Document 10738924

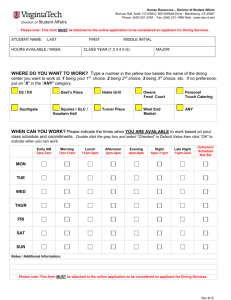

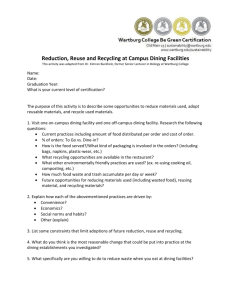

advertisement