Interactions Between Insecticides, Spray pH, & Adjuvants

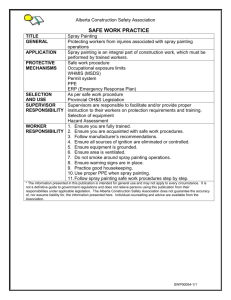

advertisement

Interactions Between Insecticides, Spray pH, & Adjuvants John C. Palumbo, F.J. Reyes, L. Carey, A. Amaya, and L. Ledesma Department of Entomology, Yuma Valley Agricultural Center Abstract Studies were conducted in the laboratory to investigate how the addition of a insecticides to two sources of Colorado River water would effect the pH of spray mixtures. In addition, we were curious what the effects of various labeled concentrations of buffers, acidifiers, spreader/stickers, and foliar nutrient sprays would have on the pH of spray water. Results showed that in most cases, spray concentration remained alkaline following addition of insecticides and adjuvants, with variations occurring primarily for the OPs. Buffering agents dramatically lowed pH at concentration greater than 0.25% v/v. Studies were also designed to evaluate the knockdown and residual mortality of Success against worms when applied in an acidic spray solution. Bioassays of larval mortality on field-treated foliage showed that knockdown mortality was not affected, but residual efficacy was significantly reduced when Success was applied using acidic (pH 4.2) spray solutions. Introduction Many factors can influence the performance of a pesticide. One factor that can be easily controlled is the pH of the water used in foliar sprays. Water sources from the Colorado River used for pesticide applications are alkaline with pH readings from the Yuma Valley typically ranging from 7.8 to 8.2. Use of high pH water, particularly above 8.0, may affect the performance of many pesticides. This occurs due to a reaction called alkaline hydrolysis, and it can occur when the pesticide is mixed with alkaline water or other materials that cause a rise in the pH of the spray water. Hydrolysis is the splitting of a compound by water in the presence of ions. Water that is alkaline has a larger concentration of hydroxide ions than water that is neutral; therefore, alkaline hydrolysis increases as the pH increases. Insecticides are generally more susceptible to alkaline hydrolysis than are fungicides and herbicides, and of these, organophosphates and carbamates are more susceptible than other materials. Little information is available on the degradation rate of many of the new pesticides in high pH water; some pesticides are relatively unaffected. Consequently, some pesticide labels recommend applicators to buffer spray water with a suitable acid buffer down to a range of 6-7 pH. In addition, when tank mixes of more than one pesticide or when fertilizer is combined with a pesticide, the final spray solution should be checked to determine pH. Because of the unknown effects of alkaline water on many of the new products, we wanted to know how addition of these insecticides at labeled rates/concentrations to Colorado River water would effect the pH of spray mixtures. In addition, we were curious what the effects of various labeled concentrations of buffers, acidifiers, spreader/stickers , and foliar nutrient sprays would be on the pH of spray water. Please note however that some of these studies were not designed to evaluate the insecticide performance, but rather to measure the alkalinity and acidity of final spray solutions, and the potential need for buffering these solutions prior