Document 10746527

advertisement

ANALYSIS OF HEAVY PARAFFINIC FISCHER-TROPSCH WAXES

USING GEL PERMEATION CHROMATOGRAPHY

by

HARRY ELLIS JOHNSON

B.S.,

Stanford University

(1981)

Submitted to the Department of

Chemical Engineering

in Partial Fulfillment of the

Requirements of the Degree of

MASTER OF SCIENCE

at the

MASSACHUSETTS INSTITUTE OF TECHNOLOGY

May 1983

@c

Massachusetts Institute of Technology 1983

Signature redacted---

Signature of Author

06e

Certified by

r md nt o femical Engineering

May 1983

1/4

Signature redacted

Professor Charlds N. Satterfield

Thesis Supervisor

Accepted by

Sig iature redacted

Archives

MASSACHUSETTS INSTiTUTE

OF TECHNOLOGY

OCT 2 41983

LIBRARIES

Professor Glenn C. Williams

Chairman, Department Committee

2

ANALYSIS OF HEAVY PARAFFINIC FISCHER-TROPSCH

WAXES USING GEL PERMEATION CHROMATOGRAPHY

by

HARRY ELLIS JOHNSON

Submitted to the Department of Chemical Engineering

on May 1, 1983 in partial fulfillment of the

requirements for the degree of Master of Science in

Chemical Engineering

ABSTRACT

The technique of Gel Permeation Chromatography

(GPC) was

utilized in analysis of paraffinic wax samples generated via

the Fischer-Tropsch synthesis in a slurry reactor.

Chromtograms were obtained by using standard GPC equipment with Waters

100 and 500A Ultrastyragel TM columns.

Differential number

fraction molecular weight distributions were obtained to C70

and C105 for ambient and elevated temperature injections re-

spectively.

Corresponding relation of heavy wax hydrocarbonproduct distributions to Flory plots show chain growth probability factor a value of 0.92 - 0.94.

These values are within

experimental accuracy of results found by previous investigators obtained by vapor-phase gas chromatography analysis.

The

results indicate that GPC may be used successfully in obtaining

quantitative data for heavy solid products formed by slurryreactor operation of the Fischer-Tropsch synthesis.

Thesis Advisor:

Title:

Charles N. Satterfield

Professor of Chemical Engineering

3

MASSACHUSETTS

INSTITUTE OF TECHNOLOGY

DEPARTMENT OF

CHEMICAL ENGINEERING

Room number:

6 6-2 5 0

Cambridge, Massachusetts

02139

Telephone:

253-6546

May 1, 1983

Professor Jack P. Ruina

Secretary of the Faculty

Massachusetts Institute of Technology

Dear Professor Ruina:

In accordance with the regulations of the faculty, I

submit herewith a thesis entitled "Ai1alysis of Heavy Paraffinic

Fischer-Tropsch Waxes Using Gel Permeattion Chromatography," in

partial fulfillment of the requirements for the degree of Master

of Science in Chemical Engineering at the Massachusetts

Institute of Technology.

Respectfully submitted,

,/

Signature redacted

4

ACKNOWLEDGEMENTS

I would like to thank my thesis advisor Professor Charles

Satterfield for his helpful support and critism.

I will remember to "stick to the facts".

I hope that

I also wish to thank

Professor Jeff Tester and Michel Boudart for their constant

encouragement throughout my graduate career.

I wish to thank the GEM program, Shell Development Co.,

Amoco, and Chevron for their financial support.

Thanks are

also extended to the Department of Energy for its support of

the project.

To my collegues in the department, I have unmeasureable

gratitude for all of the assistance offered during my stay at

M.I.T..

Special acknowledgements are given to Harvey Stenger,

Rich Pekela, Al Horn, Lisa Jungherr, and my officemates.

I

also wish to thank all of my friends who suffered with me

through this very trying ordeal.

I am especially grateful for

the friendship and support of Pieter VanderWerf, Brian Smiley,

Westley Spruill, and Scott Slate.

To Eugenia Brown, I offer

the sincerest thanks for her friendship and love.

Thanks also

to Sally Kreuz for the exceptional assistance in production of

this thesis.

And finally to my family,

of thanks.

I offer a thunderous chorus

To my parents I give my love and appreciation for

all they've done.

Thanks for teaching me to believe in myself

and giving me the courage to try and accomplish my goals.

most of all,

thanks for instilling in me a devotion to God.

And

5

TABLE OF CONTENTS

Page

I.

Introduction

11

II.

Objectives

15

III.

Literature Review

16

IV.

Experimental

35

IV.A.

35

35

35

35

49

49

49

IV.B.

Experimental Apparatus

IV.A.l.

Fischer-Tropsch Reactor

IV.A.2.

Ambient Temperature Apparatus

IV.A.3.

Elevated Temperature Apparatus

Experimental Procedures

IV.B.l.

Ambient Temperature Procedures

1.

Sample Preparation

2.

IV.B.2.

Chromatographic Analysis

2a.

Preparation

2b.

2c.

Analysis

Calculation

50

51

52

Elevated Temperature Procedures

1.

Sample Preparation

53

53

2.

Chromatographic Analysis

53

2a.

Preparation

53

2b.

Analysis

54

2c.

Calculation

55

V.

Results

V.A.

Ambient Temperature GPC Results

V.B.

Elevated Temperature GPC Results

VI.

Discussion

103

VII.

Conclusion

113

VIII.

Appendices

114

IX.

References

117

56

56

84

6

LIST OF FIGURES

Figure No.

3-1

Page

Development and Detection of Size Separation by

21

3-2

General Schematic of GPC Equipment.

24

4-1

Slurry Reactor Apparatus.

36

4-2

Waters M6000A Solvent Delivery System, Exploded

View.

38

Waters M6000A Solvent Delivery System, Circuit

Diagram for Hydraulic Components.

39

Injectors:

Injector;

40

GPC.

4-3

4-4

4-5

(1)

Rheodyne Model 7125 Sample

(2) Waters U6K Sample Injector.

Schematic of Waters R401 Refractive Index De-

tector Optical Unit.

42

4-6

Schematic Waters 150C Main Pump.

45

4-7

Schematic Waters 150C Injection System.

47

4-8

Schematic Waters 150C Differential Refractor-

meter.

5-1

5-2

5-3

48

GPC Chromatogram -

Injection 1-4:

Mixture of n-

Hydrocarbon Standards C22, C28, and C38.

59

GPC Chromatogram - Injection 1-7:

Mixture of nHydrocarbon Standards C24, C25, C26, C28, and

C30.

60

GPC Calibration Curve Run 2:

Phase,

Toluene Mobile

1 x 100A Ultrastyragel Column,

22C, and

n-hydrocarbon standards C19, C20, C21, C22, C23,

C24, C25, C26, C28, C30, C32, C36, C38, and C40.

61

5-4

GPC Chromatogram -

62

5-5

GPC Calibration Curve Run 3:

Toluene mobile

phase, 1 x 100A Ultrastyragel column, 24.4C, and

n-Hydrocarbon Standards C19, C22, C26, C28, C36,

and C40.

Injection 2-15:

SS-9A

65

7

Figure No.

5-6

5-7

5-8

5-9

5-10

5-11

5-12

5-13

5-14

5-15

5-16

5-17

5-18

5-19

Page

GPC Chromatogram - Injection 3-11:

SS-9E,

Attenuation 2X, Chart Speed changed to 4 inch/

min @ 5.8 minutes.

67

GPC Chromatogram - Injection 3-12:

uation 2X, Chart Speed 4 inch/min.

68

SS9D, Atten-

Peak Height and Retention Time Distribution:

Injections 3-11 and 3-12.

70

Cumulative Weight Fraction Molecular Weight Distribution:

Injections 3-11 and 3-12.

71

Differential Number Fraction Molecular Weight

Distribution:

Injections 3-11 and 3-12.

72

GPC Calibration Curve Run 4.

Toluene Mobile

Phase, 1 x 100A Ultrastyragel Column, 23C, nhydrocarbon Standards C20, C28, C32, C36, C40

and Polystyrene Standards 800, 1800, and 2000.

74

Peak Height-Retention Time Distribution:

Injec-

tion 4-11.

