn with North at the top of the page. Give approximate distances, i.e. “3 miles past McDonalds”. Good routes to your town without detours are appreciated. Generally, the town is not hard to find, but details in town are what is needed. On a separate sheet of paper, you must include written instructions to go along with the map. SECOND WEEK THROUGH END OF INTERNSHIP You will be responsible for one technical report during each work week (after the first week) of the internship. The reports should follow guidelines contained on page 22 and examples on pages 28-31. These reports may reflect technical areas with which you have come in contact within your work. Weekly technical reports do not have to necessarily reflect your past week’s work. Reports may also cover any technical area within the scope of your internship company. As you work, keep a list of potential technical topics as you come upon them, they will assist you in selecting future report topics. Technical reports are intended to develop your technical writing skills and keep the coordinator informed of your work and your progress. Additionally, each week you are to complete and submit a “Weekly Activity Log”, see pages 17, 20 and 21. Be sure to follow directions for both reports. The following time schedule must be followed to insure orderly and clear communication between the intern, company supervisor, and the university coordinator. 1st week: Report promptly to work and perform assigned duties. Schedule an appointment with your company supervisor for the Monday or Tuesday of the second week to review your first report. Write the first report over the weekend. 2nd week: Review the report with your company supervisor. If the report is accurate and complete, have your supervisor initial the report and send to the following address. If the report is not satisfactory to your supervisor, redo the report that night and resubmit for your company supervisor’s approval. 3 Send Reports to: Internship Coordinator Department of Engineering Technology One University Circle Western Illinois University Macomb, IL 61455 Reports should be mailed no later than Wednesday of the following week. If a report is to be mailed late, inform the University Coordinator by mail and indicate why and when the report will be mailed. Make a copy of your report for your own files. DO NOT fax reports without special permission from the University Coordinator. The university coordinator will review your reports and may return them to you with comments, and you will be expected to “redo” the report and re-submit it to the university coordinator within one week. Also, incorporate the comments as appropriate in the subsequent reports. After a few weeks, your reports should meet the internship standards and the coordinator will inform you when this has occurred. Special Note: Keep your reports coming in on a weekly schedule. You may receive an unsatisfactory grade if you neglect turning your reports in on time. C. Final Report The final report, in addition to the final weekly technical report, is to be written during the last week of the internship and must be a self-analysis containing the following items: 1. 2. 3. 4. 5. 6. 7. 8. A summary of what you learned during the internship. Any special highlights of your internship. Areas in which you believe you need improvement. What area of study at Western might (or did) help you in your career. Suggestions on improving the internship. Suggestions on improving the Engineering Technology Program. Overall strengths of the internship program. Overall strengths of the Engineering Technology Program. See page 27 for format and questions. The final report must be received by the Internship Coordinator no later than one week following completion of your final week of internship. Final reports received late may result in an unsatisfactory grade for your entire internship. This report is in addition to your normal weekly report. 4 V. Faculty Visitation Each intern will receive a visit by the University Internship Coordinator before the end of the internship period. There will be no unannounced visits. The intern will receive a letter announcing the time and date of the visit, along with a request for a brief conference with your supervisor and any other personnel the company or intern believes the faculty should meet. When the intern receives this letter, he/she must set up the conference with the supervisor and confirm the date in writing to the Internship Coordinator within two days. It is expected that you will confirm the visit with your company supervisor no later than one day following receipt of the visit notice. You may call the Engineering Technology office to confirm the visit, but you must also follow up with a written confirmation. (See pages 23 and 24). Because of the brief time available, and because more than one intern is visited per trip, the intern must make these arrangements and confirm them in writing as soon as possible. A short tour of the company facilities during the visit is expected as part of the visit. If there is a conflict with the proposed visit by the Internship Coordinator, please call the Engineering Technology office immediately, and we will reschedule the visit. VI. Evaluation The intern will be graded on a satisfactory/unsatisfactory basis. A grade of incomplete will only be given if your internship is not completed by the end of the school term. The following criteria will be used in determining the intern’s final grade. 1. 2. 