Investigation of Microstructure of Disordered Colloidal Systems by

r

Small-Angle Scattering

by

USETT

OCT 2 9

Wei-Shan Chiang

uNTIUEEssa

2014

LIBRARIES

B.S., Chemical Engineering (2006), National Tsing Hua University

M.S., Chemical Engineering (2008), National Tsing Hua University

Submitted to the Department of Nuclear Science and Engineering

In partial fulfilment of the requirements for the degree of

DOCTOR OF PHILOSOPHY IN NUCLEAR SCIENCE AND ENGINEERING

at the

MASSACHUSETTS INSTITUTE OF TECHNOLOGY

September 2014

Massachusetts Institute of Technology 2014. All rights reserved.

Signature redacted

Department of Nuclear Science and Engineering

August 22, 2014

Signature redacted

Certified by

Sow-Hsin Chen

Professor Emeritus of Nuclear Science and Engineering

Thesis Supervisor

Signature redacted

Certified by

Sidney Yip

Professor Emeritus of Nuclear Science and Engineering

and Materials Science and Engineering

Thesis Reader

Signature redacted

Accepted by

Mujid S. Kazimi

TEPCO Professor of Nuclear Engineering

Chair, Department Committee on Graduate Students

2

Investigation of Microstructure of Disordered Colloidal Systems by

Small-Angle Scattering

by

Wei-Shan Chiang

Submitted to the Department of Nuclear Science and Engineering

on August 22, 2014, in partial fulfilment of the requirements for the degree of

DOCTOR OF PHILOSOPHY IN NUCLEAR SCIENCE AND ENGINEERING

Abstract

Small-angle scattering (SAS) has been widely applied to study the microstructure of colloidal

systems. Although colloids cover a wide range of materials, in general they can simply be

viewed as basic building particles arranging themselves, according to their interaction, in a

continuous medium. In this study, three seemingly very different systems were investigated

under various conditions. They are the calcium-silicate-hydrate (C-S-H) gel, magnesium-silicatehydrate (M-S-H) gel, and micellar solution formed by Pluronics triblock copolymers.

C-S-H is the main binding phase of ordinary Portland cements. An elaborate analytical model for

the form factor of C-S-H basic building particles was established for the first time. This model

has ability to integrate two different models together by taking two different limits of the form

factor formula. Essential structural parameters of C-S-H gels prepared at various conditions were

extracted through model fitting. It was found in this study that microstructure of C-S-H gels

changes from continuous planar pore structure to discrete colloidal structure when increasing

water content or adding methylhydroxyethyl cellulose additive. Open microstructure or small

globule size leads to higher flowability or facilitates the extrusion process as macroscopic

properties.

Much attention has been paid recently to the MgO-based green cements due to the little CO 2

generated during their production process compared with the ordinary cements. However, the

poor mechanical properties prevent them from implementing widescale use. This current study

on microstructure of both C-S-H and M-S-H gels indicates that the primary unit at the nanoscale

level of C-S-H to be a multilayer disk-like globule, whereas for M-S-H it is a spherical globule.

This prominent difference at the nanoscale also reflects in gel structure at micrometer lengthscale. The surface contact between the basic particles found in C-S-H gels leads to better

mechanical properties than M-S-H gels which interact through point contact. This study

therefore gives essential insight to design future robust and eco-friendly binders.

Pluronics is a class of amphiphilic copolymers which aggregate to form micelle particles in water.

Small-angle neutron scattering contrast variation measurements were conducted to extract the

microstructure, especially the solvent distribution within the micelle particles, under several

conditions. It is suggested in this study that high water content found in the micelles formed by

short copolymer chains but same PO/EO ratio promotes composition fluctuation within the

micelles and in turn stabilizes the liquid-like micelle phase. In addition, the dehydration of core

region of the micelles due to increasing concentration or temperature leads to phase transition

3

from liquid-like to crystalline micelle state. These results can deepen the current understanding

of the complicated phase behaviors of amphiphilic copolymers.

Although the three systems studied have very different features, this work demonstrates that they

can all be tackled by similar SAS analysis. Furthermore, structure-property relationships and

structure-phase behavior relationships are established based on the results.

Thesis Supervisor: Sow-Hsin Chen

Title: Professor of Nuclear Science and Engineering

Thesis Reader: Sidney Yip

Title: Professor of Nuclear Science and Engineering

and Materials Science and Engineering

4

Acknowledgments

First, I thanks for the funding supported by U.S. Department of Energy (DOE) to Prof. Sow-Hsin

Chen. Because of it, I can finish my thesis work without worrying the financial resource. During

my six years at MIT, many people helped me to make this thesis possible. Among them, I specially

thank my thesis supervisor Professor Sow-Hsin Chen, who inspired me, guided me to the field of

neutron/X-ray scattering, and challenged me to think more deeply. His enthusiasm for science has

encouraged me and his deep physical insight has helped me to understand my research problems.

Also, I would like to express my sincere gratitude to my thesis reader Professor Sidney Yip, who

encouraged me and offered me invaluable advices on both my research and my career life. My

thanks also go to Professor Piero Baglioni and Dr. Emiliano Fratini, to whom I am truly indebted

for providing unconditionally experimental materials. I would also thank Professor Bilge Yildiz to

join my thesis committee and give me suggestions despite her very busy schedule.

I owe a great debt to my collaborators Prof. Piero Baglionil, Emiliano Fratini, U-Ser Jeng, Prof.

Sung-Min Choi, Yi-Qi Yeh, Chun-Jen Su, Sung-Hwan Lim, Giovanni Ferraro, Francesca Ridi,

Kao-Hsiang Liu, Christopher Bertrand, Yun Liu, Madhusudan Tyagi, William Heller, Ken Littrell,

Eugene Mamontov, Ahmet Alatas, Dazhi Liu, Zhe Wang, Hua Li, Jer-Lai Kuo, Mingda Li, Peisi

Le, Kanae Ito for their substantial assistance in sample preparations, experiments, and all other

possible ways. I specially thank Wei-Ren Chen and Xin Li for their discussion and suggestions.

My acknowledgment also goes to the countless others at MIT, NIST, ORNL, NSRRC, who have

helped me. All of your efforts made the work in this thesis possible.

During the years at MIT, I fortunately met a lot of friends, who have made my life more enjoyable

and fun. I would like to specially thank Kao-Hsiang Liu, Stephanie Lam, Heather Beem, Michelle

Chang, Nan Li, Yu Gao, Chia-Yu Chen, Chia-Hung Chen, Yue Fan, Xiangqiang Chu, Yang Zhang,

Marco Lagi, Dazhi Liu, Fei Yan, Nicolas Stauff, and Naveen Prabhat.

I really want to thank sisters and brothers in CBCGB who support me and pray for me all the time.

I want to give thanks to my God, Jesus Christ, who guides me and leads me through the whole

Ph.D. journey. Without Him, I couldn't go this far.

5

Finally, I dedicate this thesis to my father, Chien-Wen Chiang, my mother, Mei-Lien Chang, and

my brother, Wei-Lun Chiang. I love you.

6

Contents

List of Figures ...............................................................................................................................................

9

List of Tables .............................................................................................................................................. 14

Chapter 1.....................................................................................................................................................15

Introduction.................................................................................................................................................15

1.1 Disordered Colloidal Systems...........................................................................................................15

1.2 Small-Angle Scattering (SAS)..........................................................................................................15

1.3 Overview of the Thesis .....................................................................................................................

18

Chapter 2.....................................................................................................................................................20

M icrostructure of Calcium -Silicate-Hydrate Gel................................................................................... 20

2.1 Introduction.......................................................................................................................................20

2.1.1 M icrostructure of Pure Calcium -Silicate-Hydrate Gel........................................................... 20

2.1.2 Effect of Polycarboxylic Ether (PCE) A dditives ................................................................... 25

2.1.3 Effect of M ethylhydroxyethyl Cellulose (Culm inal)............................................................ 28

2.1.4 Effect of Ca/Si Ratio..................................................................................................................29

2.2 Materials ........................................................................................................................................... 30

2.2.1 Pure C-S-H gels w ith Different W ater Content ..................................................................... 30

2.2.2 C-S-H gels with Polycarboxylic Ether (PCE) A dditives ....................................................... 31

2.2.3 C-S-H gels with Methylhydroxyethyl Cellulose (Culminal) Additives.....................................32

2.2.4 C-S-H gels with Different Ca/Si Ratio ................................................................................... 32

2.3 Analytical Form of Small-Angle Scattering (SAS) Model............................................................... 33

2.4 Results and Discussion .....................................................................................................................