to application. However, recent reports from Dow Agrosciences have suggested that the performance of Success ® (spinosad) is thought to be altered when ___________________ This is a part of the University of Arizona College of Agriculture 2001 Vegetable Report, index at: http://ag.arizona.edu/pubs/crops/az1252/ mixed and sprayed under moderately acidic (pH < 6) conditions. Thus, we also designed a study to evaluate the knockdown and residual mortality of Success against worms when applied in an acidic spray solution. Methods and Materials Effect of Insecticides and Buffering Agents on Spray pH Formulated active ingredients of a number of insecticides were used in these studies. Rates and formulations for each product are shown in Tables 1 and 2, and Figures 1-3. Water samples were collected from two sources and tested on the same day as collected. Colorado River surface water was collected from the east main canal in the Yuma Valley, about 1.5 miles east of the Yuma Agricultural Center. Ground water was collected from a well located at the Barkely Company farm shop located at Co. 19th and Ave G. Final spray concentrations of 5 and 30 GPA were selected for measuring the effects of insecticides and adjuvants on the pH of the water both before and after they were added. Each insecticide was measured at concentrations of a final spray solution of 5 and 30 GPA. For each water source, 1140 ml of water was placed in a 2 liter plastic bottle with the appropriate amount of insecticide to provide the proper concentration relative to the desired GPA. Each water source-GPA-insecticide combination was replicated 5 times. Prior to adding insecticides or buffers to each bottle, a pH measurement was taken and recorded for each replicate. A pH value was measured again at ½ hr and 24 hrs after the addition of the insecticide and buffer. All pH values were estimated by measuring a 40 ml sample of each concentration with a Mettler DL12 Titrator. All recorded pH values were averaged and presented in the following tables and graphs. Because the average pH values only deviated by a maximum 0.2 pH for any treatment (CV < 5), a statistical analysis was not conducted. Effect of Spray pH on Success Efficacy Two separate field applications were made; one on romaine and one on head lettuce to investigate the influence of spray pH on the residual efficacy of Success against beet armyworm and cabbage. Lettuce, ‘Van Mor ‘ head lettuce, and ‘ PIC’ romaine were direct seeded into double-row beds on Dec 2 at the Yuma Valley Agricultural Center, Yuma, AZ. Each plot consisted of two 30 ft long beds spaced 42 inches apart and bordered on each side by 2 untreated beds. Plots were replicated 4 times in a RCBD. Using data from the previous tests five treatments were applied to the plots: 1. Success applied at 6.0 oz/acre with no buffering agent added (pH 7.9); 2. Success applied at 3.0 oz/acre with no buffering agent added; (pH 7.9); 3. Success applied at 6.0 oz/acre with Buffer Trend 0-8-0 added (0.5 % v/v ; pH 4.2) ; 4. Success applied at 3.0 oz/acre with Buffer Trend 0-8-0 added (0.5 % v/v; pH 4.2) ; and 5. an untreated control. A single foliar application was made to romaine lettuce on March 27th and head lettuce on April 6th t with a CO2 operated boom sprayer that delivered 30 GPA at 50 psi. A directed spray was applied to each bed by 3 nozzles/bed. To measure knockdown