3. Accuracy, quality, and promptness of your weekly reports. The recommendation of your company supervisor (see pages 25 and 26). The recommendation of the university coordinator. Early in your internship, you should take time to review the company supervisor’s evaluation form with your supervisor so as to prepare them in anticipation of their evaluation of your work at the completion of your internship. You may want to leave a copy of the form with your supervisor for their future reference. A formal letter requesting their evaluation of your work and a formal thanks for providing and supervising the internship, along with a new copy of the evaluation form will be sent to your supervisor about two weeks prior to your internship completion. 5 VII. Additional Course Work Your internship is a time and energy demanding experience. Be advised NOT to take another course concurrently with the internship. Under extremely unusual circumstances, another course may be taken, but only with written permission of the company supervisor and the university coordinator. VIII. University Housing Contracts If you currently have a university residence hall room contract and will not be completing the contract due to your off-campus internship, it is your responsibility to review that contract with the University Housing and Dining Office in order to avoid payment of a penalty. IX. Registration For Your Next Semester Interns need not return to campus to complete the pre-registration process. In lieu of a campus visit, you may call the Engineering Technology advising office, 298-2100, and set up a telephone advising/registration appointment with your academic advisor. You must be free of all university encumbrances before the advisor can register you. X. Payment of Fees You may pay your fees by mail during the term you are doing your internship. The due date when fees must be paid varies from term to term. If you have any questions, call the Billing & Receivables Office at 309-298-1831. When paying by mail, be sure that you send the correct amount due. MAKE ALL CHECKS PAYABLE TO WESTERN ILLINOIS UNIVERSITY AND MAIL TO THE BILLING AND RECEIVABLES OFFICE, WESTERN ILLINOIS UNIVERSITY, ROOM 106, SHERMAN HALL, MACOMB, IL 61455. Be sure to include the following information with your payment: 1. Sequence number 2. Name 3. Amount due 4. Reason for paying by mail 5. Type of scholarship 6 XI. Dropping The Internship In the event that an internship is not obtained, please consult the class schedule book for the last day to process a drop. It is the intern’s responsibility to drop the internship prior to this date in order to avoid being assessed tuition for the class and receiving an unsatisfactory grade. CONTACT YOUR INTERNSHIP COORDINATOR AND ACADEMIC ADVISOR PRIOR TO DROPPING THE CLASS. XII. Communication One of the most important phases of your internship will be your ability to clearly communicate your thoughts and actions to the internship coordinator. Keep turn around time on written correspondence to the minimum amount. The following telephone number may be used: Engineering Technology Office 8:00 – 12:00 and 1:00 – 4:30 M-F Phone: 309-298-1091 Fax: 309-298-1061 Engineering Technology Advising Office 309-298-2100 Have the secretary take a message and your call will be returned. E-Mail: engrtechinternship@wiu.edu XIII. Exceptions Any request for exceptions to any condition or requirement set forth in this syllabus must be made in writing to the coordinator at least one semester in advance of the internship. 7 Minimum Competency for Enrolling in CSTM 493, Engr 493, and GCOM 493 Technology Internship In order to receive permission to enroll in CSTM493, ENGR 493, and GCOM 493 the student must: 1. 2. 3. 4. Successfully complete at least 60 semester hours of college credit. (Junior standing). Achieve a 2.00 overall grade point average at Western. Achieve a 2.50 grade point average in Engineering Technology departmental classes that count toward the Construction Management, Manufacturing Engineering Technology or Graphic Communication major. (Only WIU ENGR, CSTM and GCOM courses are used to figure the Engineering Technology grade point average). Successfully complete the following courses for your major in the technical area in which you plan to intern. Construction Management Majors 1. ENGR 105, CSTM 232, 334, 301, 430 and 432 2. MGT 349 3. CSTM 336 or 337 4. Complete a minimum of 30 SH at WIU. Graphic Communication Majors 1. GCOM 211, 217, 312, 313 & 417 2. Choose 3 semester hours from: GCOM 412, 414, 415, 418 or 419 3. 3 semester hours of support courses 4. Complete a minimum of 30 SH at WIU. Manufacturing Engineering Technology Majors 1. ENGR 105, 241 & 345 2. MGT 349 3. Completed 12 SH in either Design/Production or Automation/Robotics. 4. Completed a minimum of 32 SH of ENGR classes (including transfer credit). 5. Complete a minimum of 30 SH at WIU. 8 Application for Engineering Technology Internship Name: ______________________________________________________________________ WIU ID: ____________________________________________________________________ Expected Internship Term (circle one): Semester Hours (circle one): Spring ’09 / Summer ‘09 9 hrs / 12 hours Major (circle one): Construction Management Manufacturing Engineering Technology Graphic Communication WIU Email: ________________________________ Local Address: _____________________________________________________ _____________________________________________________ Local Phone: _____________________________________________________ Home Address: _____________________________________________________ _____________________________________________________ Home Phone: _____________________________________________________ Cell