77

Cumulative Weight Fraction Molecular Weight Distribution:

Injection 4-11.

78

Differential Number Fraction Molecular Weight

Distribution:

Injection 4-11.

79

GPC Calibratiop Curve Run 5.

Toluene Mobile

Phase, 1 x 100A and 1 x 500AO

Ultrastyragel

Columns, 25C, n-Hydrocarbon Standards C20, C24,

C28, C36, C40 and Polystyrene Standard 1800.

81

Area Percent Molecular Weight Distribution:

jections 5-12 and 5-17.

83

In-

Cumulative Weight Fraction Molecular Weight Distribution:

Injections 5-12 and 5-17.

85

Differential Number Fraction Molecular Weight

Distribution:

Injections 5-12 and 5-17.

86

GPC Calibration Curve 0 Run 6:

Trichlorobenzene

Mobile Phase, 1 x 100A and 1 x 50OX Ultrastyragel

Columns,

C28, C38,

50C,

n-Hydrocarbon Standards C20,

and C40.

C24,

88

8

Figure No.

5-20

5-21

Page

GPC Calibration Curve Run 7:

Trichlorobenzene

Mobile Phase, 1 x 100A and 1 x 500l Ultrastyragel Columns, 50C, n-Hydrocarbon Standards Standards C20, C24, C28, C38, C40 and Linear Polyethylene Standard 1800.

91

Area Percent Molecular Weight Distritubion:

jections 7-7, 7-8, 7-9, 7-11, and 7-12.

99

In-

5-22

Cumulative Weight Fraction Molecular Weight Distribution:

Injections 7-7, 7-8, 7-9, 7-11,and 7-12. 100

5-23

Differentioal Number Fraction Molecular Weight

Distribution:

Injections 7-7, 7-8, 7-9,7-11, and7-12. 101

5-24

Weight Percent Molecular Weight Distribution:

Injection 7-13.

102

Form of Flory Plot Postulated for 2-Site Reaction and Accumulation of Products in Liquid

Carrier

104

6-1

6-2

Carbon Number Distribution for Run 9 at 248C and

H2/CO Feed of 1.81.

6-3

Carbon Number Distribution of Liquid Carrier

After Run 9.

6-4

6-6

107

Theoretical Carbon Number Distribution Based on

Flory Equation.

6-5

106

108

Carbon Number Distribution of Heavy Paraffinic

Fischer-Tropsch Wax at Ambient Temperature Using

GPC.

110

Carbon Number Distribution of Heavy Paraffinic

Fischer-Tropsch Waxes at Elevated Temperature

Using GPC.

111

9

LIST OF TABLES

Table No.

3-1

Page

Gel Permeation Chromatography Operating Conditions - Hillman, 1971.

32

Summary of Iun 1.

Operating Conditions:

Solvent - Toluene, Temperature - 25C, Columns

1 x 100A Ultrastyragel, Flowrate - 1 ml/min,

Injection Volume 100 pl, Polarity - Positive.

57

5-2

Summary of Run 2.

58

5-3

Summary of Run 3.

64

5-6

Cumulative and Differential Weight Fraction

Molecular Weight Distribution Data:

Injections

3-11 and 3-12.

69

5-5

Summary of Run 4.

77

5-6

Cumulative and Differential Weight Fraction

Molecular weight Distribution data:

Injection

4-11.

76

5-7

Summary of Run 5.

80

5-8

Cumulative and Differential Weight Fraction Molecular Weight Distribution Data:

Injections 5-12

and 5-17.

82

5-9

Summary of Run 6.

87

5-10

Summary of Run 7.

90

5-11

Fischer-Tropsch Synthesis Operating Conditions.

92

5-12

Cumulative and Differential Weight Fraction

-

5-1

Molecular Weight Distribution Data:

5-13

5-14

5-15

Injection

7-7.

93

Cumulative and Differential Weight Fraction

Molecular Weight Distribution Data:

Injection

7-8.

94

Cumulative and Differential Weight Fraction

Molecular weight Distribution Data:

Injection

7-9.

95

Cumulative and Differential Weight Fraction

Molecular Weight Distribution Data:

Injection

7-11.

96

10

Table No.

5-16

Page

Cumulative and Differential Weight Fraction

Molecular Weight Distribution Data:

Injection

7-12.

97

5-17

GPC Weight Percent Data:

98

6-1

a Values of GPC.

Injection 7-13.

112

11

I.

INTRODUCTION

The production of synthetic fuels to supplement dwindling supplies of natural fuels has directed attention towards

development of processes which utilize abundant resources of

indigenous reserves such as coal.

Fischer-Tropsch synthsis.

One such process is the

In this procedure the indirect

liquefaction of coal to hydrocarbons is accomplished via the

catalytic reaction of synthesis gas, a mixture of carbon monoxide and hydrogen produced by gasifaction of coal in the presence

of oxygen and steam.

The hydrocarbons produced from the

Fischer-Tropsch synthesis are predominantly linear paraffins

and olefins with some oxygenates

(primarily alcohols).

The

overall reaction stoichiometry may be represented as:

Paraffins : nCO +

(2n + 1)H2

2

C H

n 2n+2

+ nH2 0 + 123 kcal

2

(1)

Olefins:

Alcohols:

nCO + 2nH 2

nCO + 2nH

C H

2

+

n 2n

+ nH 0 + 93 kcal

CnH 2n+OH

(2)

2

+

(n -

1)H 20

+ 102 kcal

(3)

where the heat of reaction is based on n=3 at 227C.

Two im-

portant side reactions may also occur:

Water-Gas-Shift:

Boudouard:

H20 + CO = CO2 + H2 + 10 kcal

2CO

-+

C(s)

+ CO2 + 42 kcal

(4)

(5)

The synthesis of hydrocarbons from carbon monoxide and

hydrogen has been known since the classical methane synthesis

12

of Sabatier and Senderens

(1902).

In 1922 Franz Fischer and

Hans Tropsch obtained their first patent on "Synthol", a mixture of oxygen-containing derivatives of hydrocarbons.

developments by Fischer and Tropsch in the 1920's

Further

and 1930's

directed the synthesis to produce predominately hydrocarbons

by using cobalt-based catalysts in fixed-bed, vapor-phase

reactors.

In 1943, Germany optained a peak production of

16,000 bbl per day.

23% diesel fuel,

oil.

The products consisted of 46% gasoline,

23% waxes and detergents, and 3% libricating

With World War II, Germany's supply of cobalt from the

Belgium Congo was severely cut and active search was initiated

to develop iron catalysts.

In the United States during the

1950's a fluidized-bed process using an iron catalyst to convert synthesis gas from then inexpensive natural gas to gasoline was installed by Hydrocol, but it never operated satisfactorily.

And as petroleum supplies became plentiful further

investigation of the Fischer-Tropsch synthesis became uneconomical.

Until recently, South Africa has been the only country

actively pursuing Fischer-Tropsch technology.

Synthetic Oil Limited

At South African

(SASOL), fixed- and fluidized-bed proce-

dures have been developed which utilize iron catalysts at intermediate pressures

(5 -

50,000 bbl per day.

25 amt), with production capacity of

Current expansion is afoot which will

ultimately increase capacity to over 100,000 bbl per day.

The Fischer-Tropsch synthesis is a linear polymerization

process.

The process begins with an adsorbed single-carbon

specie which can either grow in molecular size by addition of

13

another carbon unit or terminate by desorption into the gas

(or liquid) phase as product.

Debate still exists over the

mechanism and nature of this carbon unit.

But this does not

affect the mathematical development of an expression to predict carbon number distribution if the probability of chain

growth is independant of molecular size.

Flory

(1936) statistically derived the basic relation-

ship for any polymerization process where the primary step is

addition of monomer units one at a time onto the terminus of

a growing linear chain.

The chain growth proability factor

* is defined as:

r

=

(r

pt

where r

+ r

(6)

)

a

and rt are the rates of propagation and termination

respectively (a is independant of molecular size).

fraction m

The mole

of molecules in the polymer mixture which contains

n structural units is given by the Flory Equation:

mn

=

(1 - a)

n-

(7-)

If the added weight of each carbon unit is proportional to

chain length n, the weight fraction w

w

=

(l -c )2n

n

is given by:

(n-l)(8

A more covenient form for expressing experimental data is

the logarithmic form of the Flory Equation:

ln

(m )

n

=

n ln (x)

+

ln

(1-)

(9)

14

Therefore a plot of ln

linear with slope ln

(m n)

versus carbon number n should be

(a) and ordinate intercept

(1 - a)

at n = 1.