mortality, individual leaves (3 / rep) were collected from sprayed plants at 6-hrs after treatment and brought into the laboratory. To measure residual mortality, leaves were collected 5 days following the spray application. The leaves were removed from the upper portions of the plant that had received adequate spray deposition. Once in the lab, a leaf disk (70mm diam) was removed from each leaf and placed into petri dishes. On head lettuce leaves , five 2nd –3rd instar beet armyworm were placed within each petri dish,; for romaine leaves, five 3nd instar cabbage loopers were placed within each petri dish. Larvae were obtained from a laboratory colony at the USDA/ARS Western Cotton Research Lab in Phoenix. The dishes were placed at room temperature for a 5 d duration of infestation (78-80 F). Mortality was scored on each day to calculate cumulative mortality. Foliage consumption was estimated for each leaf with a dish at day 5 and % leaf consumption over was calculated for each treatment. All means were analyzed using a two-way ANOVA and mean differences were estimated using a protected LSD (p<0.05). Results and Discussion Effect of Insecticides, Buffering Agents and Adjuvants on Spray pH The influence of old and new active insecticide ingredients at commonly applied dosages are shown in Table 1. This data shows the measured pH values for two sources of Colorado River water at two concentrations following the addition of insecticides. The insecticides measured include pyrethroids, Ops’ carbamates and several of the new chemistries. The pH for both water sources prior to addition of insecticides was alkaline; pH values of canal (surface) water ranged from 8.0-8.2, and well (ground) water ranged from 7.5-7.7. In general, pH values for the pyrethoid formulations remained alkaline at ½ and 24 hrs, regardless of water source or concentration. However, the most variability was seen with the OPps and Carbamates. A wide range in pH values were observed across the range of OP’s measured. pH dropped significantly more at the 5 GPA concentration and in some cases, in the surface water at 24 hr. Water became acidic after additions of several compounds (Dimethoate, MSR, Orthene, Malathion), did not change much for others (Diazinon), and actually became more alkaline after addition of Lorsban. Carbamates did not alter pH nearly as much, with water remaining alkaline for both compounds. Similarly, pH values remained alkaline for endosulfan . The chloronicotinyls did not alter much with pH values remaining alkaline at ½ and 24 hrs, regardless of water source or concentration. In most cases, the pH values for water sources and concentrations remained alkaline after addition of the new compounds. Avaunt and Aphistar appeared to drop the pH the most, whereas Fulfill, Confirm and Knack resulted in very little change in pH. The data in Table 2 shows the measured pH values for Colorado River surface water at two concentrations following the combination of multiple insecticides and adjuvants. The combinations measured include several insecticides and spreader/stickers commonly used in tank mixtures for vegetable insect control. The pH for the surface water prior to addition of the insecticides was alkaline (pH 8.2). For the Success-Ammo tank-mix, no significant changes in pH values were measured after the addition of either individual compounds or