Phone: _____________________________________________________ Photo Here 9 Example of letter to be sent to companies that you are interested in interning with in the future Your Address Date Name of person that letter is directed to Title of person Company name Company address Dear (Mr., Mrs., Ms.): I am a senior/junior at Western Illinois University majoring in Engineering Technology. This summer/fall/spring I plan to complete my internship in manufacturing/construction/graphic communication. I would like to intern with (name of the company) in the area of manufacturing/construction/graphic communication. (Now include something specific about this company. It may be a type of work only they do, it may be something specific about the product they produce, but in every instance it must show them that you know more about the company than just their name.) Thank you for your consideration. A resume is attached. I am available for an interview at your convenience. Sincerely, Your Name Enclosure 10 JOHN SMITH______________________________________________ 231 Rose Dr. Macomb, IL 61455 home phone: (309) 555-5555 _ school phone (309) 444-4444 OBJECTIVE________________________________________________________ Obtain an internship in the Manufacturing Engineering Technology field, utilizing design and manufacturing production skills. EXPERIENCE_______________________________________________________ STUDENT PATROLMAN Western Illinois University • • • • Responsible for additional campus security during the evening and nights. Responsible for giving escorts around campus when called to do so. Assisted the Office of Public Safety and its Officers when necessary. Performed other miscellaneous duties when necessary. ASSISTANT SERVICE TECHNICIAL Accessibility Systems Co. • • • • • YEARS EMPLOYED (2001-PRESENT) Macomb, Illinois YEARS EMPLOYED (SUMMERS OF 1999-01) Macomb, Illinois Installed several different brands and types of accessibility systems and equipment. Performed needed service to several different brands and types of accessibility systems and equipment. Established knowledge in a broad area of the construction industry. Established knowledge of several different accessibility production companies. Developed skills in reading and understanding blueprint and shop drawings. SALES ASSOCIATE Blain’s Farm & Fleet • • • YEARS EMPLOYED (1997-1999) Geneseo, Illinois Performed many needed duties in the Automotive Department. Ordered merchandise. Provided customer service. EDUCATION_______________________________________________________ MANUFACTURING ENGINEERING TECHNOLOGY ANTICIPATED GRADUATION: MAY 2003 Western Illinois University Macomb, Illinois • Knowledgeable in AutoCAD, mechanical drafting, NC and CNC mills and lathes, various industrial welding techniques and various foundry techniques. COMPUTER SKILLS__________________________________________________________ • Windows 2000, Word, PowerPoint, Excel, WordPerfect, and limited DOS knowledge. REFERENCES______________________________________________________ • 11 Available upon request. Mary Smith m-smith@wiu.edu School: 227 Western Blvd. Macomb, IL 61455 (309) 444-4444 Home: 436 W. Davis Peoria, IL 61400 (847) 555-5555 Objectives: I am currently seeking an internship in the field of Manufacturing, where I can gain experience and knowledge while meeting organizational objectives. Education: Western Illinois University, Macomb, Illinois Fall 1999 to present. Major: Manufacturing Engineering Technology Emphasis: Electronics and Process Control Minor: Business Management Anticipated Graduation date: December, 2003 Technical Skills: Job Experience: Robotics Fluid Mechanics Electronics Digital Logic Process Control CIM CAD Atlas Saw and Tool. Summers 99-01 Metal Shop Worker. Duties Included: United Parcel Maintenance, Machine Operating, Product Delivery, Customer Service Service (UPS). Winter, Spring 98 Union Worker. Duties Included: Package Sorter, Truck Unloader, Package Scanner. U.S. Robotics. (3-Com) Summer 97 Human Resource Department Employee. Duties Included: Maintenance, Special projects, Mail room, Supplies dispersion. Academic Organization: References: Society of Manufacturing Engineers Active Student Member. Western Illinois University Spring 99 to present References will gladly be furnished upon request. Preliminary Internship Information 1. Name_______________________________________________Date____________________________ 2. Home Address During Internship ________________________________________________________ Street ____________________________________________________________________________________ City State Zip Home Phone (Include Area Code) 3. Internship Company __________________________________________________________________ 4. Company Address ____________________________________________________________________ Street ____________________________________________________________________________________ City State Zip Phone (Include Area Code) 5. Anticipated starting date_________________________ 6. Brief summary of what you anticipate doing during your internship. Ending Date __________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________ This form is to be completed and mailed to the Internship Coordinator as soon as you accept an internship. DO NOT WAIT to mail this form until you start working. RETURN TO: 13 Internship Coordinator Department of Engineering Technology One University Circle Western Illinois University Macomb, IL 61455 Internship Training Schedule Engineering Technology/Western Illinois University This form must be completed and returned to the internship coordinator