38

2.4.1 Pure C-S-H gels with Different Water Content ..................................................................... 38

2.4.2 Effect of Polycarboxylic Ether (PCE) Additives ................................................................... 48

2.4.3 C-S-H gels with Methylhydroxyethyl Cellulose (MEHC, Culminal) Additives ................... 59

2.4.4 C-S-H gels with Different Ca/Si Ratio................................................................................... 64

Chapter 3.....................................................................................................................................................69

Microstructure of Magnesium-Silicate-Hydrate Globules..........................................................................69

3.1 Introduction.......................................................................................................................................69

3.2 Materials ........................................................................................................................................... 70

3.3 Analytical Form of Small-Angle X-ray Scattering (SAS) Model................................................. 72

3.3.1 Inter-globule structure factor ................................................................................................

7

73

3.3.2 Intra-globule structure factor .................................................................................................. 73

3.4 Results and Discussion .....................................................................................................................

76

3.4.1 N anom eter to subm icron length-scale...................................................................................

76

3.4.2 Angstrom length-scale ...............................................................................................................

84

3.4.3 Submicron to m icrom eter length-scale ..................................................................................

86

Chapter 4.....................................................................................................................................................88

M icrostructure of Pluronics M icellar Solutions.....................................................................................

88

4.1 Introduction.......................................................................................................................................88

4.2 Materials ...........................................................................................................................................

90

4.3 Analytical Form of Sm all-Angle N eutron Scattering (SAN S)..........................................................91

4.3.1 Intraparticle Structure Factor ..................................................................................................... 92

4.3.1 Interparticle Structure Factor................................................................................................

95

4.4 Results and Discussion.....................................................................................................................96

4.4.1 Effect of Molecular Weight...........................................................................

98

4.4.2 Effect of Temperature..............................................................................................................103

4.4.3 Effect of Concentration............................................................................................................106

4.4.4 Effect of Hydrophobic/Hydrophilic (PO/EO) Ratio ................................................................

Chapter5.....

..............................

..................................................................... 115

Sum mary and Future Work.........................................................................................................................

5.1 Sum mary .......

110

.......................................................................................................................

115

115

5. 1.1 Cement binders........................................................................................................................

115

5.1.2 Pluronics M icellar Solutions ....................................................................................................

118

5.2 Future Work M i..... a..........

....................................................................................................

5.2.1 Cement binders ........................................................................................................................

121

121

5.2.2 Pluronics Micellar Solutions....................................................................................................123

Appendix A...............................................................................................................................................124

A List of Publications ...............................................................................................................................

124

Bibliography .............................................................................................................................................

127

8

List of Figures

Figure 2.1.1- 1 (a) Jennings' colloidal Model-II, CM-II. The C-S-H gel has a fractal structure with a fractal

dimension, D, and a cutoff length,

. (b) Structure of the basic building block of the C-S-H gel, i.e. the

globule. R is the disk radius, 0 is the angle between the wave vector

Q

and the rotation axis of the globule,

L, and L 2 are the layer thickness of hydration water and hydrated calcium silicate, respectively, and p,

and p2 are their corresponding scattering length densities (slds). p, is the solvent sld.

3

thickness of the globule.

.. ..

t is the total

....................................................................................................

22

Figure 2.1.2- 1 Chemical structure of the investigated polycarboxylic ethers (PCEs) with controlled density

(n:m) and length (p) of the side chains.34 .................................................. . . . .. . . . .. . . .. . . . .. . . .. . . .. . . . .. . . .. . . . .. . . . 27

Figure 2.1.3- 1 Chemical structure of methylhydroxyethyl cellulose (MHEC)...................................29

Figure 2.4.1- 1 Absolute intensity

I(Q)

versus

Q

for C-S-H at three different water contents: 10% (black

square), 17% (red circle), and 30% (blue triangle) at 25 C. The inset shows the enlargement of the peak

arising from the interlamellar distance of the globule. The error bars throughout the text represent one

stan dard deviation .3 ..................................................................................................................................... 39

Figure 2.4.1- 2 Model fitting results of C-S-H gel at water content (a) 10% (b) 17%. The upper left panel

shows the absolute intensity of the data (green circle) and its corresponding fitted curve (red line), the upper

right panel shows the effective Schultz distribution of the number of layers in the globules, the lower left

panel shows the structure factor S(Q) of the fractal structure, and the lower right panel shows the particle

structure factor of the globule (P(Q))orientatio,n . The error bars of the experimental data in upper left panels

represent one standard deviation and are smaller than the circle. The fitted parameters used here are listed

in Table 2.4.1- 1.3

..........

................................................................................................... 42

Figure 2.4.1- 3 Model fitting results of C-S-H gel at water content 30% at 25 *C. The upper left panel

shows the absolute intensity of the data (green circle) and its corresponding fitted curve (red line), the upper

right panel shows the effective Schultz distribution of the number of layers in the globules, the lower left

panel shows the structure factor S(Q) of the fractal structure, and the lower right panel shows the particle

structure factor of the globule (P(Q))rientatio,n . The error bars of the experimental data in upper left panels

represent one standard deviation and are smaller than the circle. The fitted parameters used here are listed

in Table 2.4.1- 1.3

..........

................................................................................................... 43

Figure 2.4.1- 4 Illustration of C-S-H globule microstructure at water content of 30%. The average number

of layers n = 10.9, the standard deviation odistance L = 11.3

= 10.2, the disk radius R = 95.0

A,

and the interlayer

A with water layer thickness L, = 7.9 A and calcium silicate layer thickness L 2 = 3.5 A.

9

The number of layers follows a Schultz distribution as shown in the upper right panel in Figure 2.4.1- 3.

The globules are indeed disk-like objects.3................................................ .. . . . .. . . . . . .. . . . .. . . . . . .. . . . .. . . . . .. . . . . . . 48

Figure 2.4.2- 1 Model fitting results of the pure C-S-H sample. (a) Experimental data of SAXS (blue open

circle) and SANS (black open circle) and the corresponding data fitting curves of SAXS (cyan line) and

SANS (red line) of the pure C-S-H sample. The SAXS experimental and fitting intensities are shift in yaxis by timing a factor 10 for clarity. (b) inter-particle structure factor S(Q) of the SAXS data (blue solid

triangle) and SANS data (black solid circle, not seen because it is almost the same curve as the s(Q) of the

SAXS data) and intra-particle structure factor P(Q) of the SAXS data (green open triangle) and SANS data

(red open circle) used to fit the data in panel (a). The difference in P(Q) comes from the different x of

neutron and X-ray. The error bars of the experimental data represent one standard deviation. The cartoons

in panel (a) show the fractal structure suggested by s(Q) and the multi-layered cylinder model we use for

P(Q) .4..........................................................................................................................................................

50

Figure 2.4.2- 2 Model fitting results of (a) SAXS data and (b) SANS data. Both panels show the

experimental data for pure C-S-H (black open square), C-S-H/PCE23-2 (blue open up-triangle), C-S-

H/PCE23-6 (magenta open left-triangle), C-S-H/PCE102-2 (navy open diamond), C-S-H/PCE102-6 (pink

open hexagon), and the data fitting curves for pure C-S-H (red), C-S-H/PCE23-2 (orange), C-S-H/PCE236 (cyan), C-S-H/PCE102-2 (green), C-S-H/PCE102-6 (dark yellow). The experimental and fitting

intensities are shifted in y-axis by timing factors of 104 (pure C-S-H), 103 (C-S-H/PCE23-2), 102 (C-SH/PCE102-6), and 101 (C-S-H/PCE102-2) for clarity. 4 ...................................... . .. . . . . .. . . . . .. . . . . .. . . . . .. . . . .. . . . 51

Figure 2.4.2- 3 The effective Schultz distribution of the total thickness t = n L of the globules for samples

of pure C-S-H (black line with solid square), C-S-H/PCE23-2 (red line with solid circle), C-S-H/PCE23-6

(green line with solid up-triangle), C-S-H/PCE102-2 (blue line with solid down-triangle), C-S-H/PCE 1026 (magenta line with solid left-triangle). The normalization condition is

J fs (t) dt = L

54

.4................