mixtures. pH values remained alkaline at ½ and 24 hrs, regardless of spray volume concentration. Similarly, pH values remained alkaline at ½ and 24 hrs in the Confirm+Warrior or Lannate +-Mustang mixtures bit in some cases, some of the compounds and mixtures actually slightly increased pH values. The effects of two common buffers on the pH of Colorado River surface water sources without the addition of insecticide are shown in Fig 1and 2. The pretest pH values for the surface source was 8.1 and 7.8 for the ground water. Both of the buffers used contained or were derived from phosphoric acid. For Buffer-Trend 0-8-0, pH values dropped immediately to an acidic nature at the low concentrations (0.06 and 0.125% v/v) staying within a range 6-7 pH for up to 6 hrs. Concentrations greater than 0.25 % resulted in a significant drop in pH (>4), regardless of water source. Similarly, pH values in Buffer P.S. dropped immediately to an acidic nature at the low concentrations (0.06 and 0.125% v/v) staying within a range 6-7 pH for up to 6 hrs. However, concentrations at 0.25 % resulted in a pH (~6), similar to lower concentrations. Concentrations greater than 0.25 % resulted in a significant drop in pH, regardless of water source, but tended to drop less in ground water at 0.5%. The effect of Success combined with buffers, an acidifier and soluble sulfur on the pH of Colorado River ground water sources are shown in Figures 3 and 4. The pre-test ph value for the surface source was 7.9. Both of the buffers used contained or were derived from phosphoric acid. The active ingredient for Success is spinosad, formulated as a soluble concentrate with 77% inert ingredients. Buffer concentrations for the Buffer-Trend and Buffer P.S. greater than 0.25% resulted in highly acidic conditions. However, we saw no significant changes in pH levels after the addition of Success, regardless of the buffer concentration. Similarly, the addition of LI 700 resulted in acidification of the water. Addition of Success did not result in any additional effect on pH. Concentrations greater than 0.06 % v/v resulted in pH values less than 6.0. The addition of Flowable Sulfur, or in combination with Success did not significantly alter the alkalinity of the spray water. It was projected that sulfur would acidifiy the water, but SulPreme is 52% elemental sulfur and in this state will not acidify water. However, once elemental sulfur is microbially activiated, as in the soil, sulfuric acid will lower alkaline conditions. The results of this information should serve as a useful guideline for growers, PCAs and applicators when considering the use of insecticide and buffers. The OPs appear to be most susceptible to changes in pH, whereas most spray solutions appear to remain at a fairly consistent pH after the addition of spray materials. However, this data should only serve as a baseline, as water pH levels from different sources or times of the year could change significantly. Furthermore, the need to buffer spray solution is commonly indicated on the label, or available from the manufacturer. In addition many of the newer compounds are stable in a fairly alkaline water and won’t require buffering. However, prior to mixing spray solution it is a good idea to measure the pH of the water before and after mixing. Again, refer to the label for specific guidelines on using additives to spray