BEFORE THE END OF THE FIRST WEEK OF THE INTERNSHIP. Please Type or Print Clearly 1. Name_______________________________________________ Date________________________________ 2. Address During Internship____________________________________________________________________ street _____________________________________________________________________________________________ city state zip 3. Internship Company__________________________________________________________________________ 4. Company Address____________________________________________________________________________ street _____________________________________________________________________________________________ city state zip Company Phone ( )______________________ Home Phone( )____________________ 5. Internship Start Date_____________________________ Internship End Date_______________________ 6. Will your plant have a vacation shutdown during your internship? Yes_______ No_______ If yes, when______________________________ Will you be working during shutdown? Yes_______ No_______ 7. Monthly Salary (If hourly, convert by using gross for 40 hrs. X 4.3)__________________________________ 8. Semester hours registered for this course: 9 s.h._______ 12 s.h._______ 9. Write a brief summary of your responsibilities with the company. Indicate the approximate time to be spent in each area. _____________________________________________________________________________________________ _____________________________________________________________________________________________ _____________________________________________________________________________________________ _____________________________________________________________________________________________ _____________________________________________________________________________________________ 10. Company Supervisor’s Name (print) ____________________________________________________________ 11. Company Supervisor’s Title________________________________________________________________ 12. Company Supervisor’s Signature___________________________________________________________ 13. Intern’s Signature_________________________________________________________________________ RETURN TO: Internship Coordinator Department of Engineering Technology One University Circle Western Illinois University Macomb, IL 61455 University Coordinator’s Signature_________________________________________ Date______________ 14 Company Description Format For Report #1 (Company Letterhead) To: ___________________________________ (Supervisor) Date: _______________________________ (Date of Submittal) ___________________________________ (Supervisor’s Title) From: ________________________________ (Your Name) Re: Report #1 _________________________________ (Week Dates) _________________________________ (Department) Company Information (Subject of Report) Provide the following information regarding your internship company: A brief description of the company to include at a minimum: A. Products produced. B. Type of customers. C. Methods of manufacturing, construction, or graphic communications. Also include a company brochure and/or booklet. 15 16 Intern Engineer Monte Colley Supervisor, Machine & Tool Design Engineer Ron Kline Manufacturing Engineer Dennis Nelson Maintenance Supervisor Ralph Hobbs Industrial Engineer Manager, Manufacturing Services James R. Quinn Plant Manager M. Lyn Johnson Safety, Environmental, Facility Engineer Steve Paul Associate Engineer COOPER POWER SYSTEMS MACOMB FACILITY Intern’s Name__________________________________ Intern’s Weekly Activity Log (to be mailed with weekly technical report) _______week starting____________ Day of Week Job Performed and Hours Worked ending____________ Analysis of Work Performed (new information learned, new skills, results or completion of tasks or projects) 1. What mistakes did you make? How did you handle the situation? 2. Give a description of the most interesting incident or experience you had during the week. Place Responses on Back of Page 17 Map and Written Directions Provide a map (please copy a regional and/or local map and highlight directions) and written directions on how to find your place of employment: 1. 2. 3. 4. 5. Assume the coordinator will be coming from Macomb unless otherwise instructed. Maps are always drawn with North at the top of the page. Give approximate distances, i.e. “3 miles past McDonald’s”. Give good routes to your town. It is appreciated if you avoid detours. Generally, the town is not hard to find, but details in town are what is needed. Note: Map and Written Directions must include the following: 1. a sheet of typed directions 2. a general map from Macomb 3. a detailed map of the local area 4. a map indicating parking location, building and proper entrance 18 Intern’s Working Hours Schedule Please complete and return as soon as possible. Normal starting time for work________________________________________________________________ Normal time for lunch break is from __________________________to_______________________________ Normal time to leave work is_________________________________________________________________ Intern’s Name ____________________________________________________________________________ Company Name ___________________________________________________________________________ Note: Please indicate any times and dates that you or your supervisor will not be available for an internship visit (for example; plant shutdown, vacations, recurring meetings, etc.) 19 Intern’s Name John Smith Intern’s Weekly Activity Log (to be mailed with weekly technical report) ___3____week Day of Week Monday Tuesday Wednesday Thursday Friday 20 starting___6-1-01___ Job Performed and Hours Worked ending_6-5-01___ Analysis of Work Performed (new information learned, new skills, results or completion of tasks or projects) Quality control inspection of part #894576 (metal hinge). 