The products formed in Fischer-Tropsch synthesis depend

on the hydrogen to carbon monoxide ratio in the synthesis gas

as well as on the catalyst and reactor conditions selected.

These products range from methane to high molecular weight

compounds such as heavy paraffinic wax.

Gas chromatography

has been successfully applied in the analysis of most FischerTropsch products.

However utilization of gas chromatography

becomes ineffective in examination of high carbon number products

(C30 +) due to the low volatility of these heavier

hydrocarbons.

For complete analysis, an additional technique is

needed that will provide quantitative data of the heavy

Fischer-Tropsch fractions.

meation Chromatography

One such technique is Gel Per-

(GPC), which involves the separation of

molecules based upon differences in their effective size in

solution.

The size sorting takes place by repeated transfer

of solute molecules between the bulk mobile phase and stagnant

liquid phase within the pores of the packing, allowing sample

characterization by its molecular weight distribution.

15

II.

OBJECTIVES

The present investigation focused on gel permeation

chromatography analysis of heavy paraffinic waxes formed during

the Fischer-Tropsch synthesis in a slurry reactor.

of fundamental and practical importance.

This is

Fundamentally, one

would like to know how high in molecular weight the FischerTropsch synthesis proceeds and if the Flory equation is applicable in this high carbon number product region.

Practically,

it is needed to know how long the reaction can be allowed to

continue before excessive accumulation of heavy hydrocarbons

might occur in the reaction apparatus.

of GPC was sought.

First, an understanding

Then application of GPC analysis to Fischer-

Tropsch wax samples was undertaken.

Finally GPC data were

interpreted and related to other results.

16

III.

LITERATURE REVIEW

attributed to work performed by Michael Tswett.

In 1903

-

Conventional founding of liquid chromatography has been

1906, Tswett recognized chromatography as a general method in

description of separation of

colored vegetable pigments in

petroleum ether on calcium carbonate.

From Tswett's early

findings, a large number of workers continued to develop

liquid chromatography to its present high performance capabilities and it has found application in various forms of

scientific disciplines

(Synder and Kirkland 1974).

The phenomena of gel chromatography were first observed

with adsorption of different sized ions in 1925

(Ungerer 1968).

The term "molecular sieving" was first used in 1926 by McBain

(Porath 1962a).

The crystalline crosslinkages of natural and

synthetic aluminum silicates, known as molecular sieves,

made possible separation of molecules according to size and

shape (Wiegner 1931,

1948).

Tiselius 1934, Claesson and Claesson 1944,

Later, Barrer and Brook established and proved correla-

tions of adsorption and molecular size in molecular sieves

(1953).

Sieving properties were also found during application

of ion exchange resins (Samuelson 1944, Rauen and Felix 1948).

A correlation between the number of crosslinkages, the degree

of swelling,

and the ion exchange capacity of the large ions

was found in the structure of ion exchange resins

Amberlite, Kumi and Myers 1949, Mikes 1958).

(Wofattite,

This property

was used in sepration of numerous compound groups including

17

amino acids, peptides, and proteins

Thompson 1952, Partridge 1952).

(Richardson 1949, 1951,

This experience directed

attention to larger-pored polysaccharide matrices.

Uncharged

crosslinked galactomannane gel was used in the desalting of

colloids (Deuel and Nenkom 1954).

Peptides and proteins

were separated on granulated starch particles

Storgards 1955, Lathe and Ruthuen 1955).

(Lindquist and

Later, it was estab-

lished by Lathe and Ruthuen that the penetration of molecules

into the gel phase depended upon structure and contration of

the gel, and a relationship between molecular size and chromatographic behavior was found

(1956).

The study of electrophoresis played an important role in

the development of gel permeation chromatography.

Preparative

and analytical methods of gel electrophoresis prompted the

examination of macromolecues and biopolymers

(Smithies 1955,

Raymond and Wintraub 1959, Davis and Ornstein 1959, Porath and

Bennich 1962).

The electroosmosis of natural substances and

proteins in dextran, a characteristic polysaccharide,

investi-

gated by Tiselius in Sweden led to the production of a new

semi-synthetic gel (1959).

Sephadex, dextran gel copolymerized

with epichlorhydrin and packed into a column, achieved good

separation even without an electric current.

A closer examina-

tion of Sephadex by Porath and Flodin marked the beginnings

of what may be called an explosive development of gel chromatography

(1959).

Since the properties of natural polysaccarides,

such as

dextran, were difficult to reproduce, application of such

materials were not found wholly suitable for chromatographic

18

uses.

In the early 1960's semi-synthetic and synthetic poly-

mers replaced the natural gel formers

Sehon 1962, Hjerten and Mosback 1962).

(Polson 1961, Lea and

Initially hydrophilic

polyacrylamide gels produced by copolymerization of acrylamide

and methylene bisacrylamide found widest application.

The

examination of gels which swelled in organic solvents began

simultaneously with that of hydrophilic gels, particularly

with attention to polystryene matrices copolymerized with

divinylbenzene.

In 1964 J.C. Moore disclosed the use of cross-linked

polystrene gels for separating synthetic polymers soluble in

organic solvents

(Moore 1964).

It was recognized that with

proper calibration, gel permation chromatography was capable

of providing molecular weight and molecular weight distribution

information for synthetic polymers.

Gel permeation chromatography is used as an analytical

technique for separating small molecules according to size

difference and to obtain molecular weight distribution information of polymers.

(The raw-data GPC curve is a molecular

weight distribution curve.)

With a concentration sensitive

differential refractometer detector, the GPC curve can become

a size distribution curve in weight concentration.

And with

proper calibrating, molecular weight averages can be calculated.

A convenient quantity which measures the average chain

length in a polymer sample is the number-average molecular

weight, Mn,

defined as:

19

Mw

n

W

=

=

EN

W

E()Mw.

(10)

'

EN

M

1

where W

and N

are the weight and number of molecules with

molecular weight Mw , respectively.

M

Ehi

and Mw

(11)

(h /Mw

)

S

where h

From GPC:

is the GPC curve height at the ith volume increment

is the molecular weight of the species eluted at the

ith retention volume, and N is the number of chains present.

Another convenient quantity obtainable from GPC data is the

weight-average molecular weight, Mw,

M

ZN Mw

2

E N__MW

2

N. Mw.

w

given by:

2w

VW. Mw

L~d

1W1(12)

EW.

ll

1

and from GPC:

M

The value of M

w

w

=

Z(h. Mw.)

(13)

Ehi

is always greater than Mn

n

except when the

values are identical in monodisperse systems.

The dispersity,

M /M , is a measure of the broadness of the molecular weight

distribution.

The Z-average molecular weight, Mz,

is related

to a higher moment of the distribution and is defined as:

Mw3

M

z

=

ZN

ENi Mw 1 2

(14)

20

(Dallas and Abbott 1979).

In the

(theoretical) model to describe GPC, the gel is

composed of a porous matrix whose pores are closely controlled

in size.

The separation mechanism involves differences in

ability of molecules to penetrate the pores.

Very large mole-

cules cannot penetrate into the gel pores and thus migrate

down the column through the interstitial volume between particles and emerge first from the column.

Smaller molecules can

to some degree penetrate into the gel pores, and thus they

are slowed in their migration through the column.

Very small

molecules that are able to completely penetrate into the gel

pores will be retained the most,

last

(Lawrence 1981).

and elute from the column

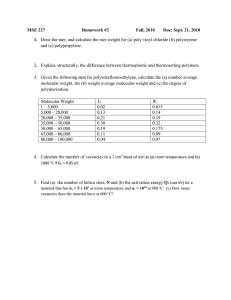

This is represented by the illustration

shown in Figure 3-1.

The retention time,

RT,

is the time required for a peak

to elute from the column following sample injection.

Its

value is sensitive to changes in experimental conditions such

as flow rate and the specific column used.

The retention

volume, RV, accounts for flow rate differences and is defined

as:

RV = F(RT)

where F is the mobile flow rate.