mixtures. Effect of Spray pH on Success Efficacy The results of this study clearly showed that acidic spray solutions had a negative impact on the residual efficacy of Success against beet armyworm and cabbage looper in lettuce. On romaine lettuce, initial knockdown mortality was not affected by Success rate or the pH of the spray solution. As expected, the 90% mortality was observed after 2 days of exposure in the bioassay dishes (Figure 1A). However, acidic pH conditions had a significant impact on the residual mortality of larvae in the 3.0 oz/acre Success treatment, where we observed about a 40% reduction in efficacy. Residual efficacy in the higher Success rate was not apparently affected by lower pH. A significant increase in foliage consumption was also observed (Table 3). Beet armyworm on treated head lettuce responded similarly , but affects of pH on residual mortality were seen at both high and low rates. Consequently mortality did not differ significantly between the untreated check and the two Success rates sprayed in acidic solutions. Larvae exposed to acidic spray solutions fed significantly more than those feeding on leaves treated with non-acidic sprays. Dow AgroSciences has reported problems with the residual efficacy of Success at pH levels below 6. This data certainly corroborates the anecdotal reports of poor Success residual performance when applied in acidic spray solutions. The reasons for this breakdown in residual centers around how spinosad is formulated. Success is formuatled as a suspension concentrate made up of suspended granules, each granule containing many spinosad monomers. When Success is mixed in spray solutions at a pH above 6, the Success granules remain intact, thus protecting it from UV degradation However, when in a acidic environment (pH < 6), the granules break, exposing the spinosad monomers to rapid degradation. Thus knockdown mortality is not immediately affected, but residual mortality becomes reduced as the sprayed product is exposed to UV light for a length of time. In this study 5 days of exposure in March/April was enough to significantly reduce residual mortality. Under normal conditions in Yuma using Colorado River water, buffers or acidifying agents should be avoided, unless extremely alkaline or for other reasons. The product should not be mixed in acid spray solutions if possible. This can be particularly important for growers and PCAs who use the product in tank-mixes with phosphorus-based foliar nutrient sprays like (0-8-0). When used as a foliar fertilizer, recommended rates range from 1-2 qts / 30-50 gal (0.5-1.0 % v/v) by ground and 1 qt / 10-15 gal (1.7-2.5%) by air. All of these concentrations resulted in highly acidic water conditions in our study. Furthermore, tank mixing with other insecticides like MSR or dimethoate could result in problems if pH is not adjusted. Finally, we recommend that pH levels of all spray mixes should be measured before these type of products are used. Table 1. Influence of Insecticides on pH levels of aqueous spray concentrations (gpa) before (Pre-test), and at ½ and 24 hours following addition of insecticide to water collected from two local sources pH Insecticide Rate, (Product/acre) Warrior T 3.8 oz Ammo 2.5EC Mustang 1.5EC Ambush 25W Capture 2EC Dimethoate 267E Diazinon 3EC Endosulfan 3EC MSR 2EC Lorsban 50W Orthene 97S Malathion 8EC