4 hrs. Learned use of GO-NO Go gauges. Learned how to read specification prints and procedures. Entered quality control results into shop records. 4 hrs. Learned how ABC Manufacturing Co. records quality control data. Quality control inspection of part #876935 (locking pins). 2 hrs. Continued use of GO-NO GO gauges. 98.9% of parts passed inspection Revised drawings of part #874839 to reflect recent engineering changes. 3 hrs. Learned to follow ABC’s drafting guidelines. Assisted Chief Engineer in packing Tool Show Display material. 5 hrs. Material was shipped to Chicago as directed. Attended operations meeting with Supervisor. 1.5 hrs. Learned that production in shop is three days behind schedule. Operated Humbart Vertical Mill. 7.5 hrs. Produced 520 end plates. Operated Humbart Vertical Mill. 8 hrs. Produced 735 end plates. Operated Humbart Vertical Mill. 3 hrs. Produced 200 end plates. Assisted Set-Up Man with job set up on spot welders. 5 hrs. Learned how to set up spot welders for welding hinge parts. WEEKLY ACTIVITY LOG Week 3, June 1 – June 5, 2001 1. WHAT MISTAKES DID YOU MAKE? HOW DID YOU HANDLE THE SITUATION? I encountered several mistakes/problems trying to alphabetize and print out an itemized version of the job bag list. Every single client had to be printed out individually; the itemized list was not printed out all at once. The reason for so many problems was because I was unfamiliar with those functions on the program. Eventually, I was able to do both, the alphabetizing aided tremendously in setting up for the itemization. For a long time, I tried to find a way to print out the entire itemized version in one shot, but I was unable to find an option to do so. Therefore, taking the only way out, I set a page break after each individual client and then printed. Furthermore, I had to use the print function before printing each page. Due to the fact the document was so large, it took quite some time to produce the itemized version. 2. GIVE A DESCRIPTION OF THE MOST INTERESTING INCIDENT OR EXPERIENCE YOU HAD DURING THE WEEK. The most interesting part of my week, was producing the job bag documents. Coming to understand the necessary organizational work that takes place just to prepare jobs for disposal was incredible. Working on the documents, I became more familiar with the Microsoft Excel application. In turn, continuing to expand my software knowledge. 21 Format for Weekly Reports (reports must be typed on company letterhead) To: (Supervisor) (Supervisor’s Title) Date: (Date of submittal) Internship Coordinator Western Illinois University From: (Your Name) (Department) Re: Report # (week dates) (subject of report) The above heading must be used, no exceptions or variations will be accepted. In the areas enclosed with parenthesis, place the appropriate names, titles, or dates. See the following page for an example of a good report. The purpose of the weekly reports is to develop your technical written skills. By explaining what you have learned or by reporting on other aspects of your internship company, you will complete the University’s Writing in the Discipline requirement. Each weekly report should be from a page and one-half to two pages in length. You may want to include with your weekly reports, companies of reports, charts, drawings, product samples or other materials that will help to clarify your reports. Make sure you receive prior permission from your supervisor before sending any of these items. Western Illinois University respects the confidentiality of your work with your internship company and will keep confidential all materials sent to us. In writing your weekly reports, relate principles and concepts of what you are learning and other information you come in contact on the job. Keep your eyes open during each week and make note of interesting items or events that may provide topics for future weekly reports. Your supervisor must sign or initial all reports sent to your university coordinator. DO NOT HOLD THESE REPORTS—SEND ONE EVERY WEEK If your supervisor is absent from the office or on vacation have your supervisor designate another person to sign reports. If no one will sign the report, send a note to the coordinator explaining why your report will be late. Omit all of the following words or phrases from your technical reports: I, we, they, them, it, us, “a long time”, and “a lot of”. Avoid repeated use of any words, especially “the”. In technical report writing, the author of the report is assumed to be doing the action or making the recommendation. Therefore, sentences like “I learned that a mark sheet, which is simply a sheet of goldenrod, should be used when making a book”, should read, “A mark sheet, which is simply a sheet of goldenrod, should be used when making a book.” Three weekly reports with the word “it” in the report instead of the correct technical term will result in the intern receiving an unsatisfactory grade for the internship. 22 (Example) Itinerary of Internship Visit Approximate Times 1. 8:30 AM Expected arrival of (fill in coordinator’s name). 2. From 8:30 to 9:15 meet with supervisor Mr. Sam Johnson and intern. 3. From 9:15 to 10:00 tour facilities with supervisor and intern. 4. From 10:00 to 10:30 meeting with intern to review past work and future requirements in conference room. 5. From 10:30 to 11:00 (other). 