Military Diving FM 20-11 C1

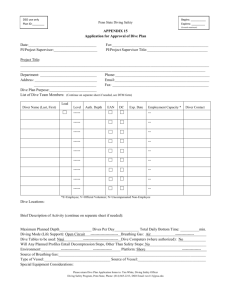

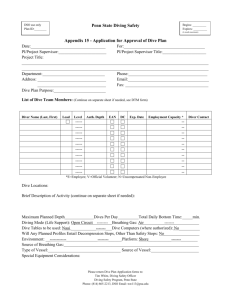

advertisement