Lannate SP Larvin 3.2EC 5.0 oz 4.3 oz 12 oz 5.1 oz 16 oz 16 oz 42 oz 30 oz 2.0 lb 1.0 lb 32 oz 0.8 lb 32 oz Canal water Well water Spray Vol, (GPA) Pre-test ½ hr 24 hr Pre-test ½ hr 24 hr 5 8.0 7.2 7.6 7.6 7.0 7.5 30 8.0 7.8 7.7 7.6 7.6 7.3 5 8.0 7.9 7.8 7.6 7.7 7.6 30 8.0 8.0 7.9 7.6 7.6 7.6 5 8.0 7.8 7.7 7.7 7.7 7.5 30 8.0 8.0 7.9 7.7 7.8 7.7 5 8.0 7.9 7.7 7.7 7.8 7.6 30 8.0 8.0 7.9 7.7 7.8 7.6 5 8.0 7.7 7.7 7.7 7.6 7.5 30 8.0 7.9 7.8 7.7 7.7 7.7 5 8.0 4.0 3.4 7.5 5.5 4.4 30 8.0 6.8 6.2 7.5 7.0 6.5 5 8.0 8.0 7.9 7.5 7.3 7.2 30 8.0 8.0 8.0 7.5 7.8 7.7 5 8.0 7.8 7.6 7.6 7.6 7.6 30 8.0 7.9 7.9 7.6 7.6 7.7 5 8.0 2.4 2.5 7.6 2.6 2.8 30 8.0 5.9 6.3 7.6 6.2 6.4 5 8.0 8.4 8.6 7.7 8.3 8.5 30 8.0 8.2 8.4 7.7 7.3 7.5 5 8.0 5.8 5.7 7.7 6.0 5.9 30 8.0 6.4 6.4 7.7 6.4 6.4 5 8.0 3.9 3.6 7.7 5.4 5.2 30 8.0 6.6 6.5 7.7 6.8 6.7 5 8.0 7.9 7.7 7.7 7.8 7.7 30 8.0 7.9 7.9 7.7 7.8 7.8 5 8.0 7.2 7.3 7.7 7.4 7.4 30 8.0 7.7 7.7 7.7 7.6 7.7 Table 1. continued. pH Insecticide Provado 1 6F Admire 2F Actara 25W Platinum 2SC Cryolite Pro96 Success 2S Avaunt WG Proclaim 5SG Agrimek 0.15EC Fulfill 50WG Confirm 2F Knack EC Applaud 70WP Pirimor 50 DF Aphistar 25W Canal water Well water Rate, (Product/acre) Spray Vol, (GPA) Pre-test ½ hr 24 hr Pre-test ½ hr 24 hr 3 75 oz 5 81 77 76 77 76 75 30 8.1 7.8 7.9 7.7 7.7 7.7 5 8.1 7.8 7.7 7.7 7.7 7.6 30 8.1 8.0 7.8 7.7 7.8 7.6 5 8.1 8.1 7.8 7.7 7.7 7.3 30 8.1 8.1 7.4 7.7 7.6 7.2 16 oz 5.5 oz 8 oz 12 lb 6.0 oz 5.8 oz 3.2 oz 12 oz 4.5 oz 8.0 oz 8.0 oz 8.0 oz 8.0 oz 4.0 oz 5 8.1 8.0 8.0 7.7 7.6 7.5 30 8.1 7.9 7.8 7.7 7.6 7.4 5 8.1 7.0 6.9 7.7 7.1 6.9 30 8.1 7.0 6.9 7.7 7.2 7.0 5 8.3 7.9 7.5 7.7 7.5 7.5 30 8.3 7.9 8.0 7.7 7.5 7.6 5 8.3 7.0 7.0 7.7 7.1 7.1 30 8.3 7.5 7.4 7.7 7.4 7.4 5 8.0 7.8 7.6 7.7 7.6 7.4 30 8.0 7.8 7.3 7.7 7.7 7.4 5 8.2 6.6 6.7 7.7 6.8 7.0 30 8.2 7.6 7.5 7.7 7.4 7.3 5 8.0 8.2 8.2 7.7 8.3 7.8 30 8.0 8.2 8.2 7.7 7.7 7.7 5 8.0 8.2 8.0 7.7 7.9 7.8 30 8.0 8.2 8.2 7.7 7.5 7.5 5 8.0 7.9 7.9 7.7 7.6 7.7 30 8.0 8.1 8.1 7.7 7.7 7.6 5 8.0 7.1 7.1 7.7 7.0 7.1 30 8.0 7.6 7.4 7.7 7.4 7.3 5 8.0 7.9 8.1 7.7 7.7 8.3 30 8.0 8.0 7.9 7.7 7.7 7.6 5 8.0 7.3 7.1 7.7 7.3 7.1 30 8.0 7.8 7.2 7.7 7.5 7.2 Table 2. Influence of Insecticides mixtures on pH levels of canal water at two aqueous spray concentrations (gpa) before (Pre-test), and at ½ and 24 hours following addition of insecticide. Insecticide Success 2S Ammo 2.5EC Silwet Rate, (Product/acre) Spray Vol, (GPA) 6 oz 5 oz 0.12% v/v Success+Silwet Ammo+Silwet Success+Ammo Success+Ammo+Silwet Confirm 2SC (8 oz) Warrior T (3.8 oz) Latron CS-7 (0.12% v/v) Confirm + Latron Warrior + Latron Confirm + Warrior Confirm + Warrior + Latron 8 oz 3.8 oz 0.12% v/v pH Pre-test ½ hr 24 hr 5 8.2 7.9 7.9 30 8.2 8.1 8.1 5 8.2 8.1 8.1 30 8.2 8.1 8.2 5 8.2 8.2 8.2 30 8.2 8.2 8.1 5 8.2 7.9 7.5 30 8.2 8.1 8.0 5 8.2 8.1 8.0 30 8.2 8.2 8.1 5 8.2 8.0 8.0 30 8.2 8.2 8.0 5 8.2 7.9 7.9 30 8.2 8.1 8.1 5 8.2 8.3 8.3 30 8.2 8.3 8.4 5 8.2 7.9 8.1 30 8.2 8.2 8.3 5 8.2 8.2 8.3 30 8.2 8.2 8.3 5 8.2 8.0 8.0 30 8.2 8.2 8.1 5 8.2 7.9 7.9 30 8.2 8.2 8.2 5 8.2 7.9 7.9 30 8.2 8.2 8.2 5 8.2 7.8 7.8 30 8.2 8.2 8.1 Table 2. Continued Insecticide Rate (Product/acre) Spray Vol, (GPA) Lannate 0.8 lb Musang Kinetic Lannate+Kinetic Mustang+Kinetic Lannate+Mustang Lannate+Mustang+Kinetic 4.3 oz 0.12 % v/v pH Pre-test ½ hr 24 hr 5 8.2 8.1 7.7 30 8.2 8.3 8.1 5 8.2 8.0 7.9 30 8.2 8.3 8.3 5 8.2 8.4 8.3 30 8.2 8.4 8.3 5 8.2 8.2 7.8 30 