6. 11:00 Departure of coordinator. Note: These are approximate times, often the coordinator will be visiting three interns per day, which may shorten this time frame. Generally allow for a maximum of a 2-3 hour visit, unless otherwise previously discussed. Also note whether the appointment is AM or PM. 23 (Example) Confirmation Letter for Internship Visit Company Letterhead Date Internship Coordinator Department of Engineering Technology One University Circle Western Illinois University Macomb, IL 61455 Dear (Internship Coordinator’s Name): I have received your request for an internship visit with (Supervisor’s Name) and myself on (date and time). This date and time are acceptable to both my supervisor and me. A preliminary visitation schedule is as follows: 1. 9:30a.m. Expected arrival of (Internship Coordinator’s name). 2. 9:30-10:15a.m. Meet with supervisor, (supervisor’s name) and (your name). 3. 10:15-11:00a.m. Tour of facilities with (supervisor’s name) and (your name). 4. 11:00-11:30a.m. Meet with (your name) to review past work and future requirements. 5. 11:30a.m. Departure of (Internship Coordinator’s name). (Intern’s Name and Signature) 24 WESTERN ILLINOIS UNIVERSITY SUPERVISOR’S EVALUATION OF TECHNOLOGY INTERN Intern_____________________________________________ Dept.__________________ Company__________________________________________ Date___________________ Instructions: The immediate supervisor will evaluate the student objectively, comparing the student to other personnel assigned the same or similarly classified jobs, other students of comparable academic level, or with individual work standards. Your personal comments are most helpful. Please check only one box in each category. RESPONSIBILITY ( ( ( ( ( ) Deliberately avoids responsibility ) Reluctantly accepts responsibility ) Accepts responsibility well ) Readily accepts duties ) Actively seeks new responsibilities ATTITUDE-APPLICATION TO WORK ( ) Definitely not interested ( ) Somewhat indifferent ( ) Average in diligence and interest ( ) Very interested and industrious ( ) Outstanding in enthusiasm INITIATIVE ( ) Must be pushed frequently ( ) Hesitates ( ) Does all assigned work ( ) Goes ahead independently at times ( ) Proceeds well on one’s own ORAL COMMUNICATIONS ( ) Poorly conveys ideas ( ) Sometimes ambiguous ( ) Average expression ( ) Clearly communicates ideas ( ) Very articulate ABILITY TO LEARN ( ) Very slow to learn ( ) Rather slow in learning ( ) Average in understanding work ( ) Learned work readily ( ) Learned work exceptionally well 25 QUALITY OF WORK ( ) Very poor ( ) Below average ( ) Average ( ) Very good ( ) Excellent WRITTEN COMMUNICATION ( ) Vague, disorganized ( ) Not what is expected of a college graduate ( ) Average expression ( ) Concise, factual, effective ( ) Outstanding DEPENDABILITY ( ) Unreliable ( ) Sometimes neglectful or careless ( ) Usually dependable ( ) Above average in dependability ( ) Completely dependable RELATIONS WITH OTHERS ( ) Works poorly with others ( ) Has difficulty working with others ( ) Gets along satisfactorily ( ) Works well with others ( ) Exceptionally well accepted MATURITY – POISE ( ) Timid ( ) Brash ( ) Seldom asserts oneself ( ) Average maturity and poise ( ) Has good self-assurance ( ) Quite poised and confident QUANTITY OF WORK ( ) Low output, slow ( ) Below average ( ) Normal amount ( ) More than average ( ) Usually high output TECHNICAL KNOWLEDGE ( ) Lacking in even the basic fundamentals ( ) Not what is expected of a college graduate ( ) Average ( ) In tune with technical time ( ) Outstanding JUDGMENT ( ) Consistently uses bad judgment ( ) Often uses poor judgment ( ) Average judgment ( ) Usually makes the right decisions ( ) Exceptionally mature in judgment OVERALL PERFORMANCE + Outstanding - ATTENDANCE ( ) Regular ( ) Irregular PUNCTUALITY ( ) Regular ( ) Irregular + Very Good - + Average Marginal Unsatisfactory The student’s outstanding personal qualities are: The personal qualities which the student should strive most to improve are: The recommended areas of further study for the student are: For other remarks, please use other paper. Has this report been discussed with the student? ( ) yes ( ) no Signature_______________________________________ Printed Name_______________________ Position_________________________________________ Date________________________________ Return to: Internship Coordinator, Department of Engineering Technology, One University Circle, Western Illinois University, Macomb, IL 61455 26 FINAL REPORT (Company Name) To: ______________________________________ (Supervisor) Date: ________________________ (Date of Submittal) ______________________________________ (Supervisor’s Title) Technology Internship Coordinator Western Illinois University From: ___________________________________ (Your Name) Re: Final Report (Dates of entire internship) ___________________________________ (Department) Provide a self-analysis of your internship experiences containing the following items: 1. A summary of what you learned during the internship. 2. Tell us about the special highlights of your internship. 3. Are there any areas in which you believe you need improvement? 4. What area of study at Western helped you in your internship? 5. How do you suggest we improve the internship? 6. How do you suggest the Engineering Technology Program be improved? 7. To you, what are the overall strengths of the internship program? 8. To you, what are the overall strengths of the Engineering Technology Program? ***Be sure to use these headings when preparing your final report.