0

Figure 2.4.2- 4 Detail of the thermogravimetric measurements, presented as derivative weight loss vs.

temperature, of the four C-S-H samples synthesized in presence of additives. The pure C-S-H sample (not

shown here) gives a smooth baseline showing no features in the reported temperature range and in particular

at 380 and 400 C. 4 .................................................................................................................................... 56

Figure 2.4.2- 5 FE-SEM images of (a)-(b) C-S-H, (c)-(d) C-S-H/PCE102-2, (e)-(f) C-S-H/PCE102-6, (g)(h) C-S-H/PCE23-2, and (i)-(j) C-S-H/PCE23-6. Images on the left correspond to 25X magnification (bar

= 1 Pim) while images on the right correspond to 75X magnification (bar = 200 nm). 4 ............ . . . . . .. . . . .

. .

58

Figure 2.4.3- 1 Model fitting results of SAXS data for C-S-H (blue open circle) and C-S-H/MHEC (red

open up-triangle). The corresponding data fitting curves are denoted by black lines. The experimental and

fitting intensities for C-S-H are shifted in y-axis for clarity. The error bars of the experimental data represent

one standard deviation and are smaller than the symbols. The fitted parameters used here are listed in Table

2.4.3- 1.5

..................................................................................................................... 61

Figure 2.4.3- 2 The effective Schultz distribution of the total thickness t = nL of the multilayer disk-like

globules, due to the distribution of the number of repeating layers n, for C-S-H (blue solid square) and CS-H/MHEC (red solid circle). We assume no distribution of the disk radius R of the globules. The

fs (t) dt = 1.5....................................................................................................62

norm alization condition is

0

10

Figure 2.4.3- 3 SEM micrographs of: (a) C-S-H and (b) C-S-H/MHEC at magnification 90 kX. Scale bar

is 200 nm. . ................................................................................................................................................. 63

Figure 2.4.4- 1 Model fitting results of SAXS data for C-S-H with Ca/Si = 1.0 (blue open square) and CS-H with Ca/Si = 1.4 (red open diamond). The corresponding data fitting curves are denoted by black lines.

The experimental and fitting intensities for C-S-H with Ca/Si = 1.0 are shifted in y-axis for clarity. The

error bars of the experimental data represent one standard deviation and are smaller than the symbols. The

fitted parameters used here are listed in Table 2.4.4- 1.. ....................................................................... 66

Figure 2.4.4- 2 The effective Schultz distribution of the total thickness t = nL of the multilayer disk-like

globules, due to the distribution of the number of repeating layers n, for C-S-H with Ca/Si = 1.0 (blue solid

circle) and C-S-H with Ca/Si = 1.4 (red solid square). We assume no distribution of the disk radius R of the

globules. The normalization condition is Jfs (t) dt =1..

...........................

......

67

0

Figure 2.4.4- 3 SEM micrographs of: (a) C-S-H with Ca/Si

=

1.0 and (b) C-S-H with Ca/Si = 1.4 at

magnification 90 kX . Scale bar is 200 nm .5 .................................................

.. . . . .. . . . .. . . . .. . . . .. . . . .. . . .. . . .. . . .. . . . .

68

Figure 3.4.1- 1 The SAXS experimental data for MSH (violet open circle) and MSH* (pink open diamond).

The data fitting curves using C-S-H multilayer disk-like model are denoted by black lines. The experimental

and fitting intensities are shifted in y-axis by timing a factor of 10 for MSH for clarity. The error bars of

the experimental data represent one standard deviation and are smaller than the symbols. The fitted

param eters used here are listed in Table 3.4.1- 1................................................................................... 77

Figure 3.4.1- 2 Model fitting results of SAXS data for MSH (violet open circle) and MSH* (pink open

diamond), using polydisperse spheres as intra-particle structure factor. The data fitting curves are denoted

by black lines. The experimental and fitting intensities are shifted in y-axis for MSH for clarity. The error

bars of the experimental data represent one standard deviation and are smaller than the symbols. The fitted

param eters used here are listed in Table 3.4.1- 2.................................................................................. 80

Figure 3.4.1- 3 The Schultz distribution of the radius R of the spherical globules for MSH (violet solid

circle) and MSH* (pink solid diamond). The normalization condition is

Jfs (R)dR =1 ..................... 81

0

Figure 3.4.1- 4 Model fitting results of SAXS data for CSH (blue open diamond), MSH (red open circle),

and Mixed (olive open up-triangle), and the corresponding data fitting curves are all denoted by black lines.

The experimental and fitting intensities are shifted in y-axis for MSH and Mixed for clarity. The error bars

of the experimental data represent one standard deviation and are smaller than the symbols. The fitted

param eters used here are listed in Table 3.4.1- 2.. ................................................................................. 83

Figure 3.4.2- 1 WAXS data for CSH (blue), MSH (red), and Mixed (olive). "*" indicates the peaks

attributed to Tobermorite Cas(Si6O1 6(OH) 2).4(H20) 38 and "#" denotes the peaks contributed by Lizardite

(Mg 3Si 2Os(OH) 4). 74 The WAXS intensities are shifted along the y-axis for the sake of clarity.5

.. . . . . .

85

Figure 3.4.3- 1 SEM micrographs of: (a) CSH and (b) MSH (c) Mixed at magnification 90 kX. Scale bar

is 200 nm

.

. ....................................................................................................................

11

87

Figure 4.4.1- 1 The SANS experimental data and the corresponding model fitting curves for 0.05 g/ml

micellar solutions of (a) F88 and (b) F108 Pluronics copolymers at 60 0C in 100% D 20 (magenta open

right-triangle), 90% D 20 (olive open diamond), 80% D 20 (blue open up-triangle), and 70% D20 (red open

circle). The fitting curves are denoted by black lines. The error bars of the experimental data represent one

standard deviation and are smaller than the symbols. The experimental and fitting intensities are subtracted

by a constant incoherent background and shifted on the y-axis for the sake of clarity. (c) The neutron

scattering length density (SLD) profile of the F88 (dotted line) and F108 (solid line) micelles pmicee(r) with

the same colors as described in (a) and (b). The orange lines are SLD profile of polymeric component

ppoiymer(r). r represents the distance to the micelle center. (d) The radial water number density distribution

H(r) determined from equation (4.3.1.6) for F88 (red line) and F108 (blue line). The inset shows the

accumulated number of water distribution within the sphere with radius r..............................................102

Figure 4.4.1- 2 Illustration of microstructure change of type B Pluronics micellar solutions when increasing

molecular weight.......................................................................................................................................103

Figure 4.4.2- 1 The SANS experimental data and the corresponding model fitting curves for 0.05 g/ml

micellar solutions in 100% D 20 of (a) F88 and (b) F 108 Pluronics copolymers at temperature 80 "C (orange

down up-triangle), 70 C (magenta open right-triangle), 60 *C (olive open diamond), 50 0C (blue open uptriangle), and 40 C (red open circle). The fitting curves are denoted by black lines. The error bars of the

experimental data represent one standard deviation and are smaller than the symbols. The experimental and

fitting intensities are subtracted by a constant incoherent background and shifted on the y-axis for the sake

of clarity. The extracted water number density distribution H(r/Rmn) for (c) F88 and (d) F108. The inset is

the enlargement of H(r/Rin) within the micellar core. The colors shown in (c) are the same as described in

(a) and that in (d) are the same as described in (b) .................................................................................. 105

Figure 4.4.2- 2 Illustration of microstructure change of Pluronics micellar solutions when increasing

temperature...............................................................................................................................................106

Figure 4.4.3- 1 (a) The SANS experimental data and the corresponding model fitting curves for F108

micellar solutions in 100% D 20 at 80 *C with concentration of 0.18 g/ml (olive open diamond), 0.05 g/ml

(blue open up-triangle), and 0.01 g/ml (red open circle). The fitting curves are denoted by black lines. The

error bars of the experimental data represent one standard deviation and are smaller than the symbols. The

experimental and fitting intensities are subtracted by a constant incoherent background and shifted on the

y-axis for the sake of clarity. (b) Inter-particle structure factor S(Q). (c) The extracted water number density

distribution H(r/Rn). The inset is the enlargement of H(r/Rin) in shell region. (d) The extract polymeric SLD

distribution ppolymer(r). The colors shown in (c), (d) are the same as described in (b)...............................109

Figure 4.4.3- 2 Illustration of microstructure change of type B Pluronics micellar solutions when increasing

concentration of the copolymers...............................................................................................................110

Figure 4.4.4- 1 (a) The SANS experimental data and the corresponding model fitting curves for micellar

solutions in 100% D2 0 at 40 C for F108 0.05 g/ml (magenta open right-triangle), L64 0.05 g/ml (olive

open diamond), L64 0.01 g/ml (blue open up-triangle), and P84 0.01 g/ml (red open circle). The fitting

curves are denoted by black lines. The error bars of the experimental data represent one standard deviation

and are smaller than the symbols. The experimental and fitting intensities are subtracted by a constant

incoherent background and shifted on the y-axis for the sake of clarity. (b) The extracted water number

density distribution H(r/Rin). The colors shown in (b) is the same as described in (a).............................113

12

Figure 4.4.4- 2 Illustration of microstructure change of Pluronics micellar solutions when varying PO/EO

ratio (hydrophobicity/hydrophilicity character)........................................................................................114

Figure 5.1.1- 1 Summary of structure-property relationships of cement binders studied........................118

Figure 5.1.2- 1 Summary of structure-phase behavior relationships of micellar solutions studied.........121

13

List of Tables

Table 2.1.2- 1 Characteristics of the Polycarboxylate-type Superplasticizers 34

. . .. . .. . . .. . .. .. . .

