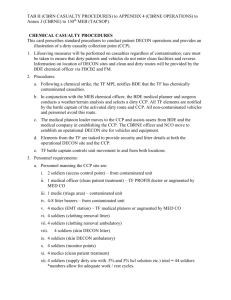

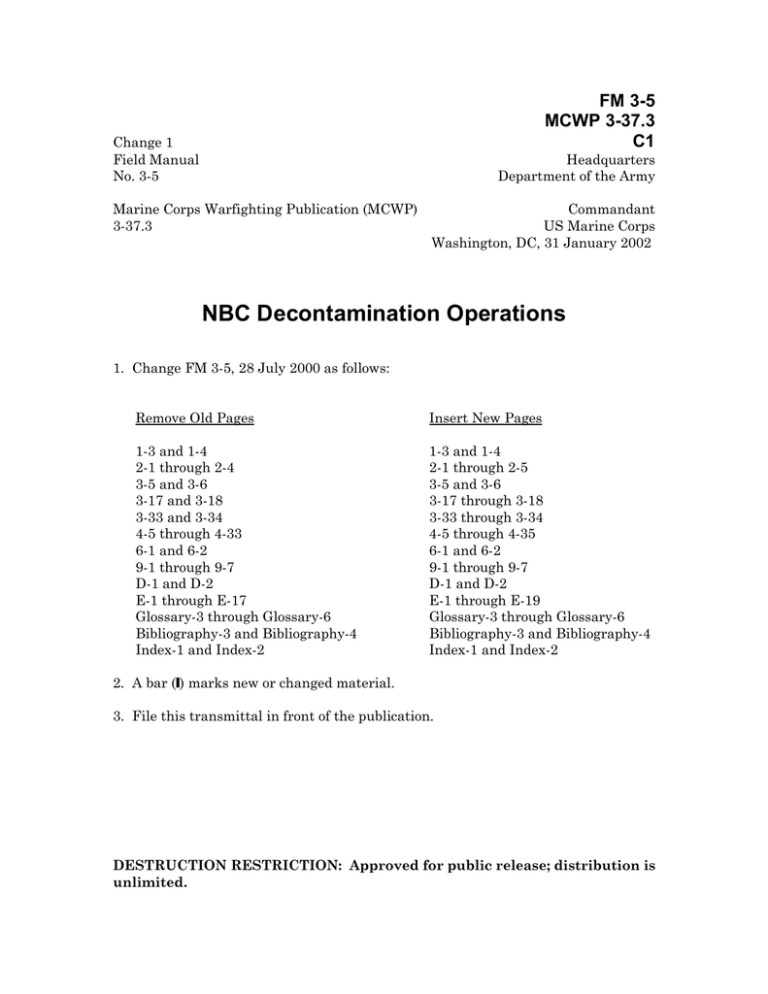

FM 3-5 MCWP 3-37.3 C1

advertisement