*** 27 In the following four pages are three actual reports submitted by previous technology interns. Please review these reports in light of the technical writing requirements for this course. As you will see, these reports contain material that both meet and does not meet our required guidelines. These reports are intended to be used for instructional purposes only. They DO NOT reflect acceptable reports. 28 (MUST USE COMPANY LETTERHEAD) To: John Smith Chief Resident Engineer Date: October 8, 2002 Internship Coordinator Western Illinois University From: Kristen Jones Engineering Technology Re: Report 9 October 1-5, 2001 Laying Storm Sewer Pipe When laying storm sewer pipe, a trench must be properly dug first. The elevation of the trench should be four inches below the bottom of the pipe and the flow line of the finished pipe should be at the specified depth and grade. When sheeting or shoring is not required and the trench depth is less than five feet, the trench width should be 18 inches wider than the external diameter of the pipe. The trench should be excavated three feet wider than the external diameter of the pipe for trench depths of five feet or more that have sheeting or shoring. During storm sewer construction, if a water main is exposed, the requirements of the IEPA should be followed for the horizontal and vertical separation of a water main from the storm sewer. When laying storm sewer pipe, the trench should be kept free of water while the pipe is being placed and until the joint has been sealed. Before the pipes are lowered into the trenches, the ends of the pipes should be cleaned. The pipes should be lowered carefully to avoid excessive handling in the trench. The placement of pipes should start at the outlet end with the spigot ends pointing in the direction of flow. The laying of pipes should continue toward the inlet end with pipes adjoining and at the proper line and grade. At the outlet end of the pipe, the flow line should be six inches or more above the flow line of the open ditch at the outlet. The mouth of each pipe placed should be protected to prevent any earth or bedding material from entering. To achieve a sewer with a smooth, uniform invert, the pipes should be fitted and matched before placed in the trench. The word “Top” or “Bottom” may be marked on the inside of reinforced concrete pipe. Any pieces of concrete pipe that are marked with “Top” or “Bottom” should be placed according to the marks. Preformed flexible gasket, mastic joint sealer, or external sealing bands should be used to seal all joints for concrete sewer pipe. Each joint should be wiped clean on the inside once the joint is sealed. To ensure tight joints, each section of pipe should be pushed or pulled tightly to the section already in place. A precast concrete plug should be used to fill lifting holes on the pipe. The plugs should be sealed and covered with mastic or mortar. 29 The entire width of the trench should be backfilled with moist fine aggregate once a section is properly placed. The fine aggregate should be placed longitudinally along the pipe. The trench should be backfilled to the center of the pipe elevation and backfill on each side of the pipe should be even. The remainder of the trench should be backfilled to the finished surface. (MUST USE COMPANY LETTERHEAD) To: R.D. Stone Supervisor, Electronic Page Layout Date: 10/07/01 Internship Coordinator Western Illinois University From: Joe Michaels Engineering Technology Re: Report #7 10/01/01 – 10/05/01 Style Sheets Working with style sheets is the smartest way to work when the user is doing a document which is more than two pages long. They allow the user to apply formatting and change formatting. If the user is typing up a long book, for example and the user went through the whole book setting the font of each paragraph, the size of each paragraph, and the alignment of each paragraph, it would take the user forever. Not to mention if the whole book is finished and there is a problem with the leading, the font, or the size of the paragraph, the user would have to go through each individual paragraph in the whole book and fix each problem that way. Instead, if the user uses style sheets for all of these attributes, it is just one click of the button and every heading or paragraph in the whole book can be fixed. First of all, there is applying the format. To first start a style sheet, the user has to go up to the edit menu and select style sheets. When selected, a dialog box will open and then the user can choose the style sheet he would like to apply. For example, if the user wants a “heading” style sheet for all the headings in the book, the user can choose the attributes for that style. An example of that would be like having a bold, 16-point font, which is to be centered and have a half-inch space below it, before the paragraph starts. So whenever the user decides to make a heading and clicks on the heading title in the style sheets menu, all of those attributes will be applied. Quark allows you to create all kinds of styles like titles, footnotes, paragraph styles, and more different levels for subheads. The user can and should create a different style sheet for each and every sort of paragraph in your document. Changing the format is where style sheets can be real helpful, especially when doing a long book and changes need to be made. If style sheets were not applied and a mistake is made with the leading in every paragraph, the user would have to go to each individual paragraph and do the changes manually. But when style sheets are applied, all the user has to do is change the