27

Table 2.4.1- 1 Parameters extracted from the model fitting for samples measured at 25 C3 , a,b,f ........ 44

Table 2.4.2- 1 Parameters extracted from the model fitting of SAXS and SANS data 4,a...........................52

Table 2.4.3- 1 Parameters extracted from the model fitting of SAXS data of C-S-H and C-S-H/MHEC,a

.................................................................................................................................................................... 61

Table 2.4.4- 1 Parameters extracted from the model fitting of SAXS data of C-S-H with Ca/Si = 1.0 and

C-S-H with Ca/Si = 1.45,a .........................................................................................................

66

Table 3.2- 1 Chemical composition of the different silicate hydrates investigated. 5 .............. . . .. . . . .. . . . .

. .

72

Table 3.4.1- 1 Parameters extracted from the model fitting of SAXS data of M-S-H samples using C-S-H

multilayer disk-like modela ......................................................

77

Table 3.4.1- 2 Parameters extracted from the model fitting of SAXS data of CSH, MSH, MSH* and Mixed

samplessa

...................................................................

79

Table 4.2- 1 Properties of PEO-PPO-PEO Triblock Pluronics Copolymers Used in this Work ........... 91

Table 4.4- 1 Parameters Extracted from Global Model Fitting of SANS Data of PEO-PPO-PEO Triblock

Pluronics Copolym ers U sed in this W orka............................................................................................. 96

Table 4.4- 2 Parameters Related to Hydrationa

.........................................

97

14

Chapter 1

Introduction

1.1 Disordered Colloidal Systems

A colloid is a system where dispersed insoluble particles are disorderedly suspended

microscopically throughout another substance. Unlike a solution, in which solute and solvent form

only one phase, a colloid has a dispersed phase, i.e. the suspended particles, and a continuous phase,

i.e. the medium of suspension. To qualify as a colloidal system, the mixture should not settle or

would take a very long time to settle appreciably. The dispersed particles have a linear dimension

between 10-9 m (10 A) and 10-6 m (1 im). For particles with smaller size range (r<250 nm), an

ultramicroscope or an electron microscope is required to see the structure in real-space. Particles

with size larger than 250 nm are normally easily visible in an optical microscope. On the other

hand, small-angle neutron scattering (SANS) and small-angle X-ray scattering (SAXS) are shown

to be powerful tools to probe the microstructure and the interactions in the colloidal systems with

particle size between 1 nm to 100 nm. 2

1.2 Small-Angle Scattering (SAS)

Small-angle scattering (SAS) is the collective name for the techniques of small-angle neutron

(SANS), X-ray (SAXS) and light (LS) scattering. Radiation is elastically scattered by a sample in

15

these techniques. By analyzing the resulting scattering pattern, we can obtain information about

the size, shape, orientation, or polydispersity of some components of the sample and the

interactions between the particles constituting the sample. SAS is a well-developed scattering

technique to study colloidal systems such as biological system, micellar solutions, and cement gels,

etc.

The small-angle scattering measures the spacial differential cross-section per unit volume as

1

N

I(Q)=i(Xb

2

(1.2.1)

2)

where bl is the scattering length of lth atom and is independent of the wave vector Q. For a isotropic

one component system bi = b. Then

I(Q)

(1.2.2)

= -- b2S(Q)

V

In a two phase system, such as micellar solutions, the scattering objects, i.e., micelle particles, can

be distinguished in appropriate conditions from the continuous solvent. Let's assume that there are

total N atoms in the system, Np macromolecules in solutions, N atoms in each macromolecule,

and Ns atoms for solvent molecules. Then we can re-write equation (1.2.1) into:

16

I

-

I(Q)=/

Np N.

j=1 1=1

Np

1

N,

1

- b,)eQ*i0' +

j=1

b, eiQrJ;

(1.2.3)

j=1

2

N.

[b(bm

V

e"

j=1

N.

Z (bmjn

j=1 1=1

Sy

bs

'' +

bme

2

NS

' .- r

m

s-b,)e'Q('R)]eiQR

1=1

+ Eb,

e'Q"

j=1

where bmyi is the scattering length of lth atom in the jth macromolecule, bs the scattering length of

a solvent atom/molecule. Since the solvent molecule is typically very small compared to 27t/Q, it

can be treated as a uniform continuous media. Thus, the last term in the above equation

Zb, e'Q"

j=1

is just 6(Q), which contributes only at

Q = 0.

Therefore, this last term can be considered as zero

since SANS only measures the intensity at a finite

Q value.

If we can further assume that each

macromolecule in the solvent is the same, and it is spherically isotropic, a more useful expression

is written as

N

I(Q)

(bm

2

N

-b, )e'Q (''~RI)

=1

V p'

e(1.4

s

=1

'(1.2.4)

= NPP(Q) Sin,.(Q)

V

where

Nm

2

P(Q)= Z(bmj, - bs)eiQ-( I-R)

(1.2.5)

Z=1

17

N_

2

(1.2.6)

e1QR2

Sit ,.(Q)=

N ;=

P(Q) is called the intra-particle structure factor, or form factor. Sinter(Q) is called the inter-particle

structure factor. P(Q) is only determined by the structure of each individual macromolecule and

Sinter(Q) describes

the correlations between the centers of macromolecules. In the study of the inter-

colloidal correlation in solutions, people usually drop the subscript and use S(Q) as the interparticle structure factor.

In general, the fitting of I(Q) require the knowledge of both P(Q) and S(Q). P(Q) describes the

size, shape, polydispersity, etc., of scattering objects. In principle, for a simple liquid sample, S(Q)

can be calculated through the Orstein-Zernike (OZ) equation once the inter-particle potential is

known.

1.3 Overview of the Thesis

This thesis is consisted of five chapters. Chapter 1 is a general introduction of disordered colloidal

systems that I am interested in and the main method, i.e. small-angle scattering (SAS), I used to

tackle the systems.

In the main body, I discuss my investigations on the microstructure of three seemingly very

different systems: calcium-silicate-hydrate (C-S-H) gels (Chapter 2),3-5 magnesium-silicatehydrate (M-S-H) gels (Chapter 3),5 and Pluronics micellar solutions (Chapter 4). Due to their

common feature of basic building particles dispersing disorderedly in a continuous medium, I

demonstrate that they can be tackled similarly through small-angle scattering. Wide-angle X-ray

18

scattering (WAXS) and scanning electron microscope (SEM) were also used to support and

supplement the findings. In each of these chapters, relevant sample descriptions, SAS analysis

models, data analysis results and discussion are explained. Most of the contents are based on my

publications in the past siX years, listed in Appendix

In Chapter 5 gives the summary of the current .work and some perspective of future work.

19

Chapter 2

Microstructure

Hydrate Gel

of

Calcium-Silicate-

2.1 Introduction

2.1.1 Microstructure of Pure Calcium-Silicate-Hydrate Gel

Cement is a synthetic material of largest production in modern society. There is more than 11

billion metric tons of cement consumed every year all over the world. However, to manufacture

one ton of Portland cement clinker, approximately 0.8 tons of C02 is emitted into the air, which

contributes 5% - 7% of the total human-made C02 emissions. 6 The requirement of reducing cement

usage therefore motivates many studies on properties of cement for the sake of a more efficient

use of this material. Hydrated calcium silicate gel (CaO)x(SiO2)(H20)y or shortly C-S-H is the

main binding phase in the commercial cement pastes. Its presence is critical to the development of

strength and durability of a cement paste. Studies of the microstructure of C-S-H and its effect on

the cement properties are therefore essential to the optimized usage of C-S-H-based cements.