8.2 8.3 8.2 5 8.2 8.0 8.4 30 8.2 8.3 8.2 5 8.2 7.6 7.4 30 8.2 8.2 8.0 5 8.2 8.0 7.7 30 8.2 8.2 8.0 Table 3. Cumulative Residual Mortality to Success and Foliage Consumption on treated lettuce at 5 DAT. Larvae were allowed to feed on treated foliage for 5 days. Cabbage Looper On Romaine Lettuce Treatment Beet Armyworm On Head Lettuce Larval Mortality (%) Foliage Consumption (%) Larval Mortality (%) Foliage Consumption (%) Success 6 oz + Buffer (pH 4.2) 94.4 a 9.2 c 30.0 bc 42.5 b Success 6 oz (pH 7.9) 85.9 a 10.8 c 75.3 a 9.2 c Success 3 oz + Buffer (pH 4.2) 27.8 b 40.5 b 20.0 c 45.8 b Success 3 oz (pH 7.9) 90.3 a 16.7 c 56.7 ab 18 c Untreated 0.0 c 98.3 a 16.7 c 61.5 a Means within column followed by the same letter are not significantly different (protected LSD., P<0.05) Fig 1. Impact of Buffer on the pH of Colorado River surface water (West Main Canal). 9 Buffer-Trend, 0-8-0 8 1/2 hr 6 hrs pH 7 6 5 4 3 2 0 0.06 0.12 0.25 0.50 1.0 Buffer Concentration (% v/v) 9 Buffer P.S. 1/2 hr 6 hrs 8 pH 7 6 5 4 3 2 0 0.06 0.12 0.25 Buffer Concentration (% v/v) 0.50 1.0 Fig 2. Impact of Buffer on the pH of Colorado River ground water (Co.19th and Ave G). 9 Buffer-Trend, 0-8-0 1/2 hr 6 hrs 8 pH 7 6 5 4 3 2 0 0.06 0.12 0.25 0.50 1.0 Buffer Concentration (% v/v) 9 Buffer P.S. 1/2 hr 6 hrs 8 pH 7 6 5 4 3 2 0 0.06 0.12 0.25 Buffer Concentration (% v/v) 0.50 1.0 Fig 3. Impact of Buffer and Success to the pH of Well Water 9 Buffer-Trend, 0-8-0 Buffer-Trend 0-8-0 Buffer-Trend + Success 8 pH 7 6 5 4 3 2 0 0.06 0.12 0.25 0.50 1.0 Buffer Concentration (% v/v) Buffer P.S. 9 Buffer P.S. Buffer P.S. - Success 8 pH 7 6 5 4 3 2 0 0.06 0.12 0.25 Buffer Concentration (% v/v) 0.50 1.0 Fig 4. Impact of an acidifier and sulfur combined with Success on the pH of well water. 8.0 LI 700 LI 700 LI 700 + Success 7.5 7.0 pH 6.5 6.0 5.5 5.0 4.5 4.0 0 0.03 (4 oz) 0.06 (8 oz) 0.125 (1 pt) 0.250 (2 pt) 0.038 (3 pt) 2.0 (5 pts) 2.5 (6 pts) Concentration - % v/v ( Product /100 gal) 8.5 Sul-Preme 52 Sulfur Sulfur + Success 8.0 pH 7.5 7.0 6.5 6.0 5.5 0 0.8 (2 pts) 1.25 (3 pts) 1.6 (4 pts) Concentration - % v/v (Product / 30 GPA) Figure 5. Effect of Acidic Spray Conditions on Success Efficacy Against Cabbage Lopper on Romaine lettuce Cabbage Looper (Knockdown Mortality ) Larvae Infested 6-hrs After Treatment Larval Mortality (%) 100 80 60 Success 6 oz + Buffer (pH 4.2) Success 6 oz Success 3 oz + Buffer (pH 4.2) Success 3 oz Untreated 40 20 0 1 3 Cabbage Looper (Residual Mortality ) Larvae Infested 5 Says Aafter Treatment 100 Larval Mortality (%) 2 Days After Infestation 80 60 40 20 0 1 2 3 4 5 Days After Infestation Foliage Consumed (%) Cabbage Looper - Residual Feeding Damage (5 DAI) 100 80 60 40 20 0 6 oz Buffer 6 oz 3 oz Buffer 3 oz Untreated Figure 6. Effect of Acidic Spray Conditions on Success Efficacy Against Beet Armyworm on Head lettuce Beet Armyworm (Knockdown Mortality ) Larvae Infested 6-hrs After Treatment Larval Mortality (%) 100 80 60 Success 6 oz + Buffer (pH 4.2) 40 Success 6 oz (pH 7.9) Success 3 oz + Buffer (pH 4.2) Success 3 oz (pH 7.9) Untreated 20 0 1 5 Beet Armyworm (Residual Mortality ) Larvae Infested 5 Days After Treatment 100 Larval Mortality (%) 2 3 4 Days After Infestation 80 60 40 20 0 1 2 3 4 5 Days After Infestation Foliage Consumed (%) 70 Beet Armyworm - Residual Feeding Damage (5 DAI) 60 50 40 30 20 10 0 6 oz Buffer 6 oz 3 oz Buffer 3 oz Untreated