format. Say that the book was turned in for proof, and the book came back and all the headings were a little too big of a point size. Since the user set a style, the user can change the heading throughout the whole book in one touch of a button instead of going through the whole book manually. Just open up the style sheet labeled heading and go to the edit section. This will 30 allow the user to edit any of the attributes that were applied to the style. Just bring down the point size and click save and all the type, which was applied to the heading style, will be brought down to the newly applied size instantly. So using styles in large projects is vital when working in Quark. Styles will allow the user to make many changes throughout the whole book instantly. (MUST USE COMPANY LETTERHEAD) To: Jessica Potter Supervisor, Machine and Tool Design Date: 08/12/01 Industrial Internship Coordinator Western Illinois University From: Robert Johnson Re: Report #7 08/03/01-08/07/01 BACKTURN LATHE CNC controlled lathes are used to produce most of the dry turned insulators; however, manually operated backturn lathes still play a major roll in daily production. Backturn lathes are located in the turning department. The turning department transforms dried slugs of clay into insulators with a desired external profile. Backturn lathes are used because of their versatility and ease of setup. Two reasons for using backturn lathes are for short runs and specialty shapes with small radii, undercuts, or counterbores. A backturn lathe is a manually operated machine with one horizontal spindle on the left end called the headstock and an air actuated tailstock on the right end. The lathe has two spindle speeds. Low speed is for rough-cut and high speed is for finish cut. Tooling for the backturn lathe includes a turning shaft, a template, and various tools that mount in a multiple tool turret. The end of the turning shaft has a male Morse taper that slides into the headstock spindle and is secured by a draw bolt. The length of the turning shaft is filled with spacers and two rubber doughnuts. Pressure from the tailstock compresses and expands the rubber doughnuts. The expanded rubber doughnuts grip the bore of the clay slug during the turning process. The clay slug is turned on this mandrel assembly so the finished external profile will be concentric with the bore. The template is made of eleven gauge cold rolled steel and has the profile of the finished shape machined along one edge. The opposite edge is straight and is clamped to a bar directly above the turning shaft. An aluminum C shaped tool arm pivots at the bottom of the lathe in a plane perpendicular to the turning shaft and slides from left to right in a plane parallel to the turning shaft. An indexing multiple tool turret attaches midway on the tool arm and positions the cutting tool on center of the turning shaft. The turret holds various tools necessary to produce the desired profile. Mounted at the top of the tool arm is a tracer pin and handle. 31 The sequence of operation for a backturn lathe is as follows. Slide a clay slug onto the turning shaft. Swing the tailstock into position and press the foot switch to extend the tailstock. Rock the clay slug back and forth to confirm that the rubber doughnuts have expanded and are gripping the bore. The tool turret must be indexed to the appropriate tool to rough-cut. Index the multiple tool turret by hand to the correct position. Grasp the tool arm handle in one hand and press the low spindle speed push button switch to begin the rough cut. Move the tool arm left and right along the length of the clay slug until the tracer pin is nearly touching the template. Press the high spindle speed push button switch to begin the finish cut. Start at the right end of the clay slug and feed to the left. Pull the handle of the tool arm towards the spindle until the tracer pin rests against the template. While pulling the handle towards the spindle with one hand, rotate the tracer pin with the other hand and feed the tool arm to the left. Feed the tool arm to the left at a slow and consistent rate until the left end of the clay slug has been reached. Too rapid feed rate will chip and/or explode the clay slug. Additional cutting operations are performed after the finish cut. Index the tool turret to the appropriate tool and position the tool arm to the location on the template where the operation occurs. Position the tool arm to the left end of the lathe and pivot the arm back to allow room for scotchbriting. Scotchbrite is a 2” by 10” by .25” thick abrasive pad used to smooth the surface of the insulator and to remove excess dust. Hold the scotchbrite by each end and press the middle portion against the spinning finished surface. Move the scotchbrite along the entire length of the surface of the insulator. Turn the spindle off and press the foot switch to release tailstock pressure. Swing the tailstock backwards out of the way and carefully slide the insulator off of the turning shaft. Place the finished insulator on a foam pad on the ware rack adjacent to the lathe. The process of producing insulators on a backturn lathe requires much skill from the operator, is repetitious, and may seem obsolete. However, the ability of produce specialty shapes with little setup time makes the backturn lathe a valuable asset to the turning department. 32 Bibliography for ENGR 493 Technology Internship Hacker, Diana, A Pocket Style Manual. 2nd ed. Boston: Bedford Books, 1996. Pfeiffer, W. Pocket Guide to Technical Writing. 3rd ed. Ohio: Pearson Prentice Hall, 2004. ISBN 0-13-047611-0 33