C-S-H is a gel-like material. Existing C-S-H structural models relay on two different theories. On

one side, Feldman and Sereda (FS) and others7 '8 considered the C-S-H gel network as formed by

irregular C-S-H interconnected layers with adsorbed and interlayered water molecules. On the

other side, Power and Brownyard (PB) and others 91' 0 supposed the existence of basic C-S-H units,

which generate the C-S-H gel structure as a colloid made of small bricks and its associate gel pores.

20

Subsequently, Jennings11-13 combined the FS and PB hypothesis and obtained a hybrid model able

to give an exhaustive interpretation of several experimental evidences such as those derived from

scattering measurements14

15

and sorption isotherms experiments." According to Jennings'

Colloidal Model-II (CM-II)," C-S-H gel present in a hydrated cement paste can be described

schematically as shown in Figure 2.1.1- 1(a). This gel is consisted of assemblies of hydrated

globules immersed in aqueous solvent or air depending on the equilibrium water content. In this

context, the globules are multi-lamellar objects with an average thickness of about 4.2 nm. Inside

the globules, water can be located in both the interlayer spaces and the very small cavities, called

intraglobular pores (IGP), with dimensions around 1 nm. These building blocks pack together to

form a porous structure with two main classes of pores: the small gel pores (SGP) with dimension

of 1-3 nm and large gel pores (LGP) with size in the range from 3 to 12 nm. Greater pores are

usually referred as capillary pores.

21

(a)

(b)

D

z

1L

L~

0*L

t

Figure 2.1.1- 1 (a) Jennings' colloidal Model-II, CM-II. The C-S-H gel has a fractal structure with a fractal dimension,

D, and a cutoff length, J. (b) Structure of the basic building block of the C-S-H gel, i.e. the globule. R is the disk

radius,

0 is the angle between the wave vector

Q

thickness of hydration water and hydrated calcium silicate, respectively, and

scattering length densities (slds).

L,

and the rotation axis of the globule,

PAis the solvent sld.

p, and p

2

and

L2 are the layer

are their corresponding

t is the total thickness of the globule.3

Microstructure information is essential to predict and understand the mechanical behavior of the

material at larger length-scales.'

6

In the cement field, several empirical relations were developed

to show that the compressive strength is a function of the cement microstructure, especially the

porosity. This is valid in general for other brittle materials."7 The advancement of statistical

nanoindentation technique allowed one to locate the high and low density C-S-H phases in cement

pastes prepared at water-to-cement ratios lower than 0.4. Moreover, it provided strong evidences

for the existence of a ultra-high density phase along with the well-known high and low density CS-H phases.' 8"19

22

Neutron scattering technique has been extensively used on cement pastes to investigate the

structure of the developing C-S-H gel14, 5 ,20 and to access the dynamics of the water confined in

the gel porosity.2 1-23 In particular, Allen and coworkers" used small-angle neutron scattering

(SANS) technique to study the developing gel structure during the hydration process in Ordinary

Portland Cement (OPC). Their results suggested that C-S-H gel is formed by discrete globules

with 5 nm diameter which further aggregate together to give a scale-invariant structure with

correlation lengths up to about 40 nm. Based on this scenario, their analytical model comprises an

inter-globule structure factor, S(Q), describing the fractal nature of clustering with a mass fractal

dimension D of about 2.6 and an intra-globule structure factor, P(Q), representing an "effective"

spherical shape with a diameter of about 5 nm. This picture turns out to be consistent with their

SANS and small-angle X-ray scattering (SAXS) results.14" 5 However, since they only explored

the Q-range up to about 0.2

Q was

A-1, where Q is the magnitude

of scattering wave vector, their highest

not enough to explore the details of the globule and therefore its internal structure is still

uncertain.

Very recently, Pellenq and coworkers 24 proposed a molecular model of C-S-H based on a bottomup atomistic simulation. Starting from a dry orthorhombic tobermorite lattice with a 11 A interlayer

spacing and using Grand Canonical Monte Carlo (GCMC) technique, they obtained a model in

which water is present both in the interlayer space and in the intralayer cavities inside the calcium

oxide layers. This model with calcium/silicon ratio (C/S) = 1.65 results in an interlayer spacing

ranging from 11.3 A to 11.9 A and C-S-H density of 2.56 g/cm 3 , a value close to the experimental

result of 2.6 g/cm 3 found by Allen et al.14 for a very similar C/S ratio = 1.7. Dolado et al.2 5,2 6

simulated the formation of C-S-H structures through the polymerization of Si(OH) 4 species which

were allowed to react in the presence of solvated calcium ions. This approach is very general and

23

is not based on any pre-imposed structural model. Their main results25 show that at low C/S ratios,

the simulated C-S-H systems resemble mixtures of 1.1, 1.4-nm tobermorite and jennite structures

with pentamers or longer chains, while at high C/S ratios, only short 1.4 nm tobermorite and jennite

pieces seem to be formed. Intermediate C/S ratios gradually evolve from long to short chains, and

from tobermorite- to jennite-like features. Notably, their recent MD simulations 2 6 suggest that CS-H gel forms a three-dimensional branched structure as a result of interweaving and restructuring

processes of growing C-S-H segmental branches (SB). Moreover, they showed that the scattering

and diffraction patterns calculated from SB structures are in good agreement with both SANS data,

measured by Allen et al.14 for

Q > 0.05 A-1,

which give evidence for a peak at

Q

and recent X-Ray Diffraction (XRD) investigations, 6

~ 0.5 A-1 linked to d-spacing in the calcium silicate layers of

about 12 A. Skinner et al.6 used XRD method to show that the synthetic C-S-H is nanocrystalline

with a characteristic nanograin size of about 3.5 nm and disclosed a remarkable resemblance of

synthetic C-S-H structure with 11

A tobermorite.

McDonald et al.2 ' analyzed NMR data of white

cement pastes considering water in both intra- and inter-C-S-H pores and proposed an alternative

microstructure of C-S-H gel without assuming a finite building block. They suggested that the CS-H intra-layer distance is about 15

A,

while the inter-C-S-H porosity is around 41 A thick.

Although all these studies indicate a characteristic intra-layer length-scale of 10-15

A, a direct link

between this length-scale and the globule proposed in CM-II is still missing.

In this study, we assume the globule to be a multi-lamellar object with unknown total thickness t

and radius R as depicted in Figure 2.1.1- 1(b). The globule has a layered sub-structure where

water and calcium silicate layers are alternatively repeated. The present approach is so general that

changing the two descriptive parameters t and R takes into account disks-like objects (t «2R),

spheroidal geometries ( t = 2R ) and even rod-like symmetries ( t

24

>> 2R

). In the following

discussion, we denote L as the inter-layer distance of the sub-structure. L can be decomposed into

one layer of water with thickness Li and one layer of calcium silicate with thickness L 2 and

therefore L = L, + L 2. The resultant unknown total thickness of the globule can then be calculated

as t = iL, where n is the average number of layers in one globule derived from our model fitting.

To the best of our knowledge, this model is the only one that can successfully describe the internal

structure of the globule itself and to justify SANS intensity distributions from low-Q region up to

1 ^-. Our model differs from the results of Dolado et al.2 6 and McDonald et al.27 , which do not

consider in an explicit way the existence of a primary building block for the C-S-H gel structure.

2.1.2 Effect of Polycarboxylic Ether (PCE) Additives

The mechanical properties of cement depend on the progressive maturation of hydrated porous

phases due to the continuous reaction of water with the cement. This hydration process can last for

several years. It is strongly affected by additives, many of which have been developed in recent

years. The efficiency of these additives to produce high-performance concretes (HPC), i.e. cement

with extremely low porosity and enhanced strength and elasticity, is continuously being

improved. 2 8,2 9,30 Superplasticizers (SPs) are compounds irreplaceable to the construction industry

that are used as additives to produce HPC. These polymers have been shown to improve the

flowability and workability of concrete pastes, to keep the water content of cement low, and to

ensure the high mechanical strength, shrinkage, and durability of the hardened cementitious

composite. 28 ,2 9 ,3 0 The comb-shaped polycarboxylic ethers (PCEs) are among the most effective

SPs used in the cement industry. The simplest PCEs are composed of a polyacrylic or

polymethacrylic anionic backbone with grafted polyethylene oxide (PEO) uncharged side chains.