(15)

The peak capacity factor,

k', is a more basic retention parameter.

Physically, k'

represents the ratio of the weight of solute in the stationary

phase to that in the mobile phase.

RT k

T

RV- V

T

0

o

This is defined as,

m

_

m

(16)

21

(A)

TIME

SEQUENCE:

Sample

Injected

(B)

Small

(D) Solutes

Eluted

Large

(C) Solutes

Eluted

Size

Separation

00C>,

C-

.

.

49~K

Refractive

Index Detect

Chromatogram

(Concentration

Elution Curve)

Injection

(A)

(B)

(C)

(D)

RT = RV/F

Figure 3-1:

Development and Detection of Size Separation by

GPC (Yau, Kirkland, and Bly 1979).

22

= RT for an untetained peak and Vm = F(T ) for the

where T

retention volume of unretained solute.

To account for differences in stationary-phase loading,

the solute distribution coefficient, KLC,

is defined as:

k' V

K

LC

=

V

m

(17)

S

where Vs is the equivalent liquid volume for a stationary

phase.

Physically, KLC is the ratio of solute concentration

in the stationary phase to that in the mobile phase.

Transfer between mobile and stationary phases occurs

as solute molecules migrate through the column to continually

redistribute themselves between the phases to satisfy thermodynamic equilibrium.

This implies equivalance of chemical

potential of each solute component in the two phases.

For

dilute solutions at equilibrium, solute distribution can be

related to the standard free energy difference,

AG*, given

by:

AG* =

-

AG* =

AH*

RTlnK

(18)

with

-

TAS*

(19)

where K is the solute distribution coefficient, R is the universal gas constant, T the absolute temperature, and AH0

and

AS* are standard enthalpy and entropy differences between

phases, respectively.

In GPC,

solute distribution is governed

primarily by entropy changes between phases

Therefore,

with AH0

~ 0, KGPC is given by,

(Dawkins 1976).

23

KGPC

eAS/R

(20)

Temperature changes have only a small indirect effect on GPC

retention since they only affect polymer solute molecule size,

which in turn affects AS*.

Large fluctuations of temperature

of GPC experiments should be avoided.

The results of temperature, flow rate, and steric mixing

experiments show that GPC retention is an equilibrium, entropycontrolled,

size-exclusion process.

The diffusion in and out

of the pores of the solute is fast enough with respect to

flow rate to maintain equilibrium solute distribution.

Extensive developments in liquid chromatography have

made available a variety of equipment which can be used in

gel permeation chromatography.

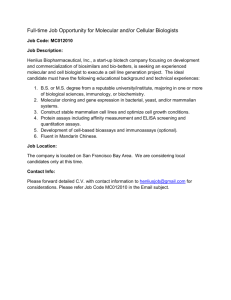

A general schematic for GPC

equipment is shown in Figure 3-2. The instrumentation used in

GPC is needed to function rapidily and reliably.

In the solvent

delivery system a constant, reproducible supply of solvent

to the column is required.

The sample injector must introduce

sharp volumes of sample without disturbing the flow of the

solvent.

High efficiency columns are needed to give maximum

separation capability and provide reproduciable information over

extended periods of time.

Specific detectors with wide sensi-

tivity ranges are used to monitor the separation.

A detailed

description of apparatus used in this study will be presented

in Section IV.A.

Gel permeation chromatography was primarily developed

for measuring molecular size distribution of polymer products.

24

8

7

6

5

3

2

Figure 3-2:

General schematic of GPC equipment:

(1) Solvent

Supply; (2) Solvent Delivery System; (3) Injector;

(4) Sample Syringe; (5) Columns; (6) Differential

Refractometer Detector; (7) Computerized Data

Handling Device; (8) Recorder.

25

A series of narrow molecular weight range fractions of anionic

polystyrene samples were efficiently separated in polystrene

columns with aromatic and chlorinated solvents

(Moore 1964).

Further investigation by Hendrickson and Moore

(1966) found

that by calibrating columns with carefully characterized

polymers, it was possible to prepare a curve relating the

elution volume to the logarithm of the average molecular chain

length

(or effective angstrom chain length) given by:

Angstrom chain length

where C.A.U.

(A)

=

2.5 + 1.25

(C.A.U.)

is the size in carbon atom units.

(21)

These calibra-

tion curves were often linear over a large range of chain

length, and molecular weight distributions of unknown polymer

samples could then be calculated.

Analysis of polystyrene,

polyvinylchloride, and polypropyleneoxide dissolved in THF

showed some deviation from the molecular chain length correlation.

Hendrickson and Moore suggested five basic forces that

might be expected to modify elution volume of compounds in

GPC:

(1) changes in width of the network openings in the column

packing beads,

(2)

solvent -

tion of solute molecules,

(5)

solute association,

(4)

(3)

dimeriza-

intramolecular bonding, and

adsorption of solute onto or into the gel surface.

fore,

There-

simple chain length was an inadequate size parameter in

correlation of elution volumes of some non-normal samples.

Smith and Kollmansberger

(1965) reported on the separa-

tion of a number of alkanes and halogenated aromatic compounds

by GPCalso using THF as the solvent.

They established that

26

the apparant molecular volume is the important parameter influencing the degree of separation,

(where molar volume

(ml/nole)

is defined as molecular weight divided by density at 25C.).

Later, Edwards and Ng

(1968) investigated the use of bulk

molar volume for various compounds (including normal hydrocarbons) and showed that there was a linear relationship between logarithm bulk molar volume and elution volume for normal

hydrocarbons.

The elution behavior of about 100 model com-

pounds was studied to show the effectiveness of GPC as an

analytical tool.

It was found that organic functional groups

exert a systematic influence on GPC elution behavior, reinforcing the theory that such behavior is the result of

solute's association with the solvent, the gel packing, or

itself.

By measuring these effects with model compounds, gen-

eralized observations for characterization of nonfunctional

minor components of lower molecular weight epoxy resins was

accomplished.

Rather than using standards such as polystyrene and

polypropylene glycols to calibrate GPC columns, Sweeney,

Thompson,

and Ford (1970) used normal paraffins and cali-

brated by carbon number.

This calibration was used to deter-

mine relationships between boiling point, carbon number,

elution volume.

and

A limited number of branched hydrocarbons

were also investigated as well as a brief quantitative study

to determine response factors for the normal hydrocarbons.

Lambert

(1970) recommeded that a set of molar volume

values for n-alkanes be used as standards to calibrate GPC

27

columns.

Molar volume is given by:

Molar volume

(ml/mole @ 20C)

= 33.02 + 16.18

+ 0.004

where C.A.U.

(C.A.U.)

(C.A.U.)

(22)

is as previously defined.

Debate still exists over the appropriate parameter to

use in calibration of GPC columns.

Mori and Yamakawa

(1980)

obtained relationships among oligostyrene, n-hydrocarbons,

and oligoethylene glycol in chloroform and tetrahydrofuran.

Different elution behaviors of oligomers in different eluents

made it difficult to use molar volumes or effective chain

lengths as the calibration parameter.

The n-hydrocarbons are

non-polar compounds and were assumed to elute without solutesolvent association or the adsorption on the gel.

Molecular

weight conversion equation for several oligomers based on

molecular weight of oligostryene and n-hydrocarbons were de-

derived, making it possible to use these as reference standards when molecular weights of oligomers are measured.

A wax is a complete mixture of high molecular weight

organic components.

Hatt and Lamberton (1956) defined a wax

as "a thermoplastic of low mean molecular weight and low mechanical strength."

hydrocarbon,

They classified waxes into three categories:

natural

(ester), and synthetic waxes.

Hydrocar-

bon waxes, derived from petroleum, can be further sub-divided

into two groups, the paraffinic and the microcrystalline

waxes.

Paraffinic waxes consist primarily of long chain nor-

mal paraffins, with small amounts of branched chain and

28

cycloparaffin in the approximate range of C18 -

C42.

The

microcrystalline waxes consist mainly of branched chain paraffins of high molecular weight.

The natural

(ester) waxes,

excreted by most animals and plants, are more complex in

composition and consist mostly of mixtures of esters of long

chain

(C18+) fatty acids and alcohols.

of free acids, alcohols, paraffins,

Appreciable amounts

resins, dihydride alcohols,

hydroxy acids, ketones, and sterols are also present.