25

Each of these pieces can be tuned to produce several graft copolymers varying in the molecular

weights and chemical structures. The effect of adding PCEs depends on the chosen chemical

3

structure, which can dramatically alter the interaction between PCEs and the cement matrix. 1-36

The adsorption of the PCEs on the surface of the cement particles increases if the density or length

of the PEO side chains is decreased. In particular, the decrease of side chain density increases the

number of negative charges (i.e. the number of free carboxylic groups on the backbone) while the

shortening of the PEO chain length reduces the overall steric hindrance, rendering the negative

charges on the backbone more accessible. It was therefore concluded by Zingg et al.3 7 that the

enhanced adsorption of the PCEs on cement particles is induced by the interaction of the carboxylic

groups on the PCE backbone with calcium ions and that different levels of adsorption modify the

rheology and hydration kinetics of the final cement pastes.

While the influence of PCEs on the macroscopic observables of cement (rheology, mechanical

properties, and hydration dynamics) has been reported in the literature,31-36 the change of the C-SH microstructure due to the PCE additives remains mostly unknown. In this study, we use the

combination of small-angle neutron scattering (SANS) and small-angle X-ray scattering (SAXS)

techniques to investigate the microstructural changes of the C-S-H (I) gel before and after the

addition of PCEs with defined chemical structures. Pure C-S-H gel together with four C-S-H gels

including different PCEs, namely, PCE23-2, PCE23-6, PCE102-2, and PCE102-6, were studied. 34

The details of chemical structures of these polymeric additives are listed in Table 2.1.2- 1 and

pictured in Figure 2.1.2- 1. To the best of our knowledge, this is the first time that the influence of

PCE additives on the microstructure of C-S-H gel has been studied in detail.

26

L

n

-m

NaO

0

0

H3C

P

Figure 2.1.2- 1 Chemical structure of the investigated polycarboxylic ethers (PCEs) with controlled density (n:m)

and length (p) of the side chains. 34

Table 2.1.2- 1 Characteristics of the Polycarboxylate-type Superplasticizers3 4

length of side

MNa

MWb

chain (p)

density of side

chains (n:m)

(g/mol)

(g/mol)

PDIC

PCE 102-2

102

2:1

16 800

78 000

4.7

PCE102-6

102

6:1

14 600

67 000

4.6

PCE23-2

23

2:1

8700

25 600

2.9

PCE23-6

23

6:1

7600

18 900

2.5

aMN: Number average molecular weight. bMw: Mass average

molecular weight. PDI = MW/MN: polydispersity index.

27

2.1.3 Effect of Methylhydroxyethyl Cellulose (Culminal)

The continuous extrusion of cement-based mixtures is a method to produce sheets, bricks, spacers,

sewer pipes, etc. It is one of the most promising applications to obtain new cementitious materials.

Compared with the production process of conventional ceramic materials, continuous extrusion

uses considerably little energy. Extrusion is a processing technique shown to impart high

performance characteristics to fiber-reinforced cementitious materials. 38 During the extrusion

process, a highly viscous and plasticlike mixture is forced to go through a die, which has a rigid

opening of desired cross section.

In order for the cement pastes to have extrusion process, an additive must be added to confer

fluidity and plasticity to the final paste and to enable it to be passed through the die, extruded, and

handled without changing in shape or cracking. One of the best-performing classes of polymers

used in extrusion process is methylhydroxyethyl cellulose (MHEC). Alesiani et al. 39 studied the

effect of MHEC on C 3 S by using NMR. Their results showed that the cellulosic additive interacts

with the water present inside the paste. Under these conditions, the hydration process becomes

more efficient as the water is gradually released from the cellulose ether to the calcium silicate.

In this study, we intend to investigate the MHEC effect on the microstructure of C-S-H gel. The

chemical structure of MHEC is sketched in Figure 2.1.3- 1.

28

CH 3

0U

OH

H2C

0

1OHO

\ OH

CH 3

O

O

I

HO.,C/CH2

H2

Figure 2.1.3- 1 Chemical structure of methylhydroxyethyl cellulose (MHEC).

2.1.4 Effect of Ca/Si Ratio

C-S-H is a nonstoichiometric compound. There are large local variations of Ca/Si molar ratio in

cement pastes, between 0.6 and 2.3 or greater. 40 4 2 For hydrated Portland cement pastes, the

average Ca/Si molar ratio of C-S-H is around 1.7. The Ca/Si ratio of C-S-H in hardened C3S or

neat Portland cement pastes is about 1.75 in avarage, 42 with a range of values within a given paste

from 1.2 to 2.1. If there is a supplementary cementing material in the paste, then the mean Ca/Si

value is further reduced, in some cases to less than 1.42 Dolado et al. 25,26 simulated the formation

of C-S-H structures through the polymerization of Si(OH) 4 species which were allowed to react in

the presence of solvated calcium ions. This approach is very general and is not based on any preimposed structural model. Their main results 25 show that at low C/S ratios, the simulated C-S-H

systems resemble mixtures of 1.1, 1.4-nm tobermorite and jennite structures with pentamers or

longer chains, while at high C/S ratios, only short 1.4 nm tobermorite and jennite pieces seem to

29

be formed. Intermediate C/S ratios gradually evolve from long to short chains, and from

tobermorite- to jennite-like features.

In this study, we intend to investigate the effect of Ca/Si ratio on the microstructure of C-S-H gel.

2.2 Materials

2.2.1 Pure C-S-H gels with Different Water Content

Synthetic C-S-H was prepared by hydrating pure C 3 S in an excess of water. A chemically pure

batch of tricalcium silicate was obtained from CTG-Italcementi (Bergamo, Italy) as a gift. The

specific surface area detected by N2 sorption isotherms (BET) and mean radius of the C3S used in

the present study resulted in 0.65 m2/g and 4.66 pm, respectively. Several C-S-H batches were

prepared by mixing 4 g of C 3S with 1150 g of distilled water. The water was previously boiled and

kept sealed to avoid any subsequent carbonation, taking place during the C 3S hydration reaction.

The excess of water in respect of C3S was essential to prevent any portlandite (Ca(OH)2) coprecipitation, without altering the C-S-H formation. The resulting C3S/water dispersions were

sealed in plastic bottles to avoid carbonation and continuously stirred for at least 40 days. The

synthesis was conducted at room temperature (i.e. 25 "C). This synthetic route is known to

minimize the Ca(OH)2 content while forming quite polydisperse C-S-H phase, which is usually

refereed as C-S-H (I).43 The dispersion was filtered under a N2 atmosphere to avoid carbonation

and the obtained solid was dried in an oven at 60 *C for three hours. The resulting C-S-H gel was

dried to the desired water content using a vacuum oven operating at temperatures below 100 C.

This maximum working temperature allows water to evaporate without causing structural damages.

Energy-dispersive X-ray spectroscopy (EDX) evidenced an average Ca/Si ratio of 1.5 with a

30

standard deviation of about 0.3 confirming the expected inhomogeneity of the sample. EDX

spectra were recorded using a X-sight Oxford-Cambridge microprobe coupled with a SEM

microscope. Thermo Gravimetric Analysis was performed both to determine the effective

hydration of the so-prepared C-S-H gels and to confirm a low carbonation level. Final water

content was obtained considering the weight lost up to 200 C and was normalized only to the

amount of C-S-H present in the sample, while Ca(OH) 2 and CaCO3 contributes were calculated

according to the literature 44 and subtracted out from the original weight of the sample. The

percentages of Ca(OH)2 and CaCO3 were always in the range 5-10% in respect of the total mass

of the samples. Thermogravimetric experiments were carried out with a SDT Q600 apparatus (TA

Instruments) heating the sample at 10 C/min from 25 C to 1000 C under a constant flux of pure

N2 (100 mL/min). 10%, 17% and 30% water content cases were achieved at the end of the drying

process.