Syn-

thetic waxes may be entirely synthetic, such as polyethylene

types, be prepared from petroleum waxes, or be prepared from

other natural materials.

Many elaborate procedures have been utilized in complete

analysis of waxes

(Robinson and Johnson 1966).

widespread use of chromatographic techniques,

Prior to

lengthy pro-

cesses of fractional distillation and fractional crystallization were used.

Infra-red spectroscopy has been applied in

the fingerprinting of single wax compounds by comparison with

infra-red spectrums of known waxes.

properties

Investigation of wax

(melting point, inflexions on cooling curves, speci-

fic gravity, penetration hardness, and refective index) have

been used for the quality control of all types of waxes, however, the information given by these methods is not completely

reliable.

Robinson and Johnson noted two problems involved

in complete analysis:

1.

Separation of wax constituents according to their

chemical nature,

etc.

i.e.

ester, alcohols, paraffins,

29

2.

Separation of the fractions into individual single

chemical species must then be identified.

Chromatographic techniques are superior due to, i)

efficiency of separation,

iii)

ii)

simplicity of operation, and

direct indication of the identity of components from

their rention data.

Paper chromatography was used to separate the mercuric

acetate-methanol adducts of the allyl esters of the fatty

acids by Kaufman of Pollenberg

(1957).

Reversed phase paper

chromatography was used to separate even-numbered acids up

the C36

in Beeswax, Carnuba wax, and Montan wax by Kaufmann

and Das

(1963).

The major problem in paper chromatography

is the low solubility of wax acids in solvents at room temperature, and elevation of temperature increases the complexity

of the method.

Gas chromatography of waxes has been largely investigated.

Adlard and Whitham

(1958) separated paraffin hydrocarbons up

to C36 using a silicone coated column at 270C.

Normal paraffins

were removed from kerosine by means of Linde 5A molecular

sieve by Whitham (1958).

O'Connor and Norris (1960 and 1962)

extended this procedure to the higher molecular weight paraffins waxes.

Gas chromatography of separated fractions gave

the ratio of normal to non-normal paraffins, the relative

amounts of each normal paraffin,

and the relative amounts of

total non-normal paraffin of each carbon number in a paraffin

wax.

Unfortunately this separation procedure required long

time periods

(15 days) which minimized the use of this method

30

for routine analysis.

Scheneck and Esima

(1963) used Linde 5A

sieves in conjuction with a gas chromatography column using

silicon stationary phase for paraffins in crude oils and rock

extracts.

Gas-solid chromatography was used by Scott and Rowell

(1960) to separate C15 and C36 paraffins using an alumina

column deactivated with sodium hydroxide at 390C.

co-workers

Levy and

(1961) separated and identified 67 components

pre-

sent in a refined paraffin using mass spectrometry in conjuction with gas chromatography

(8-foot columns packed with 10%

microwax distillation residue on Chromosorb W.

at temperatures

of 300C).

Levy and Paul

(1963) used a dual column, dual flame

ionization, temperature programmed gas chromatograph to obtain

carbon number distributions of C19 to C36 paraffinic waxes

using 12-foot 1/8-inch copper tubing packed with 0.82% microcrystalline wax distillation residue on 80-100 mesh Diatoport

S over the temperature range 140-330C at 2.3C per minute.

Resolution of a homologous series of the even-numbered alkanes

from tetradecane through dopentacontane was accomplished on

6-foot aluminum columns packed with 0.1% Apiezon L on 60-80

mesh glass microbeads over the temperature range 40 to 350C

at 5.6C per minute by Perkins, Laramy, and Lively

(1963).

Hydrocarbon components in the range C25 to C68 of four microsrystalline waxes were resolved on dual 2-foot columns packed

with SE 52 on Chromosorb G using a temperature programmed

dual flame ionization gas chromatograph by Ludwig

(1965).

Column chromatography was found to be rather inefficient

31

in total characterization of waxes.

Cole and Brown

(1960)

used a specially prepared alumina column for separation of

complex waxes into fractions according to their chemical nature, however incomplete separation often occurred.

Wiedenhof

(1959) used column chromatography prior to X-ray diffraction

measurements on wax fractions.

Ion exchange column chromato-

graphy was used in determination of free wax acids, wax soaps,

and total hydrocarbon content in waxes by Presting and Janicke

(1960).

Robinson and Johnson recommended use of ion exchange

column chromatography only as a precursor to gas or thin

layer chromatography

(1966).

With the introduction of GPC by Moore

(1964), column

chromatography became a more useful technique in wax analysis.

Hillman

(1971) found that by selecting the appropriate porosity

range of Styragel column packing, waxes in carbon range C15

to C100 could be closely examined.

By using a series of

Styragel columns it was possible to characterize hydrocarbon

and ester waxes dissolved in organic solvents.

Operating

conditions for study are shown in Table 3-1.

The GPC unit was calibrated using 0.1% solutions of nhydrocarbons (C16, C20, C28, C32, C36, C48)

molecular weight range polystrenes

from Waters Associates).

and narrow

(No. 25168, 26169, 25171

Retention times were plotted versus

carbon number, the carbon number for polystrenes being calculated by effective carbon number

(equation 21).

Calibration

plots were essentially linear over the range interest but

showed marked deviation at high molecular weights where the

TABLE 3-1:

Gel permeation chromatography operating conditions-Hillman, 1971.

I

Column Porosities

(A)

100, 500, 10,

II

100,

100, 100, 500

III

100,

400, 500, 103

3 x 104

Column Temperature

70

30

80

Solvent

Toluene

Tetrahydrofurane

o-Dichlorobenzene

Inhibitor

Nil

Quinol

Stavox CP

1.0

1.0

0.5-1.0

1.0

1.0

1.0

Sample size (ml)

2

2

2

Sensitivity

x2

x2

x2 for fingerprinting

x4 for polyethylene

70

30

80

70

30

80

70

30

80

Flow rate

(*C)

(ml/min)

Sample Concentration

Inlet

heater

Syphon heater

(*C)

(*C)

Detector heater

(*C)

(%)

(5g/gall)

L&J

33

molecular exclusion of the column system was approached.

The

extrapolation of the linear region for the n-hydrocarbons

passed through the point for the lowest molecular weight polystyrene standard.

In the actual hydrocarbon wax analysis,

carbon numbers corresponding to the retention times of the

maxima of the gel permeation chromatograms were read off the

applicable calibration curve.

A correction factor of twice

the standard deviation of the gaussian peak obtained for injection of pure C36 was introduced to account for peak broading

during elution.

Improvements in the efficiency of small pore packing

materials and column preparation advanced the speed and convenience of GPC to that of gas chromatography.

Lack of vola-

tility, or absence of significant differences in polarity,

solubility, or ionic characteristics are not significant problems in GPC analysis.

Krishen and Tucker found that the

high efficiency of the GPC column affords a separation of components as distinct separate peaks, in the short time, and

provided a useful technique for extending the molecular weight

range beyond that covered by gas chromatography

Harmon

(1977).

(1978) used GPC in characterization of hydrocar-

bon waxes, reporting molecular size distribution profiles,

coupled with melting point profiles from differential scanning

calorimetry, as the basis for comparison and selection of

replacement waxes for use by the B.F. Goodrich Company.

Styragel columns were used by Sosa, Lombana, and Petit

in analysis of crude paraffinic waxes

(C16 - C50) waxes

(1978).

34

Molecular weights

(Mn and Mw)

and molecular weight distribu-

tions of waxes containing various amounts of oil were determined.

The method of GPC was choosen because temperatures re-

quired to analyze n-paraffins having chain lengths above C40

are almost at the upper useful limit of routine gas chromatography.

Gas and gel permeation chromatograms were presented

and were found to complement each other well.

35

IV.

A.

EXPERIMENTAL

EXPERIMENTAL APPARATUS

A.

1.

Fischer-Tropsch Reactor

The Fischer-Tropsch synthesis reactions were carried out

in a semi-continuous, slurry-bed catalytic reactor system.

A

schematic of the slurry reactor unit is shown in Figure 4-1.