2.2.2 C-S-H gels with Polycarboxylic Ether (PCE) Additives

Synthetic C-S-H was prepared by hydrating 4 g of pure tricalcium silicate (C3S) in 1150 g of: pure

water or 0.14 % w/w PCE aqueous solution (i.e. 0.4 g of polymer per 100g of dry C3S). The

chemically pure batch of C 3 S (CTG-Italcementi, Bergamo) had a specific surface area of 0.65 m 2/g

(BET). The molecular formulae of the four PCEs used in this study (i.e. PCE23-2, PCE23-6,

PCE102-2, PCE102-6) are reported elsewhere along with relative polydispersities. 34 PCE23-2 and

PCE23-6 have PEO side-chains, which are five times shorter than PCE102-2 and PCE102-6, while

series 6 (i.e. PCE23-6 and PCE102-6) has more free carboxylic groups on the backbone. As a

result, the adsorption ability results: PCE102-2 <PCE102-6 < PCE23-2 < PCE23-6. The hydration

reaction was conducted at 25 C for 40 days. The dispersions were filtered and the water content

31

was standardized by dehydrating the samples at 60 0C in a N2 atmosphere. Final water content was

about 20% as determined by thermogravimetric analysis on the so obtained solids. The sum of

Ca(OH)2 and CaCO3 contents was always lower than 5% in all cases. Further specific details on

the synthesis can be found elsewhere. 3 The details of chemical structures of these polymeric

additives are listed in Table 2.1.2- 1 and pictured in Figure 2.1.2- 1.

2.2.3 C-S-H gels with Methylhydroxyethyl Cellulose (Culminal)

Additives

Stock solutions of sodium metasilicate (Na2SiO3-4H20) and calcium nitrate (Ca(NO3)2-6H2O)

were prepared. The solutions with volume of 1:1 Ca:Si ratio were cooled to about 00 C and mixed

by stirring in a two-necked round-bottomed flask. Methylhydroxyethyl cellulose (commercial

name Culminal) was added as additive (2.4% w/w respect to the amount of tricalcium silicate).

The flask was kept in an ice-water bath under continuous N2 flux. The sodium silicate solution

was added first, followed by slow addition of the magnesium solution. The product was warmed

to ambient temperature and the precipitate settled readily, leaving a clear supernatant solution. In

order to remove residual sodium, the precipitate was washed (diafiltrated) with deionized water

under a N2 atmosphere (to avoid carbonation).

2.2.4 C-S-H gels with Different Ca/Si Ratio

Pure C-S-H gel was prepared through a double-decomposition synthesis according to the method.

Stock solutions of sodium metasilicate (Na2SiO3-4H2O) and calcium nitrate (Ca(NO3)2-6H2O)

32

were prepared. The solutions with volume of 1:1 Ca:Si ratio and 1.4:1 Ca:Si ratio were cooled to

about 0*C and mixed by stirring in a two-necked round-bottomed flask in order to prepare C-S-H

gels with Ca/Si ratio of 1 (sample C-S-H) and 1.4 (sample CSH-B). The flask was kept in an icewater bath under continuous N 2 flux. The sodium silicate solution was added first, followed by

slow addition of the magnesium solution. The product was warmed to ambient temperature and

the precipitate settled readily, leaving a clear supernatant solution. In order to remove residual

sodium, the precipitate was washed (diafiltrated) with deionized water under a N2 atmosphere (to

avoid carbonation). At the end of the process, a small fraction of the supernatant was analyzed for

Na* concentration using flame atomic absorption spectroscopy ([Na'] <0.20

0.01 ppm) to ensure

that the by-product NaNO3 was completely removed by the washing procedure.

2.3 Analytical Form of Small-Angle Scattering (SAS) Model

The C-S-H gel can be pictured as shown in Figure 2.1.1- 1(a). The gel is consisted of globules

packing into a fractal-like object, which is immersed in an aqueous solution or air depending on

the water content. The self-similar fractal structure with a fractal dimension D only extends to a

maximum cutoff dimension of . Denoting the number density of the globule in the C-S-H gel as

N,

and the equivalent spherical radius of the globule as Re, the effective pair correlation function

of the fractal structure can be written

1

4rrN, ReD

rD-3

(2.3.7)

exp

)

g(r)= D

as45,46,47

Therefore, we can derive the inter-globule structure factor of the porous C-S-H gel as

33

zr

sin(Qr) g(r)

S(Q) =1+NNpddr 4rr2

Qr

U

1

D 7(D -1) sin (D -1)tan' (Q )

[i + (g )- 2 (D-1)/2

(QRe)D

=1+

2.3.8)

sin (D -1) tan-1(Q

)

+

Re

45,46,47

(D -1)1

+ (Q

)2

(D-

)/

2

In equation (2.3.2), F(x) is the gamma function. The value of S(Q) at

limS(Q)=1+F(D+1)(

Q=

0 limit is given by

/ Re)D , which becomes Q-independent and flat with the magnitude

proportional to the D-th power of s/Re. This low-Q limit can be used to determine the magnitude

of . For the works done for pure C-S-H at different water content and C-S-H in the present of

PCE additive, the value of

was set to be 670

A

as obtained by Allen et al. 14 determined from

their low-Q data. For other cases, the parameter of was treated as a fitting parameter because we

had access to the even lower

Q data.

The model for the internal structure of the globule having layered sub-structure is depicted in

Figure 2.1.1- 1(b). Although Jennings' model doesn't assign a specific shape to the globules, SANS

data was analyzed by assuming a general form factor for the basic units constituting the gel, where

the aspect ratio can vary from cylinders to disks passing through spheroidal objects. In Figure

2.1.1- 1(b), R is the disk radius, 9 is the angle between the wave vector

Q

and the globule rotation

axis, L1 and L2 are layer thickness of hydration water and hydrated calcium silicate, respectively,

andpi and p2 are their corresponding scattering length densities (slds). ps is the solvent sld. Finally,

n represents the number of repeating layers inside a globule. The interlayer distance, L, is equal to

the water layer thickness, Li, plus the calcium silicate thickness, L2, i.e. L = LI + L2. It is important

34

to note that different combinations of R, L and n can change the overall aspect ratio of the globule

from a cylinder-like to disk-like object. In this regard, the presented model of particle structure

factor includes both of these cases naturally.

We define the normalized particle form factor as F(Q, pu)

-

_1

r

VP

PVP

p = cosO and

V

p(F) exp(iQ " F)d3r , where

is the volume of the globule. The newly derived normalized particle structure

factor P(Q, p) is given by

2J(QR

P(Q, P) = F(Q, p)2

1-

p2)

C2(A2 +B2),3-5

(2.3.9)

QR 1- p2

where

sin QuLI

B

Q

2

Q+Ln

sn

- L2) Bi

sinQp(nL

Qp

2

2

n[ L1 +L 2

2

2

+

Qp(nL-L 2 )

+

A=Xco

sin QpL2

co Qp(nL + L1 )

2

sin QpL2

.si Qpu(nL + L,) sn2

2

(2.3.10)

Qp

(2.3.11)

Qpu

2

2

ji QpL

(2.3.12)

2

=

Pl - Ps

- PS

(2.3.13)

pA -Ps

The particle structure factor P(Q, p) of the object shown in Figure 2.1.1- 1(b) must then be

averaged over all possible directions of globule axis relative to the scattering vector Q , i.e.

35

= JP(Q,p) dp. It can be shown that the derived particle structure factor satisfies

(P(Q))

\

Orientation

0

1 at

the normalization condition (P(Q, u))rea

Q = 0.

The number of layers n, the cylindrical globule radius R, and the interlamellar distance L should

in general have their own distributions. These will further smooth the function

(P(Q).

Here we only introduce an "effective" distribution for the number of layers to take into account all

the possible distributions of n, R, and L. It is straightforward to show that a polydispersity on L has

similar effect with the one on n. In this regard, the polydispersity on n is defined to be effective

because if polydispersities are present even on R and L these will be included in that of n. We

assume the effective polydispersity as a Schultz distribution

fs(n)= Z+1

n

)n)_

nZexp -

Z+1 n /F(Z+1)

(2.3.14)

Z>-1

where n is the mean of the distribution, Z is a width parameter, and F(x) is the gamma function.

2) 1 / 2

The standard deviation of the distribution can be calculated by an = (n2 -

= n /(Z + 1)V/2.

Therefore, the orientationally averaged globule particle structure factor is then further averaged

over the effective number of layer distribution, i.e., (P(Q))rientati,,n

-

f (P(Q))rIenttin f, (n) dn

0

As a result, the measured SAS intensity distribution in the unit of cm-1 can be expressed as:

I(Q) = Np {nrR2 [(P, - Ps)L + (p - Ps )L2 ]1 2(P(Q))

Orientatinn

2

36

S(Q)+ bg[l / cm]

(2.3.15)

From the discussion above, in principle we have unknown fitting parameters in the final form of

SAS intensity distribution listed as: an overall pre-factor which accounts for the number density

of the scattering objects; six parameters contained in (P(Q))rientatio,n: inter-lamellar distance L,

calcium silicate layer thickness L2, average number of layers ni in the globule, the width parameter

Z of Schultz distribution, sld contrast ratio parameter X = (p1 - Ps) /(P 2 - Ps), disk radius of the

globule R; two additional parameters coming from S(Q): the cutoff length

and the fractal

dimension D. For SANS measurement, a flat background bg due to the incoherent scattering of

hydrogen atoms in the sample is also added. The equivalent radius Re can be calculated as

Re = (3nR 2L/4)("3 1.