The stainless-steel, 1-liter autoclave was operated isothermally

in semi-batch mode.

Pre-mixed synthesis gas was feed into the

autoclave by a pneumatically-controlled valve while volatile

products were removed overhead.

The catalyst and inert liquid

carrier remained in the reaction vessel.

were collected in a wax trap

(held at 2C).

(held at 70C)

Condensable products

and a cold trap

A detailed discussion of the reactor system and

procedures followed during operation are found in the Ph.D.

thesis of G.A. Huff and related publications by Satterfield

and Huff.

A.

2. Ambient Temperature Apparatus

Analysis of Fischer-Tropsch wax samples at ambient temperature was performed on two gel permeation chromatographic

apparatuses.

sions:

This equipment may be categorized into five divi-

solvent delivery system, injector, columns, detector,

and data compiling system.

1.

Solvent Delivery System

In both sets of GPC components used at ambient temperature,

Waters Associates Model M6000A pumps were utilized to deliver

a constant flow of solvent.

Diagrams of this pump are shown in

Vant

Ab

PI

P -6

Corriar

Som pla

P

9

-8-

I-

P

10

-11

_

LA~)

a.'

3*

4

1

Wox

Sompla

Figure 4-1:

Oil

Sompla

(1) Gas Cylinder with Premixed CO/H 2 Mixture;

Slurry Reactor Apparatus:

(2) Pressure regulator; (3) Automated Flow controller; (4) Back-Pressure

Regulator; (5) 1-Liter, Mechanically Stirred Autoclave with Thermocouple

at (a) and Turbine Impeller at (b); (6) Pressure Gauge; (7) Wax Receiver;

(8) Ice-Cooled Receiver; (9) Back-Pressure Regulator; (10) Gas Sample

Valve; (11) Soap-Film Flowmeter (Huff 1982).

37

Figures 4-2 and 4-3.

The M6000A is a dual head reciprocating

piston positive displacement pump, in which solvent enters

through an inlet check valve during the first half of the

piston stroke and exits through an outlet check valve during

the second half of the stroke.

Each pump head delivers 100

microliters of solvent per stroke.

A steady flow of solvent

was provided by precise timing of the pistons. The flow rate

of the pump was adjustable in 0.1 ml/minute increments between

0 and 9.9 ml/minute.

2.

Injector

Two types of injectors were used in these experiments,

a Rheodyne Model 7125

(Run 5).

4-4.

(Runs 1 -

4)

and Waters Associates U6K

Schematics of these injectors are shown in Figure

The Model 7125 is a six port sample injection valve.

The sample loop, whose volume corresponds to the injection

volume, is loaded by syringe through a needle port built into

the valve shaft.

While in the load position, solvent from

the pump flows directly to the columns and sample from the

syringe may be loaded into the sample loop.

When flipped to

the inject position, solvent from the pump pushes the samples

from the sample loop into the column.

The U6K has a 2 ml last-in-first-out sample loop into

which any sample amount under 2 ml can be injected.

load, the solvent flows through the restrictor loop.

While on

To in-

ject a sample into the sample loop, the needle port valve is

locked by flipping the injector valve to inject, allowing

solvent flow through the sample loop to carry the sample into

the columns.

I

~Ii I-M~4

~r

1

-

Figure 4-2:

-

-

k

Waters M6000A Solvent Delivery System, Exploded View

Equipment Manuals).

(Waters GPC

W00

39

AC j.L3QA V

-E -- OT 2

IREFERENCE

HIGM CI4OLAASSEMBLY

TRANSEEREA

PUMP

MEA

OUTLET

ACESSORY

EE NOT &I

C.

E

OUTAsETOLO

VALV

FITFILTER

CONNECTION

-414ALs D*asAD UfA

MITLET

LTE-

-XLT

CHIECK

VALVI

ASSEMBLY

LEFT

IS 3 G ME

IU I 04CT

syaPyN

Pump 14EAO

OUTLET

CECK

VALVE

v.4

CMAVS

CI

ASSEMASLY

PUMP'NG

a

141GO4

PUW 04EAO

6--FLAVTA

-FHLI-

wOLET

CHECK

OLET

CHICK

VALVE

sEMBLY

fRACitOft

cC T .

OUTLET PO0-4

ctsE NoE Is)

VALVI

ASSEMBLY

INLE T

MsANIFOLD

ASSErSIBy

PvRG1 iNft TL

14 7O

O WCTM

7-r3 COLL ECT LINE)

"AVTE VALVE

WASTEPORT

FLT

....

m. SOLVENT

IETO

DEsTECT.R

SOLVE.T

PiSOVE4 EOLV ST63)

L

VAV I

L T

SOLVENT PIES 0tvC.11

ASLENTlm PLaSIO IR 0 ME

Figure 4-3:

Waters M6000A Solvent Delivery System, Circuit

Diagram for Hydraulic Components (Waters GPC

Equipment Manual).

40

-,e

LIFJ

Vets

IL

At\/pop

U.I

_J_

Poll

e' ;Kt

ri~~~

j;C~

.2~

PLU

flleneto

INJFCT

(1) Rheodyne Model

Sample

7125

Injector

LJ

(2)

Figure 4-4:

C

Waters U6K Sample Injector

(1) Rheodyne Model 7125 Sample Injector

Injectors:

Manual); (2) Waters U6K Sample

(Rheodyne Injector

(Waters GPC Equipment Manual).

Injector

41

3.

Columns

The columns used were Waters Associates Ultrastyrageltm

Gel Permeation Columns.

As discussed in Section III,

is a cross-linked styrene/divinylbenzene copolymer.

Styragel

The Ultra-

styragel columns are available in a variety of pore sizes

50

ranging from 100 to 10 A.

Ultrastyagel columns have better

resolution that their precursor, Waters

p Stryageltm columns.

Ultrastyagel columns provide the highest resolution per column

of any GPC

column currently used for separation of hydrocarbons,

low to intermediate MW polymers,

synthesis reaction products,

and polymer additives as well as other samples.

produces 10,000 -

15,000 plates per cm column.

Each column

Two sizes of

Q

columns were used in this investigation, 1 x 100A

(Runs 1-4)

0

and 1 x 100A0 in series with 1 x 500A

(Run 5), each 30 cm in

length.

4.

Detector

A Waters Associates R401 refractive index detector was

used in all GPC analyses.

and electronic units.

The detector consists of optical

The optical unit,

a schematic shown in

Figure 4-5, consists of a light source shone through a slit,

lens, and the sample cell to a mirror.

a

It reflects off the mir-

ror, back through the sample cell and the lens, to a rotable

piece of glass used as the zero adjust,

and finally to a cadmium

sulfide detector which measures the position of the beam.

The

beam's deflection is proportional to the refractive index difference between the contents of the sample cell, which contains

flow from the column and flow directly from the pump.

MIRROR

SAMPLE

-

LENS

-

REFERENCE

Figure 4-5:

-

0-TTETL

MASK

-

0PTICAL

ZERO

DETECTOR

LIGHT

SOURCE

AMPLIFIER &

PWRSPL

RECORDER

ZERO

ADJUST

Detector Optical Unit (Waters

Schematic of Waters R401 Refractive Index

GPC Equipment Manual).

43

The cadmium sulfide detector outputs a voltage proportional to the beam deflection.

This signal is sent to the

electronics unit, which amplifies the signal and outputs it as

a voltage between -100 and +100 millivolts.

The amplification

of the signal from the optics unit is controlled with an attenuator switch with settings from 128X (least sensitive)to 1/4X

(most sensitive).

A zero test setting on the attenuator and a

potentiometer labeled RECORDER ZERO allow the zero setting of

the detector to be matched with the zero setting of the recorder.

A polarity switch allows the polarity of the signal to be reversed.

a chart marker switch sends a

small output to the recorder to

allow events to be marked.

5.

Data Compiling

A Houston Instruments 0 -

10 millivolt 2 channel recorder

with friction driven chart speeds variable over a wide range

was used in Runs 1 -

4.

One channel was used to record the out-

put of the differential refractometer, the other channel was

not used.

The output from the detector was passed through a

two resistor voltage divider, which transformed the 100 millivolt

output to a 10 millivolt output.

A Waters Associates M730 Data Module was employed in Run

5 to compile chromtographic data.