The combination of SANS and SAXS data analysis allows us to extract all the structural

in equation (2.3.9) should be further convoluted to the

I(Q)Measure =

I(Q) ®

Q

resolution function R(Q) , i.e.

,

parameters much more accurately by introducing additional fitting conditions. For SANS, I(Q)

R(Q) while for SAXS, dQ/Q is very small (< 0.02 ) so for the first

approximation, we neglect the

Q resolution effect

in the X-ray case. For the work of pure C-S-H

gels at different water content, we conducted SANS experiment only to do data analysis. For the

work of C-S-H with PCE additives, we used the combined SANS and SAXS measurements to

extract all the structural parameters. We concluded from this work that SAXS itself only can get

good enough results. Therefore, for other cases (C-S-H gels at different Ca/Si ratio and C-S-H gel

with Culminal additive), only SAXS experiments were carried out to investigate the microstructure

of the C-S-H gels.

37

2.4 Results and Discussion

2.4.1 Pure C-S-H gels with Different Water Content

Our goal in this work is to determine the effect of the equilibrium water content (WC) on the

geometrical parameters (interlayer distance L, average number of layers n , and radius R of the

basic unit, i.e. globule) of the C-S-H gel with good accuracy using formula derived in section 2.3.

While reducing the water content, the gel passes from a situation where the small gel pores are

partially filled (30%) to a situation where only one monolayer of water is present on the C-S-H gel

(10%).

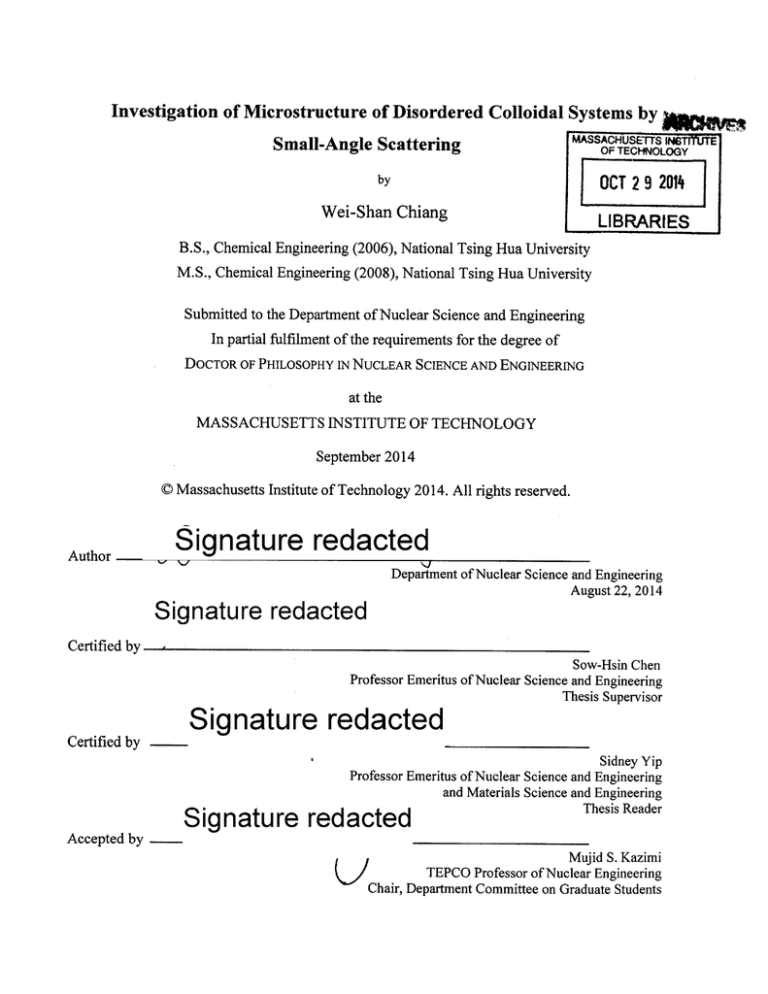

Figure 2.4.1- 1 shows the absolute intensity of C-S-H with three distinct water contents of 10%,

17%, and 30% at 25 C. The low-Q region in all the three cases is a straight line when plotted in

log-log scale, suggesting that the globules pack together to form a fractal object. At high-Q region,

there is a diffraction peak associated with the interlayer distance within the globule itself. The inset

in Figure 2.4.1- 1 displays an enlargement of SANS curves in the peak region. It is clear that on

increasing the water content, the high-Q peak shifts to a lower

Q position,

which corresponds to a

larger interlayer distance. The peak width at water contents of 10% and 17% is much broader and

less defined than the 30% case. This suggests fewer repeating units (i.e. smaller n ) for lower WC

cases. The flat incoherent background level reflects the total amount of water confined in the C-SH gel.

38

102

0.05

%

I

0.08

0.00.04

101

5

-.

0

0.4

100

10-1

0.5

0.55

0.6

0.65

0.7

0.75

0.

25 0 C

-

-2

0.45

-A-

10%

17%

30%

10

I0'

10-2

100

Q-A1

I(Q)

Figure 2.4.1- 1 Absolute intensity

versus Q for C-S-H at three different water contents: 10% (black square),

17% (red circle), and 30% (blue triangle) at 25 C. The inset shows the enlargement of the peak arising from the

interlamellar distance of the globule. The error bars throughout the text represent one standard deviation.3

Figure 2.4.1- 2 shows the fitting results of C-S-H samples at water content of (a) 10%, (b) 17%,

and Figure 2.4.1- 3 shows that of 30%, all measured at 25 C. Our model agrees with the data over

the entire Q-range from 0.02 A' to 1.00 A-1 (see the upper left panel in Figure 2.4.1- 2 and Figure

2.4.1- 3). The fitted parameters for all the investigated samples are listed in Table 2.4.1- 1. When

conducting the fitting process, the parameter

fixed to

was taken from result of Allen et al.14 and kept

= 670 A. This approximation is reasonable for two reasons. Firstly, the

covered in the present experiment is not small enough (i.e. lowest

39

Q measured

Q

range we

is only 0.01

A-1)

to

allow us for a precise estimation of . Secondly, slightly changing

during the fitting process does

not affect the fitting results of other parameters significantly. An ultra SANS experiment is

required to unambiguously determine

. Re in our S(Q) is not a fitting parameter but is

mathematically calculated by Re = (3nR2L / 4)1 , taking into account the parameters extracted

from the globule geometry. For pure C-S-H gel with 10% and 17 % water content, the small gel

pores (SGPs) are empty so that p, should be close to the air sld while for 30% hydrated C-S-H

gel, the SGPs are almost filled by water so p, should be close to the bulk water sld. We therefore

use two different fitting sld contrast ratios X = (p1 - Ps) (p 2

-

Ps), one for 10% and 17% cases

and the other for 30% case, during the fitting process. To reduce the fitting parameters, we assume

here that the globule has the same radius R and the hydrated calcium silicate layer has the same

thickness L 2 for all the three investigated C-S-H gels. The interlayer distance, L , therefore only

changes with the water layer thickness, L. The assumption is reasonable since the C-S-H gels are

prepared by drying the same product into different water contents and the calcium silicate

dimensions (R and L2 ) should be fixed while only water contents can be changed.

Our results show that as the water content passes from 10% to 30%, the interlayer distance

increases as clearly shown by the shift of the peak positions in the inset of Figure 2.4.1- 1.

Interestingly, Yu and Kirkpatrick 4 8 showed by thermal analysis and XRD experiments that upon

heating, water could be lost by tobermorite in steps that corresponded to decreases in layer spacing

from 14 to 12, 11 and 9.6

A.

Only two of these cases can be compared with the present results (L

9 A for 10% and 17% and L ~ 11 A for 30%). It is worth to note that an interlayer spacing of

12 A is a value typical of the basal spacing for semi-crystalline C-S-H often observed in many

synthetic C-S-H preparations 6 and in particular when C-S-H (I) is the prominent phase. 49 Our

40

globally fitted calcium silicate thickness L 2 is 3.5 A, which is close to GCMC simulation results

as reported by Pellenq et al.2 4 ,50 Their molecular model was shown to be mechanically stable