The M730 is a versatile

printer-plotter-integrator offering a choice of calculation

methods and baseline corrections, and individual sample calculations with ten calibration files.

Parameters for set-up, peak

integration,

and calculation are entered prior to injection

of samples.

Integration can be controlled by user selection of

timed events.

A typical plot is marked with an injection mark,

44

retention times,

and start and stop integration marks.

The

calculated results, retention time, area, molecular weight, and

area/molecular weight, are printed after plotting of the chromatogram.

For detailed discussion of operation of the M730, con-

sult the Waters Data Module Instruction Manual.

A.

3.

Elevated Temperature Apparatus

The waters Associates 150C ALC/GPC was used in all elevated

temperature runs.

The Model 150C is a fully automated, micro-

processor-based system consisting of all the fundamental GPC

components plus it has capability for precise temperature control.

High temperature control is extremely important when:

1.

The sample is difficult to dissolve at room temperature

2.

The sample is difficult to keep in solution at room

temperature

3.

The viscosity of the sample in solution is high, or

4.

The viscosity of the solvent is high.

Each component of the self-contained Model 150C is designed for

superior system operation.

The 150C operates automatically

under microprocessor control and functions in the same manner

for single or multiple samples.

via the front panel keyboard.

operating commands are entered

The microprocessor stores the

instructions and organizes them into the required sequence of

mechanical operations.

The solvent delivery system,

shown in Figure 4-6, con-

sists of a noncircular, computer-designed gear drive which overlapes piston strokes to provide constant flow for smooth baseline.

A small pre-pump, in-line filter and debubbler ensure

45

TO INJECTOR COMPARTMENT

PRESSURE

TRANSDUCER

OUTLET 1

CHECK

VALVES

INLET

CHECK

VALVES

BUBBLE

I TRAP

0NLN

INE

MANIFOLD

TO REFERENCE

SIDE OF

REFRACTOMETER

Figure 4-6:

FLE

*

LOW PRESSURE

DETECTOR

PURGE VALVE

Schematic of Waters 150C Main Pump

Equipment Manual).

SOLVENT

SUPPLIED

BY PRE-PUMP

(Waters GPC

46

highly accurate,

resetable solvent delivery to the inlet of the

high pressure pump.

Compressibility compensation provides

accurate flow rates fo 0 to 9.9 ml/minute in 0.1 ml/minute increments.

The programmable injection system,

shown in Figure 4-7,

provides automatic spin, filtration, and injection volumes from

10 to 500 -pl for each of sixteen sample vials.

The 150C per-

forms injection of samples just as an operator would manually

with a syringe.

It cleans the syringe, places the needle into

the sample vial, withdraws a specified amount of sample, injects,

and marks the chromatogram.

The column oven accepts up to 10 columns.

designed to operate from ambient to 150C.

This oven was

It maintains samples

and solvent temperatures constant for consistent and reliable

results.

The programmable heating rate reduces thermal shock to

columns.

The columns used were 1 x 100A and 1 x 500A Ultra-

styragel columns.

A sensitive, linear universal refractive index detector,

shown in Figure 4-8, is utilized in the 150C.

Light passes

through the flow cell and is reflected by a mirror behind the

flow cell.

The reflected light then passes through the flow cell

again and is focused on a photodetector sending an output voltage to the recording device.

When a difference between refrac-

tive indices of the two fluids in the cell chambers is detected,

the refracted light beam falls upon a different part of the

photodetector,

causing a change in the photodector voltage out-

put which is indicated by deflection on the chart recorder.

A

47

SYRINGE

SYRINGE

VALVE

(V2)

(OPENED)

HOLDING LOOP

RES

YRI

MOTORl)E

A TUATED

PISTON

TO COLUMN

TSYRINGE

SE

VENT

INJECT

fl

CLOSED)

BYPASS

T7 7771RESTRICTOR

V'11

SOLVENT

FROM

FILTERED

SA!.MPLE

Figure 4-7:

SAM PLE

VIAL

Schematic of Waters 150 Injection System (Waters

GPC Equipment Manual).

PUMP

48

SAMPLE FROM INJECTOR

COLL UMN SET

CL IMIN

COMPART MENT

SAMPLE SIDE

SILICON

PHOTODETEC TOR

TO

_

COLLIMATING LENS

OUTLET

TEE

a

REFERENCE SIDE

-REAR

MIRROR

FROM PUMP+

BUBBLE TRAP

FIBER OPTICS CABLE

REFRACTOMETER

LIGHT SOURCE

INTERNAL

LOW NOISE

SIGNAL CABLE

W WASTE

CONTAINER

TO R.I. ELECTRONICS

PUMP

COMPARTMENT

Figure 4-8:

Schematic of Waters 150C Differential Refractometer (Waters GPC Equipment Manuals).

49

counter-current heat exchanger ensures thermal stability to

0.0005C.

Fiber optics light transmission provides cooler opera-

tion of the light source for sensitive detection and longer

life.

Usage of a quartz halogen light source provides extra

sensitivity by increasing signal to noise ratio.

Rapid and reproducible data recording with automatic

calculation of GPC data was obtained with the Data Module

M730

(as described in Section 4.A.2.5).

For a more complete

description of the 150C and its components, consult the Waters

Model 150C ALC/GPC Instruction Manual.

B.

EXPERIMENTAL PROCEDURES

B.

1.

Ambient Temperature Procedures

The procedure of obtaining a molecular weight distribution using GPC is broken into three parts:

sample preparation

and solvent selection, actual chromatographic analysis to generate chromatograms,

and calculation of molecular weight informa-

tion from the resultant chromatograms.

1.

Sample Preparation

Samples from 0.02 -

0.2 weight% were prepared by dissolving

a known weight of sample in a given volume of solvent.

Larger

concentration of samples could cause "viscous fingering," a

phenomenon in which the sample components being separated reach

a high enough concentration in the column to begin to interact

with each other, causing poor separation.

The solvent used in

all ambient experiments was HPLC grade Toluene supplied by VWR

Scientific.

Toluene was chosen because of its capatibility with

50

the column system, refractive index difference from samples, and

easy accessibility.

Samples were filtered through Millipore

Corporation Millex-GV .22 pm filters.

2.

2a.

Chromatographic Analysis

Preparation

The solvent is vacuum filtered through 1/2 micron Millipore filters to prevent particulate contamination to the columns.

The pump is then primed by drawing solvent through the pump inlet into a syringe.

ensure that

The pump is turned to a high setting to

the pump outputs to a low pressure.

Solvent is

pushed from the syringe into the pump until the pump can operate

on its own.

The M6000A pump will pump the volume to which it

is set immediately once primed.

The reference valve on the pump is positioned at REFERENCE

and the pump is set at 3 ml/minute to purge the reference cell.

A few minutes purging is sufficient.

Flow is then returned to

0 ml/minute and the reference valve is turned to the column

position.

If the Rheodyne injector is used a syringe full of solvent

is used to flush the sample loop.

If the Waters injector is

used, the valve is turned to INJECT and the sample port valve

to UNLOCK, the pump turned back to 3 ml/minute, and the loop

purged for three sample loop volumes.

After purging, the flow

should again be retuned to zero, the sample port valve locked,

and the injection valve to LOAD.

After the injector is flushed, the flow rate can be

brought slowly up to the operating flow rate,

1 ml/minute in

51

all

ambient experiments.

Care must be taken to ensure that the

pressure does not oscillate considerably, which could be due to

failure of the pump inlet check valve.

If this occurs, the pump

must be reprimed with degassed solvent.

The chart recorder is zeroed relative to the refractive

index detector by turning the detector to ZERO TEST and adjusting

the recording zero knob until flipping the polarity switch

produces

little

or

no deflection of the chart recorder pen.

The optics are zeroed by turning the detector to its lowest sensitivity and adjusting the optical zero to the chart recorder

zero,

and repeating this process in the next higher sensitivity

until the desired

sensitivity is reached.

Sensitivities of 4X

and 2X were used in all ambient experiments.

2b.

Analysis

Once the baseline has steadied and the appropriate sensitivity level reached, samples are ready for injection.

The

desired amount of sample is injected into the sample loop with

a clean syringe.

Injection volumes of 100 pl were used in all

ambient experiments.

When using the Rheodyne injector, the

injector must be on LOAD.

Several hundred microliters of air-

free solvent are injected into the loop and around the injection

port to clean the syringe loop.

Injection of the appropriate

amount of air-free sample then follows.

the injector.

The syringe remains in

When the Waters injector is used, the injector

also must be on LOAD and the sample port unlocked.

After the

sample is unlocked in the injector, it is withdrawn and the

sample port locked.

If the sample port is not locked injection

will cause depressurization of the columns.

52

To inject the sample, flip either injector to INJECT.

The Rheodyne injector must be flipped quickly as there is no

flow when the injector is between LOAD and INJECT.

After one

sample loop volume has flowed through the injector, it can be

flipped back to LOAD,

flushed with solvent.

and in the case of the Rheodyne injector

In any case, the syringe should be rinsed

with clean solvent.

The output of the detector, the chromatogram, is recorded

on the chart recorder

(Runs 1-4)

or the Data Module

(Run 5).

Sufficient time should be allowed for complete elution of sample

before injection of another sample.

This time can be approxi-

mated from flow rate values and column lengths.

After all samples have been run,

the flow rate is slowly

returned to zero, and all instrumentation is turned off except

the detector.

The detector is designed to remain on continuously,

and turning it off will decrease its usefullness.

2c.

Calculation

In order to obtain molecular weight data from a chromatogram,

calibration of the column is first required.

If nar-

rowly dispersed standards are available (as is the case in this

investigation)

calibration is quite simple.

Injecting samples

of the standards and determing their retention time is all that

is required to formulate a calibration curve.

A plot of log

molecular weight versus peak retention time yields a linear

calibration curve which conforms to the equation,

log

(MW)

= D

o + D 1 (RT)

(23)

53

where MW is the standard's molecular weight, RT its retention

time, and D

and D

are calibration constants computed from a

linear fit of data from analyses of a series of standards.

Analysis of a chromatogram involves drawing a baseline

and measurement and interpretation

of the detector response.

The magnitude of the detector response is proportional to the

amount of eluting sample at a specific retention time.

This

retention time is related to the corresponding molecular weight

by the calibration curve via Equation

(23).

To calculate molecular weight distributions, the sample

peak is cut into equally spaced slices, each slice has a retention time and an area.

The area of each slice is directly re-

lated to the weight of a particular molecular weight fraction

in the whole sample.

The complete procedure for computation of

molecular weight distribution is found in Appendix I and is

illustrated in Sections

B.

1.

2.

V.A and B.

Elevated Temperature Chromatography

Sample Preparation

Samples are prepared as in the ambient experiments, except

that sample vials supplied with the 150C are to be used and

placed in the rotary carriage prior to analysis.

The same

sample size and solvent considerations are employed.

The sol-

vent used in all elevated temperature experiments was filtered

HPLC grade 1,2,4 - Trichlorobenzene supplied by Fischer Scientific.

2.

Chromatographic Analysis

2a.

Preparation

54

The prepump is primed by forcing solvent into the prepump

via the external supply line with a syringe or by drawing solvent into the prepump through the solvent drawoff valve.

The

main pump is primed by depressing the SYSTEM PURGE button.

The

flow rate should be set to a flow rate consistent with anticipated

use.

Allow the SYSTEM PURGE to operate for three minutes.

The

injector is now purged by depressing the INJ PURGE button to

flush all flow paths within the injector and to cycle the injector syringe one complete cycle.

Since operating at elevated temperature, time must be

allowed for the system to equilibrate and maintain a stable

baseline.

The 150C is automatically zeroed by inputting a zero

to the scale factor.

Auto zero moves the baseline signal to

the 0 millivolt location and holds it there for twenty-four

seconds.

This allows the system to automatically compensate

for any long term drift that might occur over extended periods

of operation.

2b.

Analysis

Operation of the Model 150C for GPC quantitation is very

simple due to the automated nature of this apparatus.

The

general routine is as follows:

1.

Set data,

time, chart speed, plotting mode, pen con-

trols, GPC mode, and calibration mode.

2.

Set integration parameters for standards to detect

standard peaks

(injection volume, sensitivity, polarity,

ect.).

3.

Inject standards of known molecular weight to determine retention times.

55

4.

A calibration

table

of retention

times and molecular

weights is entered.

5.

The coefficients of the equation representing the

calibration curve are internally calculated.

6.

Slice width, integration parameters for analysis,

and timed events to control baseline are set.

7.

A

Samples are injected and results are calculated.

complete discussion of parameters and detailed operational

procedures can be found in the Waters

2c.

150C Instruction Manual.

Calculation

The Data Module M730 was used to record and report chroma-

tographic data obtained from the 150C.

Manual computation

methods described in Section IV.B.l.2c were also employed to

provide continuity between ambient and elevated temperature

runs.

56

V.

V.A.

RESULTS

AMBIENT GPC RESULTS

To gain an understanding and appreciation for gel permeation chromatography fundamentals,

samples of pure and mix-

tures of pure normal paraffin standards in carbon number range

C19 -

C40 were injected in Runs 1 and 2.

are presented in Tables 5-1 and 5-2.

Summarized results

Injections of mixtures

were used to determine whether or not discrete separation by

carbon number could be achieved.

As seen in the chromatograms

shown in Figures 5-1 and 5-2, separation by GPC will not resolve mixtures by carbon number unless wide separation exists

between the components in the mixture.

Separation of Fischer-

Tropsch wax samples will resemble chromatograms like

Figure 5-2,

exhibiting a bell-shaped curve representative of the distribution

of molecular weight fractions.

In order to correlate retention

time and molecular weight data, a calibration curve was constructed using data from Run 2 for C19 - C40 shown in Figure

5-3.

Equation (23) can now be used to estimate molecular weights

from retention times for samples of unknown molecular weight.

The calibration coefficients determined for the operating conditions of Run 2 are,

D

D

0

=

4.71

=

-0.31

The chromatogram from injection of a slurry wax sample from

Huff's Run 9 is shown in Figure 5-4.

The detector response peaks

at a retention time of 6.86 minutes which corresponds to C28 from

57

SolventOperating Conditions:

Summary of Run 1.

Toluene, Temperature-25C, Columns - 1 x 100A

1 ml/min, Injection

Ultrastyragel, Flowrate

Volume - 100 pl, Polarity - Positive.

-

TABLE 5-1:

MW

log MW

WT

C22

310.59

2.49

.0238

7.5

C28

394.74

2.60

.1589

7.2

C38

535.00

2.73

.0261

6.8

1-2

C40

563.06

2.75

.2123

6.6

1-3

C19

268.51

2.43

.2180

7.8

1-4

C22

310.59

2.49

.0114

7.5

C28

394.74

2.60

.0807

7.1

C38

535.00

2.73

.0114

6.7

C20

282.54

2.45

.0500

7.6

C24

338.64

2.53

.0431

7.2

C28

394.74

2.60

.0431

7.0

C36

506.95

2.71

.0431

7.0

C40

563.06

2.75

.0341

6.6

C24

338.64

2.53

.0363

7.3

C25

352.67

2.55

.0465

7.3

C26

366.69

2.56

.0420

7.3

C28

394.74

2.60

.0397

7.3

C30

422.80

2.63

.0409

7.3

C24

338.64

2.53

.0205

7.4

C25

352.67

2.55

.0205

7.4

C26

366.69

2.56

.0205

7.4

C28

394.74

2.60

.0216

7.4

C30

422.80

2.63

.0239

7.4

1-1

1-5

1-6

1-7

Cn

%

Injection

RT

(min)

58

5-2:

Summary of Run 2.

Operating Conditions:

olventToluene, Temperature-22C, Columns - 1 x 100A Ultrastyragel, Flowrate- 1 ml/min, Injection Volume

100 pl, Polarity - Positive.

Inj ection

*

Cn*

MW

log MW

WT

%

-

TABLE

RT

(min)

2-1

C19

268.51

2.43

.1182

7.46

2-2

C20

282.54

2.45

.1136

7.36

2-3

C21

296.52

2.47

.1159

7.29

2-4

C22

310.59

2.49

.1091

7.19

2-5

C23

324.61

2.51

.1114

7.12

2-6

C24